- 9 - LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only or training and service purposes

* Caution

- Color Temperature : COOL, Medium, Warm.

- One o R Gain/G Gain/ B Gain should be kept on 0xC0, and

adjust other two lower than C0.

(when R/G/B Gain are all C0, it is the FULL Dynamic Range

o Module)

* Manual W/B process using adjusts Remote control.

(1) A ter enter Service Mode by pushing “ADJ” key,

(2) Enter White Balance by pushing “G” key at “. White

Balance”

(3) Stick the sensor to the center o the screen and select

each items(Red/Green/Blue Gain) using D/E (CH +/-) key

on R/C.

(4) Adjust R/G/B Gain using F/G (VOL +/-) key on R/C.

(5) Adjust three modes all(Cool/Medium/Warm) : Fix the one

o R/G/B Gain and Change the others.

(6) When the adjustment is completed, Enter “COPY ALL”.

(7) Exit adjustment mode using EXIT key on R/C.

* A ter You inish all adjustments, Press °∞In-start°± button

and compare Tool option and Area option value with its

BOM, i it is correctly same then unplug the AC cable.

I it is not same, then correct it same with BOM and unplug

AC cable.

For correct it to the model’s module rom actory JIG model.

* Push The “N STOP KEY” a ter completing the unction

inspection. And Mechanical Power Switch must be set “ON”.

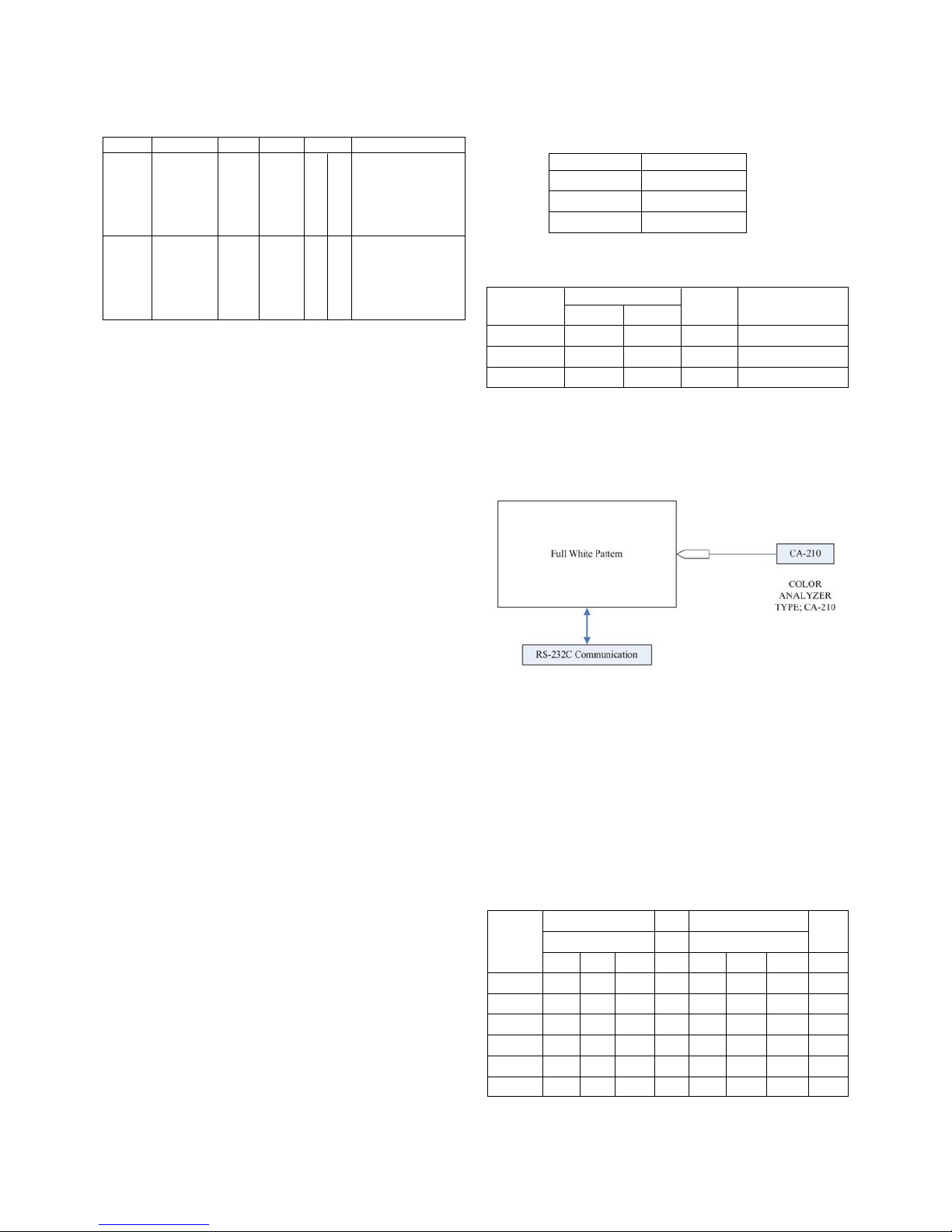

* To check the coordinates o White Balance, you have to

measure at the below conditions.

