FlowMaster Rotary Driven Hydraulic Pump

Page Number - 6 7.5A-18100-G01 Form 403139

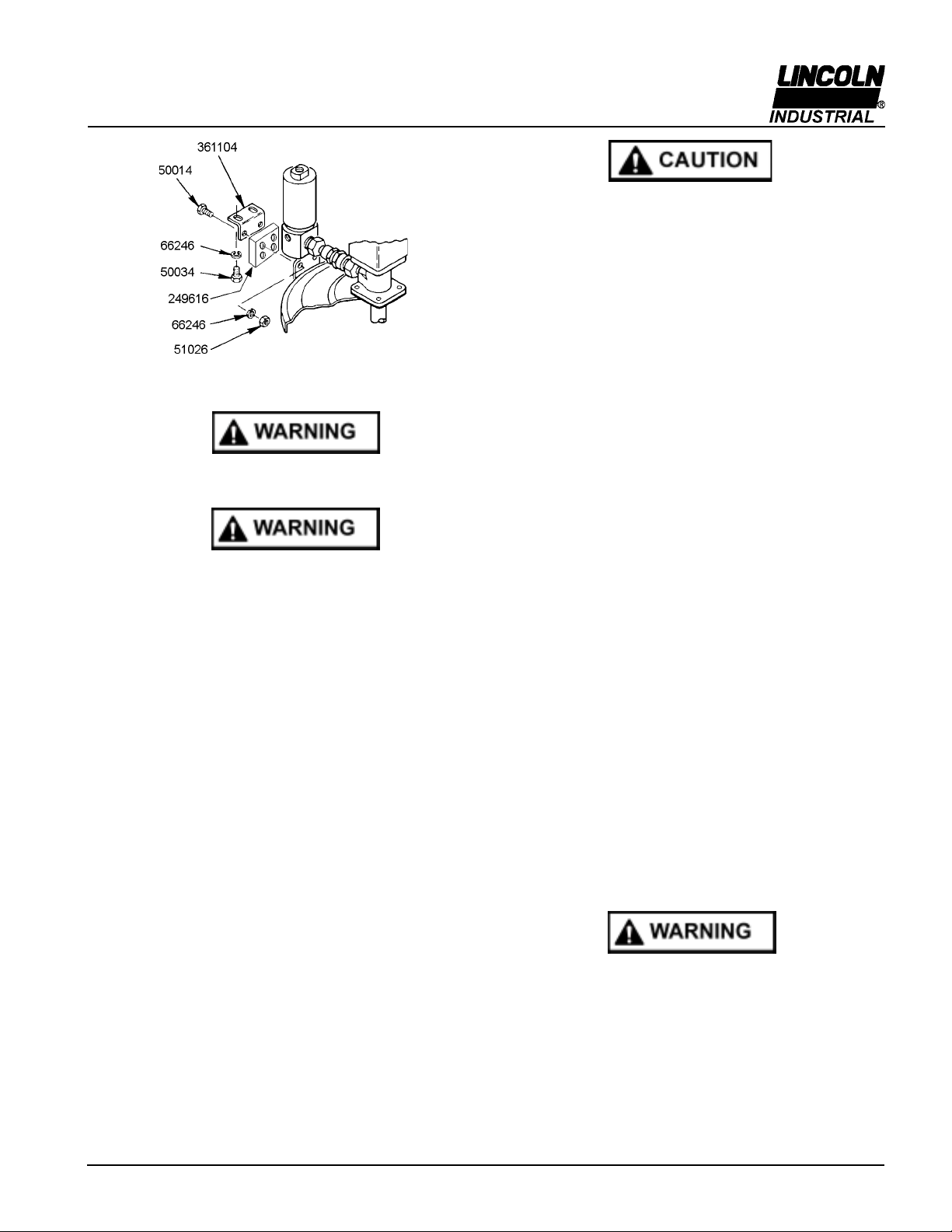

Disassem ly Procedure (See illustration #6)

Tools Required:

- Hex Bit Socket Wrenc es (3/8 square drive) wit 3/8 ex,

5/32 ex, 1/4 ex.

- 3/8 O.D. Steel Rod

- 12 Crescent Wrenc

- Spanner Wrenc (for 3/8 diameter tube, 1/8 pin)

- 1/2 to 3/8 square drive adapter

- Torque wrenc (1/2 square drive, 0 - 50 ft-lb capacity)

- Torque wrenc (3/8 square drive, 0 - 120 in-lb capacity)

- 1/4 nut driver

- Screwdriver (flat blade, 1/8 blade widt )

1. Remove t e four Socket Head Screws (33) and separate

Manifold from t e Hydraulic Motor (42).

2. Remove Pipe Plug (45) and drain t e crankcase oil from

t e Pump Housing (46).

3. Remove six self-t reading Screws (29) and remove t e

Housing Cover (30) and t e Cover Gasket (31).

4. Remove Retaining Ring (57) and pull t e S ovel Plug

(56) from t e Housing Tube (55).

5. Remove two Socket Head Screws (44) and separate t e

Hydraulic Motor (42) from t e Pump Housing (46).

6. Remove two Outlet Pin Nuts (50) from t e Pump Housing

(46).

