Water temperature selector

Press the button to select water temperature.

The water temperature

[40 C 50 C60 C Cold 30 C] can be

selected in Coloreds, or Synthetic.

95 C is selected for Whites only.

By pressing the button while operating the washer,

the present temperature is displayed.

Rinse hold

If you desire to leave fabrics in the machine without spinning after rinse to

prevent them wrinkling, you may select rinse hold by pressing the spin

button.

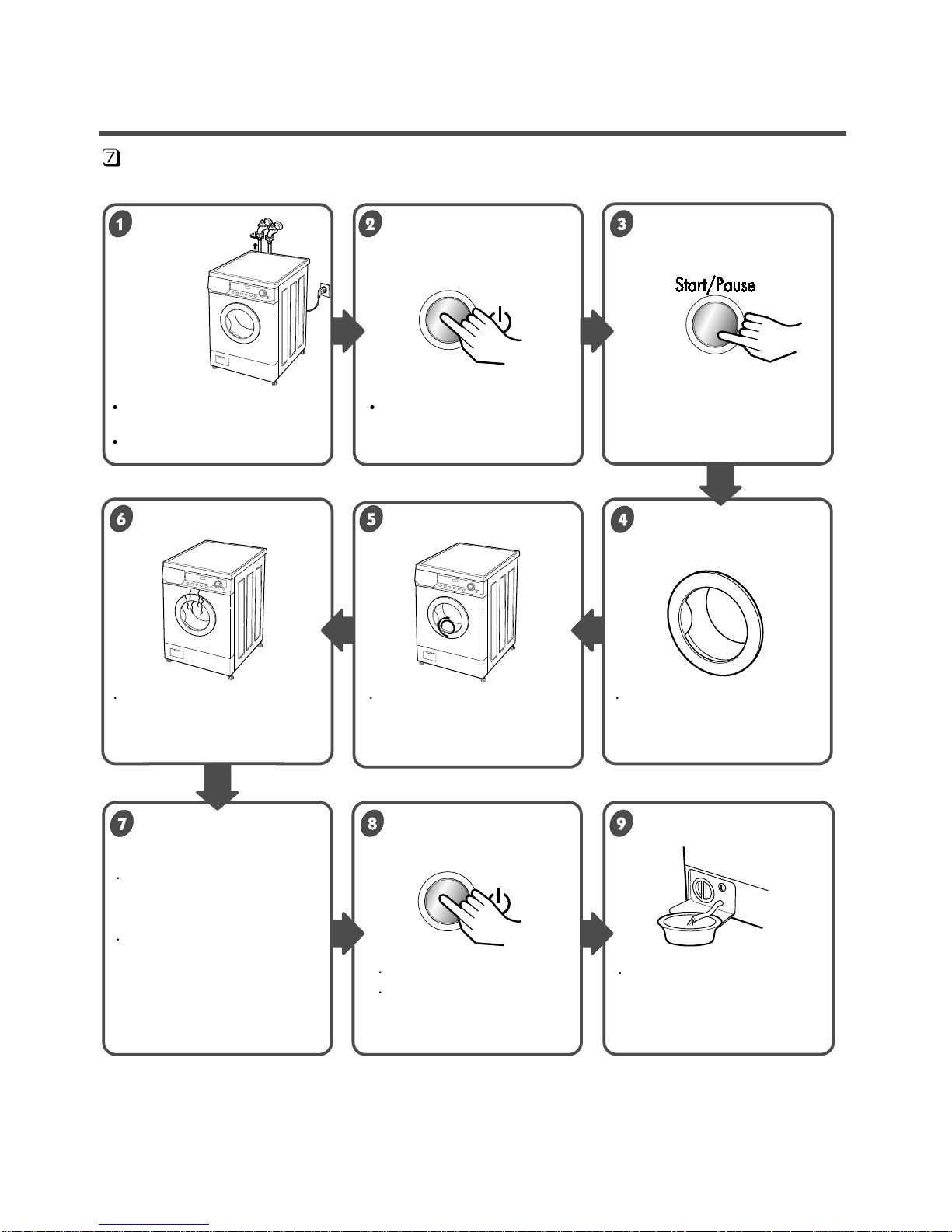

If you want to drain and spin, when Rinse Hold function is proceed, Press

the Start/Pause button to cancel the Rinse Hold function and select spin

speed or program. Press the Start/Pause button again to start program.

If you want to drain only, select the no spin or pump program.

If lamp turns on, that function has been selected.

Option

Bio

If you want to elimenate protein

stains(milk, blood, chocolate...),

you may select Bio by pressing

the option button.

[You can select Bio when

temperature is higher than 60 C

in Whites, Coloureds and

Synthetic.]

Rinse+

If you wish to rinse more, the

Rinse+option will remove any

trace of detergents.

Eco

By selecting Eco, the water

temperature is reduced and

washing time is lengthened.

So you can economize in your

consumption of energy.

[You can select Eco when

temperature is higher than 60 C

in Whites, Coloureds and

Synthetic.]

Pre Wash

If the laundry is heavily soiled,

“Pre Wash”course is effective.

Pre Wash is available in

Coloureds, Whites and Synthetic

Program.

Child - lock

Child Lock system can be set and canceled by pressing

both [Temp.] and [Time Delay ] button simultaneously.

Once Child Lock is set, all button are inoperable.

Child Lock system can be set anytime even during

Power-off and operation.

It is automatically cancelled when an operational error

occur.