Other features

Lock Lift

If the elevator needs to be made inoperable for a short

period of time the following procedure should be followed.

Traction model

Move elevator to the first floor and press and hold the blue up

button for 10 seconds. The display will show lift car locked.

To unlock, press and hold the blue up button for 10 seconds.

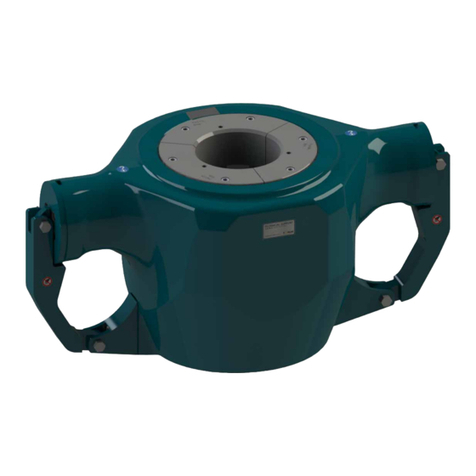

Hydraulic model

Move elevator to the ground floor and press and hold the green

down button for 10 seconds. The display will show lift car locked.

To unlock, press and hold the blue up button for 10 seconds.

Long-term shut off

If the elevator is to be rendered inoperable for longer periods of

time, please contact your service provider.

Periodic examination

Once installation is complete and the elevator has been

commissioned, the service counter will be set to ZERO and

the LCD display will inform you when your next service is

due if required earlier than at six monthly intervals.

If necessary, the Engineer may recommend more frequent

examinations to ensure continued safe and reliable operation.

Any recommended repairs will be noted, including a time scale

for completion.

Should a defect directly affecting safety which requires immediate

repair be reported, the elevator will have to be taken out of service.

Any maintenance or service should be recorded in the elevator’s

service log.

Periodic servicing

The elevator should be thoroughly serviced by a competent

person within six months of commissioning and thereafter at

intervals not exceeding six months.

NOTE!

Call outs and service visits may be combined to minimise

disruption. At each service any serious defects should be rectified,

and Engineering Test carried out and logged.

4