English English

5

GENERAL DESCRIPTION

General Physical Description

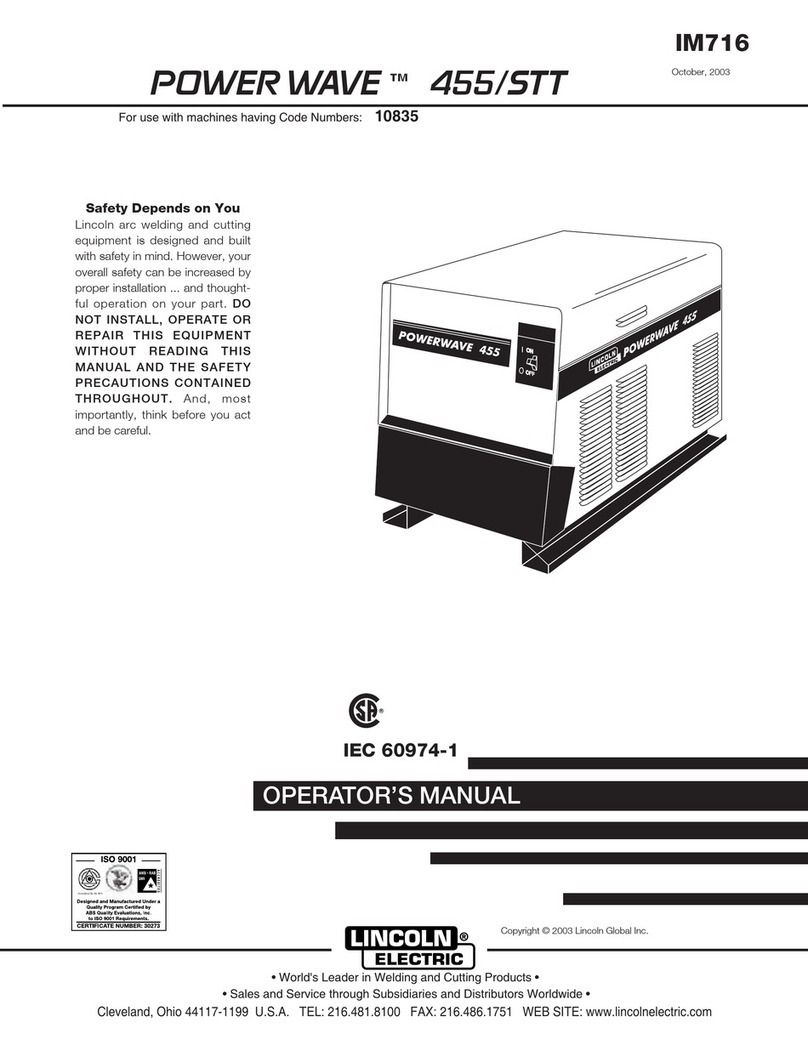

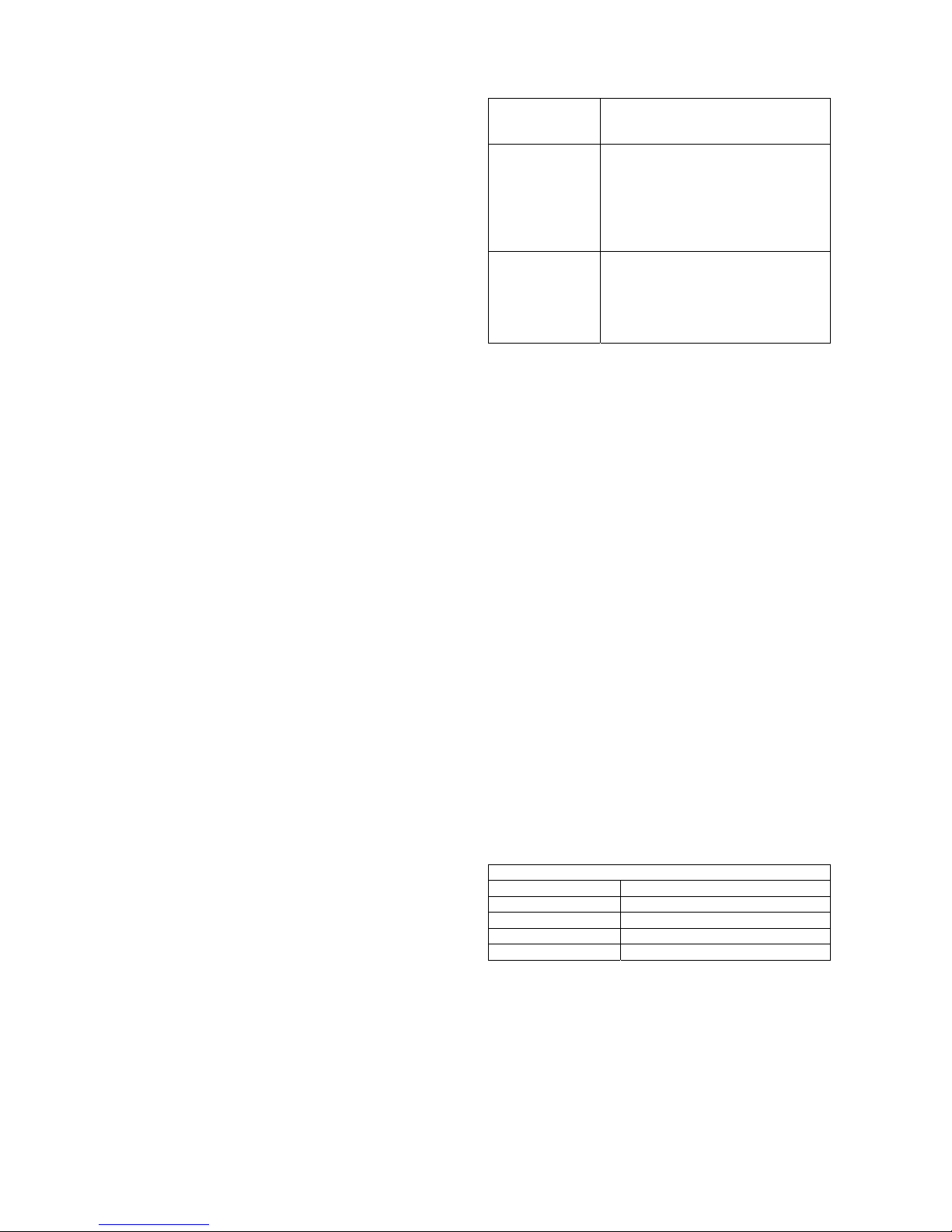

The POWER WAVE® STT® MODULE (CE) is an

accessory enabling compatible power sources to

perform the STT® function without limiting the normal

multi-process rating of the host machine. It is intended

for use with medium range “S”– series Power Wave ®

power sources such as the S350. The module itself is a

low profile pedestal, designed to seamlessly integrate

with compatible power sources and water coolers.

General Functional Description

The POWER WAVE® STT® MODULE (CE) is

essentially a high speed, high capacity output switch,

connected in series with the positive output of the power

source. It communicates module status and identification

information to the power source via the ArcLink®

protocol, and receives a high speed synchronized

switching command via a dedicated digital link.

DUTY CYCLE

The POWER WAVE® STT® MODULE (CE) is rated at

450 amps at a 100% duty cycle. It is further rated to

support 500 amps at a 60% duty cycle and 550 amps at

a 40% duty cycle. The duty cycle is based on a ten-

minute period. A 60% duty cycle represents 6 minutes of

welding and 4 minutes of idling in a ten-minute period.

Note:

The POWER WAVE® STT® MODULE (CE) is capable

of withstanding a peak output current of 750 amps. The

allowable maximum average output current is time

dependant, and ultimately limited by the host power

source.

COMMON WELDING PROCEDURES

MAKING A WELD

Choose the electrode material, electrode size, shielding

gas, and process (GMAW, GMAW-P, GMAW STT etc.)

appropriate for the material to be welded.

Select the weld mode that best matches the desired

welding process. The standard weld set shipped with the

host power source encompasses a wide range of

common processes that will meet most needs. If the STT

modes are not available, or if a special weld mode is

desired, visit www.powerwavesoftware.com or contact

the local Lincoln Electric sales representative.

The power source controls the POWER WAVE® STT®

MODULE (CE) based on the selected weld mode.

