Linear LTC2937 User manual

1

dc2313af

DEMO MANUAL DC2313A

Description

Programmable

Six Channel Sequencer and

Voltage Supervisor with EEPROM

Demonstration circuit 2313A showcases the LTC2937, a

programmable six channel power supply sequencer and

voltage supervisor.

The LTC2937 provides flexible sequence control for up

to six power supplies. It enables and disables the sup-

plies with configurable sequence order and time delays,

monitorsthe suppliesfor power-up and power-downtime,

and for overvoltage and undervoltage. It cooperates with

other LTC2937 parts in the system to coordinate power

sequencing activities. It provides flexible fault response to

autonomouslysupervisethepower supplies, and powerful

debug tools to diagnose any problem that causes a power-

supplyfault.Itholdsconfigurationinnon-volatileEEPROM

for completely automatic power system supervision.

The DC2313A board demonstrates the powerful features

of the LTC2937 using six onboard LDO voltage regula-

tors, or by controlling an optional, externally-powered

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and

LTpowerPlay is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners.

performance summary

DC1361board(an8-channelpower supply board).Multiple

DC2313A boards can also share timing and sequencing

signals to supervise more than six regulated supplies in

a coordinated manner.

The DC2313A connects to a PC through the DC1613 USB-

to-I2C/SMBus/PMBus Controller. This connection enables

the LTpowerPlay™ software, to have completecontrol over

the LTC2937 through the convenient LTpowerPlay GUI.

The GUI allows control over all of the LTC2937 registers,

and visibility into the status of the part in real time, and

it works with Linear Technology demo boards as well as

custom boards with an I2C interface.

Design files for this circuit board are available at

http://www.linear.com/demo/DC2313A

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Voltage Range All 6 12 14 V

IIN Current to the Board Sequenced-Down 3.8 mA

IIN Current Sequenced-Up, No Loads 17.5 mA

V1-V6 Voltage Range Volts at the Turret 0 6 V

EN1-EN6 Voltage Range Volts at the Turret†0 6 V

Regulated LDO Voltage Tolerance Load Current < 20mA –1 1 %

Rated Output Current *V_OUT pins Load Current Per Channel 20 mA

Board Operating Temperature Powered 0 60 °C

Serial Clock Frequency I2C Bus Operating 10 400 kHz

†NOTE: Analog switches U7, U8, and U9 (LTC222) are powered by 5V, and limit the maximum voltage range allowed at their S and D pins. The LTC2937

can tolerate up to 16.5V on its ENn pins.

