Page Number - 2 Form 422455

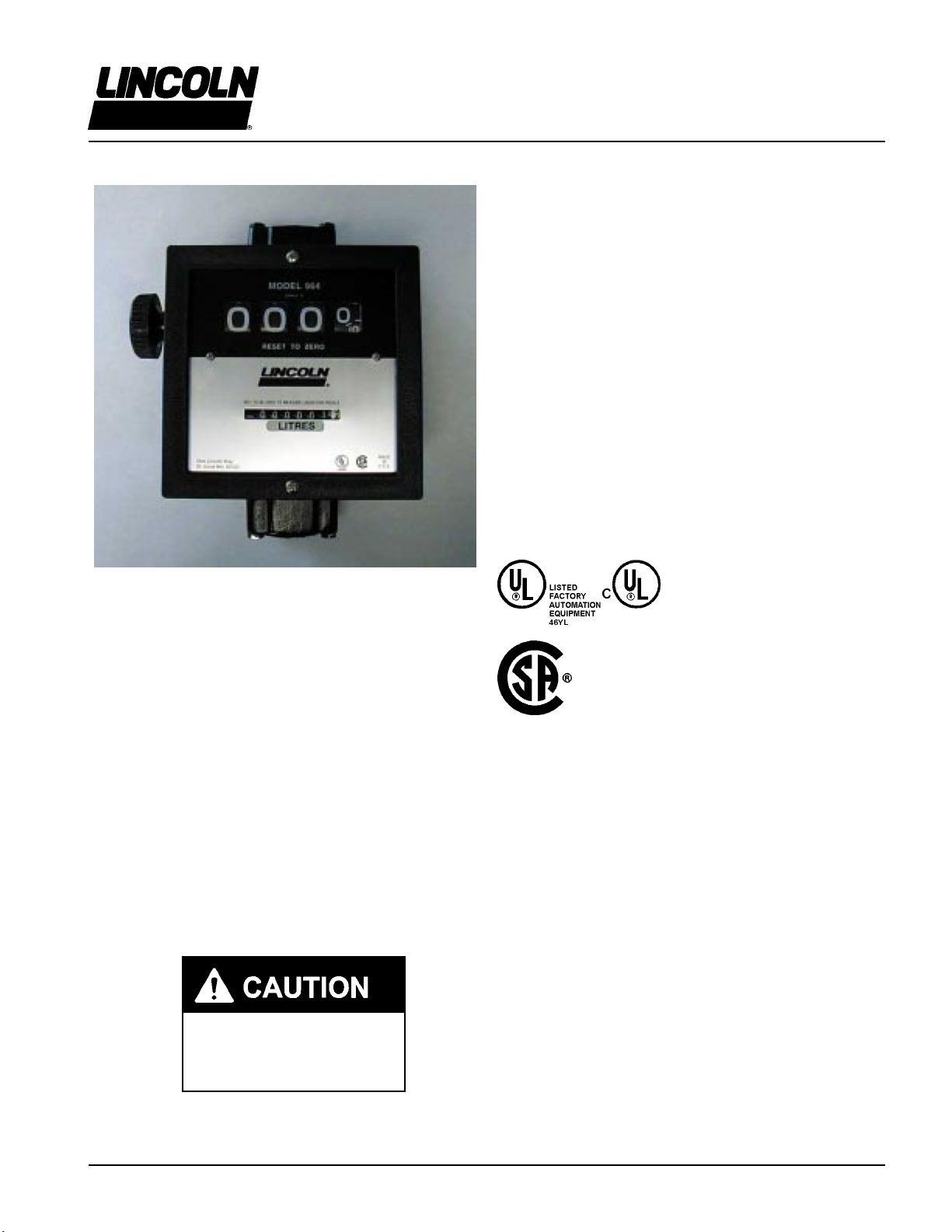

Models 961 & 964

Volume Meters

Series D

INSTALLATION

Meters are furnished for vertical piping, up to down flow

(horizontal piping; left to right flow) unless otherwise speci-

fied. Flow ports can be changed to any of four positions for

horizontal or vertical piping and for either direction of flow.

1. Determine direction for fluid to flow.

2. Install meter observing directional arrow on casting.

3. Remove four screws (item 28).

4. Rotate meter cover assembly (item 37) to desired

orientation.

5. Replace four screws.

ASSEMBLY & DISASSEMBLY

Meter consists of a chamber housing, measuring chamber,

gear train, counter assembly and cover. Meter can be

completely disassembled without disturbing piping, or

meter can be partially disassembled as required.

