Page Number - 6

CENTRO-MATIC®

4.1A-68010-B99 Form 402883

7. Besure thatall wiresare connectedtothecorrectlocationson

theterminalstrips.

8. Connecttheribboncableplugfromthekeypad(6)tothemating

plugonthetimer/controllerboard(4). Theplugshouldbeplugged

intothetimer/controllerboardsothattheribboncablehasno

twistinit; it must beparallelto the face of theenclosurewhen the

keypadisinstalled.

9. Whenreinstallingthekeypad(6),besurethattheribboncableis

gentlyfoldedintotheenclosurebehindthekeypad,andnot

pinchedbetweenthekeypadandenclosure.

Solenoid Valve Replacement

(See Illustration 3)

Warning!Electicalshockhazard. Disconnectand

lockoutallpowertothepumpunitbeforeremoving

thekeypadofthetimercompartment.

(Note:Replacementofthesolenoidvalvedoesnotrequireremovalof

thepumpassemblyfromthemountingsurface)

1. Turnofftheairandpowersupply topumpassembly.

2. SeeTimer/ControllerReplacement,above,toremovethekeypad

(6)andtimer/controllerboard(4).

3. Disconnectairlinefrompumpassembly. Removeanymuffleror

connectionsfromtheexhaustport.

4. RemovetheenclosurebyremovingtwoPhillipsheadscrews(2)

fromthebottomsideoftheenclosure(1).

5. Astheenclosureisremovedfromtheassembly,gentlypullthe

solenoidandgreengroundwiresthroughthegrommet(3)inthe

enclosurebacktowardsthesolenoidvalve.

6. Removethesolenoidvalve(14)usinga3/32allenwrenchto

removethetwo cap screws(15)holding it tothebottom of the air

cylinder(11). Donotlosethegasket(13)thatisplacedbetween

thevalveandaircylinder(11).

7. Whenreplacingthesolenoidvalve,makesurethesolenoidvalveis

thecorrectpartnumberandvoltageasthevalvetobereplaced.

8. Reassembleinreverseoftheaboveprocedure. Takecareinpulling

thesolenoidandgreengroundwiresthroughthegrommet(3).

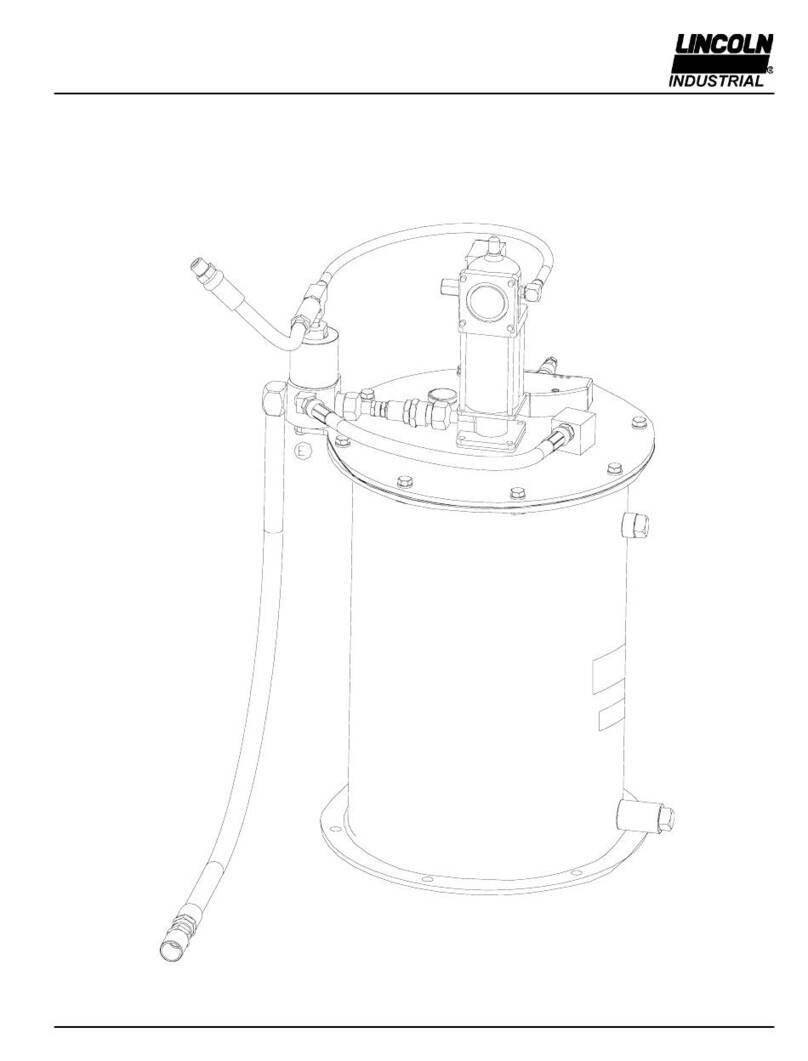

Oil Reservoir Service

(See Illustrations 3, 6 & 7)