2

dc2313af

DEMO MANUAL DC2313A

Ltc2937 features

how to use this Document

the Dc2313a BoarD

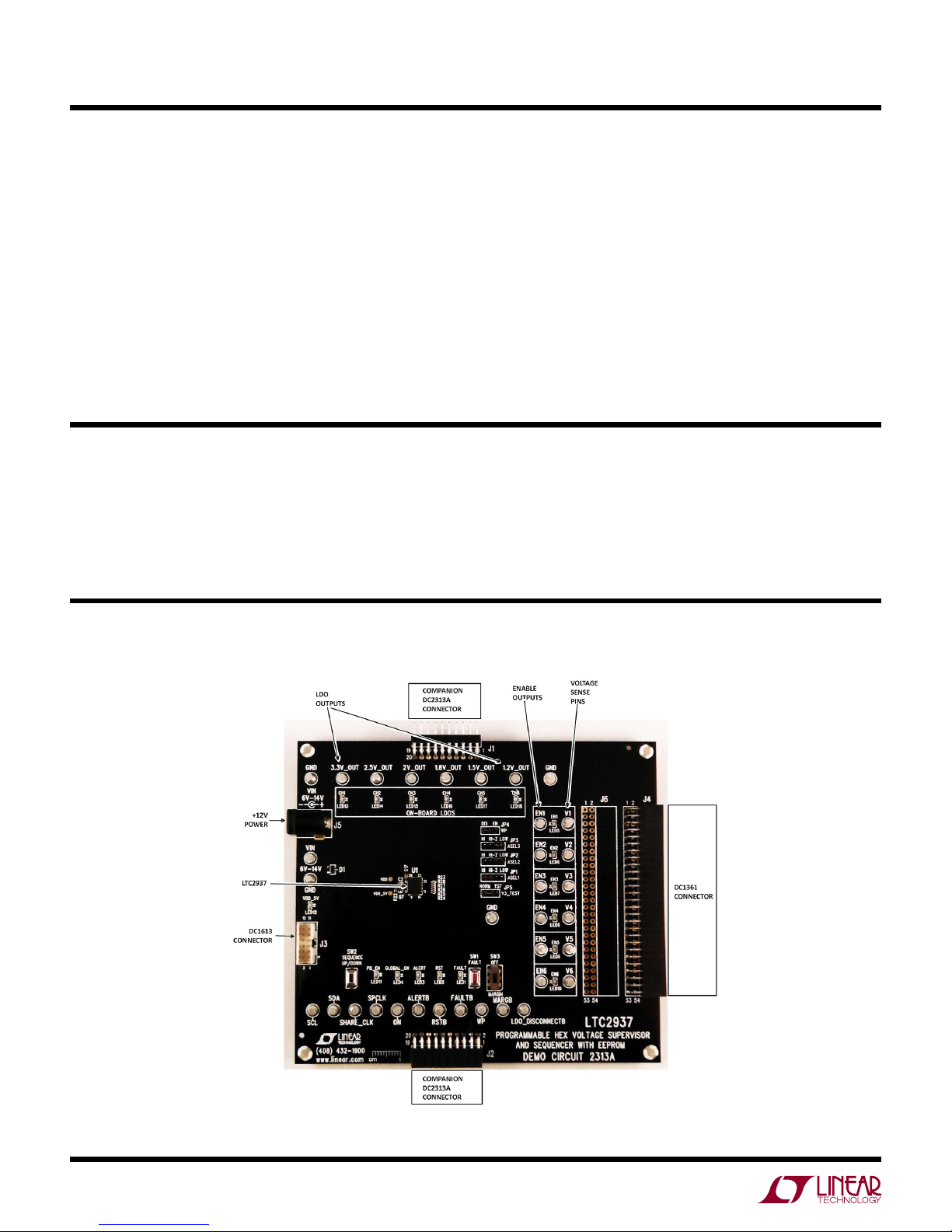

Figure 1. DC2313A Board

• Time and Event-Based Supply Sequencing

• 12Programmable Undervoltage and Overvoltage Com-

parators (0.75% Accuracy)

• Stalled Power-Supply Detection

• Single Wire Synchronization Allows Controller Expan-

sion to 50 Devices (300 Power Supplies)

• Configuration and Fault Logging in EEPROM

• EEPROM Rated to 85°C, 10k Writes, 20 Year Retention

• Supported by LTpowerPlay GUI

• Fault and System Status Registers

• Reset Output with Programmable Delay

• I2C/SMBus Interface

• Wide Input Supply Voltage Range: 2.9V to 16.5V

• 28-Pin QFN (5mm ×6mm) Package

This demonstration manual introduces the LTC2937

through a series of simple exercises using the DC2313A

demo board and the LTpowerPlay software. Each exercise

introduces one or two key features of the part, as well as

recommended methods for interfacing to it. The LTC2937

has more useful features than can be covered here. The

userisreferred tothe LTC2937 data sheet, and to additional

exercisesin the DC2313AAdvancedUserGuidedocument.

