TALEX Spółka z ograniczoną odpowiedzialnością Sp. K.

ul. Dworcowa 9C

77-141 Borzytuchom

tel. (59) 821 13 26

www.talex-sj.pl

The Instruction Manual

LEO 320 PROFESSIONAL shredder

2.

Rules of safe operation

2.1 User safety

The shredder can only be used by adults, who have learnt its operation and read this

instruction manual, and are properly qualified. The shredders should be operated with all

necessary precautions, in particular:

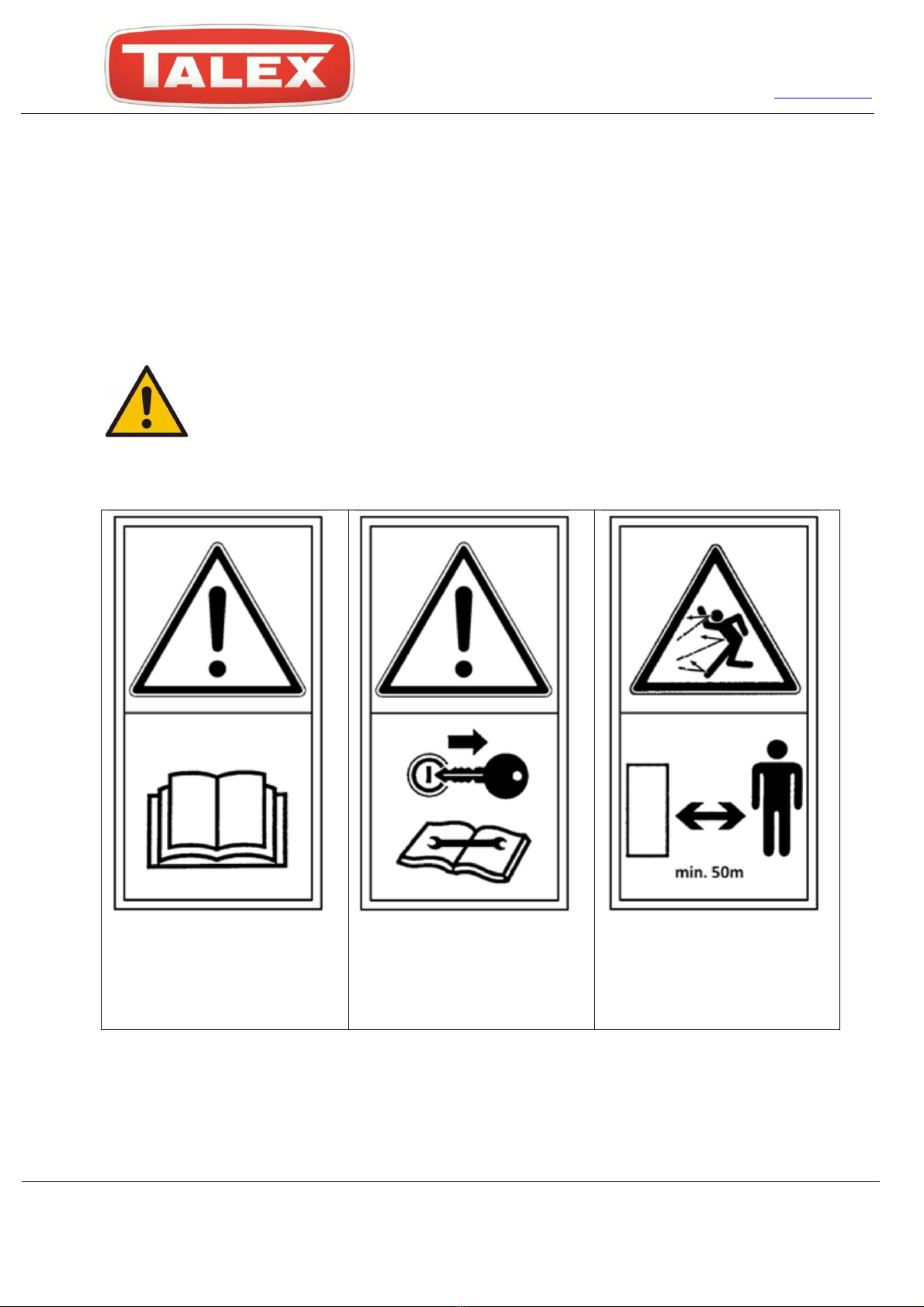

In addition to this instruction manual, also observe the general rules of health

and safety at work.