For a more detailed description, and specific operating

instructions, consult the power source Instruction

Manual.

Steady green

System okay. The power source and

wire feeder are communicating

normally.

Blinking green

Occurs during a reset and indicates

the power source is identifying each

component in the system. This is

normal for the first 60 seconds after

power-up, or if the system

configuration is changed during

operation.

Alternating

green and red

Non-recoverable system fault. If the

power source or wire feeder status

LED is flashing any combination of

red and green, errors are present in

the system. Read the error code

before the machine is turned off.

RECOMMENDED PROCESSES AND

EQUIPMENT

RECOMMENDED PROCESSES

The POWER WAVE® STT® MODULE (CE) is

recommended for all process supported by the host

power source including, but not limited to SMAW,

GMAW, GMAW-P, GMAW-STT.

PROCESS LIMITATIONS

The POWER WAVE® STT® MODULE (CE) is

unaffected by the voltage at the load, and therefore

processes are only limited by the current and duty cycle

ratings listed in the specifications for the product. The

POWER WAVE® STT® MODULE (CE) is designed to

protect itself from the excessive transient voltages

associated with highly inductive weld circuits. These high

inductance circuits may result in unsatisfactory

performance, but will not damage the module.

Although the STT Module can be configured to support

negative electrode polarity processes, such as

Innershield, the STT process must be configured to use

positive electrode polarity.

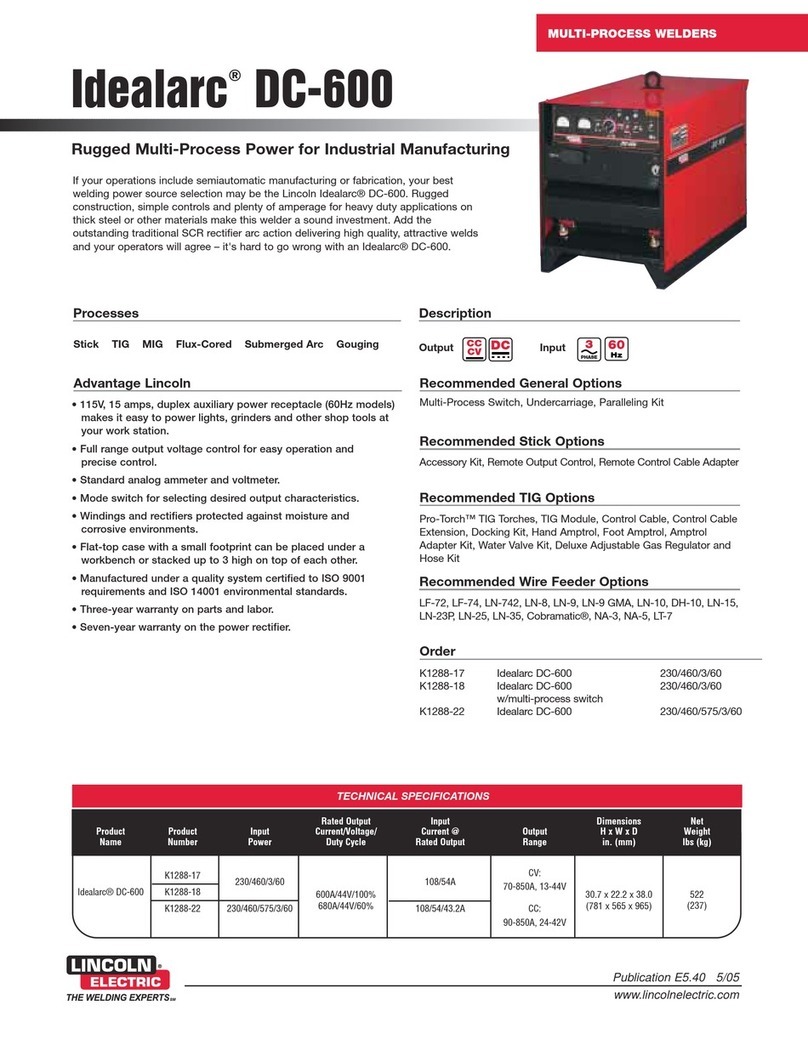

EQUIPMENT LIMITATIONS

The POWER WAVE® STT® MODULE (CE) is intended

for use with compatible medium range “S” – series

POWER WAVE® power sources such as the S350.

