1.1 Technical Data Transfer Motor Likorall™ 240/242 overhead li

Prod. No. 3126043 (disconnued since 2010-10-06)

Instruction Guide Transfer Motor Likorall • 7EN20109 2Liko • www.liko.com

This device is built for indoor operation.

Type B according to the degree of protection

against electric chock.

Class ll equipment.

Safety Instructions.............................................................................................. 2

Technical Specications .................................................................................... 2

Product Description ............................................................................................ 3

Mounting Transfer motor .................................................................................... 3

Manuever........................................................................................................................ 4

Care and maintenance ....................................................................................... 4

Safety Instructions

Table of Contents

Technical Specications

Transfer speed: 15 cm/sec (5,9 in./sec)

Electronics: 24 V 5 A. Uses Likorall's battery.

Dimensions

Transfer motor: 145x75x225 mm. WxHxL.

Building height 50 mm.

Material: Aluminium and plastic.

IP-class 43

Before using make certain that:

• the lift is assembled as the instructions says.

• the rail end-stops are securely in place.

•that lift equipment is securely connected to the lift.

• all manuals for both lift and accessories have been carefully studied and fully understood.

• persons using the equipment have received appropriate instructions and training.

• all lift components, material, and seams are intact and show no signs of damage or wear.

• the appropriate lifting accessory regarding type, size, material and design in proportion to the

patient is used.

• the patient is positioned rmly and securely so that no part of the body can be injured.

• that the lift strap is not twisted or worn and that it can move freely in and out of the lift unit.

Before lifting always make certain that:

• the sling is correctly attached to the lift.

•the sling loops are correctly attached to the hooks on the sling bar. This should be checked

when beginning to lift the patient - when the sling straps are taut, but the patient is still seated.

• that the patient, if using Likorall unaccompanied, is equipped with a personal alarm.

Likorall with Transfer Motor 3126043 and 3126044 comply with the requirements of directives

for medical-technical Class I products and with the requirements according to IEC 60601-1, IEC

60601-1-2, EN ISO 10535.

Likorall with Transfer Motor 3126044 also complies with the requirements according to CAN/

CSA C22.2 No.606.1.

Maximum load mounted on Likorall 240: 180 kg (400 lbs.)

Maximum load mounted on Likorall 242: 200 kg (440 lbs.)

NOTE! This instruction guide contains information that is important for users of the product.

A complete understanding of the contents of the instruction guide is essential, and only personnel who

are well informed should use the equipment. Remember to keep the instruction guide readily acces-

sible for users of the product.

