4Electric/Hydraulic TT Thruster 140 - 300

Introduction

Important information about this manual

Throughout this manual, you will see safety and product damage

warnings. You must follow these warnings carefully to avoid

possible injury or damage.

The type of warnings, what they look like, and how they are used

in this manual are explained as follows:

Dear Customer,

Thank you for choosing Lewmar TT Thrusters. Lewmar products

are world renowned for their quality, technical innovation and

proven performance. With a Lewmar thruster you will be

provided with many years of outstanding service.

Product support

Lewmar products are supported by a worldwide network of

distributors and Authorised Service Representatives. If you

encounter any difficulties with this product, please contact your

national distributor, or your local Lewmar dealer. Details are

available at:

To the best of our knowledge, the information in this manual

was correct when it went to press. However, Lewmar cannot

accept liability for any inaccuracies or omissions it may contain.

In addition, our policy of continuous product improvement may

change specifications without notice. As a result, Lewmar cannot

accept liability for any differences between the product and the

manual.

Approvals

For CE approval certificates contact Lewmar.

General

Please ensure that you thoroughly understand the operation

and safety requirements of the thruster before commencing

the installation. Only persons who are completely familiar with

the controls and those who have been fully made aware of the

correct use of the thruster should be allowed to use it. If there is

any doubt of how to install or operate this unit please seek advice

from a suitably qualified engineer.

• Please ensure that you thoroughly understand the operation

and safety requirements of the thruster.

• Your thruster should not be operated close to swimmers, as

a powerful suction of water is generated when in use.

