2

SAFETY

As a rule of thumb, for many mild steel electrode, if the air is visibly

clear and you are comfortable, then the ventilation is generally

adequate for your work. The most accurate way to determine if the

worker exposure does not exceed the applicable exposure limit for

compounds in the fumes and gases is to have an industrial hygienist

take and analyze a sample of the air you are breathing. This is

particularly important if you are welding with stainless, hardfacing or

Special Ventilation products. All Lincoln MSDS have a maximum fume

guideline number. f exposure to total fume is kept below that

number, exposure to all fume from the electrode (not coatings or

plating on the work) will be below the TLV.

There are steps that you can take to identify hazardous substances in

your welding environment. Read the product label and material safety

data sheet for the electrode posted in the work place or in the

electrode or flux container to see what fumes can be reasonably

expected from use of the product and to determine if special

ventilation is needed. Secondly, know what the base metal is and

determine if there is any paint, plating, or coating that could expose

you to toxic fumes and/or gases. Remove it from the metal being

welded, if possible. f you start to feel uncomfortable, dizzy or

nauseous, there is a possibility that you are being overexposed to

fumes and gases, or suffering from oxygen deficiency. Stop welding

and get some fresh air immediately. Notify your supervisor and co-

workers so the situation can be corrected and other workers can

avoid the hazard. Be sure you are following these safe practices, the

consumable labeling and MSDS to improve the ventilation in your

area. Do not continue welding until the situation has been corrected.

NOTE: The MSDS for all incoln consumables is available on incoln’s web-

site: www.lincolnelectric.com

Before we turn to the methods available to control welding fume

exposure, you should understand a few basic terms:

Natura Venti ation is the movement of air through the

workplace caused by natural forces. Outside, this is usually

the wind. nside, this may be the flow of air through open

windows and doors.

Mechanica Venti ation is the movement of air through the

workplace caused by an electrical device such as a portable

fan or permanently mounted fan in the ceiling or wall.

Source Extraction (Local Exhaust) is a mechanical device

used to capture welding fume at or near the arc and filter

contaminants out of the air.

The ventilation or exhaust needed for your application depends upon

many factors such as:

• Workspace volume

• Workspace configuration

• Number of welders

• Welding process and current

• Consumables used (mild steel, hardfacing, stainless, etc.)

• Allowable levels (TLV, PEL, etc.)

• Material welded (including paint or plating)