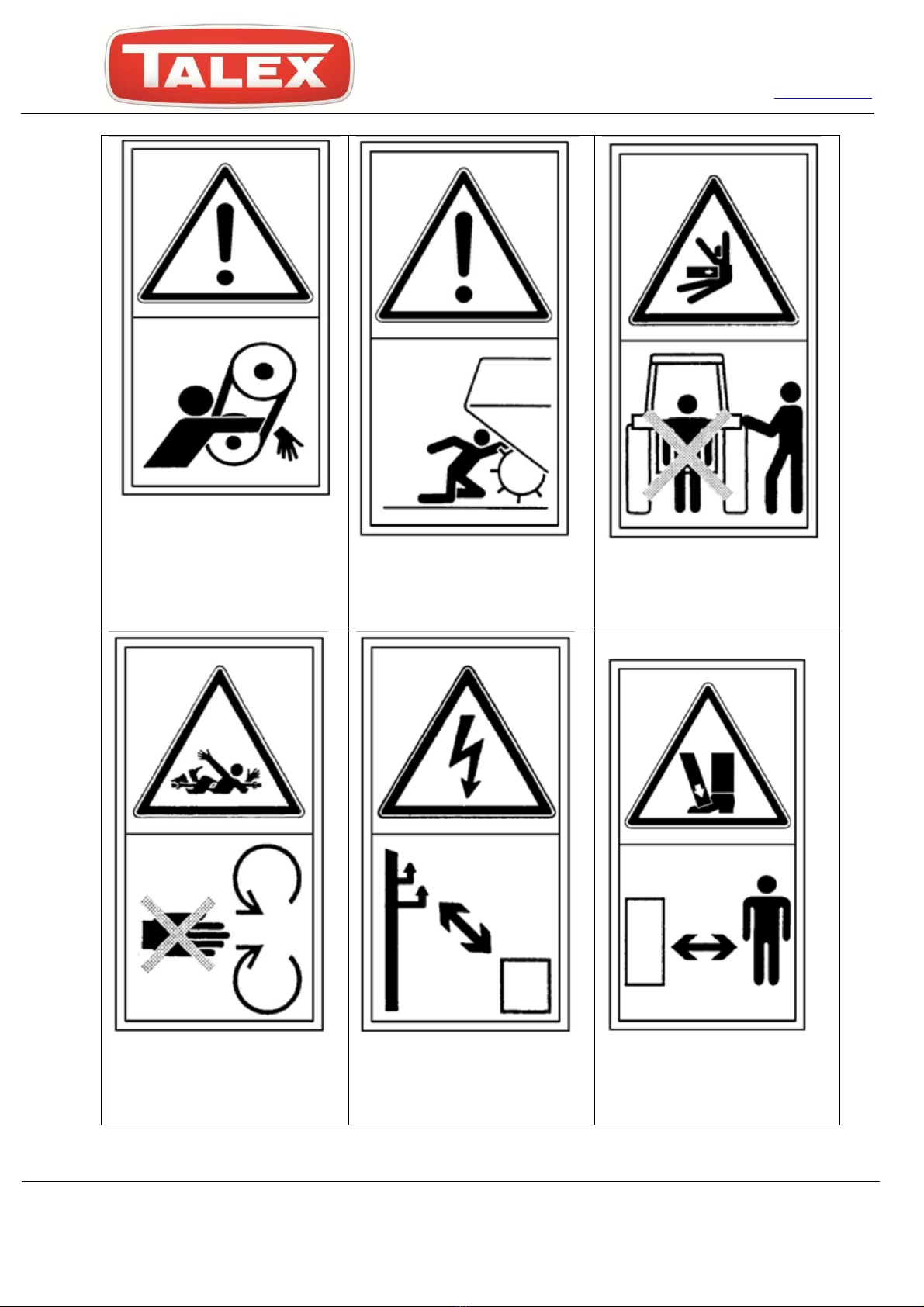

Observe warning symbols placed on the machine.

It is strictly forbidden, to operate the machine by persons under the influence of

alcohol or other intoxicants.

Never allow the vehicle towing the shredder to be driven by a person other than the

shredder operator, and under no circumstances allow any other persons to be on the

vehicle, or by the machine, during its operation.

The shredder may be operated by an operator licensed to drive the vehicle onto which the

shredder has been mounted, in line with the recommendations of its manufacturer.

The operating position of the operator, while working with the shredder, is the cabin of

the vehicle to which the machine is attached.

Please note, that there are many elements of the shredder that may cause an injury (sharp

edges, protruding parts, etc.). While using the equipment, exercise particular caution

when moving close to the above-mentioned critical spots and obligatorily use the

following personal protection equipment:

-

protective clothing,

-

protective gloves,

-

protective footwear.

It is forbidden to carry persons or objects on the machine.

It is forbidden that the machine should be operated by persons who are not

familiarized with the instruction manual.

The person operating the shredder should be provided with a first-aid kit containing

measures for first aid, along with instructions regarding their use.

Take special care when driving on public roads, and comply with the applicable road

traffic regulations.

When driving on public roads, it is essential to use the electric outline lighting of the

vehicle, check its efficiency and visibility, and keep it clean. On the machine or on the

rear of the vehicle a triangular plate must be fitted, distinguishing low-speed vehicles.

Care should be taken about clarity and visibility of the reflective lighting and warning

signs located on the structural elements of the machine.

The transportation speed should be adjusted to the condition of a road surface, it should not exceed

however 20km/h.

Do not leave the vehicle with the shredder on a hillside or other sloping surfaces, without