Lincoln Electric CV-655 User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric APEX 3 Series User manual

Lincoln Electric

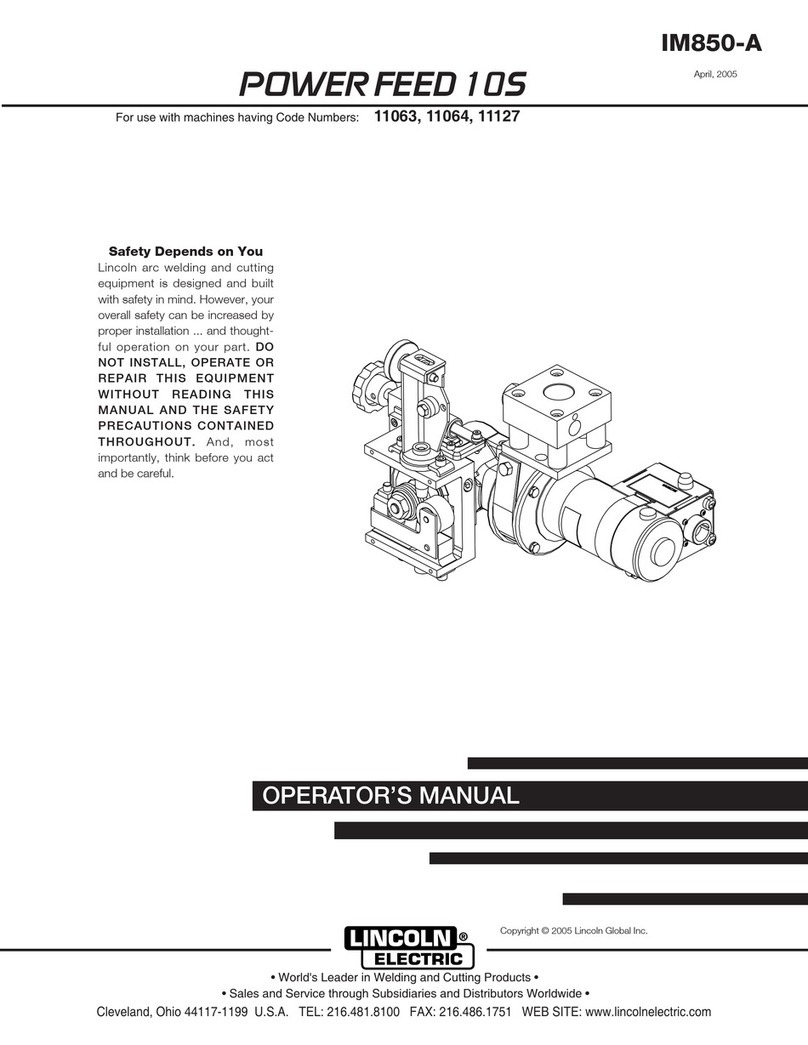

Lincoln Electric POWERFEED 10S IM850-A User manual

Lincoln Electric

Lincoln Electric handy mig User manual

Lincoln Electric

Lincoln Electric COOLARC 46 User manual

Lincoln Electric

Lincoln Electric VRTEX 360 User manual

