4-4

CIRCUIT DESCRIPTION

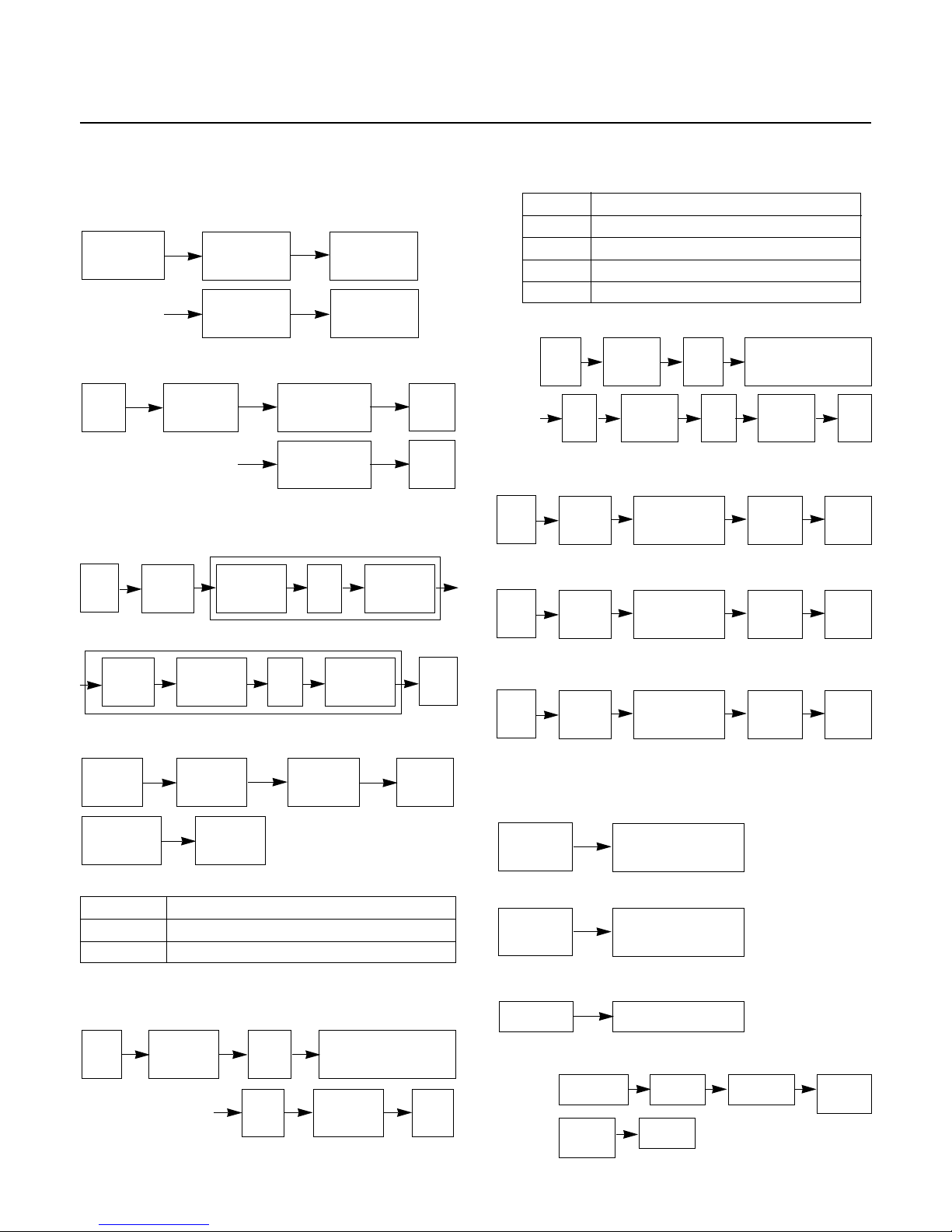

GENERAL DETAILS

•The low voltage transformer supplies the necessary

voltage to the micom controller when power cord is

plugged in.

•When the door is closed, the primary switch is ON, the

secondary switch is ON, and the monitor switch opens

(contact COM and NO).

WHEN SELECTING COOKING POWER

LEVEL AND TIME

•The micom controller memorizes the function you set.

•The time you set appears in the display window.

•Each indicator light turns on to indicate that the stage

has been set.

WHEN TOUCHING THE START BUTTON

•The coil of the relay is energized by the micom

controller.

•Power input is supplied to the high voltage transformer

through the fuse to the primary switch and relay 4.

•Turntable rotates.

•The fan motor rotates and cools the magnetron by

blowing the air (coming from the intake on the

back cover).

•The air is also directed into the oven to exhaust the

vapor in the oven through the upper plate.

•Cooking time starts counting down.

•3.2 volts AC is generated from the filament winding of

the high voltage transformer. This 3.2 volts is applied to

the magnetron to heat the magnetron filament through

two noise-preventing choke coils.

•A high voltage of approximately 2100 volts AC is

generated in the secondary of the high voltage

transformer which is increased by the action of the high

voltage diode and charging of the high voltage

capacitor.

•The negative 4,000 Volts DC is applied to the filament

of the magnetron.

WHEN THE OVEN IS SET AT ANY LEVEL

EXCEPT MAXIMUM.

•The micom controller controls the ON-OFF time of

relay 4 by the applied signal to vary the average output

power of oven as POWER LEVEL. (refer to page 1-1)

•One complete cycle of relay 4 is 32 seconds.

WHEN THE DOOR IS OPENED DURING

COOKING

•Both the primary switch and relay 4 are cut off primary

winding voltage of the high voltage transformer.

•ON-OFF of relay 4 is coupled electrically with opening

and closing of the secondary switch.

•When the door is opened, the secondary switch is

opened and when the door is closed, the secondary

switch is closed.

•The cooking time stops counting down.

•Relay stops functioning.

•As the door is opened, if the contact of primary switch

and relay 4 fails to open, the fuse opens due to the

large current surge caused by the monitor switch

activation, which in turn stops magnetron oscillation.

WHEN TOUCHING THE START BUTTON

WITH THE HEATER COOKING

FUNCTION SELECTED

•The contacts of the primary switch and the secondary

switch close the circuit.

•A.C. voltage is applied to the heater through thermostat

as shown by the solid line.

•Turntable rotates.

•The fan motor rotates.

•The air is also directed into the oven to exhaust the

vapor in the oven through the base plate and back

plate.