2

Table of Contents

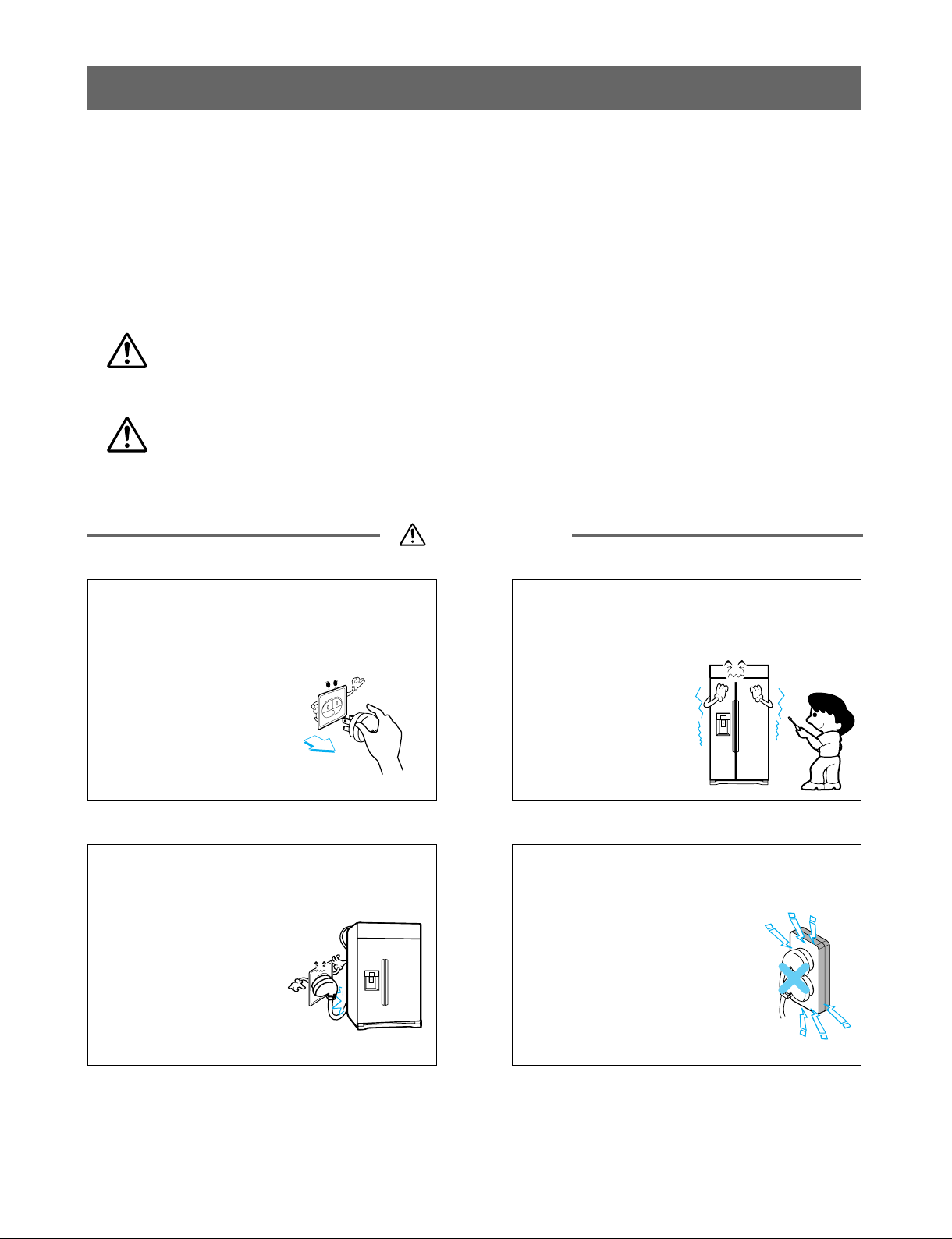

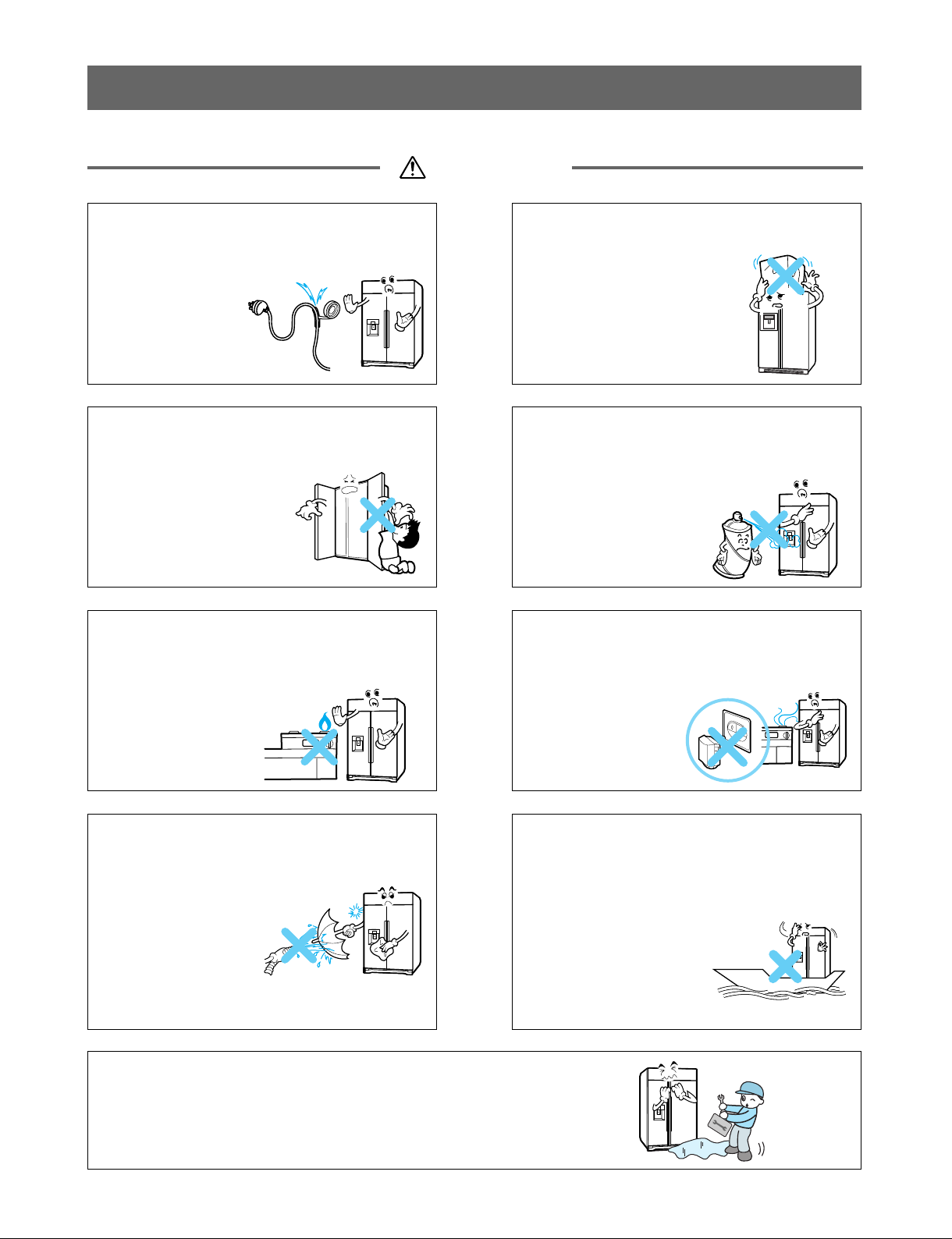

Chapter 1 Safety Warning and Cautions ........................................................................................ 3

Chapter 2 Product Standards ......................................................................................................... 8

Chapter 3 Circuit Diagram ............................................................................................................... 9

Chapter 4 Specifications ............................................................................................................... 10

1. Specifications ............................................................................................................................... 10

2. Parts ............................................................................................................................................. 11

Chapter 5 Micom Function ............................................................................................................ 13

1. Control Panel Figure .................................................................................................................... 13

2. Description of Function ................................................................................................................ 14

Chapter 6 Icemaker and Dispenser Operation and Repair ........................................................ 20

1. Operation ..................................................................................................................................... 20

2. Icemaker Functions ...................................................................................................................... 21

3. Defect Diagnosis Functions ......................................................................................................... 22

Chapter 7 Trouble Diagnosis ........................................................................................................ 23

1. Sealed System Repair ................................................................................................................. 23

Chapter 8 Troubleshooting ........................................................................................................... 30

1. Troubleshooting by Error Codes .................................................................................................. 30

Chapter 9 How to Disassemble and Assemble ............................................................................ 56

1. Door .............................................................................................................................................. 56

2. Handle .......................................................................................................................................... 57

3-1. Dispenser .................................................................................................................................. 57

3-2. Display PCB ............................................................................................................................. 57

3-3. Ice Button .................................................................................................................................. 58

3-4. Water Button ............................................................................................................................. 58

3-5. Duct Door .................................................................................................................................. 58

3-6. Cap Duct Motor ......................................................................................................................... 58

3-7. Funnel ....................................................................................................................................... 58

4. Water Valve Disassembly Method .............................................................................................. 59

5. Fan and Fan Motor Disassembly Method .................................................................................... 59

6-1. Multi Duct Freezer .................................................................................................................... 60

6-2. Grille Fan Freezer...................................................................................................................... 60

6-3. Multi Duct Refrigerator .............................................................................................................. 60

6-4. Grille Fan Refrigerator .............................................................................................................. 60

7-1. Lamp Cover (Back).................................................................................................................... 61

7-2. Lamp Cover (Side)..................................................................................................................... 61

8. Airtight Compartment .................................................................................................................... 62

Exploded View ................................................................................................................................ 63