English 5 English

Installation and Operator Instructions

Read this entire section before installation or operating the

machine.

Exploitation conditions

This machine can operate in harsh environments.

However, it is important to use the following simple

preventive measures that will ensure its long life and

reliable operation:

Do not place or operate this machine on a surface with

an incline higher than 15° from horizontal.

Do not use this machine for pipe thawing.

This machine must be located where there is free

circulation of clean air without restrictions for air

movement. Do not cover the machine with paper, cloth

or rags when switched on.

Dirt and dust that can be drawn into the machine

should be kept away from the item.

This machine has a protection rating of IP23. Keep it

dry when possible and do not place it on a wet ground

or in puddles.

Locate the machine away from a radio controlled

machinery. Normal operation may adversely affect the

operation of a nearby radio controlled machinery,

which may result in injury or equipment damage. Read

the section on electromagnetic compatibility in this

manual.

Do not operate in areas with an ambient temperature

greater than 40°C.

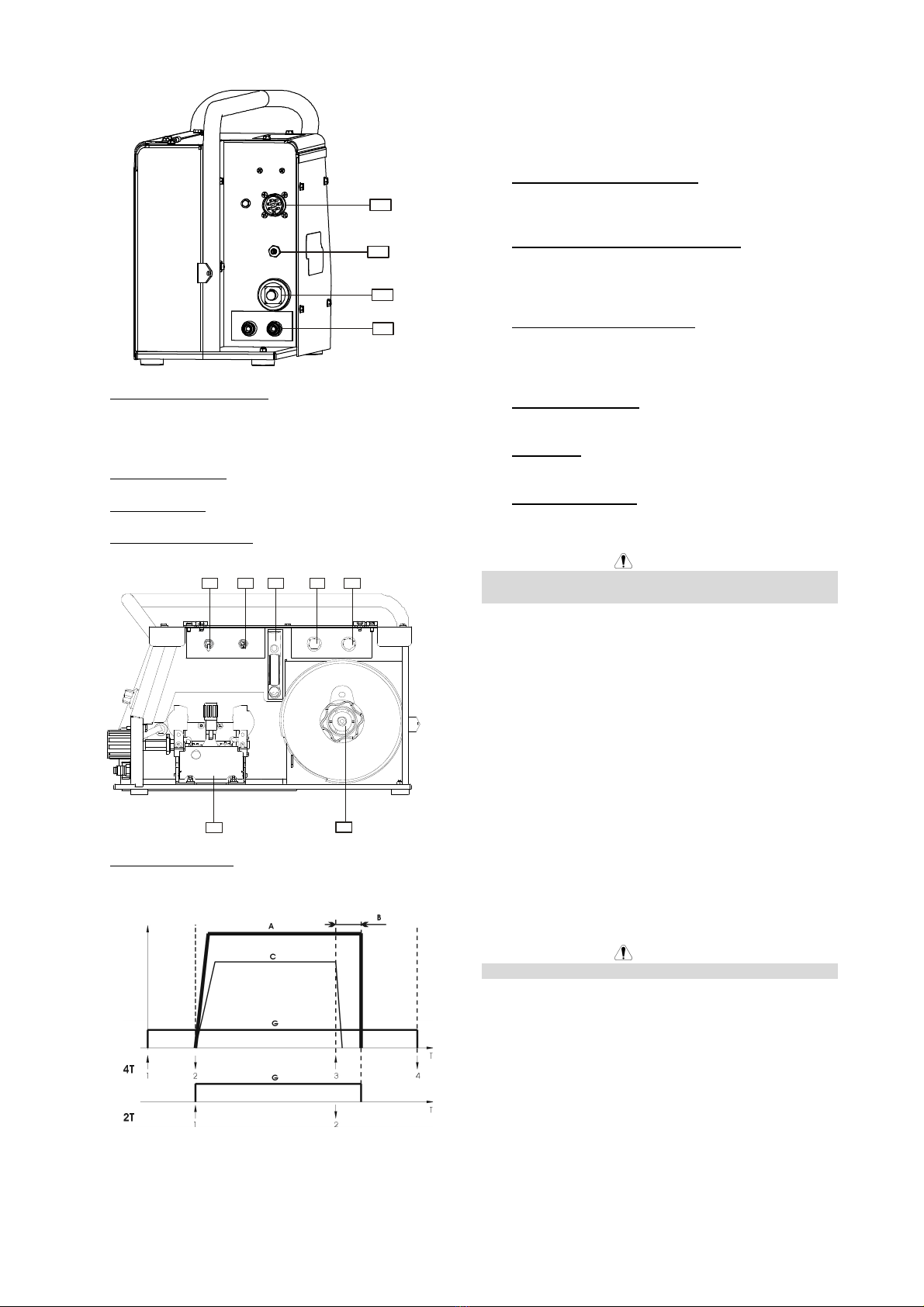

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can operate

the machine at rated welding current.

Example: 60% duty cycle:

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

Minutes or decrease

Duty Cycle

Input Supply Connection

Check the input voltage, phase, and frequency of the

power source that will be connected to this wire feeder.

The allowable input voltage of the power source is

indicated on the rating plate of the wire feeder. Verify the

connection of grounding wires from the power source to

the input source.