Lincoln Electric

Lincoln Electric RED-D-ARC FX650XL User manual

Lincoln Electric

Lincoln Electric Magnum K115 Series User manual

Lincoln Electric

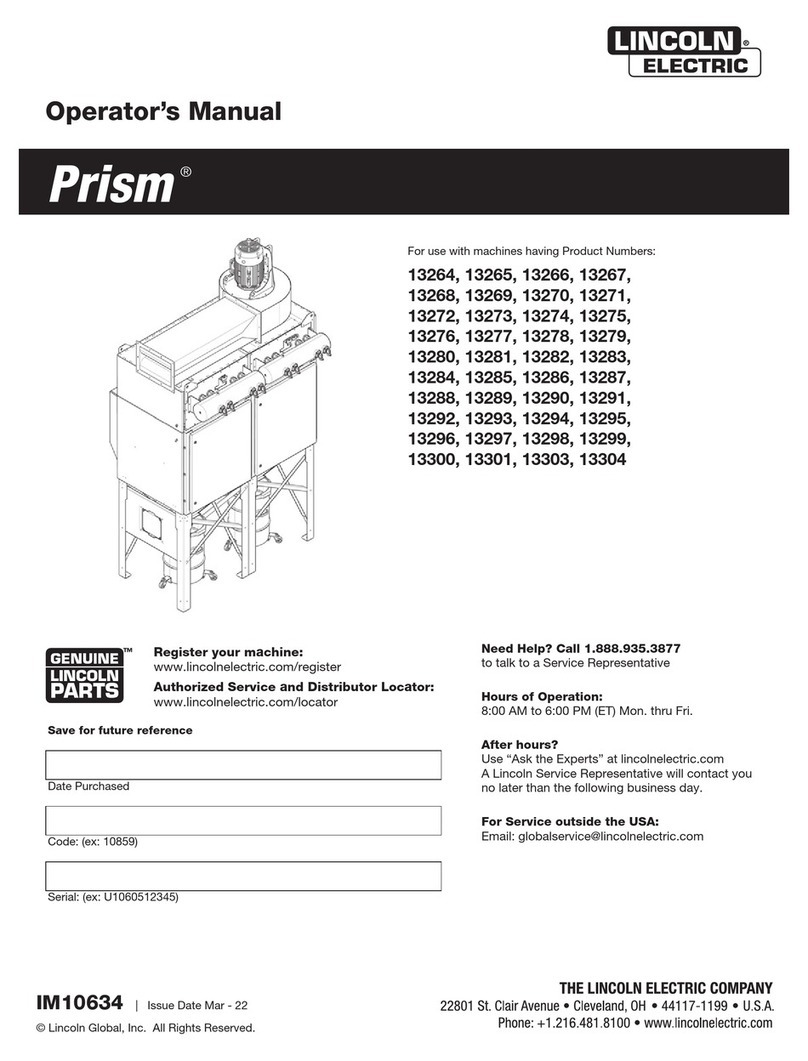

Lincoln Electric Prism 13264 User manual

Lincoln Electric

Lincoln Electric IDEALARC DC-1000 User manual

Lincoln Electric

Lincoln Electric AIR VANTAGE IM10066 User manual

Lincoln Electric

