1. Product Specification.................................................................................................................................... 3

2. Component Names and Motions.................................................................................................................. 4

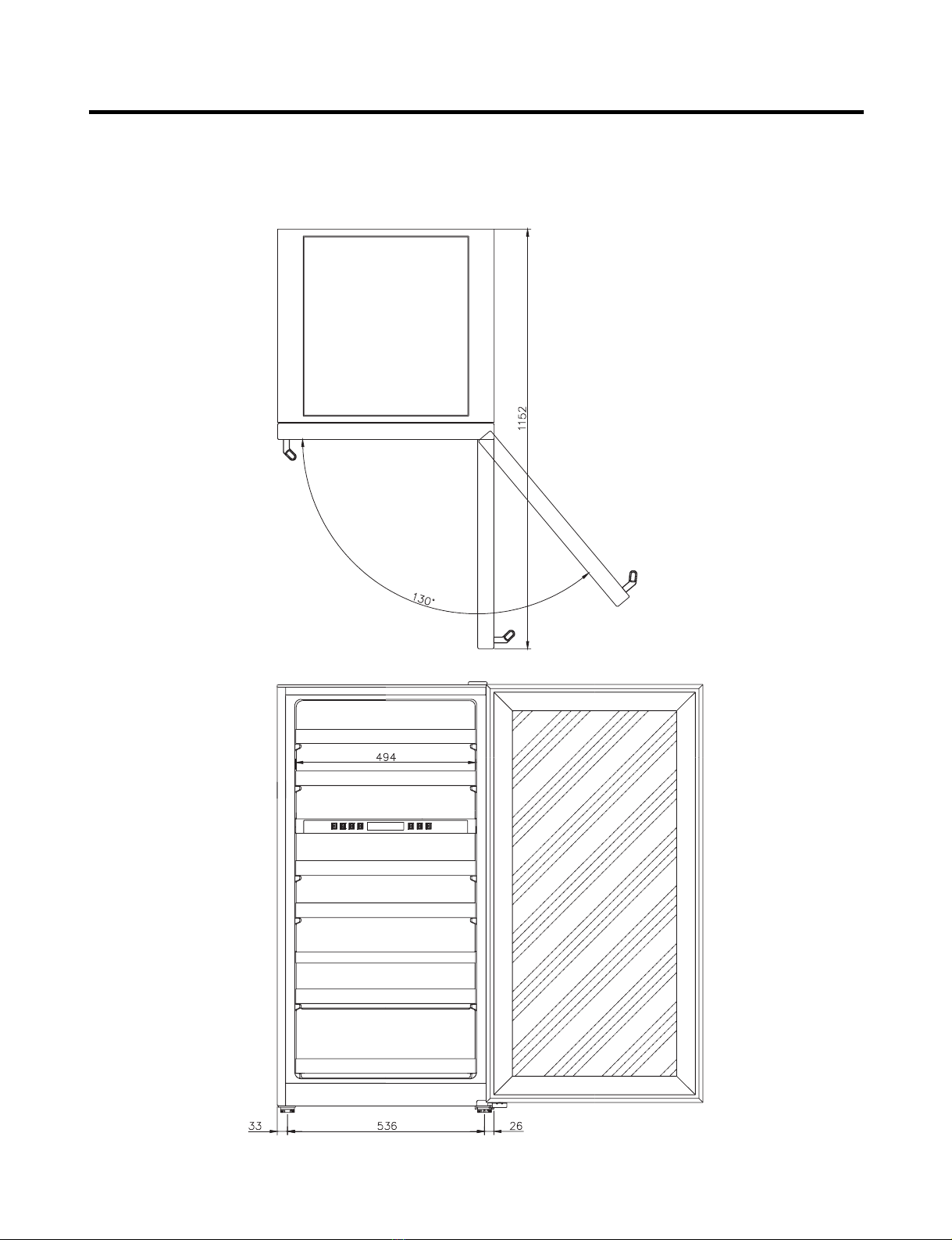

3. Exterior .......................................................................................................................................................... 7

4. Circuit Diagram ......................................................................................................................................... 12

5. Micom Function and Circuit Diagram ..................................................................................................... 14

6. Special Features ....................................................................................................................................... 30

7. Standard Self-Diagnostic Function............................................................................................................ 31

8. Maintenance ................................................................................................................................................. 32

9. Handle Disassembling, Assembling Instruction ...................................................................................... 35

10. Service Parts Chart ................................................................................................................................... 36

1. Unplug the power before you handle any electrical component.

2. If you must test the product with the power on, please wear a rubber globe in order to prevent an electric shock.

3. Check the rated current, voltage, and capacity if you are using a gauge.

4. Take caution not to let any water near the electrical component around the compressor.

5. Please use a designated part for marked parts or the circuit diagram.

6. Please remove any object from the top prior to tilting the product.

7. In order to prevent a cut from a fin, put on a glove before you repair the refrigerator or get near the heat resistor area.

SAFETY INSTRUCTIONS

TABLE OF CONTENTS

- 2 -