3©2011,2005 BRUNO INDEPENDENT LIVING AIDS, INC.®

SRE-2750 INSTALL 05-17-2011

IMPORTANT NOTES ............................................2

REGULATORY INFORMATION .....................................4

TECHNICAL SPECIFICATIONS ....................................5

Torque Specications ........................................5

CARTON CONTENTS and RECOMMENDED TOOLS ......................6

INSTALLATION

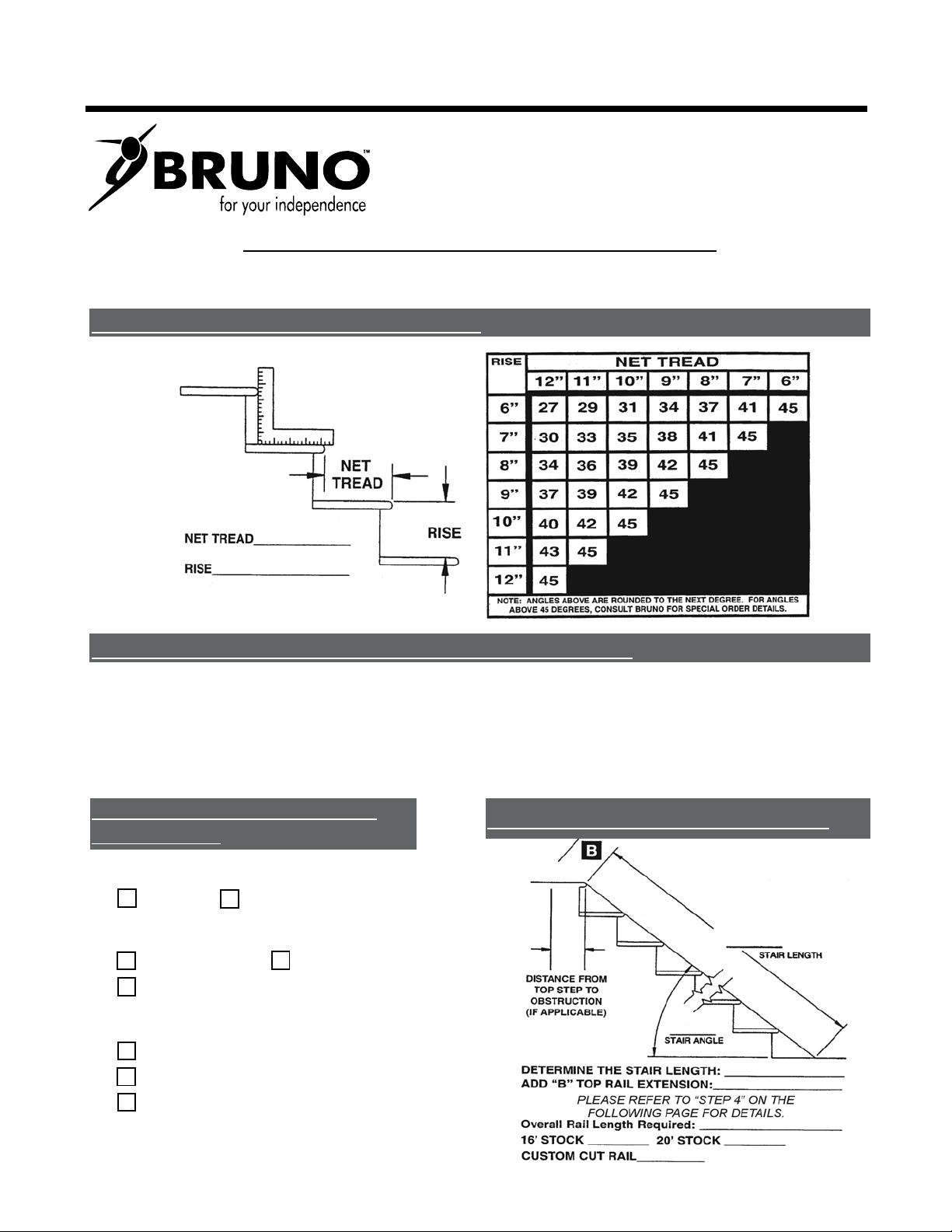

Fitting the Rail ...........................................7

Application Guide .......................................8-9

Cutting the Rail:Two-Piece Rail Installations ......................11

Cutting the Rail:One-Piece Rail Installations ......................12

Drilling Holes for Charge Strips ...............................13

Rail Joint Assembly .......................................14

Positioning Foot Clamp Assemblies ......................... 14-15

Clamp Wedge Locks.......................................16

Mounting the Carriage on the Upper Rail ........................17

Adjusting the Carriage Angle ............................. 17-18

Right-hand Installations ....................................18

Installing the Seat Assembly.................................19

Installing the Final Limit Ramp and Switch .......................20

ELECTRICAL

Circuit Breaker ..........................................20

Connecting the Power Source (charge contact blocks) ...............21

Connecting the Battery Charger ........................... 22-23

Battery Charger LED's/Fuse Replacement........................24

Infrared Call/Send Transmitter ...............................25

Mounting the Standard IR Call/Send Transmitter...................25

Testing the Call/Send Transmitter .............................26

Circuit Board Diagnostics ................................ 26-27

Learning the Remote IR Transmitter ...........................28

TESTING ELEVATOR OPERATION .................................29

ADJUSTMENTS

Seat Height Adjustment ....................................30

Seat Cover Gap Adjustment .................................31

Seat Swivel Adjustment ....................................31

LUBRICATION ...............................................29

RIGHT-HAND OPERATION

Electrical and Mechanical Changes .............................32

Converting Rocker Switch to Left Armrest........................32

LONG-TERM STORAGE .........................................33

TROUBLESHOOTING...........................................34

YEARLY MAINTENANCE OPERATIONS .............................35

WIRING SCHEMATIC ..........................................36

EXPLODED VIEW AND BILL OF MATERIALS ...................... 37-40

LIMITED WARRANTY ..........................................41

TABLE OF CONTENTS