Lincoln Electric RANGER 305D SVM175-A User manual

Lincoln Electric

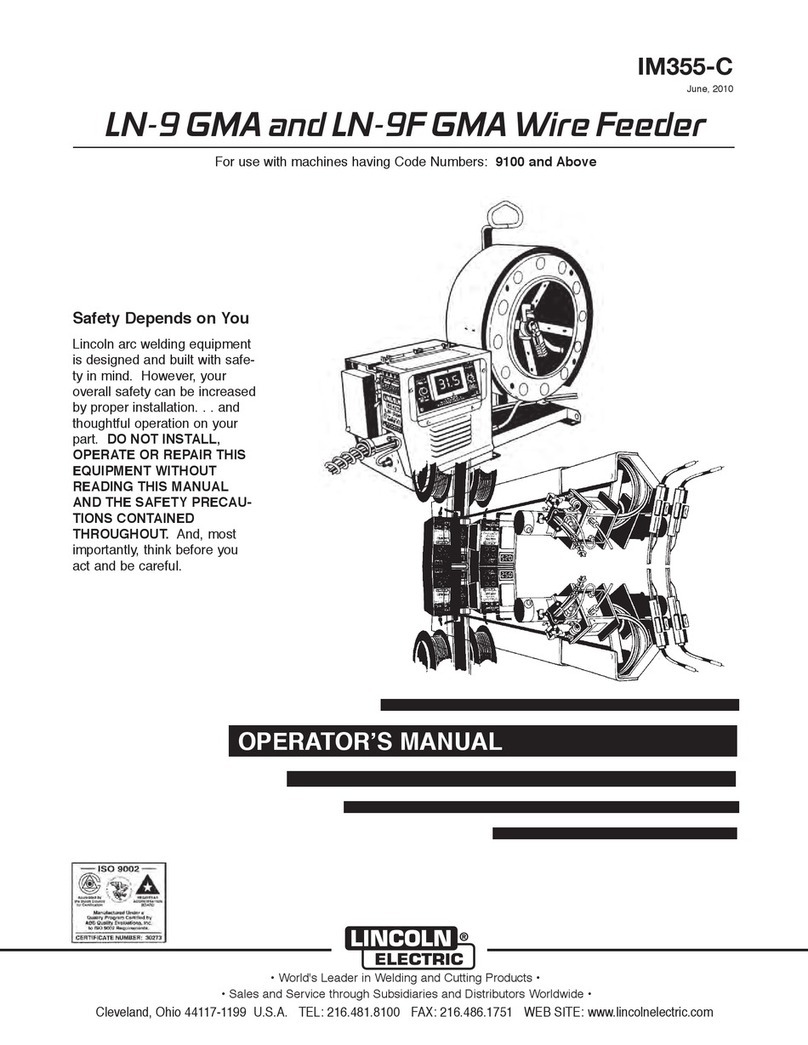

Lincoln Electric IM355-C LN-9 GMA User manual

Lincoln Electric

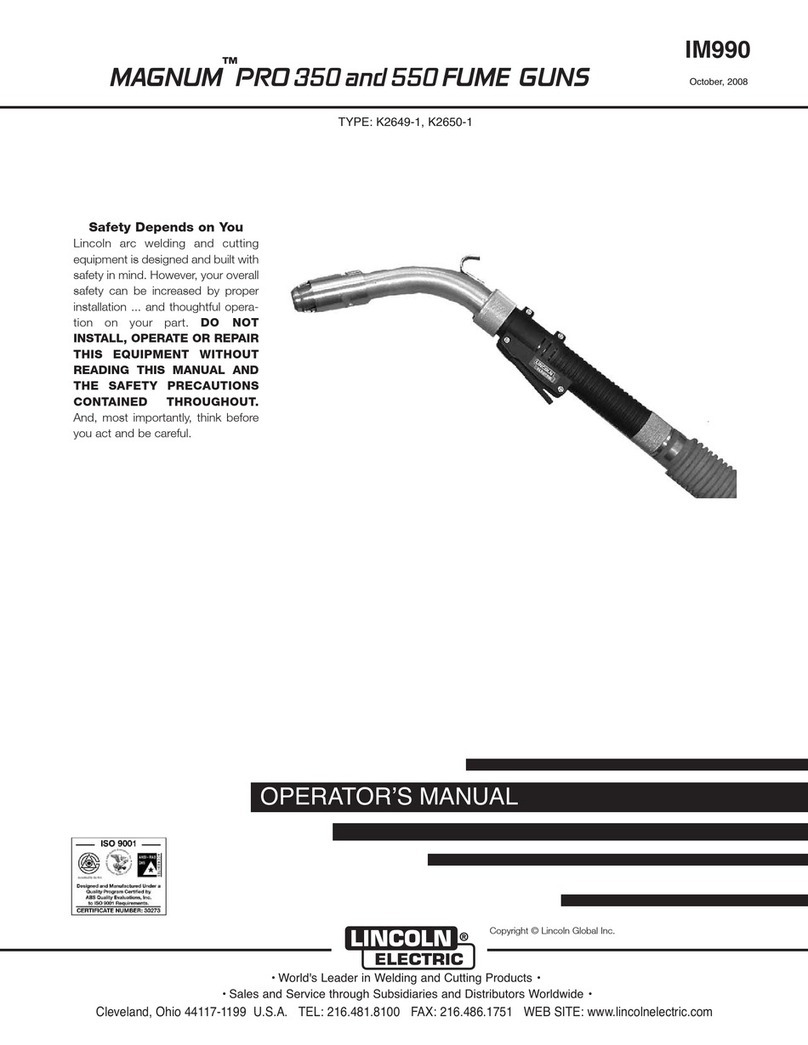

Lincoln Electric MAGNUM 350 User manual

Lincoln Electric

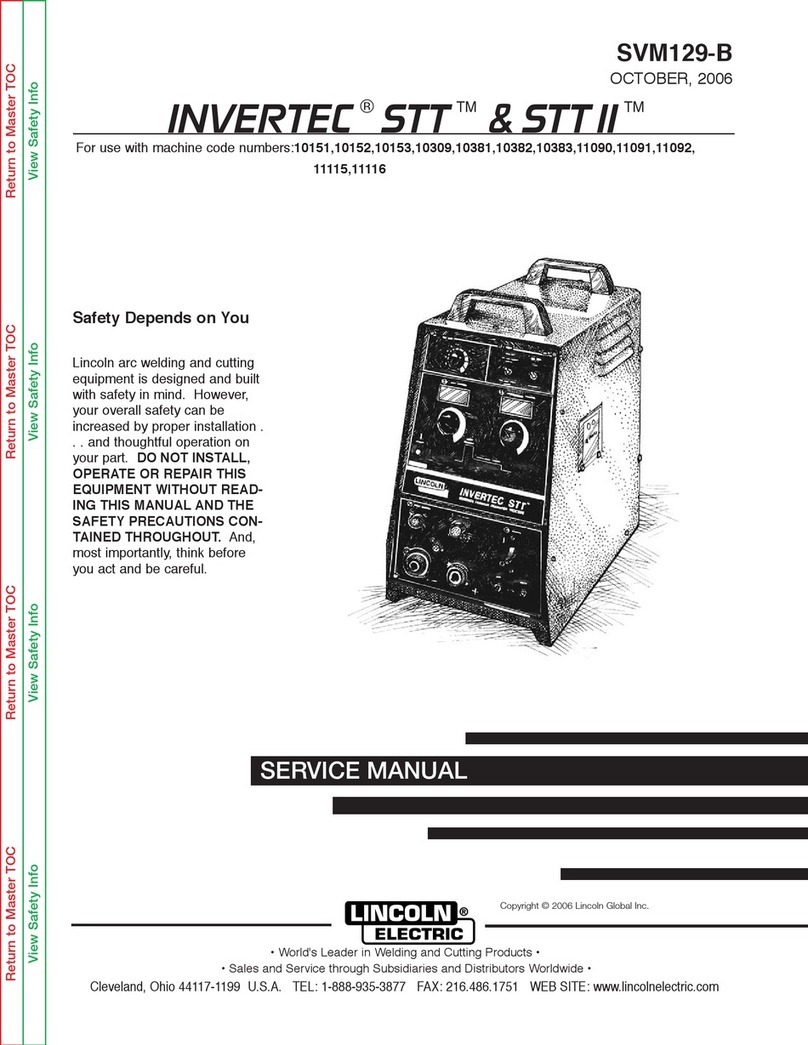

Lincoln Electric INVERTEC SVM129-B User manual

Lincoln Electric

