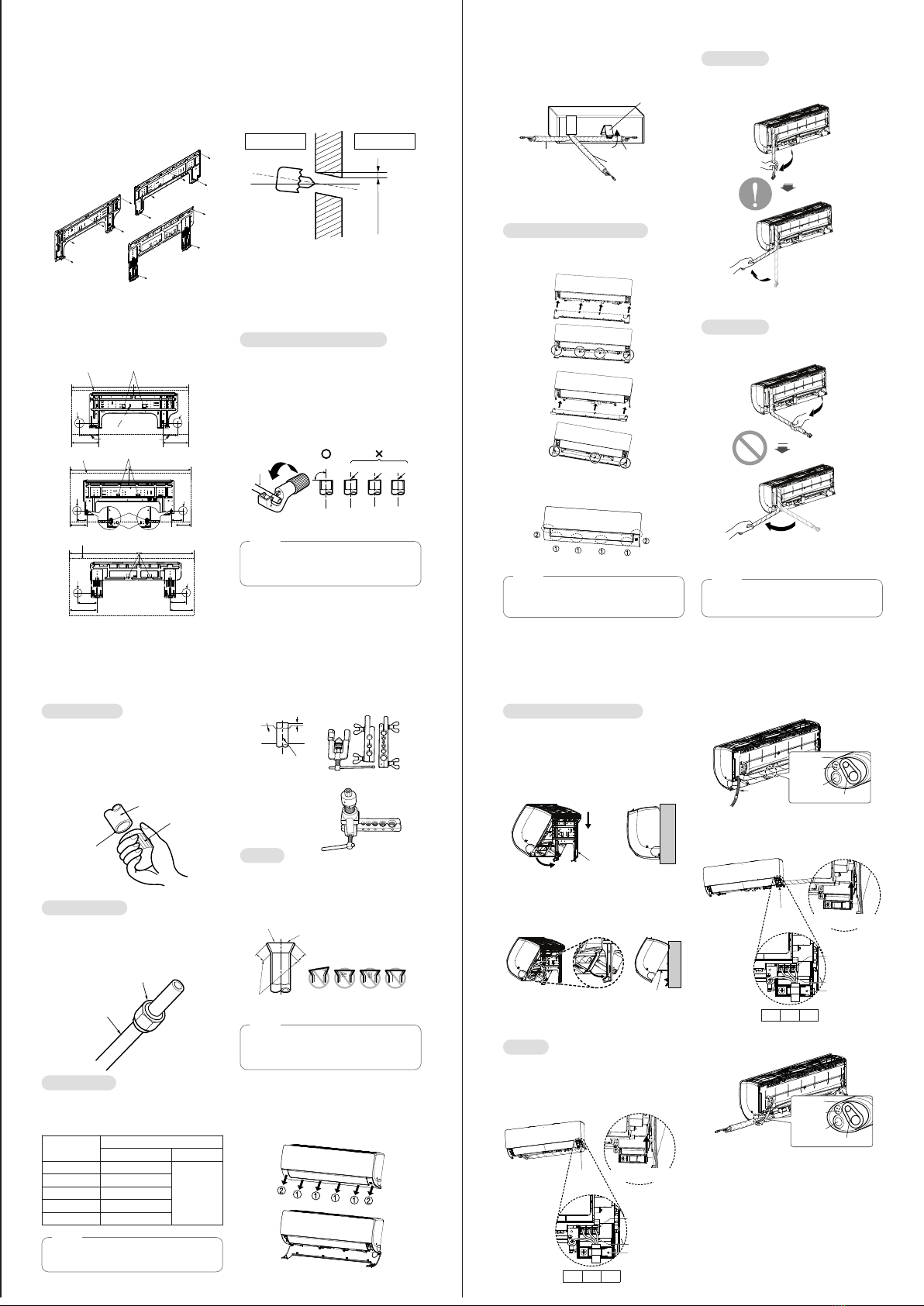

1Mount the tubing holder in the original

position.

2Ensure that the hooks are properly seated

on the installation plate by moving it left

and right.

3Press the lower left and right sides of the

unit against the installation plate until the

hooks engage into their slots (clicking

sound).

4Finish the assembly by screwing the unit

to the installation plate by using two pieces

of type "C" screws. And assemble a chas-

sis cover.

* The feature can be changed according to

type of model.

Finishing the indoor unit

installation

Checking the Drainage

1Pour a glass of water on the evaporator.

2Ensure the water flows through the drain

hose of the indoor unit without any leak-

age and goes out the drain exit.

* The feature can be changed according to

type of model.

1The drain hose should point downward for

easy drain flow.