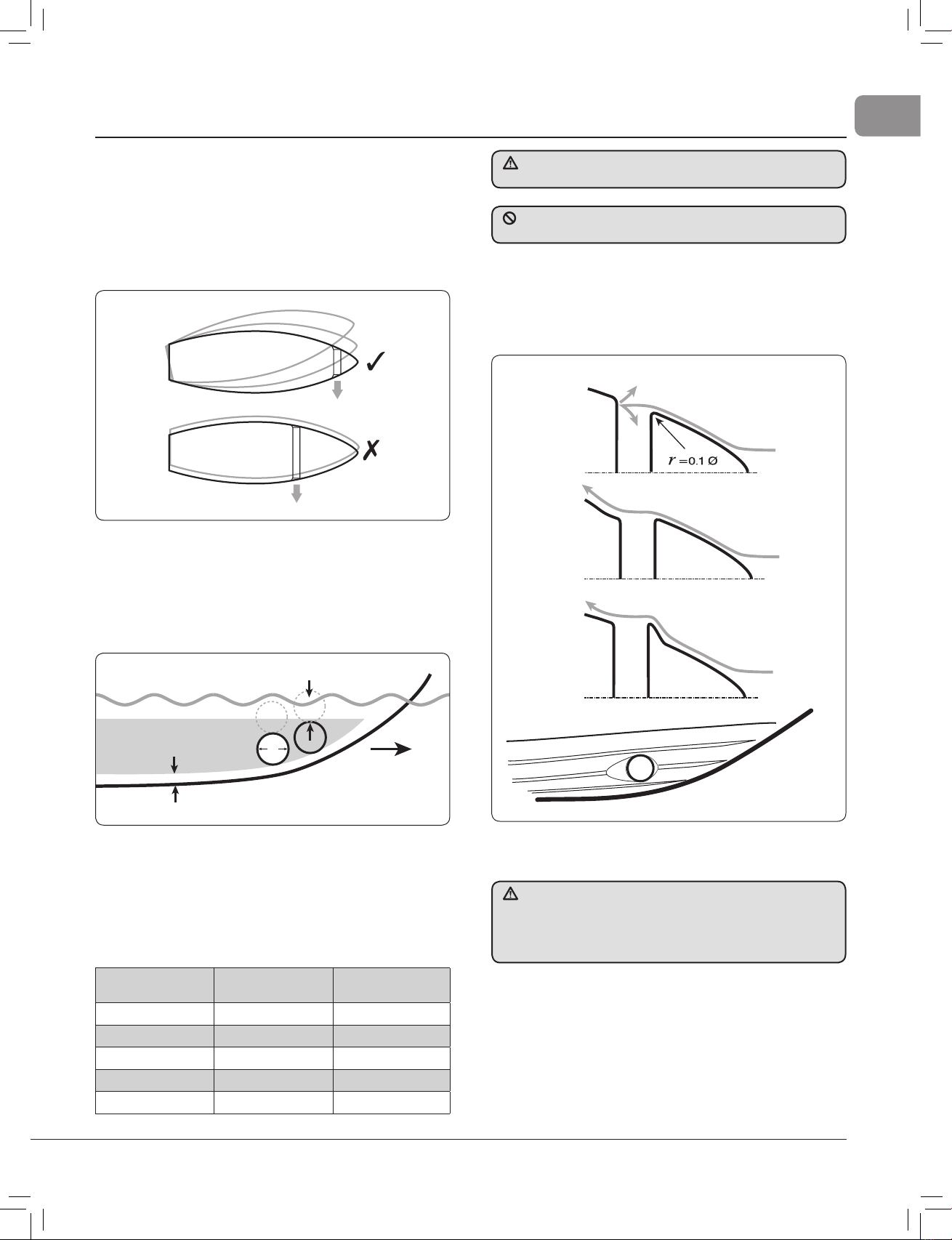

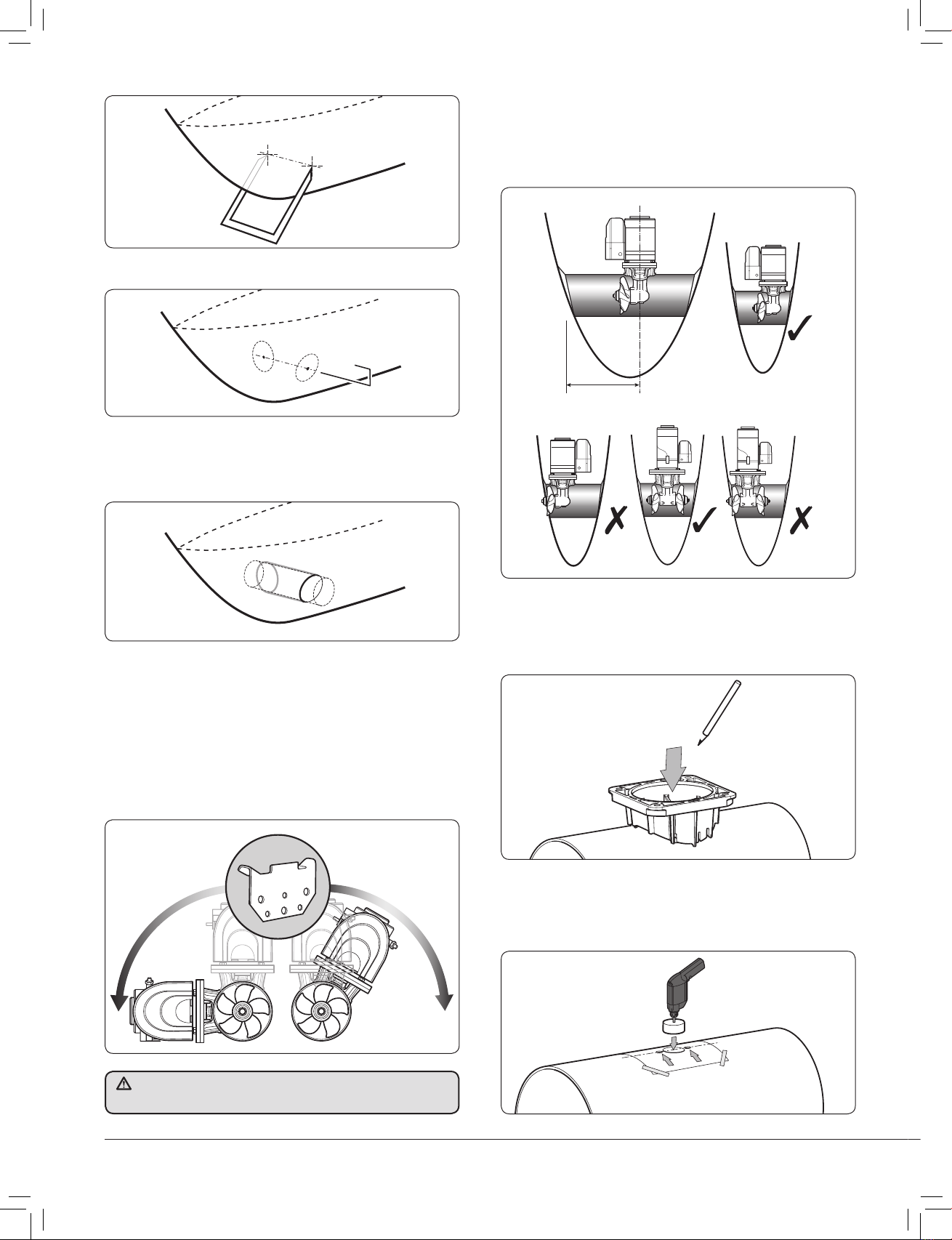

• The tunnel installation and any hull modifications should only

be carried out by a specialist. This manual is based on a GRP

tunnel installation.

• We recommend that a qualified person install the thruster.

Faulty installation will place the boat and crew in danger and

make the warranty invalid.

• It is the unavoidable responsibility of the owner or master or

other responsible party to assess the risk of any operation on

the vessel.