Picture mode : Vivid, Energy Saving : O , Below the

Advanced control, Dynamic Contrast : O , Dynamic Colour :

O

Colour Temp.

-> Picture Mode change : Vivid ? Vivid(User)

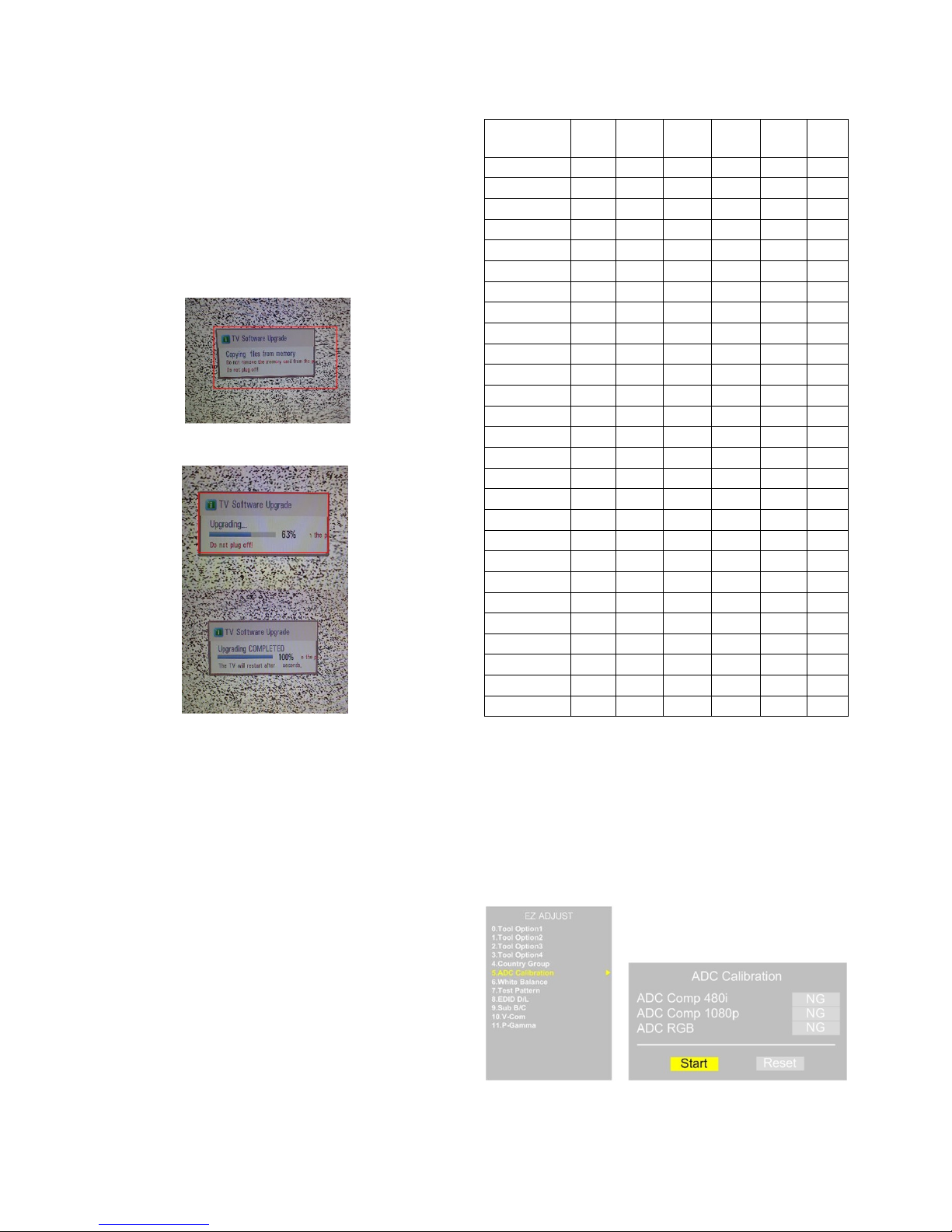

7-3. DPM op ration confirmation

(Only Apply for MNT Mod l)

* Check i Power LED Color and Power Consumption operate

as standard.

