- 8 - LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only or training and service purposes

4. SET assembly adjustme t method

* Caution : Each PCB assembly must be checked by check JIG

set. (Because power PCB Assembly damages to PDP

Module, especially be care ul)

4-1.POWER PCB Assembly Voltage

adjustme t (Va/Vs Voltage Adjustme t)

Test equipment : D.M.M 1EA

Connection Diagram or Measuring : re er to ig.4

Adjustment method

(1) Va adjustment

1) Connect + terminal o D. M.M. to Va pin o P811,

connect -terminal to GND pin o P811.

2) A ter turning VR901,voltage o D.M.M adjustment as

same as Va voltage which on label o panel right/top

(deviation; ±0.5V)

(2) Vs adjustment

1) Connect + terminal o D. M..M. to Vs pin o P811,

connect -terminal to GND pin o P811.

2) A ter turning VR951, voltage o D.M.M adjustment as

same as Vs voltage which on label o panel right/top (

deviation ; ±0.5V)

4-2. Dow load Serial umber (RS-232C)

VPress “Power on” key o service R/C.

(Baud rate : 115200 bps)

VConnect RS232 Signal Cable to RS-232 Jack.

VWrite Serial number by use RS-232.

VMust check the serial number at the Diagnostics o SET UP

menu. (Re er to below ‘6.SET INFORMATION’).

4-3. Adjustme t of White Bala ce

Required Equipment

ORemote controller or adjustment

OColor Analyzer ( CS-1000, CA-100,100+,CA-210 or same

produc: CH 10 (PDP)

* Please adjust CA-210, CA-100+ by CS-1000 be ore

measuring

OAuto W/B adjustment instrument(only or Auto adjustment)

O9 Pin D-Sub Jack(RS232C) is connected to the AUTO W/B

EQUIPMENT.

Before Adjust of White Bala ce, Please press POWER ONLY

key

Adjust Process will start by execute RS232C Command.

O Color temperature standards according to CSM and Module

OCS-1000/CA-100+/CA-210(CH 10) White balance

adjustment coordinates and color temperature.

* Manual W/B process (using adjusts Remote control)

Please Adjust in AV 1 MODE, Turn o Energy Saving Mode.

(1) Enter ‘PICTURE RESET’ on Picture Mode, then turn o

Fresh Contrast and Fresh colour in Advanced Control

(2) A ter enter Service Mode by pushing “ADJ” key,

(3) Enter White Pattern o o service mode, and change o ->

on.

(4) Enter “W/B ADJUST” by pushing “G” key at “3. W/B

ADJUST”.

* Gain Max Value is 192. So, Never make any Gain Value over

192 and please ix one Value on 192, between R, G and B.

* Auto-control inter ace and directions

(1) Adjust in the place where the in lux o light like loodlight

around is blocked. (Illumination is less than 10ux).

(2) Measure and adjust a ter sticking the Color Analyzer (CA-

100+, CA210 ) to the side o the module.

(3) Aging time

A ter aging start, keep the Power on (no suspension o

power supply) and heat-run over 5 minutes

O Auto adjustment Map (RS232C)