Instruction Guide Transfer Motor Likorall • 7EN20109 3 Liko • www.liko.com

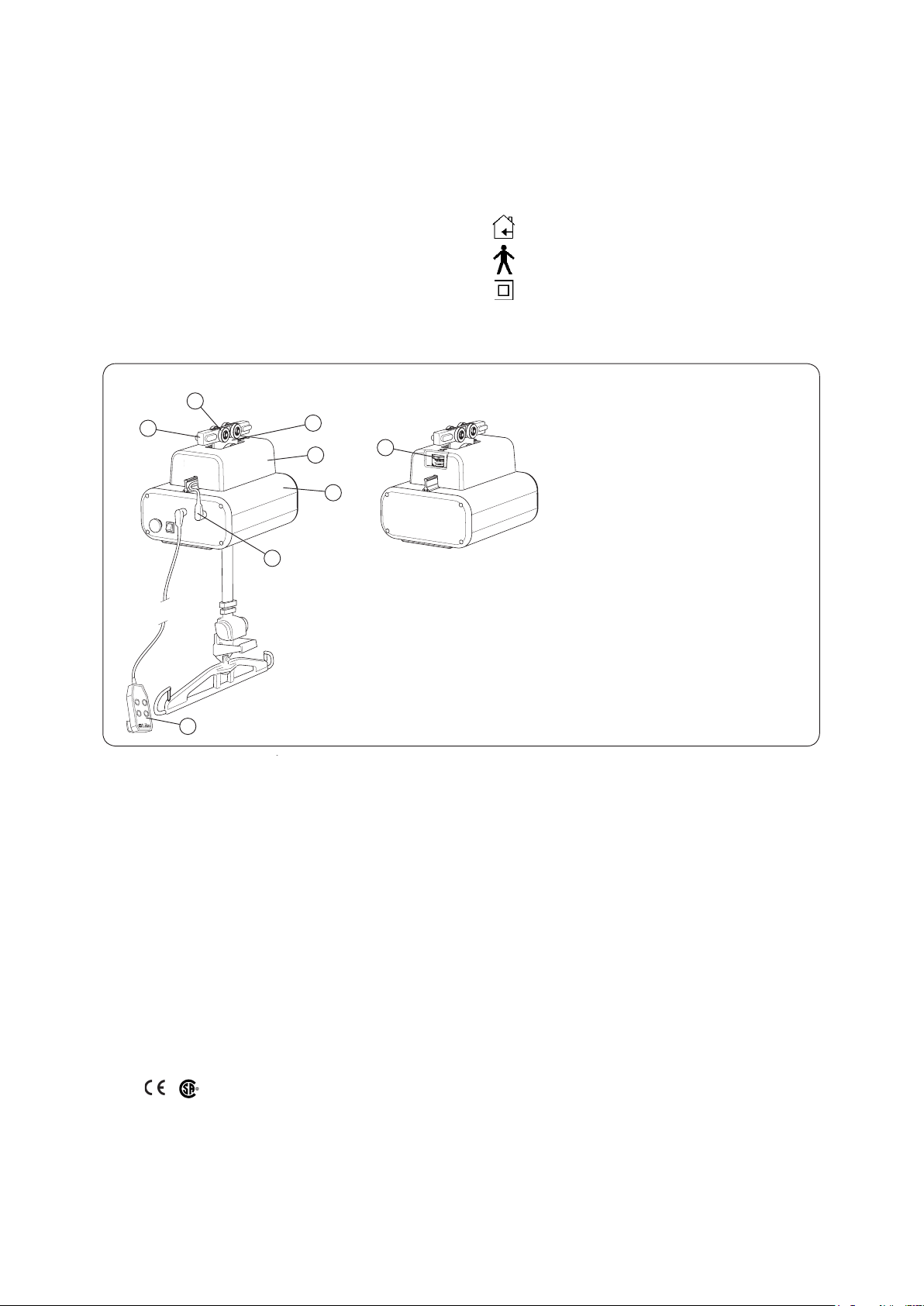

7

3

4

5

6

2

1

8

1. Lift unit Likorall 240/242

2. Transfer motor

3. Hand control with 4 buttons

4. Plastic cowl

5. Damper

6. Tension wheel

7. Drive wheel

8. Electric cable

Likorall with Transfer motor

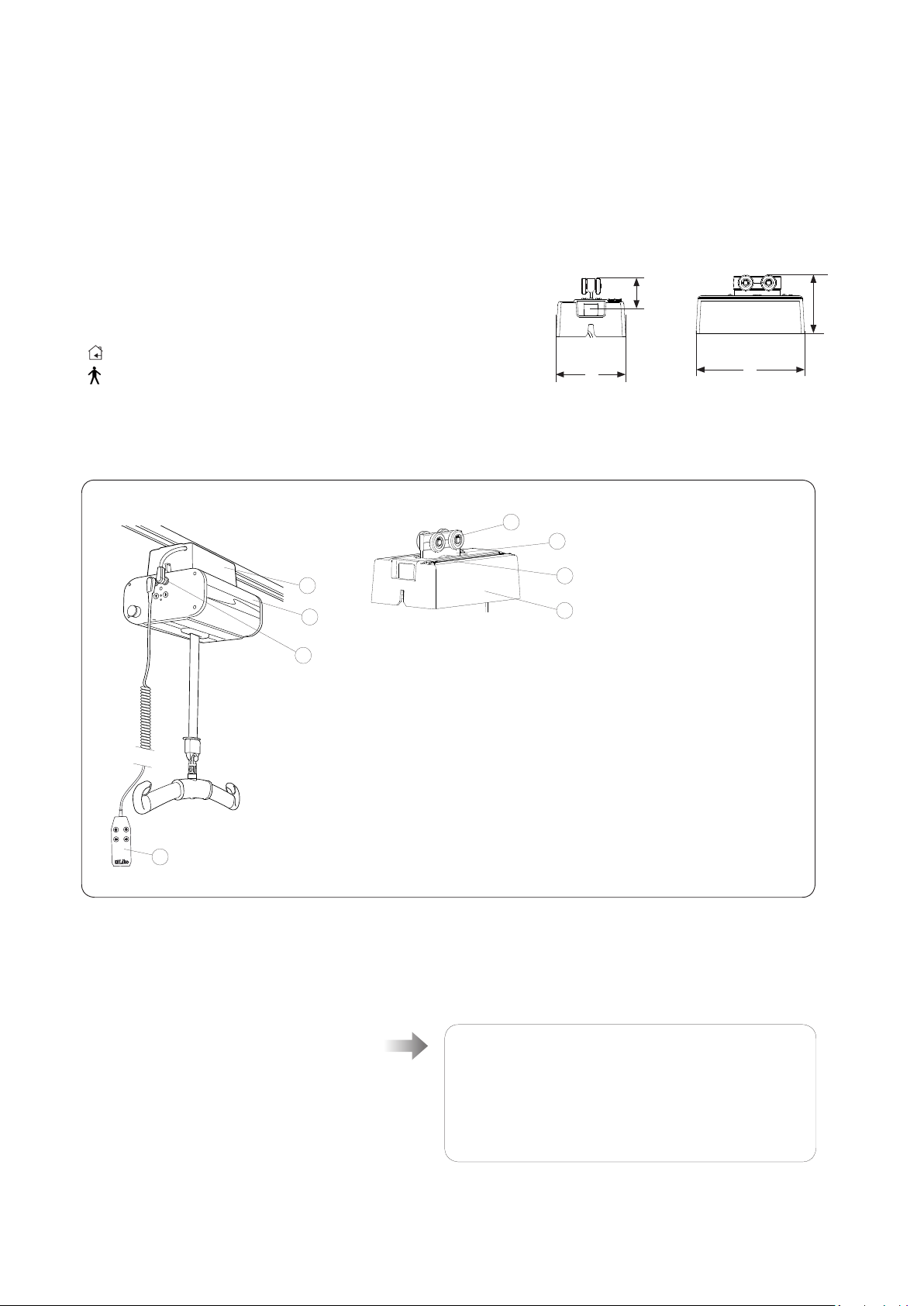

Mounting Transfer motor

1. Remove plastic cowl and fold dampers up.

Slide the Transfer motor into Likorall’s

mounting bracket.

2. Centre the Transfer motor on Likorall and afx

with screws M8x25 and locking nuts M8 in the holes

as indicated.

3. Place plastic cowl over Transfer motor and

fasten with screws M4xX5.

4. Fold out dampers and plug electric cable into outlet on

Likorall.

Instruction Guide Transfer Motor Likorall • 7EN20109 2Liko • www.liko.com

This device is built for indoor operation.

Type B according to the degree of protection

against electric chock.

Class ll equipment.

Safety Instructions.............................................................................................. 2

Technical Specications .................................................................................... 2

Product Description ............................................................................................ 3

Mounting Transfer motor .................................................................................... 3

Manuever........................................................................................................................ 4

Care and maintenance ....................................................................................... 4

Safety Instructions

Table of Contents

Technical Specications

Transfer speed: 15 cm/sec (5,9 in./sec)

Electronics: 24 V 5 A. Uses Likorall's battery.

Dimensions

Transfer motor: 145x75x225 mm. WxHxL.

Building height 50 mm.

Material: Aluminium and plastic.