• Natural airflow

Your work area has adequate ventilation when there is enough

ventilation and/or exhaust to control worker exposure to hazardous

materials in the welding fumes and gases so the applicable limits for

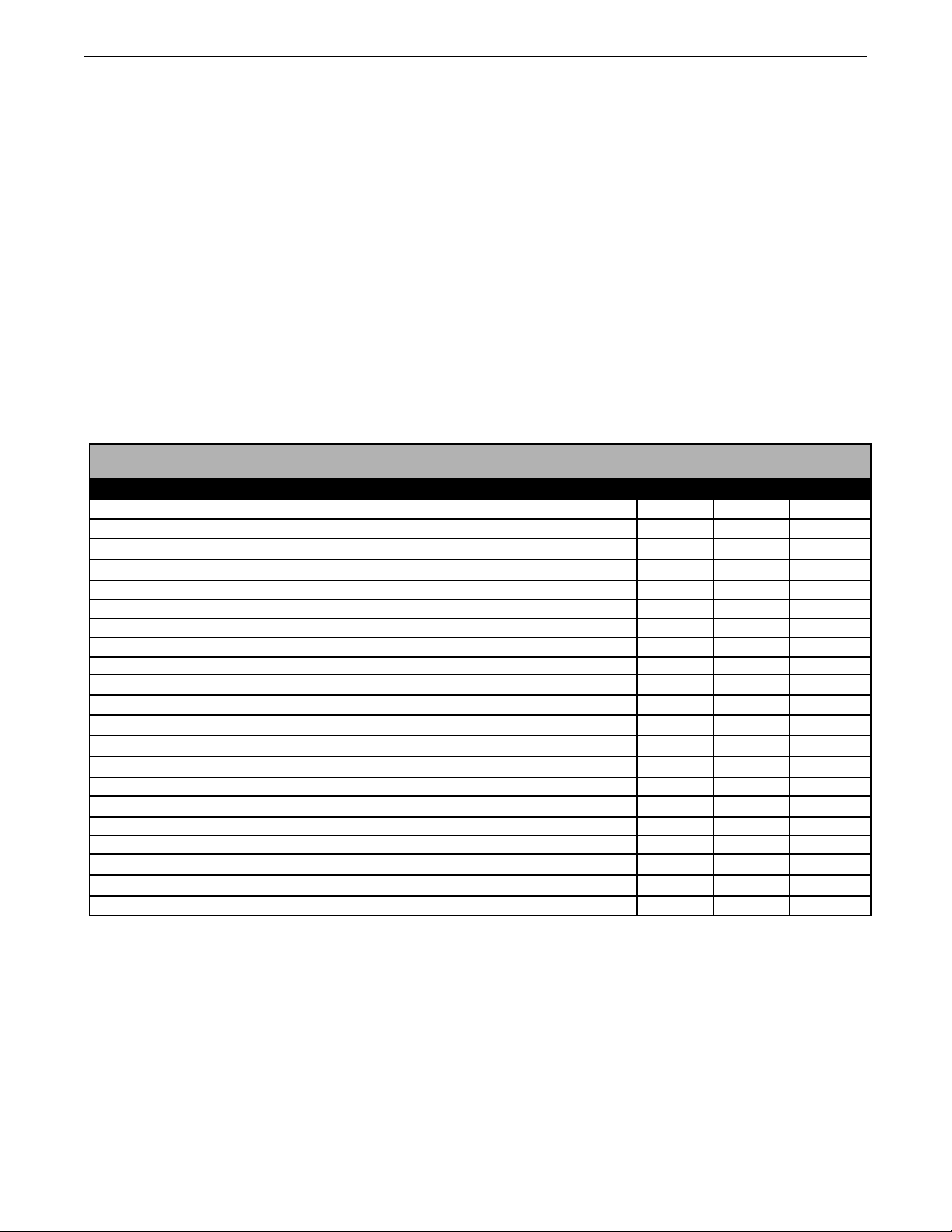

those materials is not exceeded. See chart of TLV and PEL for Typical

Electrode ngredients, the OSHA PEL (Permissible Exposure Limit), and

the recommended guideline, the ACG H TLV (Threshold Limit Value),

for many compounds found in welding fume.