Thruster supply

• The thruster is securely packed for transit. However all parts

should be inspected for signs of damage before installation. If

any parts are found to be damaged please contact lewmar.

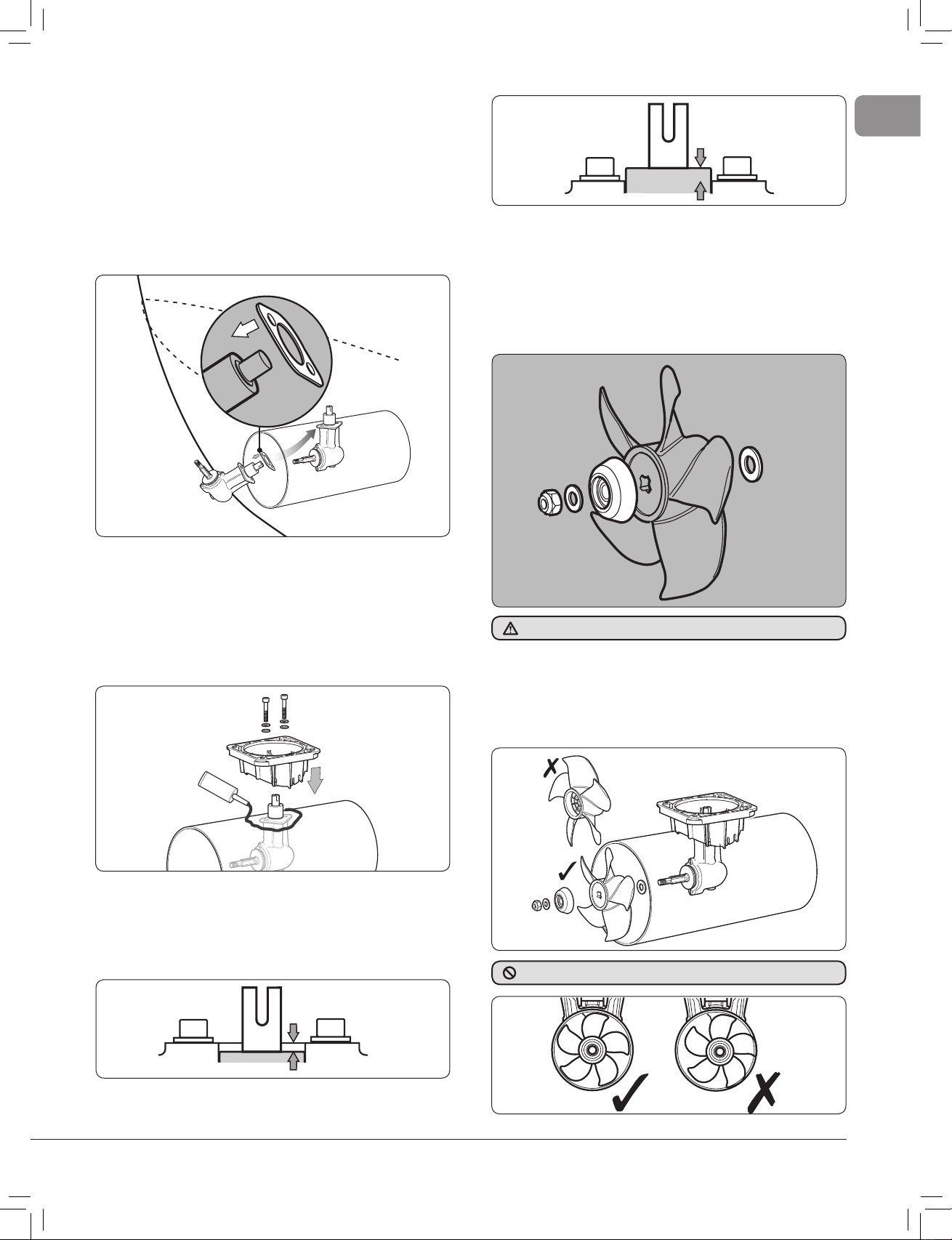

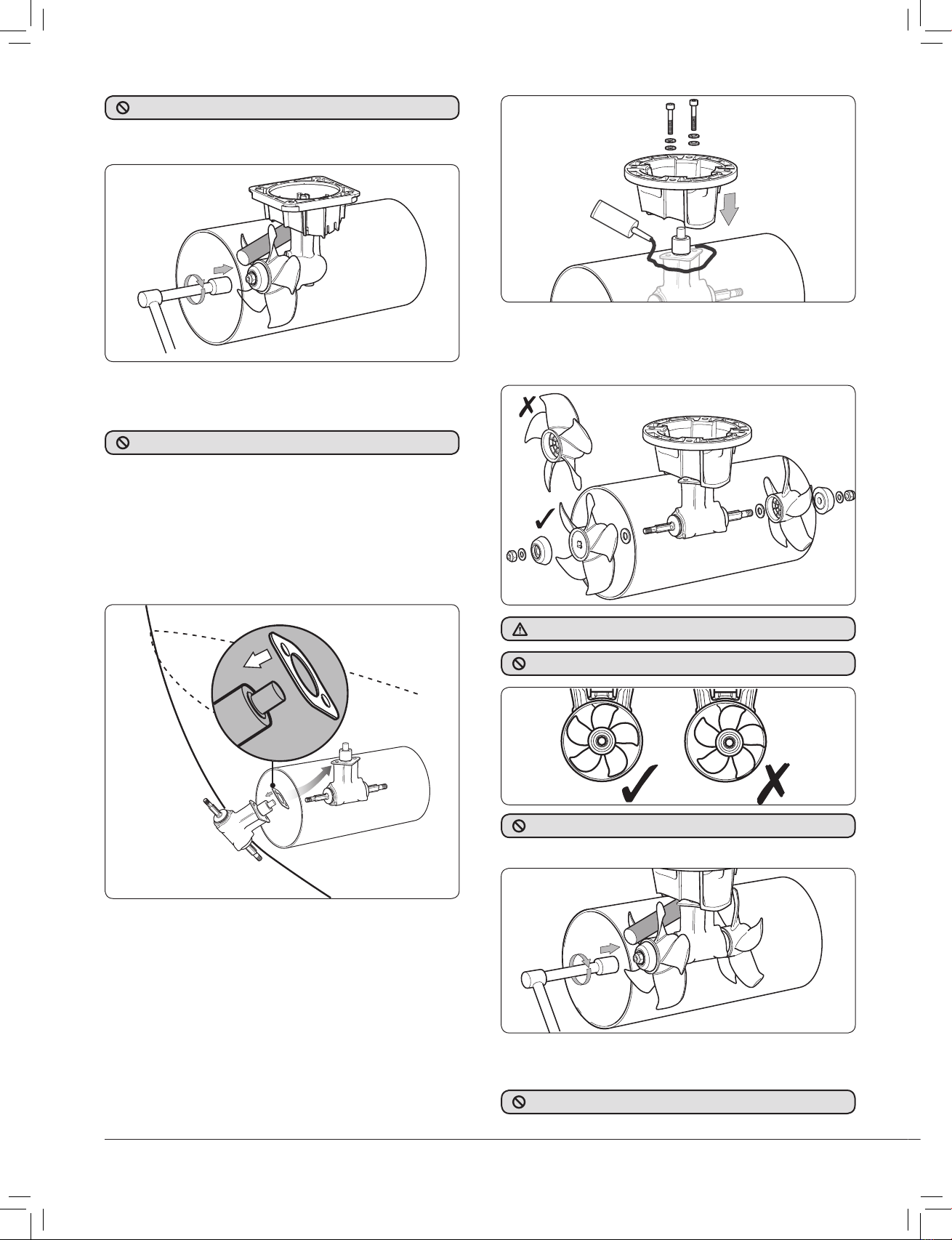

Fitting

• This equipment must be installed and operated in accordance

with the instructions contained in this manual. Failure to do

so could result in poor product performance, personal injury

and/or damage to your boat.

• Electric bow thrusters use powerful electric motors, it

is very important that there is sufficient battery capacity

and large enough cables for safe operation. Using smaller

than recommended battery and cables will cause loss of

performance and may cause dangerous overheating.

• Electric motors spark and run hot. Do not place near

flammable or sealed areas.

• Main battery must not be connected and power must not

be switched on until all covers and terminal protectors are

correctly fitted.

• It is very dangerous to run the thruster out of the water, even

for a few seconds, the motor will over speed by 300%, causing

damage to the motor seals etc. and the propeller will cause

serious damage to whatever comes into contact with it. This

action will invalidate the warranty.

• Consult the boat manufacturer if you have any doubt about

the strength or suitability of the mounting location.

Electrical

• Make sure you have switched off the power before you start

installing this product.

• If in doubt about installing electrical equipment please seek

advice from a suitably qualified electrical engineer.

Safety notices

This manual forms part of the product and MUST BE RETAINED

along with, OR incorporated into, the Owner’s Manual for the vessel

to which the thruster is ?tted.

Warning!

elpoepotyrujniesuacyamhcihwgnihtynatsniagagninrawasisihT

if the warning is ignored. You are informed about what you must

or must not do in order to reduce the risk of injury to yourself and

others.

Safety Symbol

When you see the safety symbol it means: “Do not...”; “Do not do

this”; or “Do not let this happen”.

• Electric thrusters must be located in a dry environment.

Should there be a need to install in a damp /wet location

then the IP (Ignition Protected) version must be used.