IP-class 43

Before using make certain that:

• the lift is assembled as the instructions says.

• the rail end-stops are securely in place.

•that lift equipment is securely connected to the lift.

• all manuals for both lift and accessories have been carefully studied and fully understood.

• persons using the equipment have received appropriate instructions and training.

• all lift components, material, and seams are intact and show no signs of damage or wear.

• the appropriate lifting accessory regarding type, size, material and design in proportion to the

patient is used.

• the patient is positioned rmly and securely so that no part of the body can be injured.

• that the lift strap is not twisted or worn and that it can move freely in and out of the lift unit.

Before lifting always make certain that:

• the sling is correctly attached to the lift.

•the sling loops are correctly attached to the hooks on the sling bar. This should be checked

when beginning to lift the patient - when the sling straps are taut, but the patient is still seated.

• that the patient, if using Likorall unaccompanied, is equipped with a personal alarm.

Likorall with Transfer Motor 3126043 and 3126044 comply with the requirements of directives

for medical-technical Class I products and with the requirements according to IEC 60601-1, IEC

60601-1-2, EN ISO 10535.

Likorall with Transfer Motor 3126044 also complies with the requirements according to CAN/

CSA C22.2 No.606.1.

Maximum load mounted on Likorall 240: 180 kg (400 lbs.)

Maximum load mounted on Likorall 242: 200 kg (440 lbs.)

NOTE! This instruction guide contains information that is important for users of the product.

A complete understanding of the contents of the instruction guide is essential, and only personnel who

are well informed should use the equipment. Remember to keep the instruction guide readily acces-

sible for users of the product.