Drain piping

Downward slope

Drain pan

Drain

hose

Leakage

checking

Connecting area

drain hose

Leakage

checking

To check the drainage.

CAUTION

!

The indoor unit can be dropped from the

wall, the indoor unit is not screwed

correct position on the install plate.

To avoid the gap between the indoor unit

and wall , screw the indoor unit to the

install plate correctly.

To avoid nitrogen entering the refrigerant

system in a liquid state, the top of the cylin-

der must be higher than its bottom when

you pressurize the system. Usually, the cylin-

der is used in a vertical standing position.

Air Purging

The air and moisture remaining in the

refrigerant system have undesirable effects as

indicated below.

1Pressure in the system rises.

2Operating current rises.

3 Cooling(or heating) efficiency drops.

4 Moisture in the refrigerant circuit may

freeze and block capillary tubing.

5 Water may lead to corrosion of parts in the

refrigeration system.

Therefore, after evacuating the system, take a

leak test for the piping and tubing between

the indoor and outdoor unit.

Air purging with vacuum pump

1Preparation

- Check that each tube(both liquid and gas

side tubes) between the indoor and out-

door units have been properly connected

and all wiring for the test run has been

completed. Remove the service valve

caps from both the gas and the liquid side

on the outdoor unit. Note that both the

liquid and the gas side service valves on

the outdoor unit are kept closed at this

stage.

2 Leak test

- Connect the manifold valve(with pressure

gauges) and dry nitrogen gas cylinder to

this service port with charge hoses.

Seal a small opening

around the pipings

with gum type sealant.

Trap

Trap

- Do a leak test of all joints of the tubing(both

indoor and outdoor) and both gas and liquid

side service valves. Bubbles indicate a leak.

Be sure to wipe off the soap with a clean

cloth.

- After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening

the charge hose connector at the nitrogen

cylinder. When the system pressure is

reduced to normal, disconnect the hose from

the cylinder.

There is a risk of fire and explosion.

Inert gas (nitrogen) should be used

when you check plumbing leaks, cleaning

or repairs of pipes etc. If you are using

combustible gases including oxygen,

product may have the risk of fires and

explosions.

Be sure to use a manifold valve for air purg-

ing. If it is not available, use a stop valve for

this purpose. The knob of the 3-way valve

must always be kept close.

- Pressurize the system to maximum

17.6 kg/cm2G (R22 model) or 28.1 kg/cm2G

(R410A model) with dry nitrogen gas and

close the cylinder valve when the gauge

reading reaches 17.6 kg/cm2G (R22 model)

or 28.1 kg/cm2G (R410A model). Next step

is leak test with liquid soap.

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

2Do not make drain piping like the

following.

* The feature can be changed according to

type of model.

Installing drain piping of the

outdoor unit

Depending on installation site, it may be

required to install drain plug for drainage

(Supplied with the unit). In cold areas, do not

use a drain hose with the outdoor unit.

Otherwise, drain water may freeze, impairing

the heating performance.

1See the figure below for installation of the

drain plug.