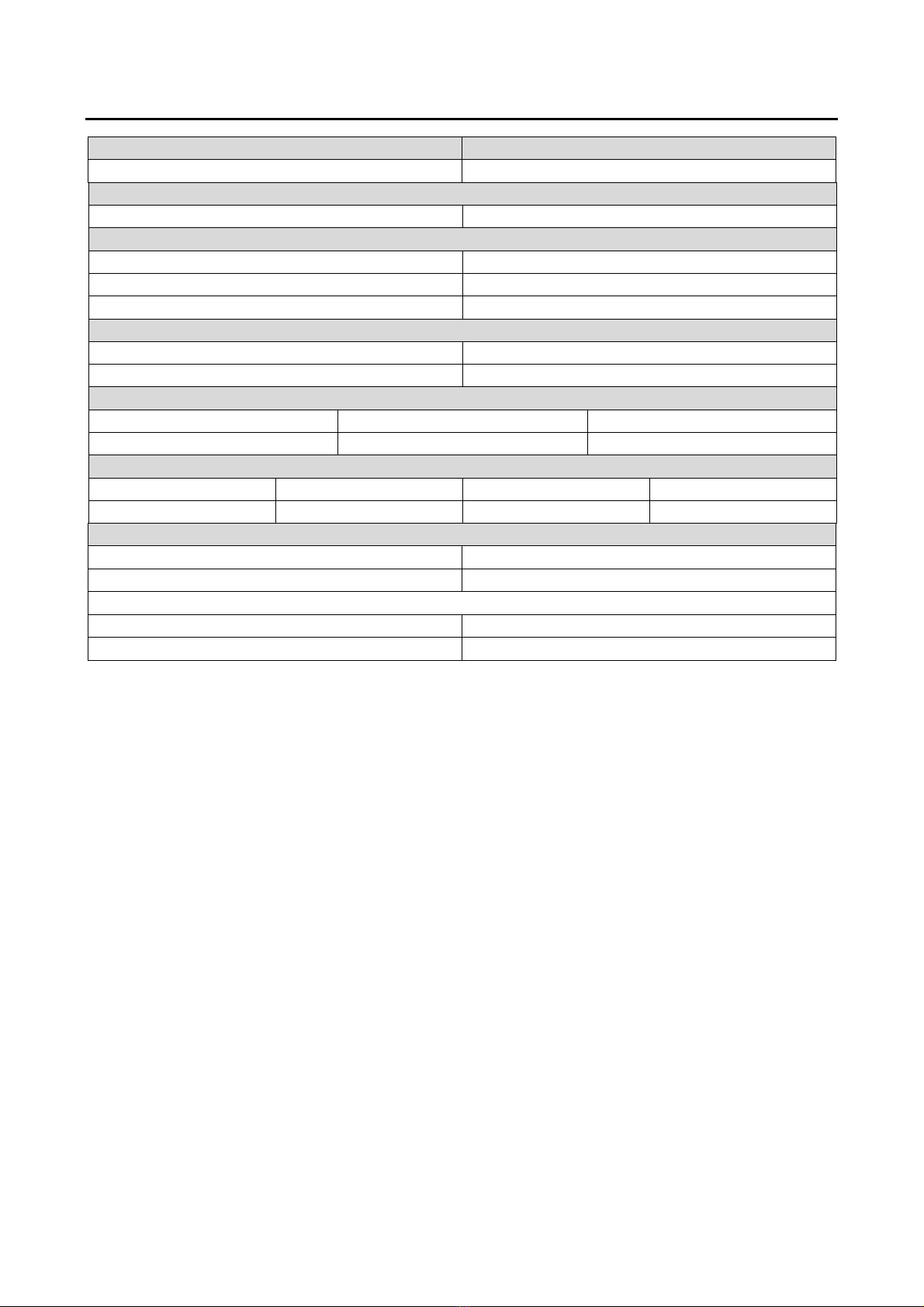

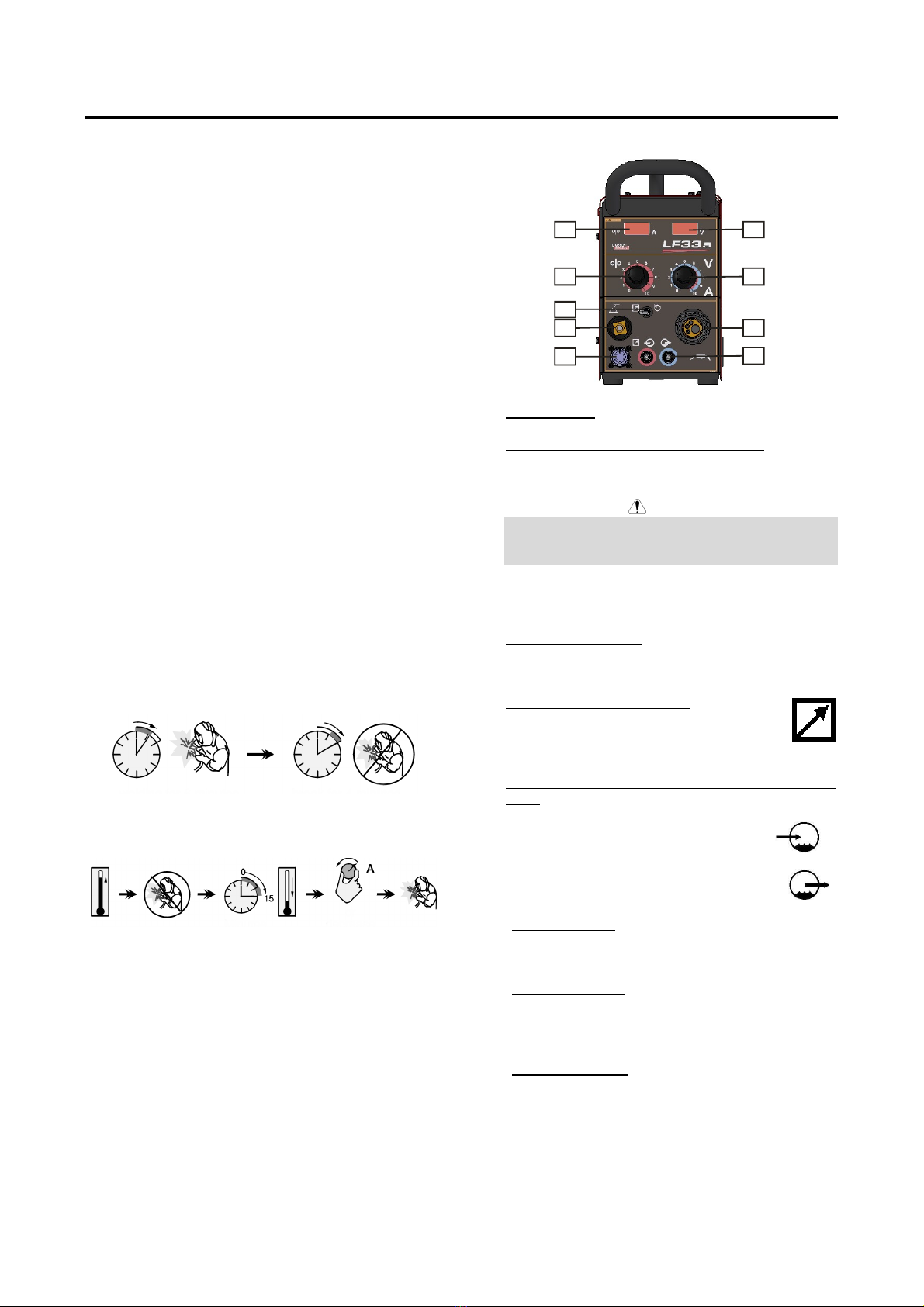

Controls and Operational Features

7

2

4

9

5

1

3

8

6

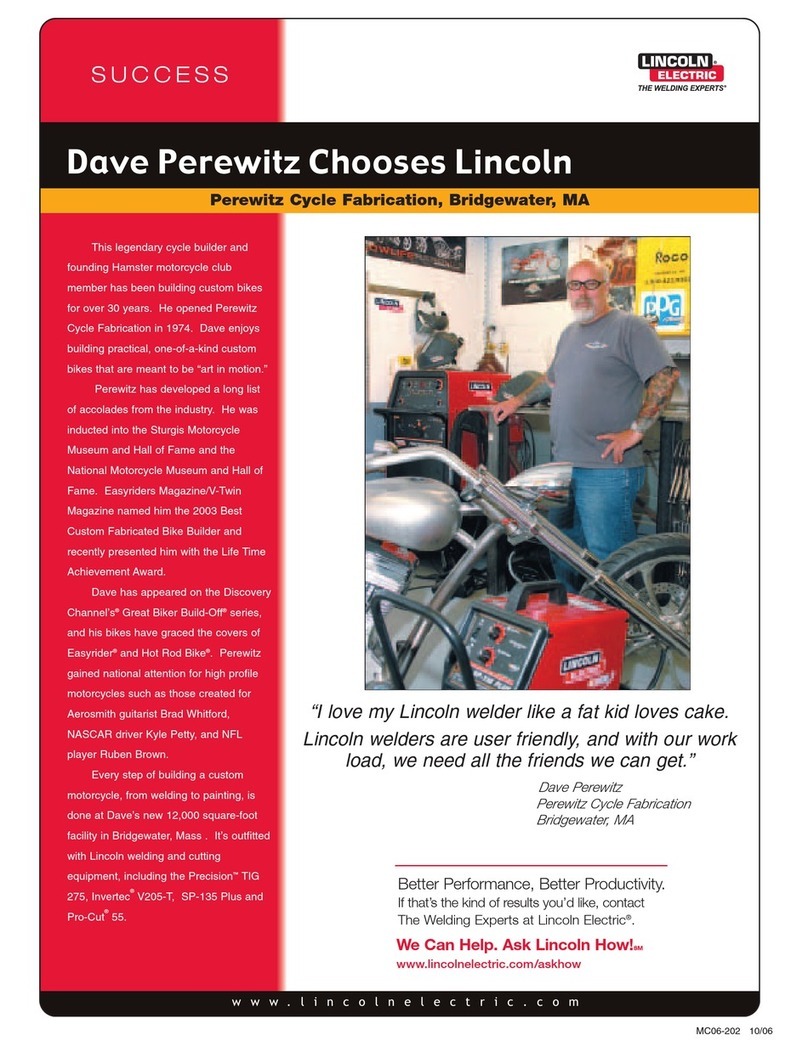

1. EURO Socket: or connecting welding torch.

2. WFS (Wire Feed Speed) Control Knob: It enables

continuous control of wire feeding speed in the range

from 1.0 to 20m/min.

WARNING

Before welding beginning and during Cold Inch Switch

using the Pro-welding Wire Speed Control Knob [16]

has also an influence on the wire feeding speed.

3. Output Voltage Control Knob: It enables continuous

control of welding voltage.

4. Local/Remote Switch: It changes the control of the

Output Voltage from the wire feeder Output Control

[3] to Remote Control Unit and vice versa.

5. Remote Control Receptacle: If a remote

control is used, it will be connected to the

remote receptacle (see Accessories for

ordering the desired unit).

6. Quick Connect Couplings (For water cooled model

only): For connecting water cooled torches.

Warm water from torch.

Cool water to torch.

7. Digital Display A: It shows the actual welding current

value (in A), and after finishing welding process, it

shows the average value of the welding current.

8. Digital Display V: It shows the actual value of

welding voltage (in V), and after finishing welding

process, it shows the average value of welding

voltage.

9. Fast-Mate Adapter: For connecting electrode touch.