2

CONGRATULATIONS on your purchase of a Lightstat TME. It represents

reliable, modern, electronic tempe rature control in addition to unique energy

saving features.

Features

• 1 Amp relay switching of up to 6 HVAC loads.

• Automatic Changeover from Heating to Cooling with a 5º F deadband

between heating and cooling to prevent short cycling of equipment.

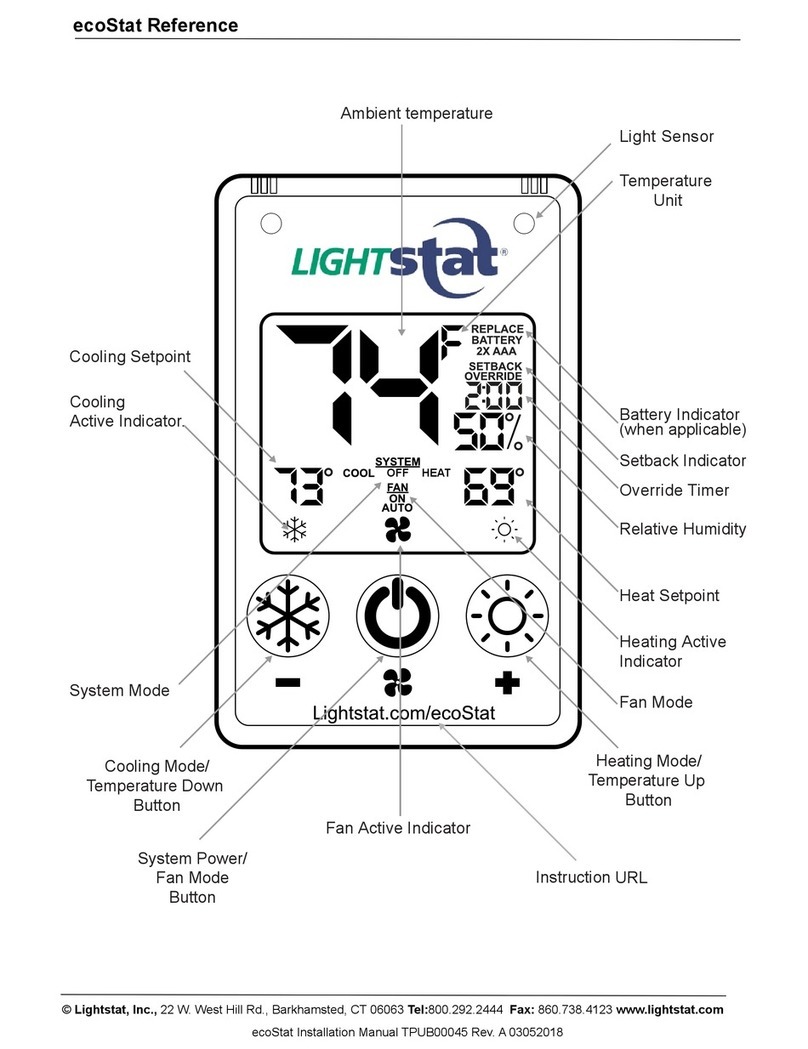

• Automatic Setback of temperatures based on light sensitivity or contact

closure (model dependent).

• System ON/OFF switch, and Fan switch for AUTO or ON fan operation.

• PRE-CONDITION feature to pre-heat or pre-cool the building prior to

occupancy at the start of the day.

• Fan control settings for Heating to allow either thermostat controlled fan

(typical of electric heat) or a limit switch controlled fan (typical of gas heat).

• Auxiliary output options to permit the O/B output to be active with a call for

Heat or Cool; for heat pump reversing valve.

• A1-A2 isolated dry contact outputs for night shutdown of dampers or

equipment.

• Connections for using a Remote Room Sensor.

• Connections for using a Supply Air Sensor.

• Light Sensitivity adjustment to permit operation in bright or dim areas (model

dependent).

• Stages of Heat and Cool stagger ON.

• Proportional plus Integral control for accurate, even temperature control.

• Factory set temperature limits to prevent overheating and overcooling.

• Minimum ON and OFF time delays for compressor protection.

• Field Check button to cancel time delays for checkout in the eld.

• Fan harvests energy from coils.

• Occupancy of less than two hours will not affect pre-conditioning timing.

• Random restart after Setback or power failure.

• RTU visible alarm.