CSM PLASMA

Cool 11000K

Medium 9300K

Warm 6500K

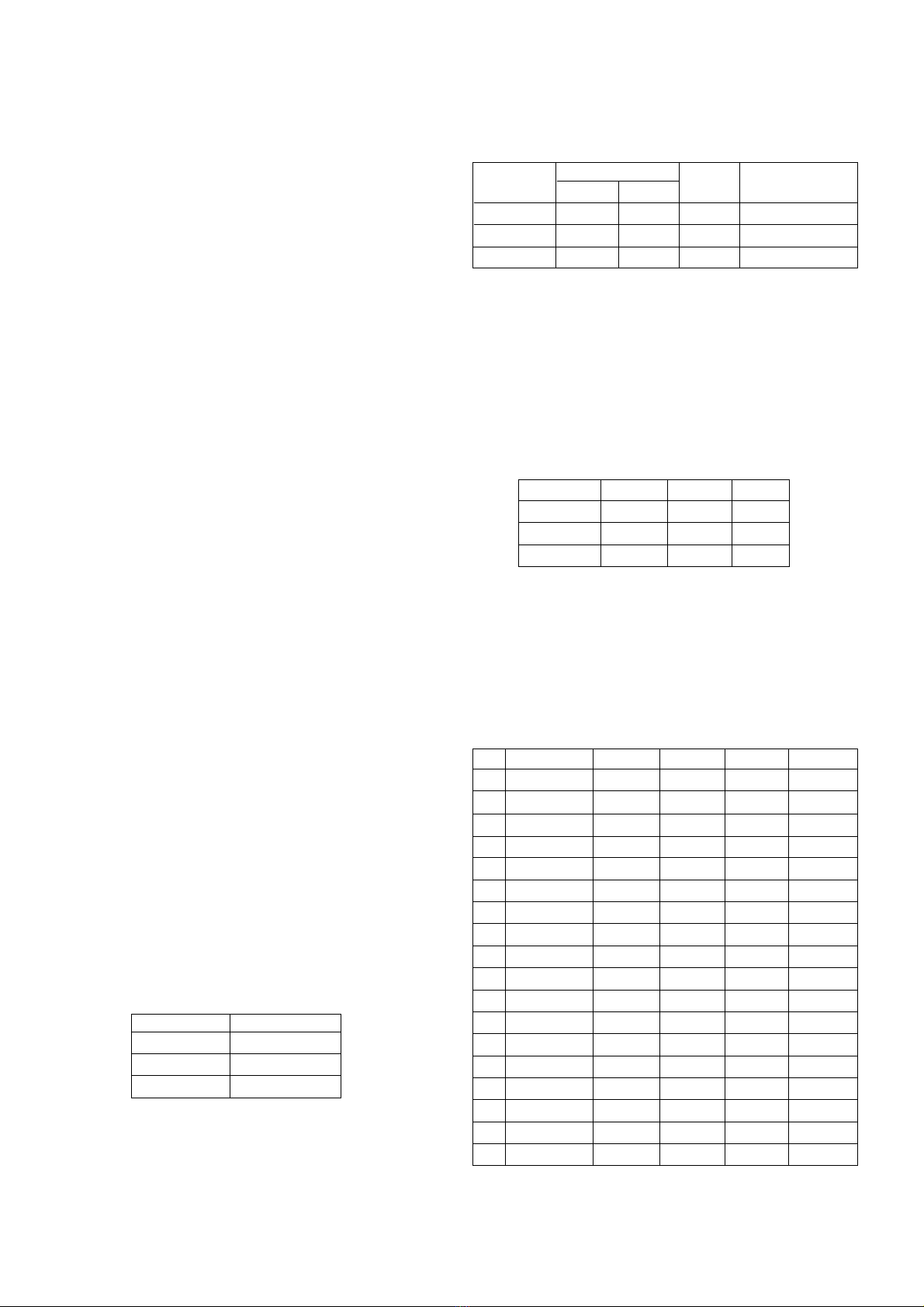

CSM Color Coordinate Temp ±Color Coordinate

xy

Cool 0.276 0.283 11000K 0.002

Medium 0.285 0.293 9300K 0.002

Warm 0.313 0.329 6500K 0.002

Min Tpy Max

R-GAIN 0 192 192

G-GAIN 0 192 192

B-GAIN 0 192 192

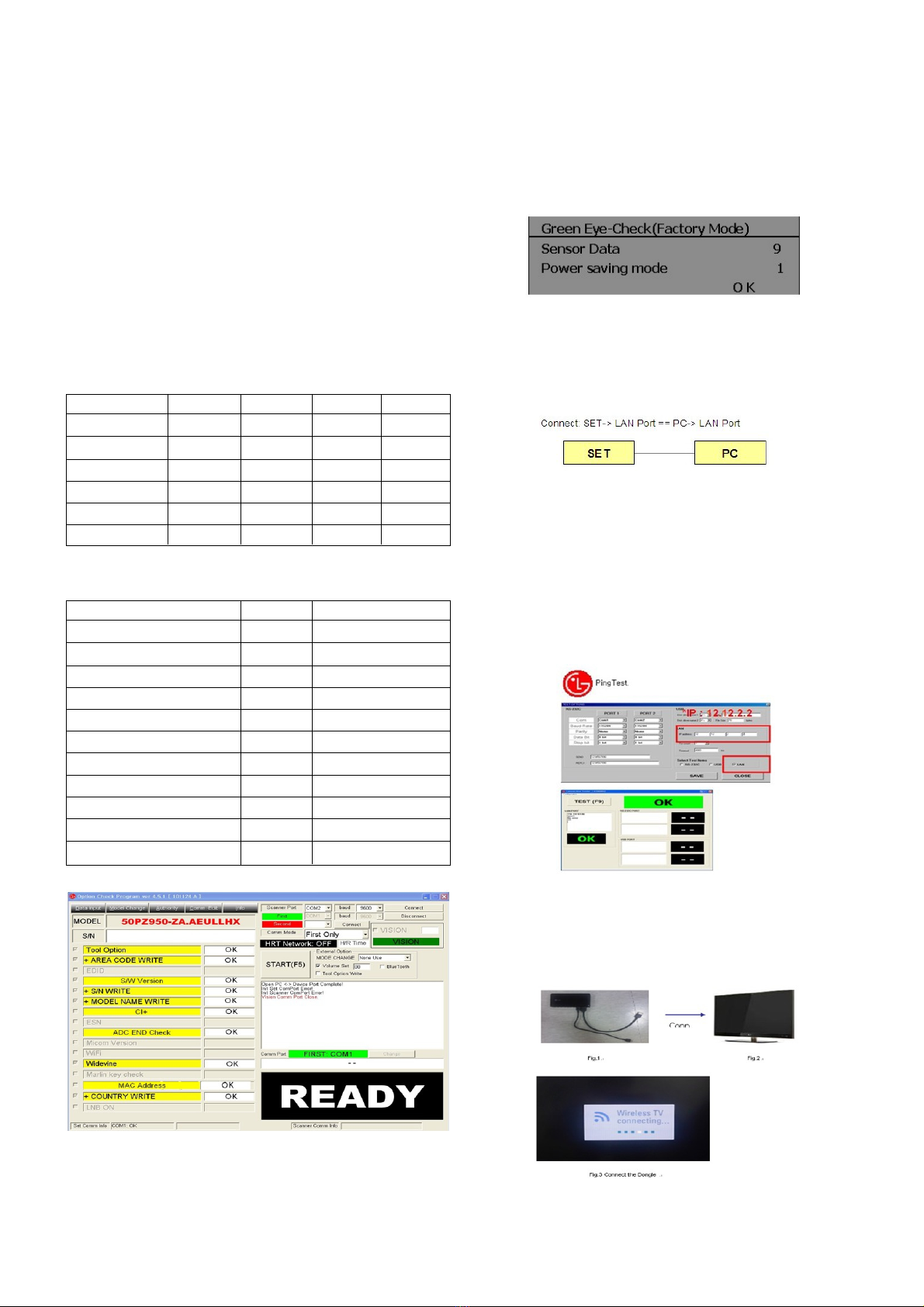

No Index CMD1 CMD2 Set ID Data

1 Start w b 0 00

2 Gain Start w b 0 10

3 Gain End w b 0 1F

4 O set Start w b 0 20

5 O set End w b 0 2F

6 End w b 0 FF

7 Medium R j a 0 00~FF

8 Medium G j b 0 00~FF

9 Medium B j c 0 00~FF

10 Warm R j d 0 00~FF

11 Warm G j e 0 00~FF

12 Warm B j 0 00~FF

13 Cool R j g 0 00~FF

14 Cool G j h 0 00~FF

15 Cool B j i 0 00~FF

16 Cool R,G,B j j 0 00~FF

17 Medium j k 0 00~FF

18 Warm j l 0 00~FF