1-1

CONTENTS

SECTION 1

SUMMARY

SERVICING PRECAUTIONS ......................................1-2

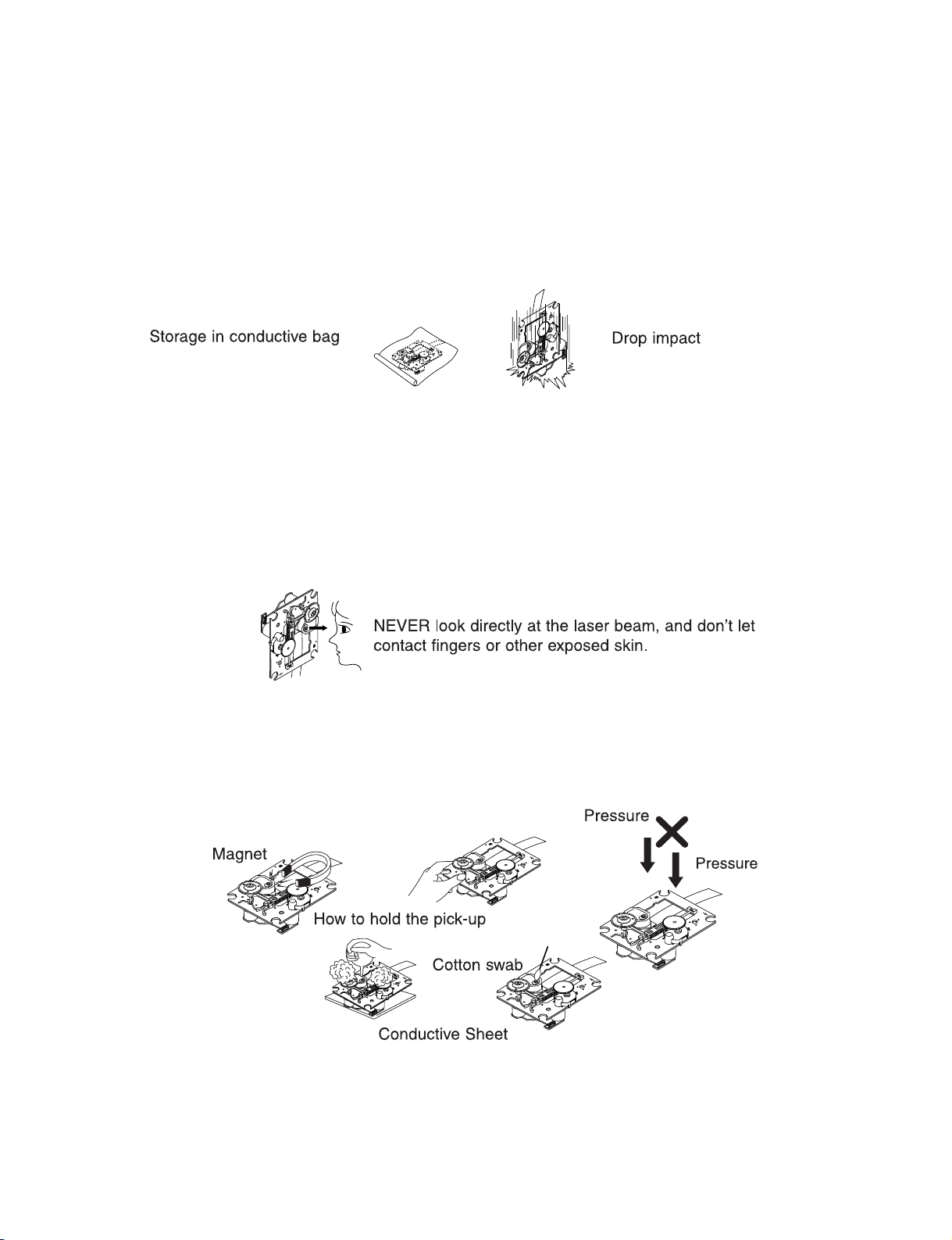

• NOTES REGARDING HANDLING OF THE PICK-UP

•

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

ESD PRECAUTIONS ...................................................1-4

SPECIFICATIONS ........................................................1-5

SECTION 2

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION..............2-1

2. DECK MECHANISM SECTION (DP-10A).............2-3

3. SPEAKER SECTION (MBS-K62V) ........................2-5

4. PACKING ACCESSORY SECTION .......................2-6

SECTION 3

ELECTRICAL

ELECTRICAL TROUBLESHOOTING

GUIDE OF AUDIO PART.............................................3-1

1. MICOM PART CHECK I ....................................3-1

2. MICOM PART CHECK II ...................................3-2

3. IC103 KS4CD21CS CHECK.............................3-3

4. FLD DISPLAY CHECK ......................................3-4

5. PWM MODULATION PART ..............................3-5

6. POWER AMP PART CHECK............................3-6

7. PORTABLE FUNCTION ....................................3-7

8. TV-AUDIO FUNCTION ......................................3-8

9. TUNER FUNCTION CHECK ............................3-9

10. SMPS POWER TROUBLESHOOTING.........3-10

11. BLUETOOH PART (OPTIONAL PART)..........3-13

12. IPOD PART (OPTIONAL PART) .....................3-14

ELECTRICAL TROUBLESHOOTING

GUIDE OF DVD PART...............................................3-15

1. POWER CHECK GUIDE.................................3-15

2. TEST & DEBUG FLOW...................................3-16

3. USB PART ........................................................3-21

WAVEFORMS .............................................................3-22

1. WHEN POWER ON, RESET & DATA

ETC WAVEFORM............................................3-22

2. OPEN / CLOSE WAVEFORM AT

POWER ON......................................................3-23

3. STARTING ACTION WAVEFORM

IN MD DEVICE ................................................3-23

4. FOCUS WAVEFORM ......................................3-24

5. AT POWER ON, SPINDLE SIGNAL AT

MD DECK .........................................................3-25

6. AT FIRST ACTION, FOCUS

SIGNAL A, B, C, D............................................3-25

7. TRACKING SIGNAL ........................................3-26