3www.liko.com

Transfer Motor Likorall ES • 7EN120112-05

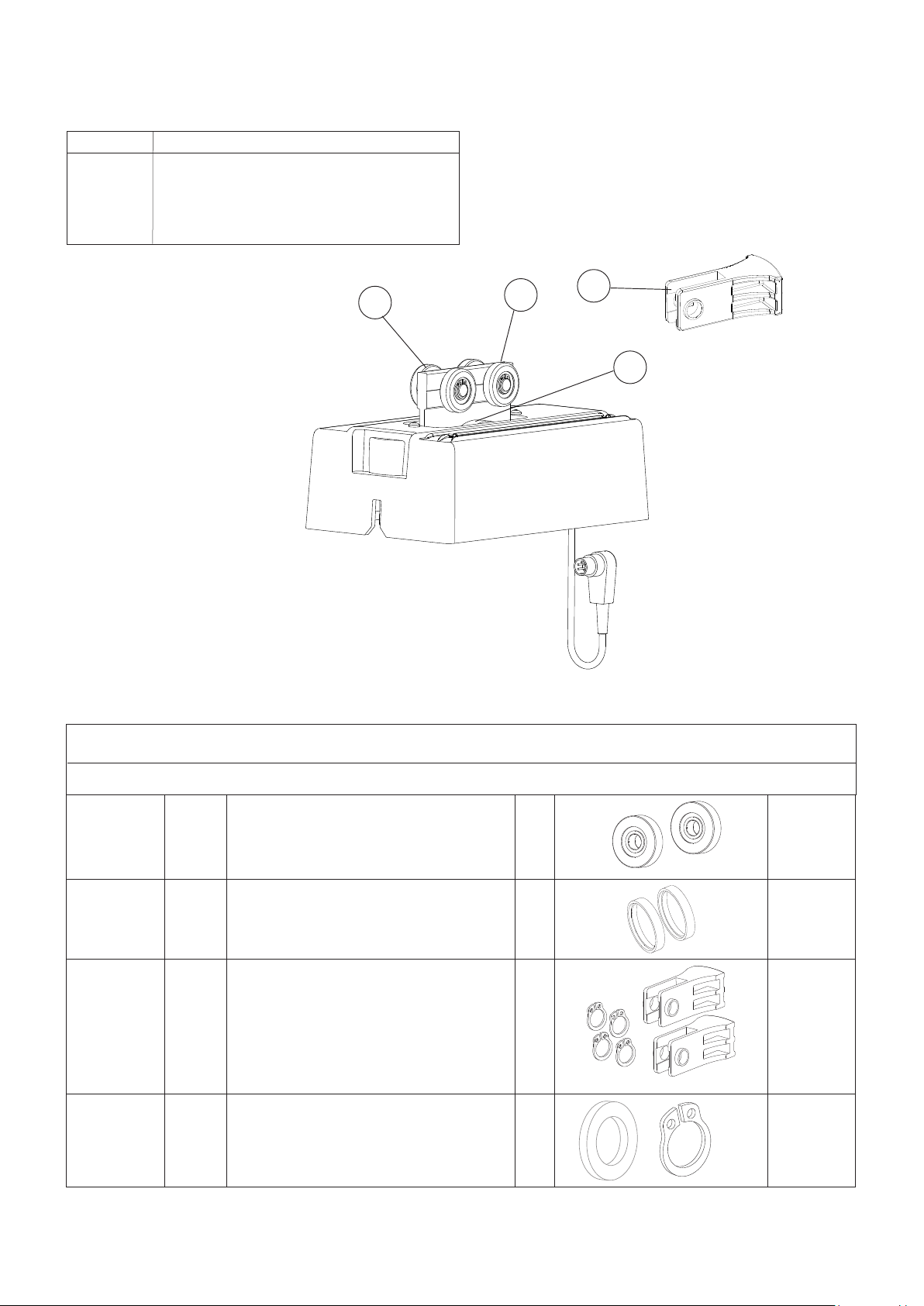

Denitions

1. Transfer motor

2. Lift Unit Likorall 242 ES/242 ES R2R/243 ES/250 ES

3. Connector cable for transfer motor

4. Hand control with 4 buttons

5. Wheel track

6. Drive wheel

7. Contact plate

8. Plastic housing

Likorall with transfer motor

4

Transfer motor

2

1

Manoeuvring

Likorall with transfer motor is operated with a light touch

on the buttons of the hand control. The arrow marking

indicates the direction. The movement is stopped when

the button is released. The hand control for the Likorall

with transfer motor has four or six buttons. The travel

direction along the rail is controlled with a press on

button or .

The buttons and are used for control of lifting

motion (up/down).

The buttons and are used for switch control.

HandControl IR Prod. No. 3126060

All models of Likorall ES can be equipped with a

wireless hand control (IR). The hand control with IR

control has six buttons and operates as the xed hand

control (please see explanation at left). The hand control

normally works within a radius of 2-5 m from the lift,

depending on the angle between the hand control

and the IR receiver on the end cover of the lift motor.