(Note: Replacementofthereservoirtubedoesnotrequireremovalof

thepumpassemblyfromthemountingsurface)

1. Turnofftheairsupplytothepumpassembly.

2. Turnoff thepower supplytothepumpunit.

3. Removelubricantfromthelubricantreservoir. Oilpumpreservoirs

maybedrainedbyremovingthedrainplug(8)fromthefrontofthe

pumpunitwith a 9/16 wrench.

4. Cleanoffreservoirtubeandareaaround reservoirtoprevent

gettingdirtintothelubricationsystem.

Warning! Failuretodrainreservoirwillresultin

lubricantleakageout ofreservoirwhenthenut(46)

securingthereservoirinplaceisremoved.

5. Disconnectsupplylinefrompumpoutlet.

6. Removenut(46)fromthetopof thereservoircap(44)usinga

1-3/8 wrench.

7. Removereservoircapfromtopofreservoir.

8. Slidethereservoirtubeoffthepumpoverthecenterpost.

9. Removegasket(35)ifnecessary.

10.Reassembleinreverseoftheaboveprocedure.

11.Tightennut(46)to10to15ft.-lbs.[1.4to2.1kg-m].

Grease Reservoir Service

(See Illustrations 3, 8 & 9)

(Note: Replacementofthereservoirtubedoesnotrequireremovalof

thepumpassemblyfromthemountingsurface)

1. Turnofftheairsupplytothepumpassembly.

2. Turnoff thepower supplytothepumpunit.

3. Removelubricantfromthelubricantreservoir.Greasepumps

maybeemptiedbycarefullyremovingthefillerfitting(7)from

theunitwitha 7/8 wrench. (Depending on how full the reservoir

is, the grease may flow out of the reservoir very rapidly.)

Warning! Failuretoremovealllubricantfrom

reservoircould resultin ahigh springforcefromthe

reservoirspring(43)and/orarapiddischargeof

greasewhennut(46)isloosenedorremoved.

4. Cleanoffreservoirtubeandareaaround reservoirtoprevent

gettingdirtintothelubricationsystem.

5. Disconnectsupplylinefrompumpoutlet.

6. Removenut(46)fromtoporreservoircap(44)usinga1-3/8

wrench. Carefullyholdreservoircap(44)againstany residual

springforcewhileremovingnut (46).

7. Removereservoircap(44)fromtopofreservoir.

8. Holding the follower down with the follower spring (43), carefully

work the reservoir off of the follower, leaving the follower and

springinplaceonthepumpassembly.

9. Removefollowerspring(43).

10. Removefollowerassemblybyslidinguptothethreadsinthe

centertube,andthenthreadingthefollowerassemblycounter-

clock-wiseoverthethreadedportionofthecentertube. Donot

force or pull the follower off of the center tube or damage will

resultto theo-ring(38 or48)inside offollowerbushing (39).

11. Removegasket(35)ifnecessary.

12. Disassemblethefollowerassemblybyremovingretainingring

(42),usingexternalretainingringpliers,frombushing(39).

Washers(40) andfollowerpacking cannow beremoved

frombushing(39). Removeo-ring(38or48)fromtheInternal

grooveintheinnerholeofthebushing(39);useapointedtool,

suchasapicktoremove.

13. Reassembleinreverseoftheaboveprocedurewiththefollowing

hints:

14. Wheninstallingthefollowerassemblyontothecentertube,

lubricatethecentertubeliberallywithgrease. Lubricatethe

o-ring(38 or 48)and the insideof bushing (39)with grease.

Thread,turning clockwise,thefollower assemblydown overthe

centerrodthreads. Donotforce ordrivewithhammer,or o-ring

damagewillresultinleakageoflubricantaroundfollower. Side

thefollower assemblydown tothe bottomof thetube.

15. Wheninstallingthereservoirtube,lubricatethefollower packing

lips(41) andtheinside ofthereservoir tube(36)with grease.

The reservoir tube will have two vent holes in the side wall of

the tubeclose toone endofthetube. Thereservoirtube(36)

mustbeplacedonthepumpwiththeventholesneartheupper