Ventil tion

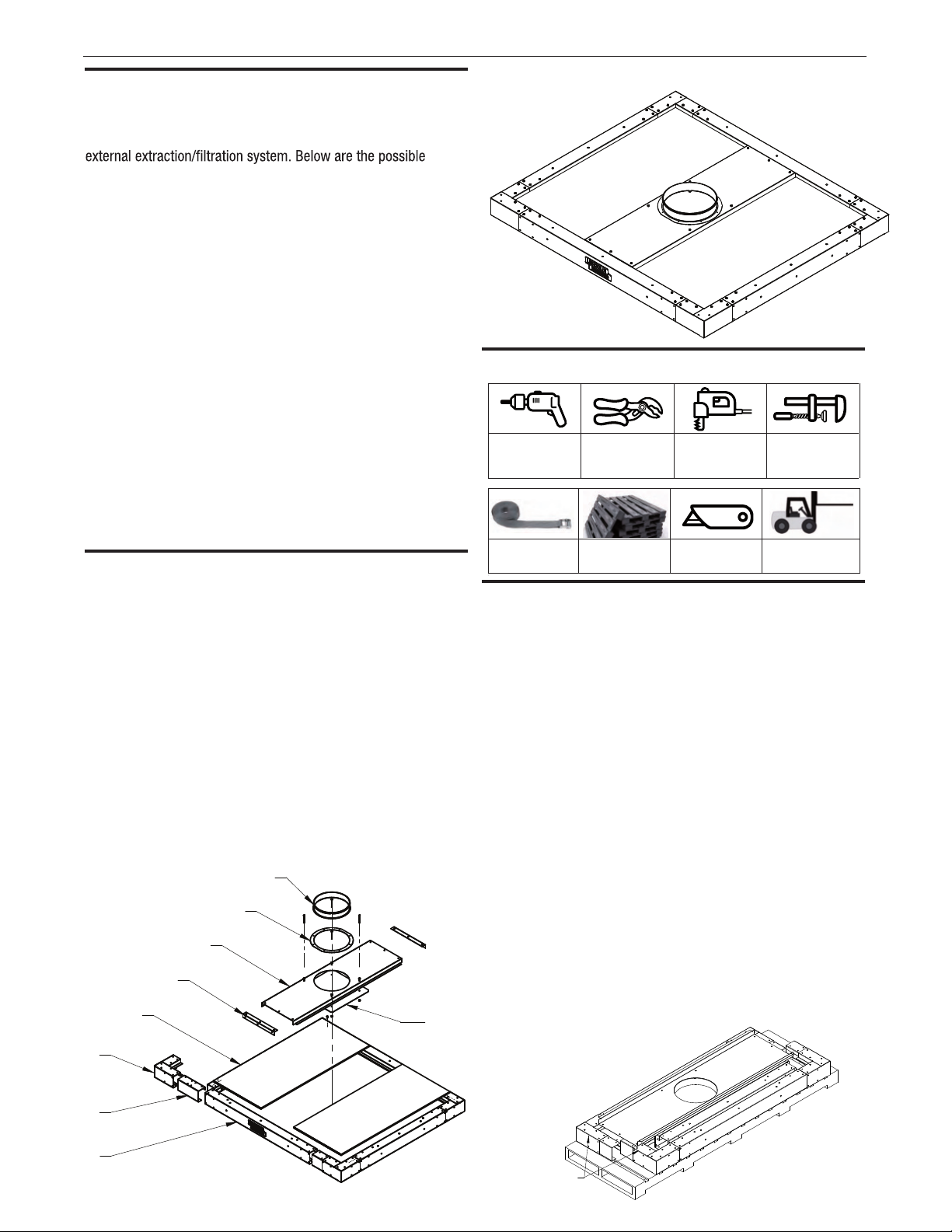

There are many methods which can be selected by the user to

provide adequate ventilation for the specific application. The following

section provides general information which may be helpful in

evaluating what type of ventilation equipment may be suitable for

your application. When ventilation equipment is installed, you should

confirm worker exposure is controlled within applicable OSHA PEL

and/or ACG H TLV. According to OSHA regulations, when welding and

cutting (mild steels), natural ventilation is usually considered

sufficient to meet requirements, provided that:

1. The room or welding area contains at least 10,000 cubic feet

(about 22' x 22' x 22') for each welder.

2. The ceiling height is not less than 16 feet.

3. Cross ventilation is not blocked by partitions, equipment, or

other structural barriers.

4. Welding is not done in a confined space.

Spaces that do not meet these requirements should be equipped with

mechanical ventilating equipment that exhausts at least 2000 CFM of

air for each welder, except where local exhaust hoods or booths, or

air-line respirators are used.

Import nt S fety Note:

When welding with electrodes which require speci l

ventil tion such s st inless or h rdf cing (see

instructions on cont iner or MSDS) or on le d or

c dmium pl ted steel nd other met ls or co tings which

produce h z rdous fumes, keep exposure s low s

possible nd below exposure limit v lues (PEL nd TLV)

for m teri ls in the fume using loc l exh ust or

mech nic l ventil tion. In con ned sp ces or in some

circumst nces, for ex mple outdoors, respir tor m y

be required if exposure c nnot be controlled to the PEL

or TLV. (See MSDS nd ch rt of TLV nd PEL for Typic l

Electrode Ingredients.) Addition l prec utions re lso

required when welding on g lv nized steel.