Table of contents

User's guide............................................................................................................................................................................................1

Table of contents.............................................................................................................................................................................3

Ty ogra hic and iconogra hic conventions...................................................................................................................4

Preliminary information..............................................................................................................................................................5

1 Safety summary..................................................................................................................................... 6

1.1 Safety.............................................................................................................................................................................6

1.2 Electrical safety.........................................................................................................................................................6

1.3 Mechanical safety....................................................................................................................................................7

2 Identification......................................................................................................................................... 8

3 Mechanical installation....................................................................................................................... 9

3.1 Overall di ensions...................................................................................................................................................9

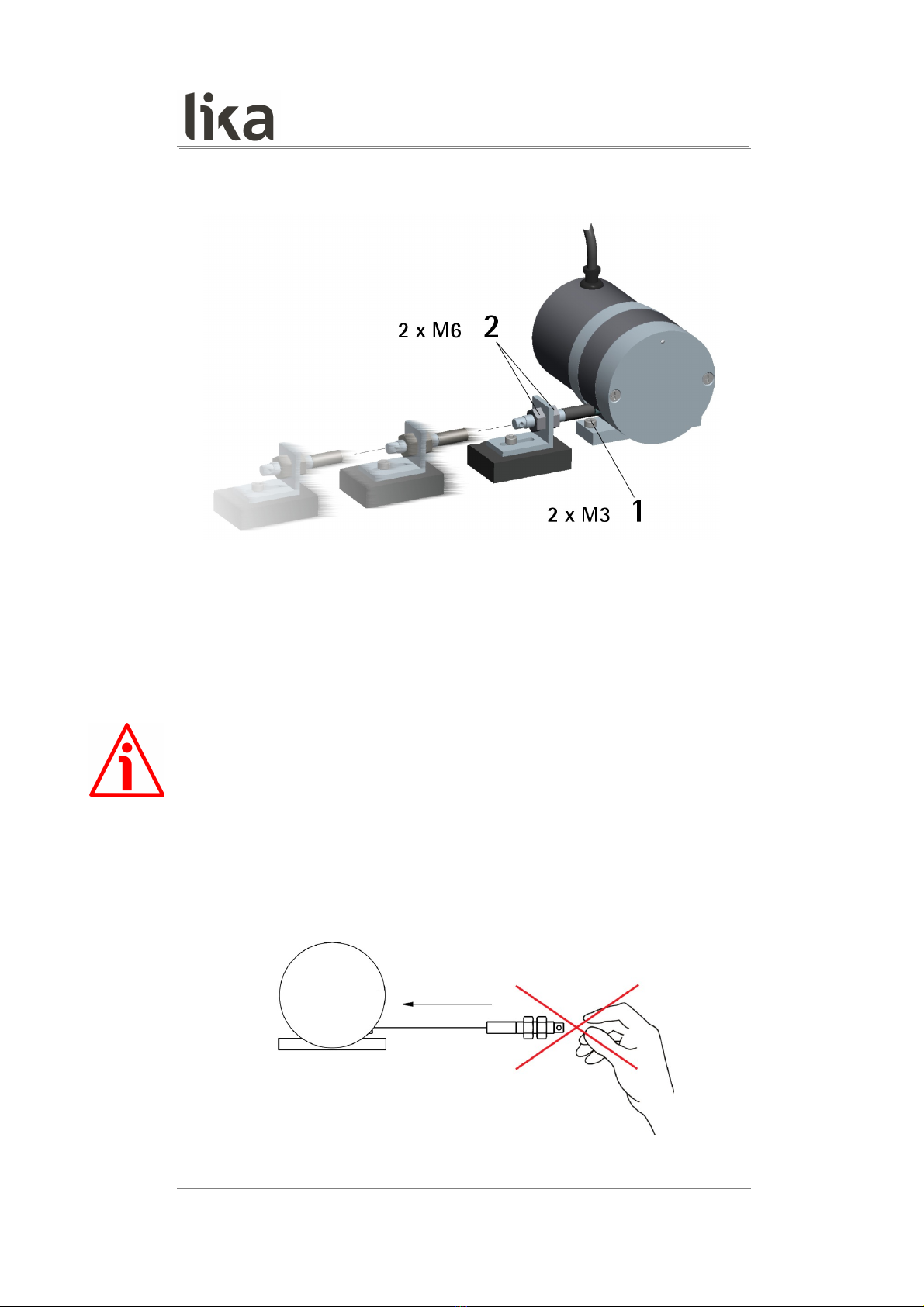

3.2 Mounting instructions.........................................................................................................................................10

3.3 Useful infor ation................................................................................................................................................11

3.4 Maintenance............................................................................................................................................................12

4 Electrical connection.......................................................................................................................... 13

4.1 Cable and connectors connections................................................................................................................13

4.2 M8 cable specifications.......................................................................................................................................13

4.3 M12 8-pin connector specifications.............................................................................................................14

4.4 Connection of the shield....................................................................................................................................14

4.5 Ground connection...............................................................................................................................................14

4.6 Zero setting input..................................................................................................................................................15

4.7 Counting direction input....................................................................................................................................16

5 SSI interface........................................................................................................................................ 17

5.1 SSI (Synchronous Serial Interface).................................................................................................................17

5.2 “LSB Right Aligned” protocol............................................................................................................................18

5.3 Reco ended trans ission rates.................................................................................................................21

5.4 Max. speed and counting frequency.............................................................................................................22

5.5 Reco ended SSI circuit..................................................................................................................................23