The HandControl IR has batteries that need to be

replaced periodically (2 x AAA, LR03).

Operation

3

Simple Troubleshooting

The Transfer motor doesn’t work/ stops 1. Check to ensure that the emergency stop button is

not pressed in.

2. Check that the hand control is correctly connected.

3. Charge the lift motor battery.

4. If the Transfer motor still does not work properly,

please contact Liko/Hill-Rom.

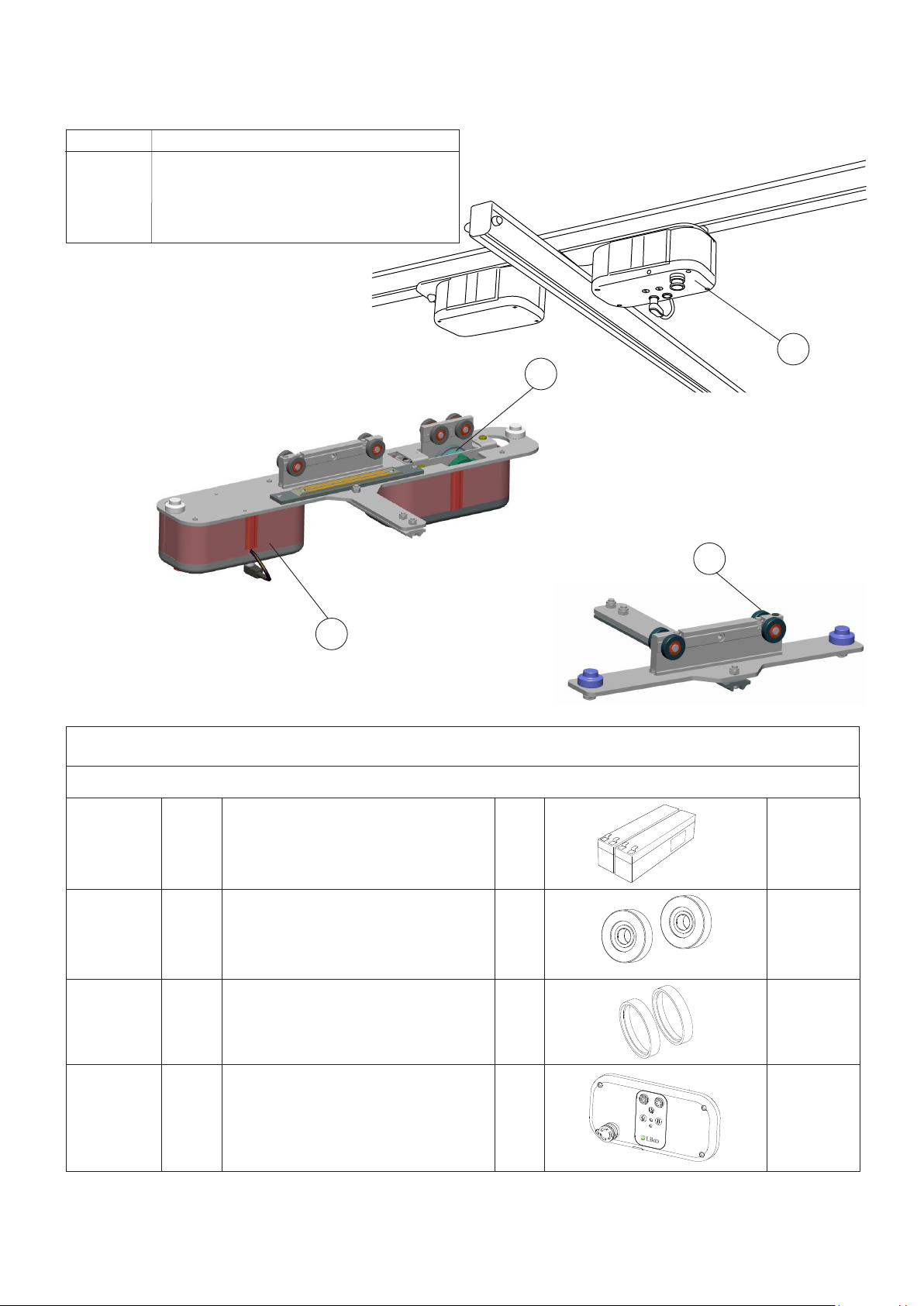

7

5

6

8

Service Manual Transfer Motor • 3EN620401 Rev. 7 4 www.liko.com l www.hill-rom.com