3

dc2313af

DEMO MANUAL DC2313A

Dc2313 operating principLes

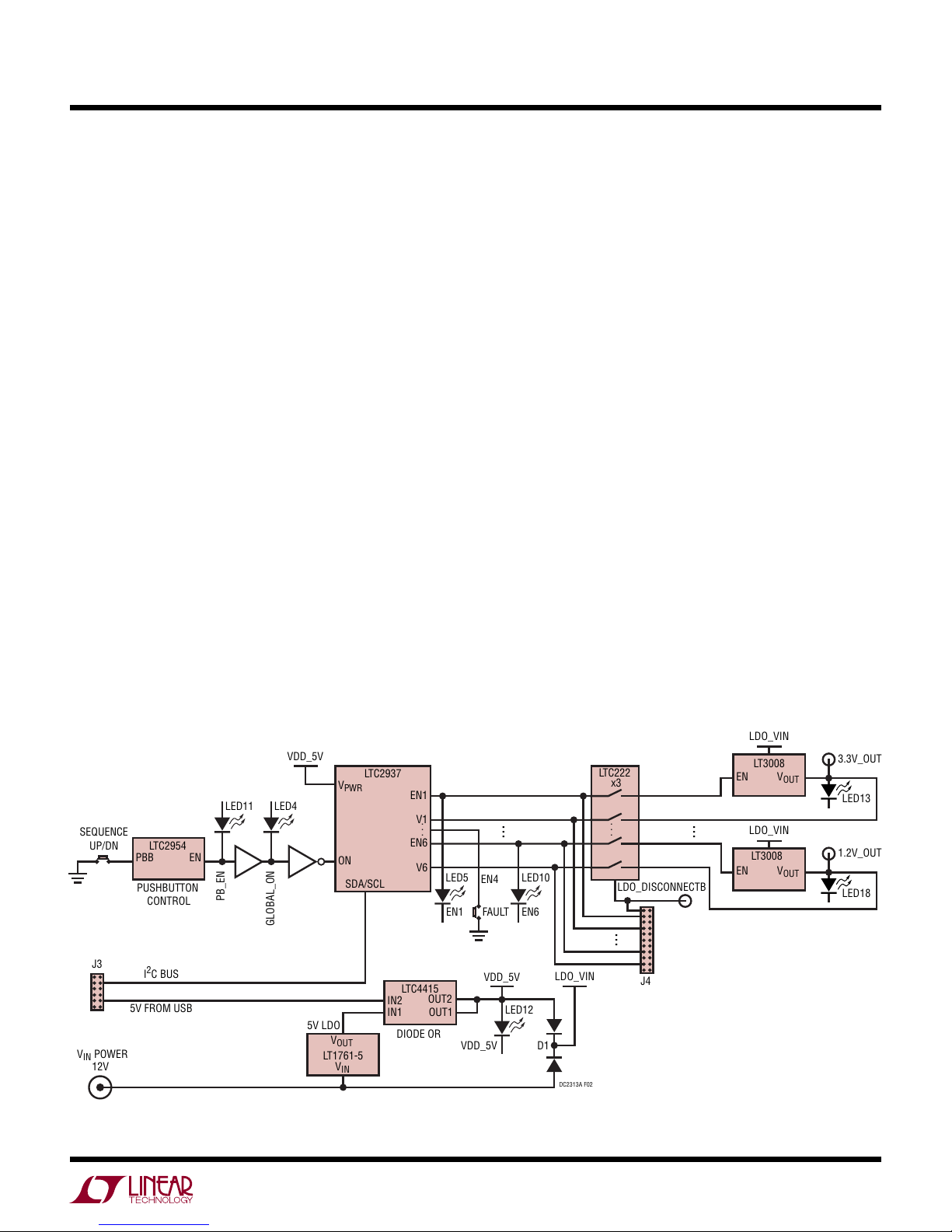

Figure 2. DC2313A Simplified Diagram

The DC2313A board is fully functional as a stand-alone

evaluation platform for the LTC2937, and does not require

any external connections, other than power. It provides

convenient access to all of the LTC2937 pins through

turrets on the board, and basic control over the part by

jumpers and pushbuttons. Connectors can attach to ex-

ternal devices for system prototyping. The board has six

LDO regulators that respond to control from the LTC2937,

and demonstrate its capabilities.

