- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts sh uld be replaced with the same c mp nents as rec mmended in this manual t prevent

X-RADIATION, Sh ck, Fire, r ther Hazards.

D n t m dify the riginal design with ut permissi n f manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing f a receiver wh se chassis is n t is lated fr m the AC

p wer line. Use a transf rmer f adequate p wer rating as this

pr tects the technician fr m accidents resulting in pers nal injury

fr m electrical sh cks.

It will als pr tect the receiver and it's c mp nents fr m being

damaged by accidental sh rts f the circuitry that may be

inadvertently intr duced during the service perati n.

If any fuse ( r Fusible Resist r) in this m nit r is bl wn, replace it

with the specified.

When replacing a high wattage resist r (Oxide Metal Film Resist r,

ver 1W), keep the resist r 10mm away fr m PCB.

Keep wires away fr m high v ltage r high temperature parts.

Due t high vacuum and large surface area f picture tube,

extreme care sh uld be used in handling the Picture Tube.

D n t lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug rem ved fr m AC s urce, c nnect an

electrical jumper acr ss the tw AC plug pr ngs. Place the AC

switch in the n p siti n, c nnect ne lead f hm-meter t the AC

plug pr ngs tied t gether and t uch ther hm-meter lead in turn t

each exp sed metallic parts such as antenna terminals, ph ne

jacks, etc.

If the exp sed metallic part has a return path t the chassis, the

measured resistance sh uld be between 1MΩ and 5.2MΩ.

When the exp sed metal has n return path t the chassis the

reading must be infinite.

An ther abn rmality exists that must be c rrected bef re the

receiver is returned t the cust mer.

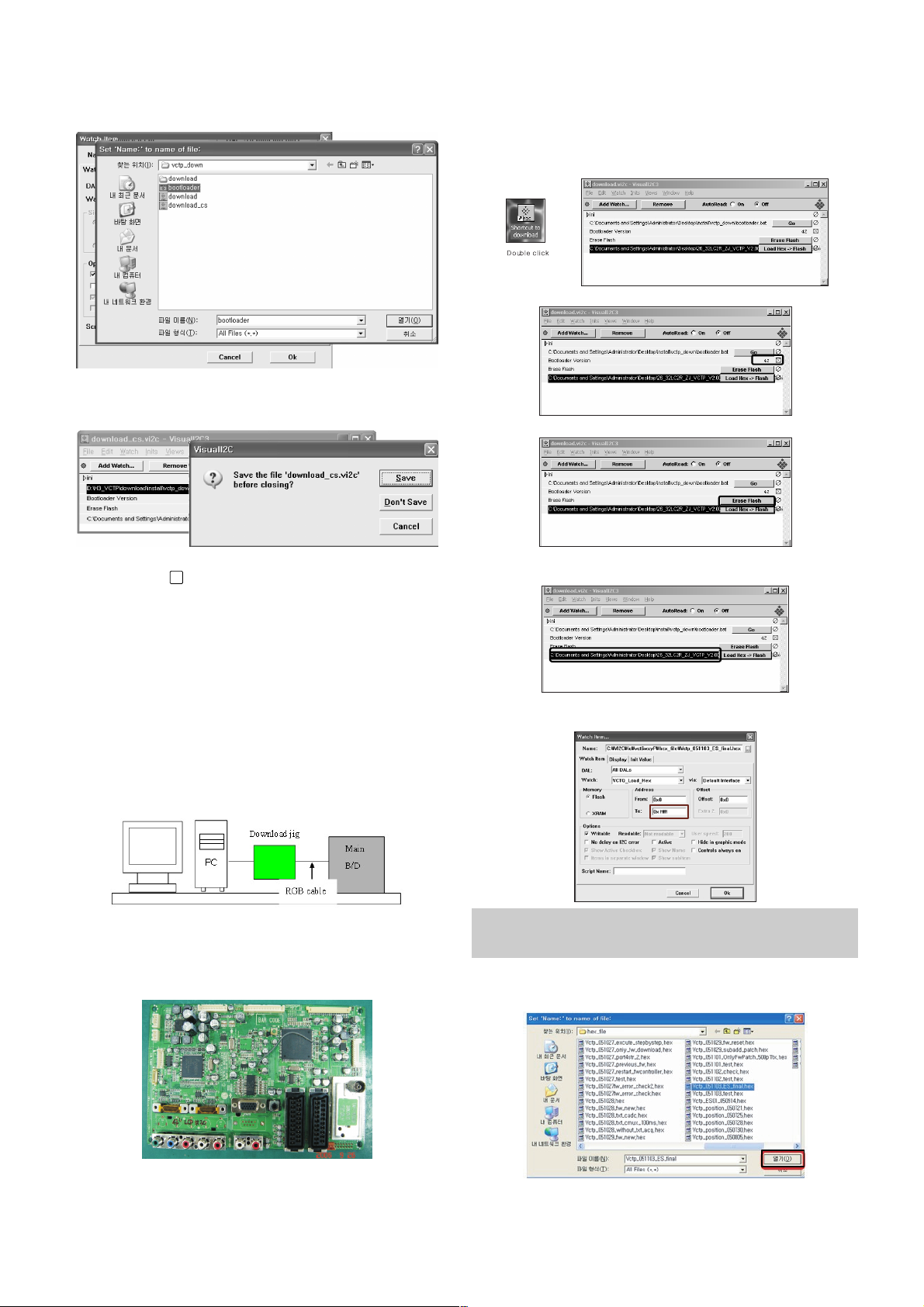

Leakage Current Hot Check (See below Figure)

Plug the AC c rd directly int the AC utlet.

Do not use a line Isolation Transformer during this check.

C nnect 1.5K/10watt resist r in parallel with a 0.15uF capacit r

between a kn wn g d earth gr und (Water Pipe, C nduit, etc.)

and the exp sed metallic parts.

Measure the AC v ltage acr ss the resist r using AC v ltmeter

with 1000 hms/v lt r m re sensitivity.

Reverse plug the AC c rd int the AC utlet and repeat AC v ltage

measurements f r each exp sed metallic part. Any v ltage

measured must n t exceed 0.75 v lt RMS which is c rresp nds t

0.5mA.

In case any measurement is ut f the limits specified, there is

p ssibility f sh ck hazard and the set must be checked and

repaired bef re it is returned t the cust mer.

Leakage Current Hot Check circuit