(1) Set Input to RGB and connect D-sub cable to set

(2) Measurement Condition: (100~240V@ 50/60Hz)

(3) Con irm DPM operation at the state o screen without

Signal

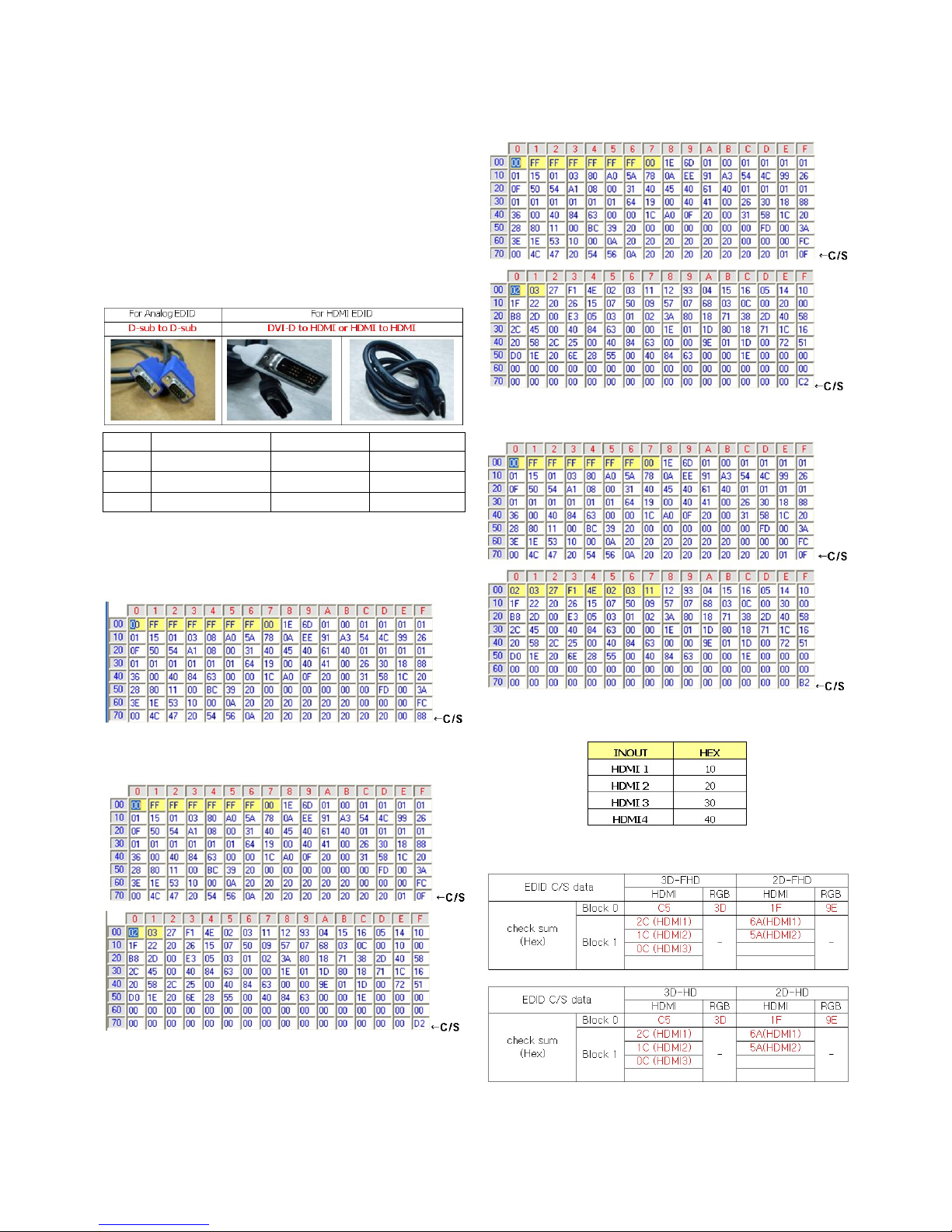

7-4. DDC EDID Writ (RGB 128Byt )

-> Not us d any mor , Us Auto D/L

(1) Connect D-sub Signal Cable to D-Sub Jack.

(2) Write EDID DATA to EEPROM (24C02) by using DDC2B

protocol.

(3) Check whether written EDID data is correct or not.

* For SVC main Ass’y, EDID have to be downloaded to

Insert Process in advance.

7-5 DDC EDID Writ (HDMI 256Byt )

-> Not us d any mor , Us Auto D/L

(1) Connect HDMI Signal Cable to HDMI Jack.

(2) Write EDID DATA to EEPROM(24C02) by using DDC2B

protocol.

(3) Check whether written EDID data is correct or not.

* For SVC main Ass’y, EDID have to be downloaded to

Insert Process in advance.

7-6. EDID DATA

(1) All Data : HEXA Value

(2) Changeable Data :

*: Serial No : Controlled / Data:01

**: Month : Controlled / Data:00

***:Year : Controlled

****:Check sum

7-7. EDID DATA Auto Download

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) I Download is success ul, OK is display, but I Download is

ailure, NG is displayed.

(5) I Download is ailure, Re-try downloads.

*Caution: Never connect HDMI & D-sub Cable when EDID

downloaded.

O Edid data and Model option download (RS232)

NO Item CMD 1 CMD 2 Data 0

Enter download A A 0 0 When trans er the

download ‘Mode In’‘Mode In’

Mode Carry the

command.

EDID data download A E 00 10 Automatically

Model download

option (The use o

download a internal pattern)