Additional functionality is accessible using the DC1613

USB-to-I2C“dongle” and LTpowerPlay software running on

aPC. The software provides adetailed view of the functions

of the LTC2937, including powerful fault management and

debug capabilities.

POWERING

The DC2313 can draw power from one of two sources.

Either 5V from the DC1613 ribbon cable connected to J3, or

from the VIN connector to 12V. The DC1613 can only supply

100mA, so when the board draws power from 5V do not

load any of the LDO outputs, as this may overload the 5V

supply. 12V must be used when loading the LDO outputs.

Multiple DC2313A boards connected together through J1

and J2 share power through the connectors, so attach 12V

and the ribbon cable to one of multiple DC2313A boards.

Only connect power to one of the boards. When the external

DC1361 board is attached to connector J4, use 12V power.

CONFIGURATION

A key feature of the LTC2937 is its non-volatile memory (EE-

PROM),anditsabilitytopower-upinthecorrectconfiguration

toautonomouslysequenceandsupervisethepowersystem.

The DC2313A comes pre-programmed with default settings

to demonstrate the sequencing and supervision capabilities

of the LTC2937. The board functions with no intervention

from LTpowerPlay or other software. The pre-programmed

settings on the board are not the factory default settings

for the LTC2937, but are intended to provide a useful dem-

onstration platform, with observable timing relationships.

The LTC2937 communicates through the I2C bus on the J3

connector. Select a bus address by changing the jumpers

ASEL1, ASEL2, and ASEL3. Each jumper can select either

HI, Hi-Z, or LOW, and the three jumpers together select

one of 27 addresses for the device. Select a unique address

for each device on the I2C bus. If multiple DC2313 boards

are connected together, each must have its own unique

ASEL jumper setting. Each LTC2937 will always respond

to its global 7-bit address 0x36. See the addressing section

in the LTC2937 data sheet for a complete address table.

VDD_5V

VPWR

ON

EN1

EN6

V1

V6

SDA/SCL

. . .

LTC2937

PBB

EN

LTC2954

IN1

OUT1

IN2

OUT2

LTC4415

LED4

LED11

D1

VOUT

VIN

LT1761-5

VOUT

EN

LT3008

VOUT

EN

LT3008

LTC222

. . .

x3

LED12

LED5

LED10

J3

SEQUENCE

UP/DN

VIN POWER

12V

J4

LDO_DISCONNECTB

LDO_VIN

3.3V_OUT

VDD_5V

LDO_VIN

PB_EN

GLOBAL_ON

I2C BUS

5V FROM USB

DC2313A F02

VDD_5V

EN1

FAULT

EN6

EN4

5V LDO

DIODE OR

...

...

...

PUSHBUTTON

CONTROL

LDO_VIN

LED13

1.2V_OUT

LED18

4

dc2313af

DEMO MANUAL DC2313A

Quick start proceDure (without software)

Begin exploring the basic features of the LTC2937 with

several exercises that do not require software. The follow-

ing procedures assume a single DC2313A board with no

DC1613connected, andnoLTpowerPlay running. Theboard

will function autonomously without external software,

which is one of the important capabilities of the LTC2937.

SEQUENCING UP

Sequence up the supplies in an orderly fashion.

1) Apply power to the DC2313A by connecting 12V to the

J5 power connector.

The VDD and RSTB LEDs will illuminate; all other

LEDs will be off.

2) Ensure that the SW3 switch is OFF, not in the MARGIN

position.

3) Press the “SEQUENCE UP/DOWN” pushbutton on the

DC2313.

Thepushbutton is de-bounced byanLTC2954, which

requires sufficient time to register the button press

andactivatetheLTC2937throughthePB_ENBsignal.

The PB_EN and GLOBAL_ON LEDs will illuminate.

The ENn LEDs will illuminate in sequence: 1-6.

The CHn LEDs will illuminate in sequence with the

ENn LEDs.