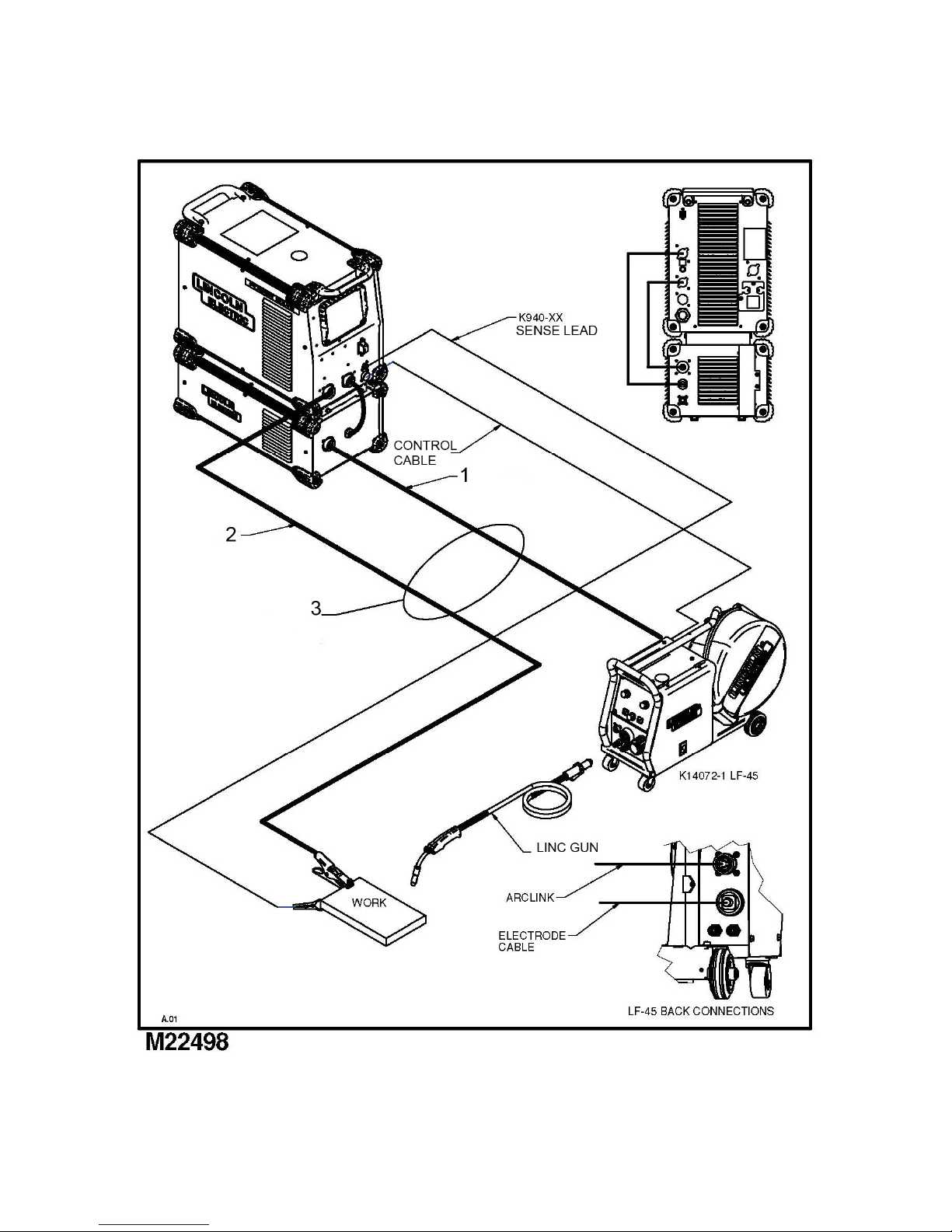

COMMON EQUIPMENT PACKAGES

Basic Package (CE)

K2921-1 STT® Module (CE)

K2823-2 Power Wave® S350 (CE)

K14072-1 LF-45

K10349-PG(W)-XX Interconnecting cable package

K3168-1 Power Wave S500 CE