iv

Water Sorption................................................................................................................................. 3-13

Maximum Flow Rates...................................................................................................................... 3-13

Using the 610-03 Digital Pressure Meter................................................................................................ 3-16

Connecting the LI-610 and 610-03 to the LI-6200 RS-232C Port.......................................................... 3-18

References............................................................................................................................................... 3-20

Section IV. CALIBRATING LI-COR INSTRUMENTS

General Information ................................................................................................................................ 4-1

Calibrating the LI-6400 H2O Analyzer................................................................................................... 4-1

Setting the H2O Span....................................................................................................................... 4-1

Calibrating the LI-7000 CO2/H2O Infrared Gas Analyzer...................................................................... 4-4

Preliminary....................................................................................................................................... 4-4

Calibration Instructions.................................................................................................................... 4-6

I. Reference (Cell A) is Known and Constant ................................................................................ 4-7

II. Reference (Cell A) is Known, but not Constant......................................................................... 4-7

III. Calibrating for REM Operations............................................................................................... 4-8

User Calibration Example................................................................................................................ 4-10

Calibrating the LI-7500 CO2/H2O Infrared Gas Analyzer...................................................................... 4-12

Preliminary....................................................................................................................................... 4-12

Zero CO2.......................................................................................................................................... 4-14

Zero H2O.......................................................................................................................................... 4-14

Span CO2.......................................................................................................................................... 4-14

Span H2O......................................................................................................................................... 4-15

Calibrating the LI-840 CO2/H2O Infrared Gas Analyzer........................................................................ 4-16

Calibrating the LI-COR LI-6262 CO2/H2O Infrared Gas Analyzer ....................................................... 4-17

Preliminary....................................................................................................................................... 4-17

Absolute Mode H2O Zero Calibration............................................................................................. 4-18

Absolute Mode H2O Span Calibration ............................................................................................ 4-18

Differential Mode H2O Zero Calibration......................................................................................... 4-19

Precautions....................................................................................................................................... 4-19

Calibrating the LI-COR LI-1600 Steady State Porometer RH Sensor.................................................... 4-20

Initial Set-up..................................................................................................................................... 4-20

Calibration: Setting the Zero............................................................................................................ 4-21

Calibration: Setting the Span ........................................................................................................... 4-22

Check Intermediate Values .............................................................................................................. 4-23

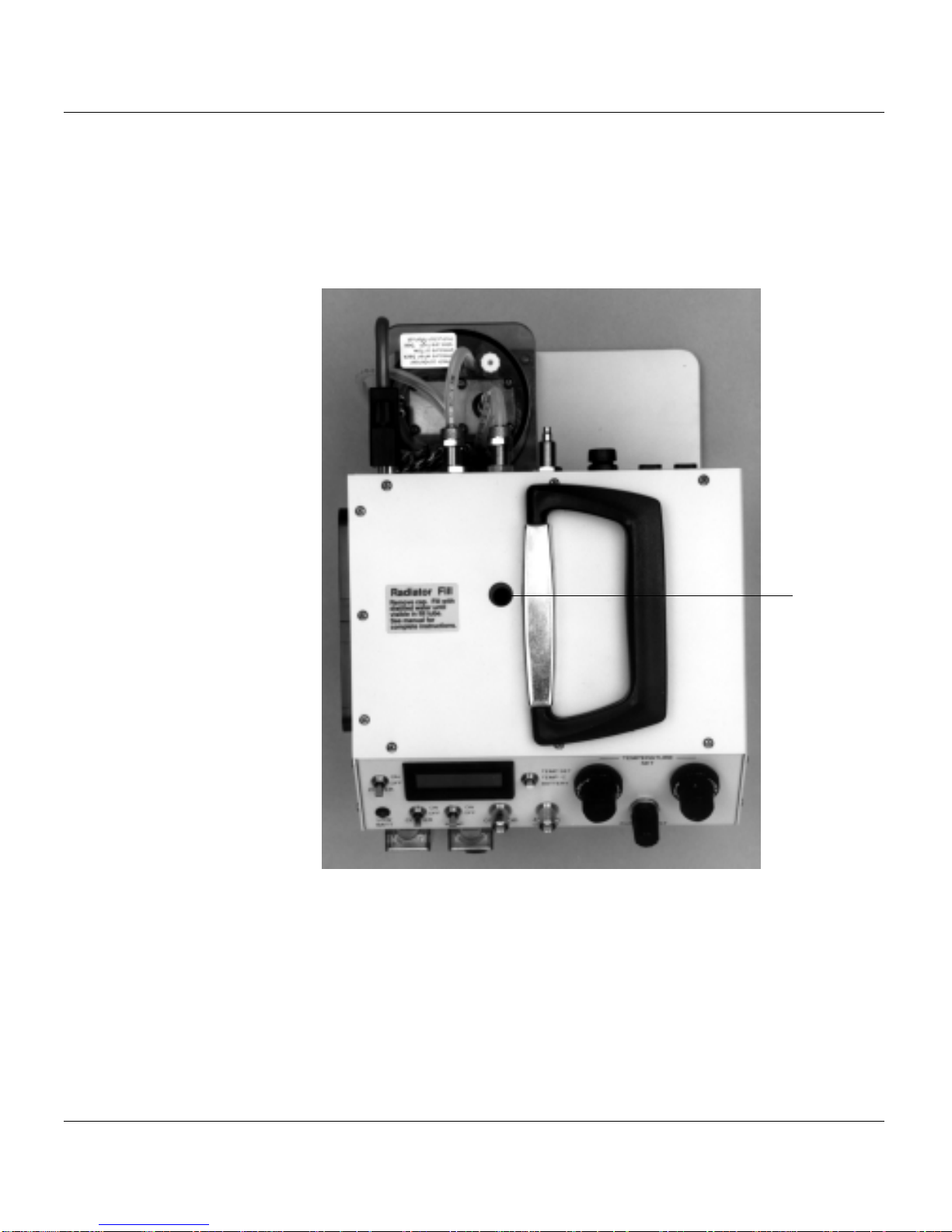

Calibrating the LI-COR LI-6200 or LI-6000 Portable Photosynthesis System RH Sensor.................... 4-24

Precalibration ................................................................................................................................... 4-24

Calibration: Setting the Zero............................................................................................................ 4-26

Calibration: Setting the Span ........................................................................................................... 4-27