2

CONTENTS

1. SPECIFICATION............................................................................................................................3

2. FEATURES & TECHNICAL EXPLANATION ................................................................................ 4

3. PARTS IDENTIFICATION ............................................................................................................ 6

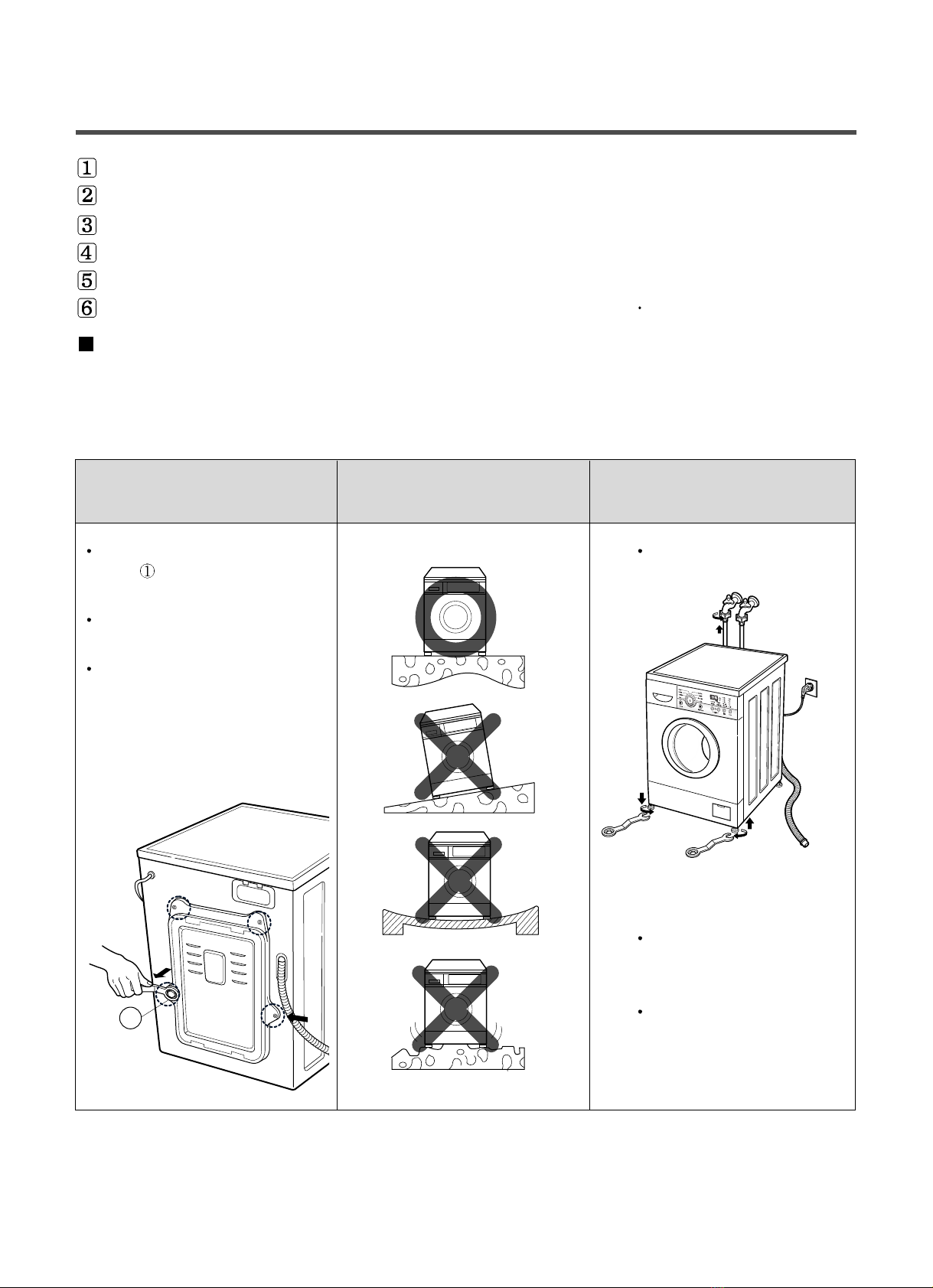

4. INSTALLATION............................................................................................................................. 7

5. OPERATION ................................................................................................................................10

6. WIRING DIAGRAM PROGRAM CHART.....................................................................................12

7. TROUBLESHOOTING.................................................................................................................13

7-1.BEFORE PERFORMING SERVICE ....................................................................................13

7-2.TEST MODE ........................................................................................................................13

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY.........................................................13

7-4.ERROR DISPLAY ................................................................................................................14

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................15

8-1. DIAGNOSIS AND ANSWER FOR ABNORMAL OPERATION ...........................................15

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING ..............................................................18

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................24

10. EXPLODED VIEW .....................................................................................................................31

10-1. THE EXPLODED VIEW OF CABINET ASSEMBLY .........................................................31

10-2. THE EXPLODED VIEW OF CONTROL PANEL & DISPENSER ASSEMBLY..................32

10-3. THE EXPLODED VIEW OF DRUM & TUB ASSEMBLY...................................................33

APPENDIX (Replacement parts list).........................................................................................34