LG LM-2421C2L User manual

Other LG Air Conditioner manuals

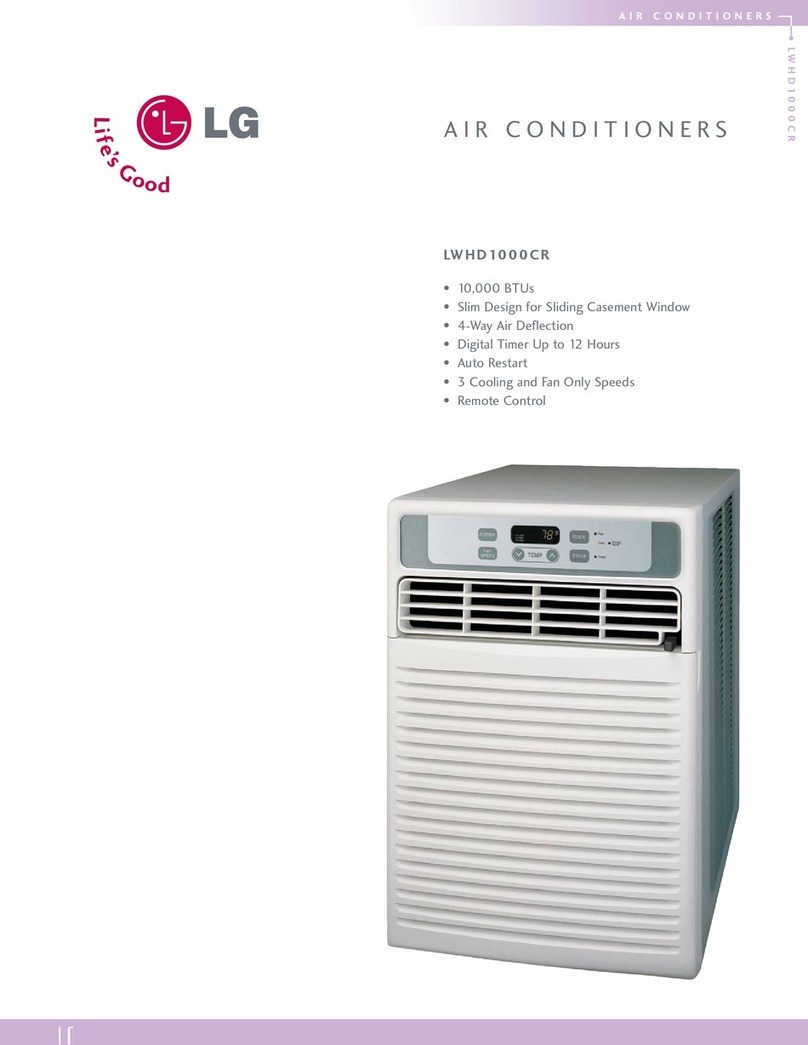

LG

LG M8003L User manual

LG

LG ARNU48GTAB4 User manual

LG

LG AT-C186PLE1 User manual

LG

LG V-net PDRYCB000 User manual

LG

LG LP1010SNR Instruction Manual

LG

LG MFL42803121 User manual

LG

LG ATNQ18GPLE6 User manual

LG

LG CV-H186BLB0 User manual

LG

LG GSNH126E0U1 User manual

LG

LG PDI Premium PQNUD1S40 Operating instructions

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

CLIMAVENETA

CLIMAVENETA a-CHD U-2T 606+2209 OPERATING AND INSTALLATION Manual

Midea

Midea EWK06CW5 user manual

Pioneer

Pioneer FAB Series installation manual

SPT

SPT WA-1511S user manual

Mitsubishi Electric

Mitsubishi Electric Mr.Slim MSZ-A24NA operating instructions

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual