English English

7

7. Carefully replace the wire harness back into the

Connection Box and place back onto the Motor

housing locating over the Motor lead grommet.

Ensure that the tachometer leads are completely

covered by the Channel that snaps into the

Connection Box. The Connection Box assembly

should be pushed all the way up to the Motor-to-

Gearbox Adapter Plate.

8. Before securing the Connection Box to the Motor

housing with the Band Strap, ensure that none of

the harness leads are being pinched underneath the

edges of the Connection Box and Channel.

9. Place the Band Strap into the "T" slot on the side of

the Connection Box and wrap it around the Motor

housing.

10. Replace the fastener between the Band Strap and

the Connection Box. Tighten so that the Connection

Box cannot move on the Motor housing

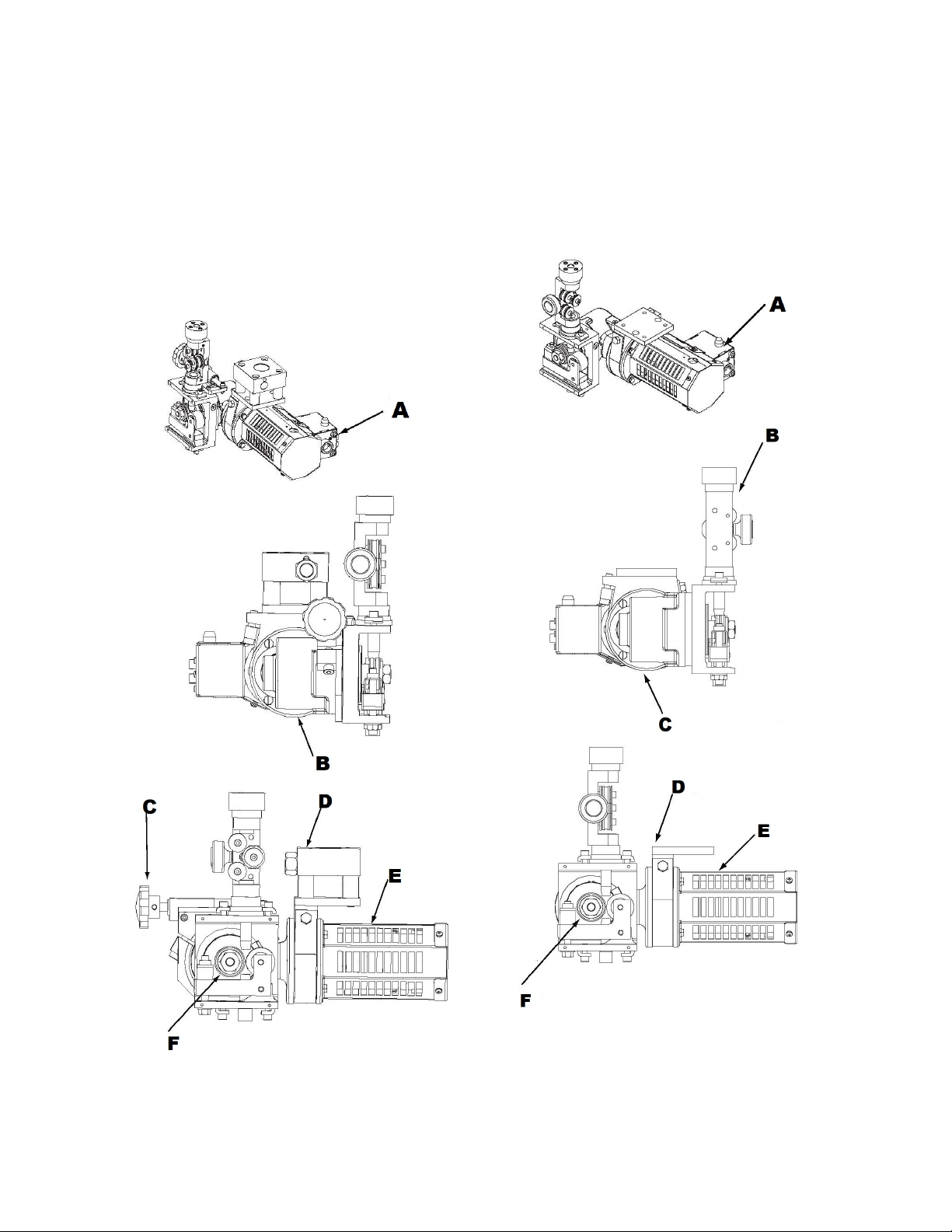

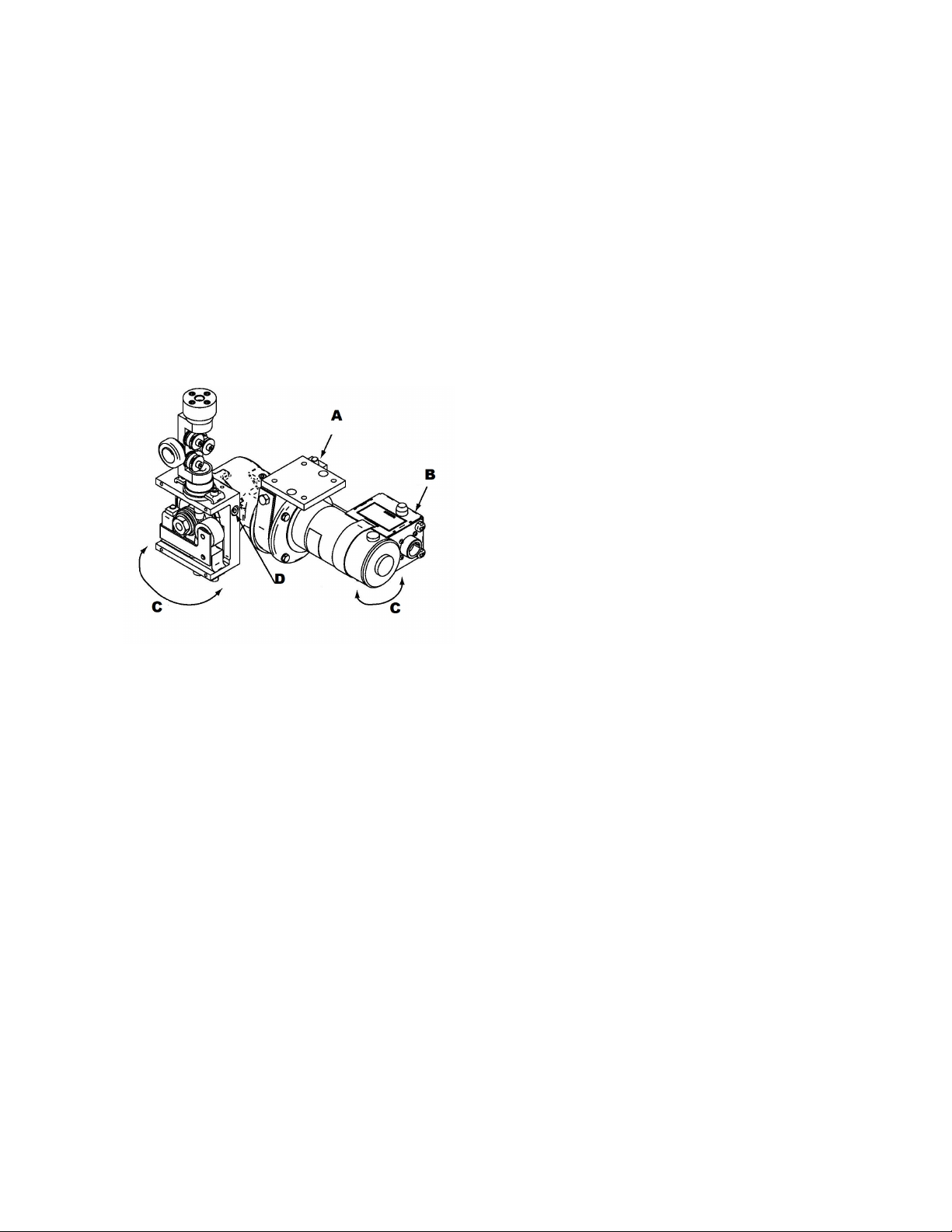

A. Loosen socket Head screw to rotate

motor/gearbox assembly

B. Remove connection box to change motor

polarity

C. Rotate

D. Loosen socket Head screw to rotate Feedplate

Figure 5

Wire Feed Mechanism

All MAXsa™ Wire Drive units are shipped with 142:1

ratio gears. Gears are included to change to either 95:1

or 57:1 ratio depending on wire size to be used.

As shipped, the drive mechanism parts are designed to

feed 2.4mm - 6.0mm wire. Other wire sizes will require

different drive rolls and guide tubes. See table 1.

The Idle Roll pressure will need to be adjusted for the

wire being used. The indicator shows two settings -

0.9 - 2.4mm

3.0 - 6.0mm

The tension adjustment is to be made after loading the

wire into the drive rolls.

NOTE: Lower tension may need to be needed to pre-

vent crushing of some cored wires or softer alloy solid

wires.

Gear Ratio Conversion

(See Figure 6)

1. Remove the 2 hex head screws and the 2 slot head

screws holding the Motor to the Wire Drive Gearbox

assembly.

2. Remove existing Adapter Plate and Motor

Assembly.

3. Take the two long screws removed in step 1 and

screw one into each of the tapped holes located on

the face of fiber input helical gear. Insert the screws

through the full thickness of the gear, and using a

screwdriver wedged between the screws to prevent

rotation, remove the hex nut that holds the gear to

the shaft. Remove plain washer.

4. Pull the gear from the shaft using the screws as a

pulling device.

5. Be certain woodruff key is properly located on the

shaft. Screw the adapter plate and motor assembly

mounting screws into the new fiber input helical

gear from the stenciled side and place the gear on

the shaft. Replace plain washer, tighten the hex nut,

and remove the adapter plate and motor assembly

mounting screws from the gear.

6. Support the pinion properly and, with the proper size

punch, drive the roll pin that holds the pinion out of

the shaft. Pull the pinion off. Remove the Ring

Magnet from the pinion gear and snap it onto the

new pinion gear. Before installing the new pin-ion

gear with the Ring Magnet onto the motor shaft,

ensure that the flat washer is located at the bottom

of the shaft. Install the new pinion and replace the

roll pin.

7. Cover the teeth of the motor pinion and the input

gear with a non-fluid molydisulfide type grease such

as Non-Fluid Oil Corporation’s A-29 Special/MS

Lubricant. This grease can be scooped from the

cavity of the gear case.

8. Reassemble the motor to the gearbox. Make sure

the gears mesh properly and the adapter plate

locating bead is in its cavity. Replace and tighten

the four screws removed in step 1.

Important: See the MAXsa™ 10, or power source

manual for instructions on configuring the system for the

new gear ratio.