7. Remove t e Pump Subassembly (1 t roug 28) from

t e Pump Housing (46). Pus ing t e subassembly up

wit a wooden or plastic rod 3/4 O.D. against t e C eck

Seat Housing (28) is elpful.

8. Remove t e Housing Tube (55) from t e Pump Housing

(46) by inserting a 3/4 rod t roug t e inlet oles at t e

bottom of t e Housing Tube (55) and unscrewing it.

9. Remove t e Bronze Bearing (51), t e O-Ring (52), and

t e Backup Was er (53) from t e Housing Tube (55).

10. Remove t e Crankrod Assembly (1 t roug 8) from t e

pump by unscrewing t e Button Head Screws (12) and

t en pulling out t e Wrist Pin Bus ings (13).

11. Remove t e C eck Seat Housing (28) from t e

Reciprocating Tube (21). T ere is a 3/8 Allen Head

socket in t e t roat of t e C eck Seat Housing (28) to

facilitate removal.

12. Unscrew t e Wrist Pin Anc or (14) from t e

Reciprocating Tube (21) and pull t e Plunger Assembly

(9 t roug 20) from t e tube.

13. Using a 1/2 wooden or plastic rod, pus t e Cup Seal

(22) and t e Pump Cylinder (24) from t e Reciprocating

Tube (21).

14. Remove t e Pump Plunger (20) from t e Plunger Link

Rod (17). A spanner wrenc , w ic uses t e oles in

t e Pump Plunger, is required.

15. Unscrew t e Plunger Link Rod (17) from t e Plunger

Tube (11) and slide off t e Cup Seal (16), t e Backup

Was er (15) and t e Wrist Pin Anc or (14).

16. Unscrew t e Plunger Tube (11) from t e Outlet Pin (9).

17. To dismantle t e Crankrod Assembly (1 t roug 8),

remove Flat Head Screws (1) and t e Counter Weig ts

(2).

18. Remove t e Retaining Rings (6) and press t e Crank

Eccentric (7) out of t e Ball Bearing (8). Be sure to

support t e Ball Bearing (8) on t e inner race.

Pump Assem ly Procedure

1. W en t e pump is dissembled, it is recommended to

replace all seals and gaskets, w ic are included in t e

270663 repair kit.

2. In t e process of disassembly, examine t e following

components and replace if excessive wear is indicated:

Ball Bearing (8), Crank Eccentric (7), Crankrod (5), Wrist

Pin Bus ings (13), Plunger Tube (11), Pump Plunger and

Upper C eck Parts (20, 19 and 18), Pump Cylinder (24),

C eck Seat Housing and Lower C eck Ball (28 and 26),

upper Bronze Bus ing (51), Housing Tube (55), S ovel

Plug (56), and Reciprocating Tube (21).

3. Assembly Procedure is t e reverse of t e Disassembly

Procedure except for t e following:

4. Install parts (22) t roug (28) into t e Reciprocating Tube

(21) after t e plunger assembly (9 t roug 20) is installed.

5. Install t e Pump Subassembly (1 t roug 28) into t e

pump Housing (46) before tig tening t e Housing Tube

(55) to t e Pump Housing (46). Be sure t e Reciprocating

Tube (21) is inserted t roug bot bus ings before

tig tening t e Housing Tube (55).

6. Use loctite 242 (or similar product) medium strengt t read

lock on all torqued t readed connections. Extreme care

must be exercised to prevent excess compound from

flowing into critical areas suc as clearance fits and ball

c eck. Allow a minimum of 30 minutes cure time before

operating t e pump.

7. Torque Specifications:

A. Plunger Tube (11) to Outlet Pin (9) - 100 to 110 In.-Lbs.

B. Button Head Screws (12) to Wrist Pin Anc or (14) 100

to 110 In.-Lbs.

C. Plunger Tube (11) to Plunger Link Rod (17) - 100 to 110

In.-Lbs.

D. Plunger Link Rod (17) to Pump Plunger (20) - 100 to

110 In.-Lbs.

E. Flat Head Screws (1) to Counter Weig t (2) - 100 - 110

In.-Lbs.

F. Wrist Pin Anc or (14) to Reciprocating Tube (21) - 20 to

25 Ft.-Lbs.

G. C eck Seat Housing (28) to Reciprocating Tube (21) -

20 to 25 Ft.-Lbs.

H. Outlet Pin Nut (50) to Pump Housing (47) - 30 to 35 Ft.-

Lbs.

I. Housing Tube (55) to Pump ousing (47) - 20 to 25 Ft.-

Lbs.

8. For Models 85480, 85481, 85482, 85483 and 85247, fill

crankcase wit SAE 10W30 motor oil up to pipe plug (45)

before fastening ousing cover (30) and ousing gasket

(31). If pump will be used in very cold environments, use

Mobil Arrow HFA Low Temperature Oil. T is oil stays fluid

even at -70°F.

For Model 85610, fill crankcase wit lig tweig t Mobil Arrow

HFA Hydraulic Oil up to pipe plug (45) before fastening

ousing cover (30) and ousing gasket (31).

9)On 85586, replace inlet strainer (63).

© Indicates c ange

©

©