Table of Contents

PNEG-681 Series II Bucket Elevator 3

Contents

Chapter 1 Introduction ..........................................................................................................................................4

General Safety Statements ................................................................................................................... 4

Receiving Inspection ............................................................................................................................. 4

Pre-Installation Notifications .................................................................................................................. 4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

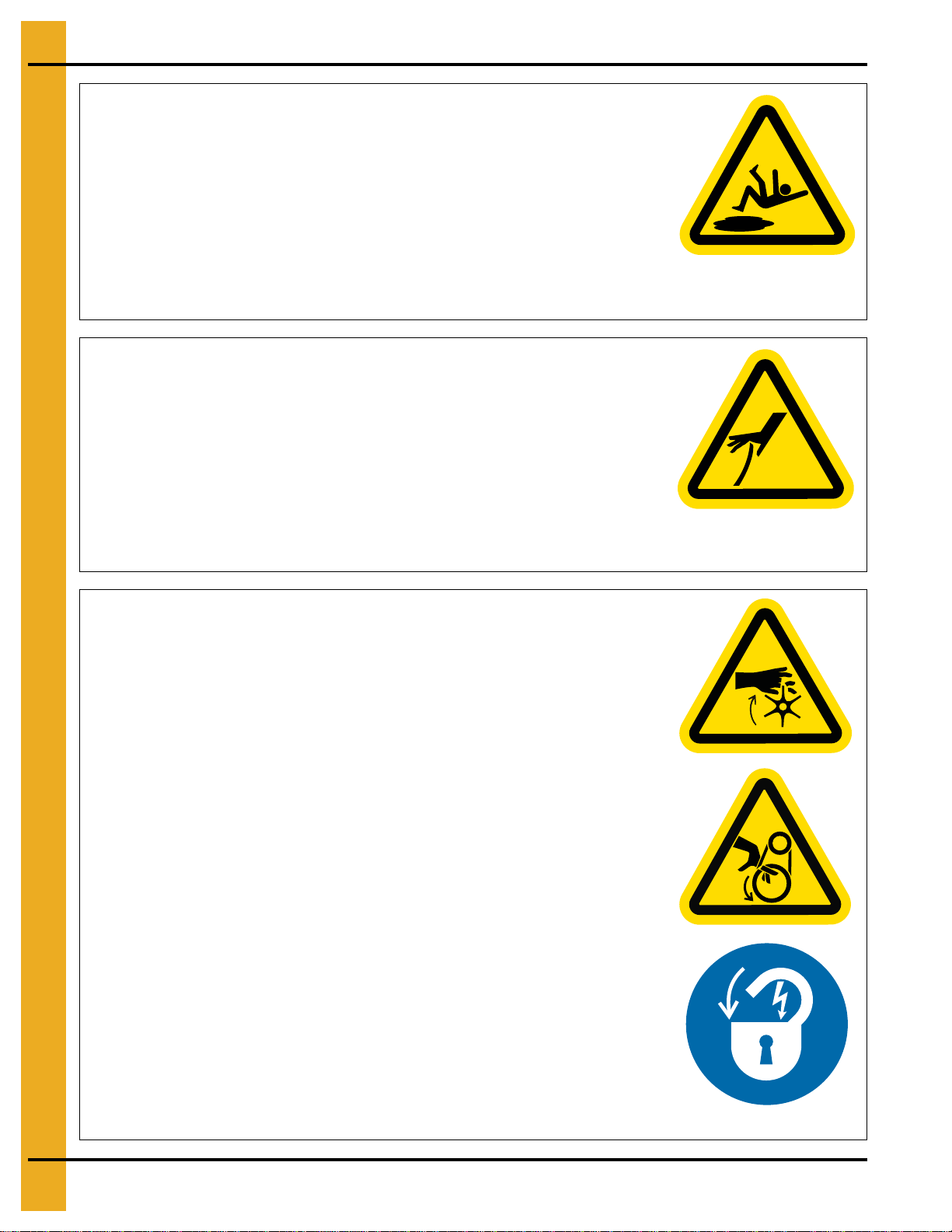

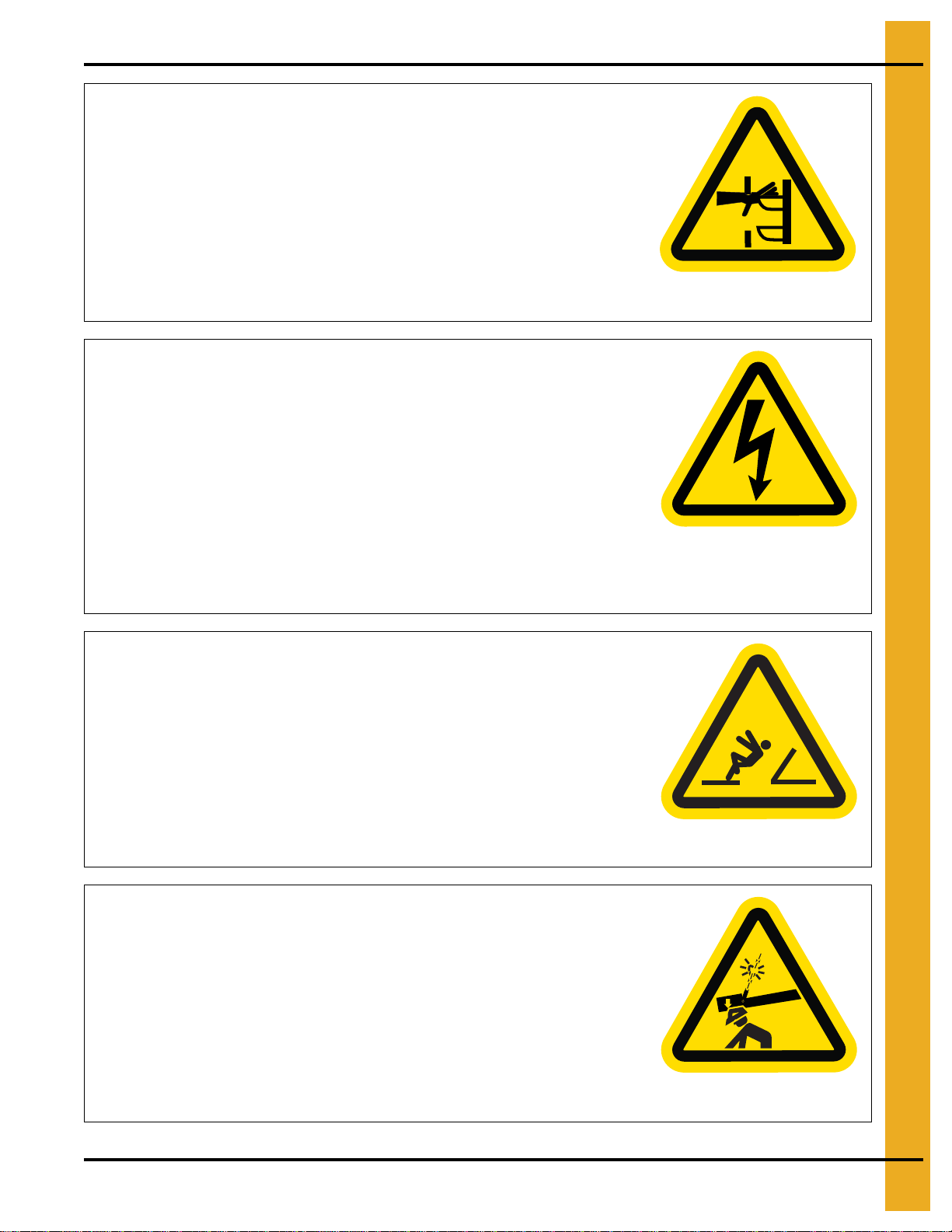

Cautionary Symbols Definitions ............................................................................................................ 6

Safety Cautions ..................................................................................................................................... 7

Safety Sign-Off Sheet ......................................................................................................................... 11

Chapter 3 Safety Decals ......................................................................................................................................12

Decal Placement ................................................................................................................................. 14

Chapter 4 Elevator Parts .....................................................................................................................................15

Part Identification ................................................................................................................................ 15

Chapter 5 Bucket Elevator Foundation ..............................................................................................................16

Chapter 6 Boot Section .......................................................................................................................................17

Attaching Boot to Foundation .............................................................................................................. 17

Inspection Sections ............................................................................................................................. 18

Chapter 7 Trunking ..............................................................................................................................................19

Standard Trunking ............................................................................................................................... 19

Pressure Relief Trunking ..................................................................................................................... 20

Trunking Installation ............................................................................................................................ 21

Chapter 8 Lower Head Section ...........................................................................................................................22

Head Bonnet Section .......................................................................................................................... 22

Chapter 9 Maintaining Plubmness .....................................................................................................................24

Chapter 10 Belting, Splicing and Buckets .........................................................................................................25

Belts ................................................................................................................................................... 25

Splicing .............................................................................................................................................. 25

Buckets .............................................................................................................................................. 26

Belt Slack Removal ........................................................................................................................... 26

Chapter 11 Drive Motor and Motor Mount .........................................................................................................28

Drive .................................................................................................................................................. 28

Motor Mount Assembly ...................................................................................................................... 28

Slide Base ......................................................................................................................................... 29

Torque Arm ........................................................................................................................................ 30

Shaft Mount Reducer ......................................................................................................................... 31

Drive Guard ....................................................................................................................................... 31

Drive Belts ......................................................................................................................................... 35

Chapter 12 Final Checks, Tracking, Start-Up and Maintenance ......................................................................36

General Final Checks ........................................................................................................................ 36

Belt Tracking ...................................................................................................................................... 37

Start-Up ............................................................................................................................................. 37

Maintenance ...................................................................................................................................... 37

Chapter 13 Appendix 1 - Reference Information ...............................................................................................38

Chapter 14 Warranty ............................................................................................................................................39