PREFACE

Thank you for choosing a general gasoline engine by the company.

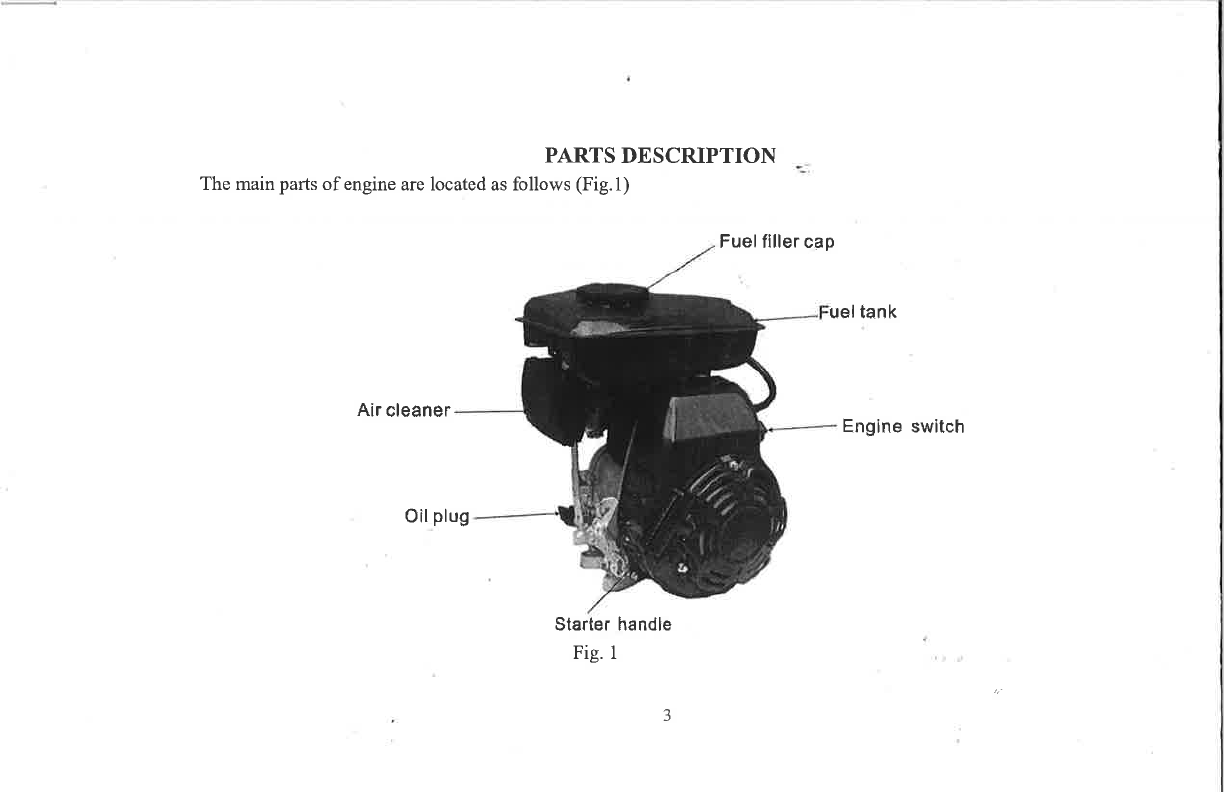

Based on the latest engine technology at home and abroad, our Co. has individuaily developed general gasoline

engine with 4-stroke single cylinder, OIIV and forced-air cooling. The engine is characterized by advanced design,

compact structure, reliable performance, low noise and small vibration. It is widely used as ideal power in many

fields such as small-scale water pump, generator set, cropper, thresher; garden machinery etc.

The manual gives information with respect to operation and maintenance of the general gasoline engine. Please

read it car.efully first before operating. To extend the serrrice life, users should strictly follow the stipulations stated in

the manual to cany out operating and maintenance.

This manual should be considered a permanent part of the engine and should remain with it if it is resold.

All the matetials and diagrams of this manual are in accordance with the newest products at the publishing time.

Due to 1evision and other change, the information descried in this manual may be a little different from the actual

status. The copyright of this manual belongs to our Co, any group or individual is forbidden to reprint or copy any it.

The manual is subject to change without notice.

Please pay special attention to statements preceded by the following words.

/1