Lincoln Electric POWERTEC i350S User manual

Lincoln Electric

Lincoln Electric IM481-B User manual

Lincoln Electric

Lincoln Electric 10084 User manual

Lincoln Electric

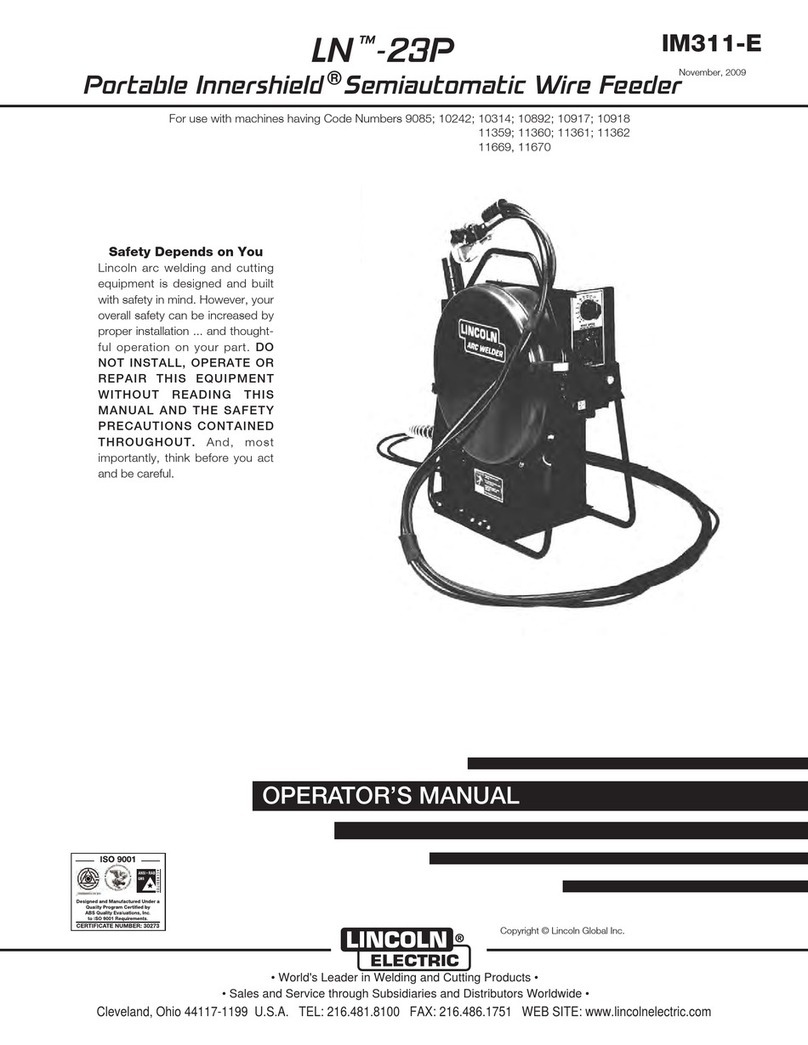

Lincoln Electric LN IM311-E User manual

Lincoln Electric

Lincoln Electric LINCGUN PROMIG 300 UD 4M User manual

Lincoln Electric

Lincoln Electric POWERTEC 200C User manual