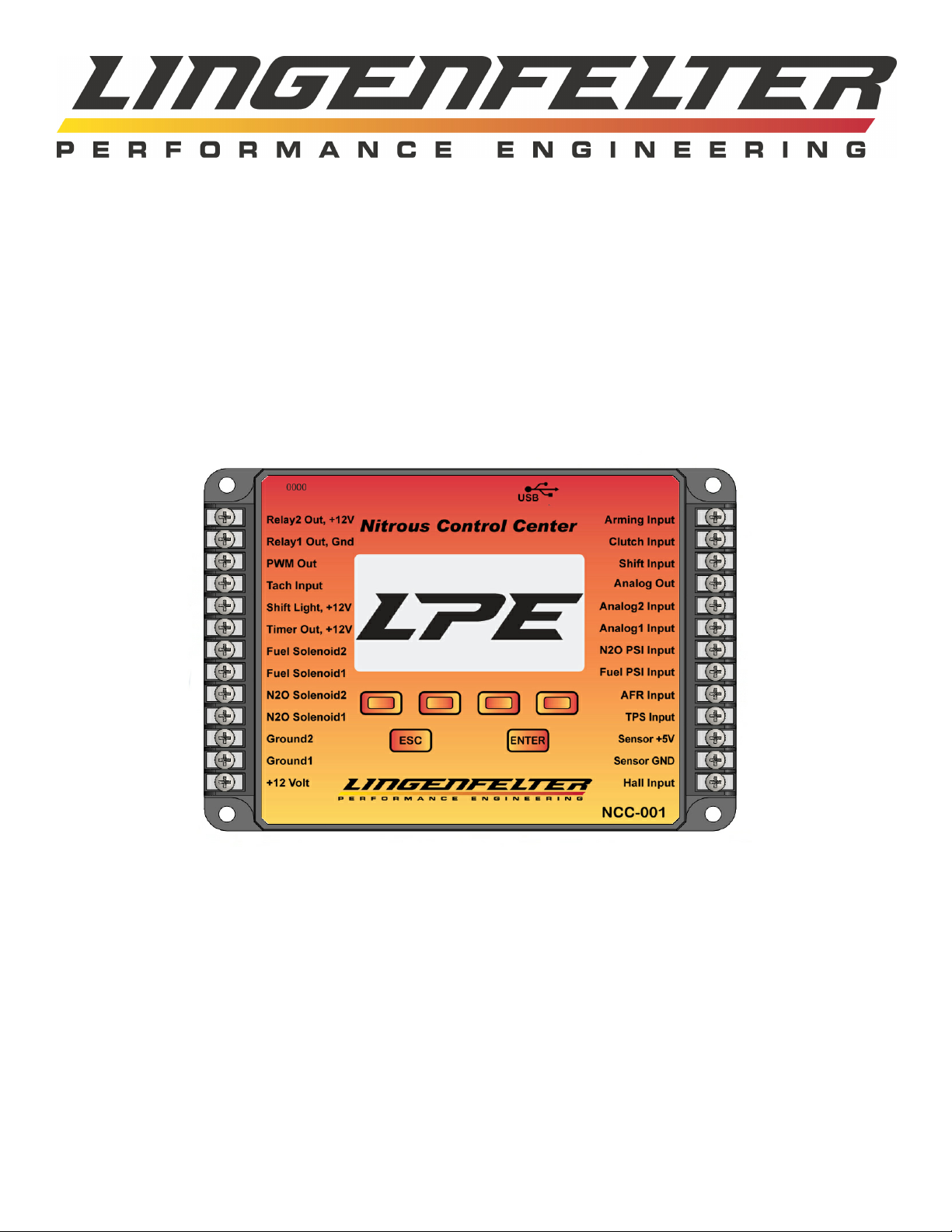

Introduction 6

1.1 NCC-001 Features

Two independent progressive stages of nitrous and fuel

oIndependent control of both nitrous and fuel duty cycle for each stage

oFour stages of nitrous (if used to only control nitrous solenoids)

Timer/RPM based output (+12V)

Relay output (+12V) - programmable based on any combination of: Arming input, clutch input, shift input, TPS

%, AFR, Nitrous1 %, Fuel1 %, Nitrous2 %, Fuel2 %, RPM, MPH, Fuel PSI, Nitrous PSI

Relay output (Ground) - programmable based on any combination of: Arming input, clutch input, shift input, TPS

%, AFR, Nitrous1 %, Fuel1 %, Nitrous2 %, Fuel2 %, RPM, MPH, Fuel PSI, Nitrous PSI

Shift light output, +12 volt

Analog voltage output, programmable - for sending to a data acquisition system or to an ECM for external fuel or

spark control. Also can link to the LNC-2000 for progressive timing retard on GM LSx V8 engine vehicles.

PWM output (for future features - not currently enabled in the software)

5 volt and ground output for Fuel Pressure and Nitrous Pressure sensors (for improved signal accuracy)

Arming input (Ground or +12 volt selectable)

Clutch input - for clutch switch, linelock, or transbrake input (Ground or +12 volt selectable)

Shift input - for gear position (Ground or +12 volt selectable)

Nitrous bottle pressure input, 0-5 volt

Fuel pressure input, 0-5 volt

AFR input, 0-5 volt

TPS input - accepts rising and falling voltage signal sensors, 0-5 volt

Two analog inputs - accepts rising and falling voltage clutch position sensors, 0-5 volt

Frequency input (vehicle speed, possible other inputs later)

oSoftware enable/disable pull-up resistor on frequency input

Engine speed (tach) input

oSoftware enable/disable pull-up resistor on tachometer input

oAccepts most engine configurations

Time based safety over-ride

Fuel pressure safety over-ride

Air fuel ratio safety over-ride

Closed loop bottle heater control (using relay output and nitrous pressure input)

Time based nitrous control

RPM based nitrous enable

MPH based nitrous enable

Gear position based nitrous enable

Independent Stage 1 and Stage 2 delay adjustments

User configurable between Hold & Wait or full reset when activation is removed and re-enabled. Hold & Wait

resumes the progressive system at the point where the system was disabled (for example, where the throttle

was released).

Independent Stage 1 and Stage 2 nitrous and fuel resume ramp rates

Independent Stage 1 and Stage 2 fuel advance settings > These settings allow you to fine tune the system so

that the low pressure fuel is delivered to the engine at the same time or before the high pressure nitrous, helping

reduce the chances of initial lean spikes when each stage of nitrous is activated

Multiple solenoid frequency settings (independent for Stage 1 & 2)

PC programmable USB interface software - Windows XP, Vista, and 7 compatible.

No PC required - can be programmed at the unit

Built in display to view inputs, outputs and settings

Data logging built in (PC required to read and view data). All channels logged at 100 samples second. 25

second logging time.

Nitrous user settings stored in each data log for ease of recalling past nitrous settings.

Free software updates (PC and Internet access required)