8. RF WAVEFORM ..............................................3-26

9. DISK TYPE JUGEMENT WAVEFORM..........3-27

INTERNAL BLOCK DIAGRAM OF ICs...................3-28

1. AK5358..............................................................3-28

2. EM639165 ........................................................3-30

3. ES29LV160E ....................................................3-32

4. HT1000 .............................................................3-34

5. IP9009...............................................................3-37

6. KS24L161 .........................................................3-38

7. MC4580 ............................................................3-39

8. PS9829B...........................................................3-40

9. PT6324..............................................................3-41

10. STR-A6252 .......................................................3-44

11. µPD78F0546R (R)............................................3-45

WIRING DIAGRAM ....................................................3-49

BLOCK DIAGRAMS ..................................................3-51

1. SMPS BLOCK DIAGRAM...............................3-51

2. MAIN & FRONT BLOCK DIAGRAM ..............3-53

SCHEMATIC DIAGRAMS .........................................3-55

1. SMPS SCHEMATIC DIAGRAM......................3-55

2. MAIN, INTERFACE & PWM

SCHEMATIC DIAGRAM..................................3-57

3. MPEG SCHEMATIC DIAGRAM .....................3-59

4. SERVO SCHEMATIC DIAGRAM ...................3-61

5. INTERFACE SCHEMATIC DIAGRAM ...........3-63

6. FRONT SCHEMATIC DIAGRAM ..................3-65

7. FRONT MIC SCHEMATIC DIAGRAM ...........3-67

8.

IPOD-1 SCHEMATIC DIAGRAM (OPTION)

.....3-69

9.

IPOD-2 SCHEMATIC DIAGRAM (OPTION)

.....3-71

10.

2 CHANNEL AMP SCHEMATIC DIAGRAM

......3-73

11. BLUTHOOTH MODULE

SCHEMATIC DIAGRAM (OPTION) ................3-75

CIRCUIT VOLTAGE CHART.....................................3-77

PRINTED CIRCUIT BOARD DIAGRAMS ...............3-79

1. MAIN P.C.BOARD............................................3-79

2. FRONT P.C.BOARD ........................................3-83

3. SMPS P.C.BOARD ..........................................3-85

4. MIC JACK P.C.BOARD ...................................3-87

5. IPOD P.C.BOARD (OPTION)..........................3-87

SECTION 4

REPLACEMENT PARTS LIST

........4-1