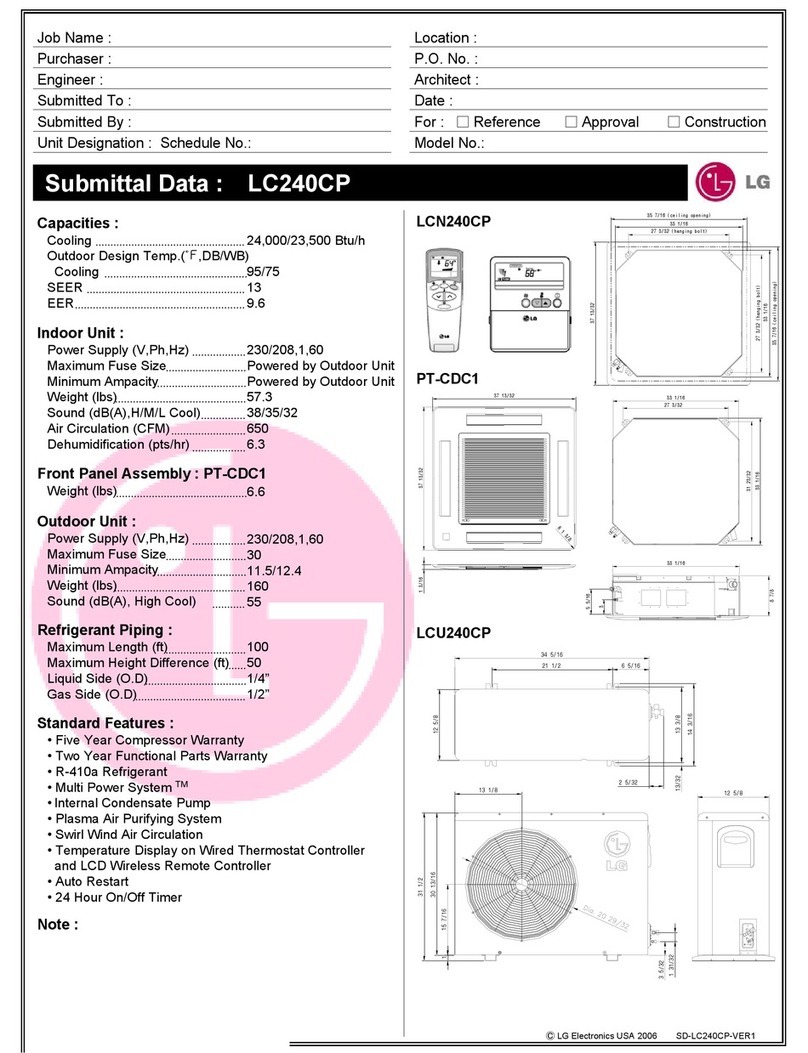

A Drain nipple

B Drain cap

C Drain washer

2

Connect a field supplied vinyl hose to the

drain nipple (A). If the hose is too long and

hangs down, fix it carefully to prevent kinks.

* The feature can be changed according to

type of model.

Do not raise

Water

leakage

Tip of drain hose

dipped in water

Water

leakage Ditch

Less than

50mm gap

Accumulated

drain water

Air

Waving

Water

leakage

B

A

C

• 6.6 kW

• 2.5/3.5/5.0 kW

Forming the Piping

Form the piping by wrapping the connecting

portion of the indoor unit with insulation material

and secure it with two kinds of vinyl tapes.

- If you want to connect an additional drain

hose, the end of the drain outlet should be

routed above the ground. Secure the drain

hose appropriately.

In cases where the outdoor unit is installed

below the indoor unit perform the following.

1 Tape the piping, drain hose and connecting

cable from down to up.

2Secure the tapped piping along the exteri-

or wall using saddle or equivalent.

* The feature can be changed according to

type of model.

In cases where the Outdoor unit is installed

above the Indoor unit perform the following.

1 Tape the piping and connecting cable from

down to up.

2Secure the taped piping along the exterior

wall. Form a trap to prevent water entering

the room.

3Fix the piping onto the wall using saddle or

equivalent.

Drain hose Vinyl tape(narrow)

Pipe

Wrap with

vinyl tape(wide)

Taping

Saddle

Drain hose

Pipings

Connecting cable

Seal a small opening

around the pipings

with gum type sealant.

Trap is required to prevent water

from entering into electrical parts.

- Remove the caps from the 2-way and 3-way

valves.

- Remove the service-port cap from the 3-way

valve.

- Apply a soap water or a liquid neutral deter-

gent on the indoor unit connection or out-

door unit connections by a soft brush to

check for leakage of the connecting points of

the piping.