The RST LED will turn off when all supplies are within

theirOV/UV limits(afterthe lastCHnLED illuminates).

The FAULT LED will remain off.

The ALERT LED will remain off.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

The DC2313A is programmed to provide human eye

observable sequence-up timing so that the time between

supplies powering-up is easily observable via LEDs. The

actual LTC2937 in-system sequence of events, and the

delays between events are all configurable.

Figure 3. DC2313A Standalone

5

dc2313af

DEMO MANUAL DC2313A

Quick start proceDure (without software)

SEQUENCING DOWN

Bring down the supplies in an orderly fashion.

1) Begin with the system sequenced-up. The LDOs are on.

2) Press the “SEQUENCE UP/DOWN” pushbutton on the

DC2313.

The PB_EN and GLOBAL_ON LEDs will turn off.

The ENn LEDs will turn off in sequence: 6-1.

The CHn LEDs will turn off in sequence with the ENn

LEDs.

The RST LED will illuminate as soon as the CH6 LED

goes off.

The FAULT LED will remain off.

The ALERT LED will remain off.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

Noticethat thesequence-downorderof eventsis thereverse

of the sequence-up order. Channels can be reconfigured

easily via register programming to sequence-up and

sequence-down in any order, and sequence-down order

is independent of sequence-up order. As with sequencing-

up, the human-friendly, eye-observable sequence timing

is easily changed through register configuration.

AUTONOMOUS FAULT HANDLING

A fault is any condition that should not exist in the

system. The flexible LTC2937 is capable of autonomously

recognizing and handling faults without software

intervention. The LTC2937 recognizes 5 types of faults:

SUPERVISOR fault, SEQUENCE fault, CONTROL fault,

EXTERNAL fault, and SHARE_CLK fault. We address

SUPERVISOR and SEQUENCE faults here. For more in-

formation refer to the LTC2937 data sheet. The following

examples, do not use software, or user/external interven-

tion to recover from the fault condition. The LTC2937 is

programmed to recover on its own.

Note that the LTC2937 ALERT pin requires a bus response

to de-assert once it asserts low. When using the LTC2937

in fully autonomous mode, we ignore the ALERT pin, and

the ALERT LED on the board. Once it is asserted, ALERTB

will remain asserted, and the ALERT LED illuminated. This

is harmless.

Supervisor Fault

A SUPERVISOR fault is caused by overvoltage (OV) detec-

tion during sequence-up, or by OV or undervoltage (UV)

detection during normal operation (after a successful

sequence-up). In this demo configuration the LTC2937

automatically detects the fault and re-starts all of the

regulators.

Create this type of fault on the DC2313A board by pressing

the FAULT pushbutton, which momentarily pulls down the

EN4 line to GND, while in the sequenced-up state. This

will briefly disable and bring down the associated LDO and

create a UV condition. The LTC2937 will recognize the low

voltage and signal a SUPERVISOR fault.

1) Start with the system sequenced-up. The LDOs are on.

2) Press and release the FAULT pushbutton. This shorts

EN4 to GND, disabling the 1.8V LDO.

3) Observe the fault response:

All ENn pins pull low immediately. All ENn LEDs turn

off.

AlloftheLDO regulated supplies turnoffimmediately.

All CHn LEDs turn off.

The LTC2937 is configured to automatically re-try

after the fault, so it will attempt to sequence-up the

supplies. Since the fault was momentary, the re-

sequence will succeed.

Pin FAULTB will assert low until the fault retry interval

iscomplete andthe re-sequencing begins. The FAULT

LED will illuminate during this interval.

Pin RSTB will assert low until the LDOs come-up

after re-sequencing. The RST LED will illuminate

during this interval.

Pin ALERTB will assert low. The ALERT LED will

illuminate. The alert state will remain until an alert

response or a read from the CLEAR_ALERTB (0x28)

comes from the I2C bus. Only a bus operation can

release the ALERTB pin.

Table of contents

Other Linear Recording Equipment manuals