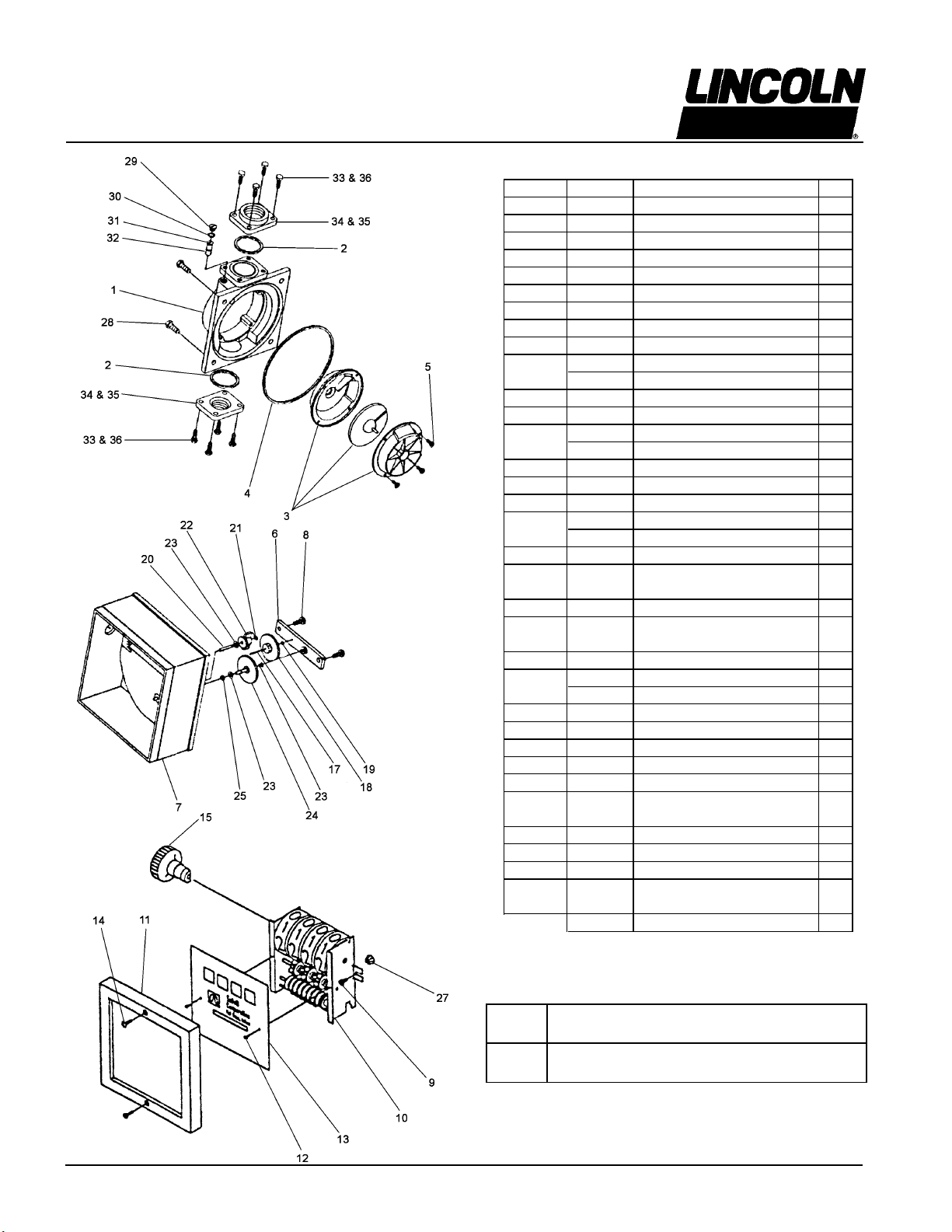

Counter Assembly

For access to counter assembly, remove reset knob (item

15) by grasping edges and pulling firmly. Knob is held in

place by a spring clip. Loosen two screws (item 14) and lift

bezel (item 11) off. Remove two screws (item 12) to detach

counter face (item 13). Remove two screws (item 9) to

extract counter (item 10). Reassemble by reversing

procedure.

Meter Chamber Assembly

To expose meter chamber assembly, gear train and seal,

remove four screws (item 28). Meter chamber assembly

consists of upper and lower chambers, a rotating disc and

four screws. Meter chamber assembly (item 3) can be

dislodged by removing four screws (item 5). Reassemble

by reversing procedure.

If replacement of any components of the meter chamber

assembly is required, the complete assembly must be

replaced due to the precise method of its construction. This

assures a proper fit and a correctly operating chamber.

Gear Train and Seal

To disassemble gear train and seal, remove two screws

(item 8) and gear frame (item 6). Remove cluster gear (item

18), washer (item 19), and shaft (item 17). Remove drive

gear (item 24) and washers (item 23) by rotating and pulling

drive gear. Remove O-Ring seal (item 25).

When reassembling seal, lubricate O-Ring with oil or

petroleum jelly and replace in cover. Place washer on drive

gear shaft. Rotate and push shaft through O-Ring and cover

carefully to prevent damage to O-Ring. Shaft must then be

guided into pinion bevel (item 27) if counter has not been

removed. Replace remaining parts to complete assembly

by reversing disassembly procedure.

OPERATING INSTRUCTIONS

For accurate measurement and to prevent meter damage,

meter and piping must always be filled with liquid and free of

air. Meter should be calibrated per instructions in this manual

prior to its use.

1. Reset meter to 0.

2. Meter is ready for use.

MAINENANCE

Meter should operate maintenance free. However, certain

liquids can dry out while in meter housing, causing the meter

to stop. If this happens, meter should be thoroughly cleaned

(see instructions below).

Cleaning Instructions:

Run a flushing fluid through meter. For a more thorough

cleaning, disassemble meter per Assembly & Disassembly

section, Meter Chamber Assembly subsection. Rinse all

meter components. Recalibrate meter following calibration

instructions.

Storage:

If meter is to be stored for a period of time, clean thoroughly.

This will help protect meter from damage.

REPAIR

Meters needing repair should be taken to an authorized

repair shop or returned to factory for service. Meters must

be thoroughly triple-rinsed before being taken in for repair.

PRIOR TO SERVICE, ADHERE TO THE FOLLOWING

INSTRUCTIONS:

If meter was used for a fluid other than a petroleum product,

it must be triple-rinsed and accompanied by a note

indicating the chemicals that have been pumped through

the unit. Meters not adhering to these specifications may be

refused service at either the repair shop or at the factory.

WHEN ORDERING REPAIR PARTS, BE SURE TO GIVE

REPLACEMENT PART NUMBER, DATE OF MANUFACTURE

AND METER SERIES NUMBER. THIS WILL ENSURE THAT

THE CORRECT REPLACEMENT PART IS SUPPLIED.