6

2-8. WATER CIRCULATION

2-7. CHILD LOCK

2-6. DOOR LOCKED LAMP LIGHTS

The recirculated water sprays from a nozzle at the top of the door gasket.

During the wash cycle, it runs continuously for the first three minutes and intermittently after that.

During the rinse cycle, it runs continuously after the drum is filled.

When the frequency of water level is lower than 22.9 kHz.

(It can be canceled when the frequency is more than 23.8 kHz.)

When the temperature inside the tub is higher than 45¡C (113¡F) and water level is not 25.5 kHz.

(It can be canceled when the water level is 25.5 kHz or the temperature inside the tub is lower than

40¡C (104¡F))

Use this option to prevent unwanted use of the washer. Press and hold STAIN CARE button for 3

seconds to lock/unlock control.

When child lock is set, CHILD LOCK lights and all buttons are disabled except the POWER

button. You can lock the controls of the washer while washing.

CHILD LOCK remains in effect after the cycle and even if the power is turned off. To UNLOCK,

press and hold the STAIN CARE button for 3 seconds.

2-9. Cycle counter

Select this function to check the number of cycles.

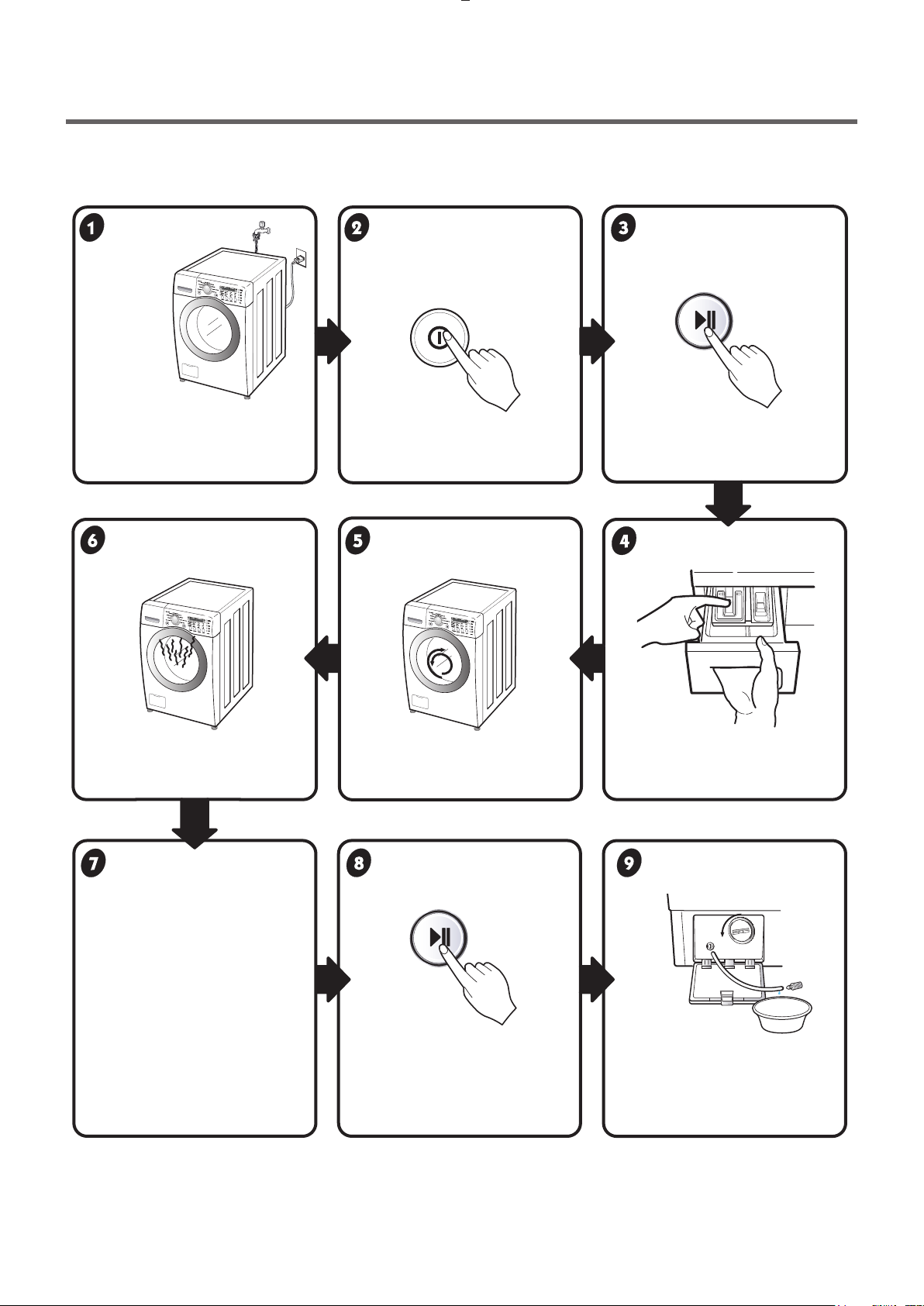

1. Press Power button.

2. Select a cycle.

3. Press Start/Pause button.

4. Press Wash and Rinse button simultaneously, then the

number of cycles will be displayed.

If less than 1000 cycle, the number of cycles is expressed

as is.

If more than 1000 cycle, the number of thousands place

and the remaining numbers appears taking turns.

E.g. in case of 1,020

1 20 blank (repeated)

The number of cycles can be reset when Main PCB is replaced.

(It does not change in case of a simple change in the program.)