- If bubbles come out, the pipes have leakage

-

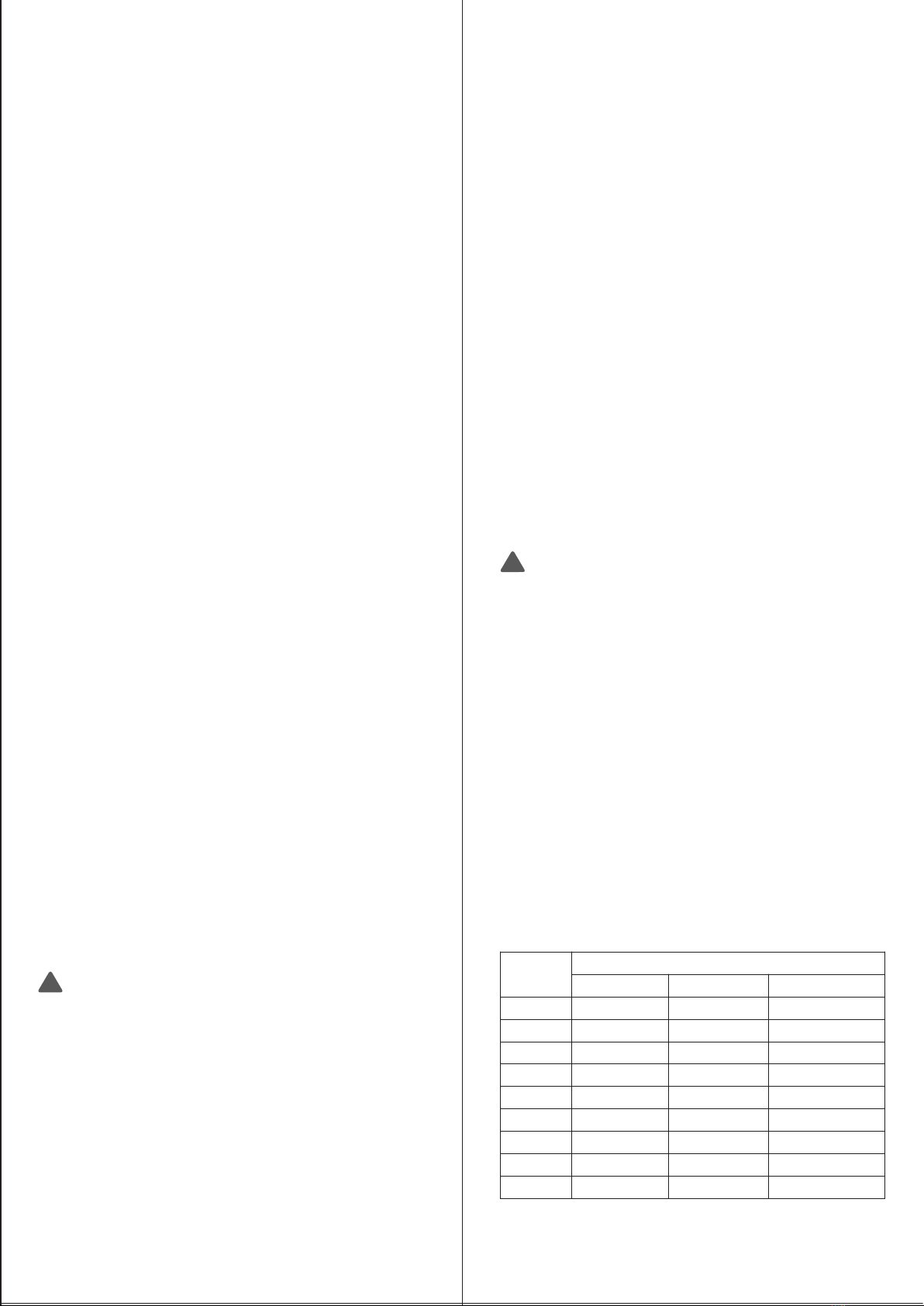

Connect the charge hose end described in

the preceding steps to the vacuum pump to

evacuate the tubing and indoor unit. Confirm

the "Lo" knob of the pressure Gauge is open.

Then, run the vacuum pump. The operation

time for evacuation varies with tubing length

and capacity of the pump. The following table

shows the time required for evacuation.

Soap water method

Evacuation * The feature can be changed according

a type of model.

- When the desired vacuum is reached, close

the knob of the 3-way valve and stop the

vacuum pump.

- With a service valve wrench, turn the valve

of liquid side counter-clockwise to fully open

the valve

- Turn the valve of gas side counter-clockwise

to fully open the valve

- Loosen the charge hose connected to the

gas side service port slightly to release the

pressure, then remove the hose.

- Replace the flare nut and its bonnet on the

gas side service port and fasten the flare nut

securely with an adjustable wrench. This

process is very important to prevent leakage

from the system

- Replace the valve caps at both gas and liquid

side service valves and fasten them tight.

This completes air purging with a vacuum

pump.

- Replace the pipe cover to the outdoor unit by

one screw. Now the air conditioner is ready

for test run.

Finishing the Job

Gas side

Outdoor unit

Liquid side

Cap

3-way or

2-way valve

3-way valve

Required time for evacuation when 30 gal/h

vacuum pump is used

If tubing length is

less than 10 m

(33 ft)

If tubing length is

longer than 10 m

(33 ft)

10 min. or more 15 min. or more

for R32 Only

• Electronic leak detectors shall be used to

detect flammable refrigerants, but the sensi-

tivity may not be adequate, or may need re-

calibration. (Detection equipment shall be cal-

ibrated in a refrigerant-free area.)

• Leak detection equipment shall be set at a

percentage of the LFL (Lower flammable

limit) of the refrigerant and shall be calibrated

to the refrigerant employed and the appropri-

ate percentage of gas (25 % maximum) is

confirmed.

• Leak detection fluids are suitable for use with

most refrigerants but the use of detergents

containing chlorine shall be avoided as the

chlorine may react with the refrigerant and

corrode the copper pipe-work.

• If a leak is suspected, all naked flames shall

be removed/extinguished.

• If a leakage of refrigerant is found which

requires brazing, all of the refrigerant shall be

recovered from the system, or isolated (by

means of shut off valves) in a part of the sys-

tem remote from the leak.

• Oxygen free nitrogen (OFN) shall be purged

through the system both before and during

the brazing process.

NOTE

* How to enter the installer mode

* How to set the code