Watts OneFlow OFTWH-R User manual

Watts-Oneflow.com

OneFlow®

OFTWH-R, OFTWH

Innovative Scale Control

Installation manual

Installation and Operation Manual

UK

OFTWH-R

OFTWH

2OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

Index

1. Introduction .................................................................................................................................................................................... 3

2. System Specifications........................................................................................................................................................... 3

2.1 Feed Water Chemistry Requirements

3. Installation ........................................................................................................................................................................................ 4

3.1 Installation Precautions

3.2 Installation

4. Operation........................................................................................................................................................................................... 5

5. Maintenance ................................................................................................................................................................................... 5

5.1 Cartridge change frequency

5.2 Replacement cartridges

6. Dimensions ...................................................................................................................................................................................... 7

WARNING!

WARNING!

It is recommended that all personnel responsible for

operation and maintenance of this product read all

installation instructions and product safety information

thoroughly before beginning the installation of this product

to ensure the best possible installation. Failure to read

and follow all safety and use information can result in

serious personal injury, property damage, or damage to

the equipment. This manual contains important operation,

maintenance and precautionary information. Please retain

this manual for future reference for parts, maintenance or

troubleshooting and present this manual to user/operator/

owner after installation.

The OneFlow®system is built with the finest and most

advanced materials and each system is quality inspected

and pressure tested prior to shipment. With proper

installation and routine maintenance, you will have years of

trouble-free operation.

Please refer to this manual when performing routine

cartridge changes. The instructions make periodic

maintenance quick and easy and ensure you will receive

maximum benefit from your system.

3

OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding. Watts Industries reserves the right to carry out

any technical and design improvements to its products without prior notice. Warranty: All sales and contracts for sale are expressly conditioned on the buyer’s assent to Watts terms and

conditions found on its website at www.wattswater.eu. Watts hereby objects to any term, different from or additional to Watts terms, contained in any buyer communication in any form,

unless agreed to in a writing signed by an officer of Watts.

1. Introduction

The OneFlow®Innovative Scale Control System provides

protection from hard scale formation on internal plumbing

surfaces. The OneFlow®system is a single cartridge-based

system that must be installed on a cold water line prior to a

single water heating device (water heater or tankless water

heater) that requires protection from the ill effects of hard water.

OneFlow®uses template assisted crystallization (T.A.C.) to

attract hardness minerals and convert them into harmless,

inactive microscopic crystal particles. These crystals stay

suspended in the water and are passed to drain. The system

requires very little maintenance, no backwashing, no salt and

no electricity. Typical hardness problems, especially build-up of

scale in heating elements, pipes, water heaters, boilers are no

longer a concern. OneFlow®is not a water softener. It does not

need additional chemicals. It is a hard scale prevention device

with proven third party laboratory test data and years of suc-

cessful commercial, residential and foodservice applications.

OneFlow®is the intelligent scale solution and is a great alterna-

tive to water softening or scale sequestering devices.

OFTWH-R - OFTWH

• OneFlow®converts hardness minerals to harmless,

inactive microscopic crystals making OneFlow®an effective

alternative to water softeners

• Virtually maintenance free - No salt bags or other chemicals

required

• No energy consumption (different compared to other scale

control technologies)

• Contributes to reduce water and electric consumption, no

control valve needed

• Innovative technology with an enhanced respect of the

environment, salt free, without additional chemicals

• Improves efficiency of all water heating devices and down-

stream plumbing components

• Simple sizing & installation – standard 3/4” connections

• Perfect solution for homes where equipment protection

is desired for longer equipment life and reduced energy

consumption

• OneFlow®cartridge-based systems are easily maintained;

change the TAC cartridge once every two years

• Mounting bracket and wrench for cartridge change-outs

included

* Exceeding maximum flow can reduce effectiveness and void

warranty. Pressure drop at peak flow rate is less than 1 bar at

27°C feed water.

** This system is delivered with 3/4” fittings.

*** See more information on our website: www.watts-oneflow.com

2. System Specifications

Inlet/outlet connections: 3⁄4" BSP threaded fittings

Peak flow rate OFTWH-R up to 23l/min

Peak flow rate OFTWH up to 38l/min

Flow capacity (continuous flow rate):

OFTWH-R up to 15,2Lit/min, 24/7/365 for 2 years for the

OFTWH-R-RM cartridge

OFTWH up to 22,7Lit/min, 24/7/365 for 2 years for the

OFTWH-RM cartridge

Maximum pressure: 90psi / 6.2 bar

Maximum temperature: 38°C

Minimum temperature: 5°C

Weight: OFTWH = 6,2Kg | OFTWH-R = 5,7Kg

Capacity: OFTWH-R-RM and OFTWH-RM cartridges do not

have a grain removal capacity, however, other elements present

in the water will gradually degrade the effectiveness of the car-

tridge. Change the OFTWH-R-RM and OFTWH-RM cartridges

at least once every two years.

A OneFlow®Innovative Scale Control system shall be installed on

the cold water service line to condition the tap water just prior to

the service line feeding the equipment it is designed to protect.

The system will be sized for maximum or peak flow rate based

on the specification of said equipment. A OneFlow®system may

also be installed to protect multiple pieces of equipment from

the ill-effects of hard water scale provided the aggregate peak

flow rate for each piece of equipment it is protecting has been

considered. The system shall be plumbed with a bypass valve to

allow isolation of filter housing to allow the bypass of untreated

water in the event that service or cartridge replacement be nec-

essary. Bypass is recommended but not required. The installa-

tion area should be suitable in size for the housing to be serviced

without encumbrance. The OneFlow®system does not require

additional water to backwash, flush, or regenerate once put into

service. The system shall not require any chemical additives and

shall not require electricity for operation.

4OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding. Watts Industries reserves the right to carry

out any technical and design improvements to its products without prior notice. Warranty: All sales and contracts for sale are expressly conditioned on the buyer’s assent to Watts terms

and conditions found on its website at www.wattswater.eu. Watts hereby objects to any term, different from or additional to Watts terms, contained in any buyer communication in any

form, unless agreed to in a writing signed by an officer of Watts.

All these water chemistry requirements are corresponding to

the average parameters of the water delivered usually, please

contact your water supplier or local autorities in order to confirm

the compliance.

Notice

* Systems using OneFlow®technology are effective at control-

ling limescale formation inside the plumbing system at influ-

ent hardness levels up to 427mg per liter (28.8°D, 51.3°F) of

calcium carbonate. Due to variances in water chemistry,

427mg per liter is a recommended hardness maximum due

to potential aesthetic issues related to soft scale residue

formation outside the plumbing system. Testing should be

performed to determine proper application where hardness

levels exceed 427mg per liter.

** Just as with conventional water softening media, OneFlow®

media needs to be protected from excess levels of certain met-

als that can easily coat the active surface, reducing its effective-

ness over time. Public water supplies rarely, if ever, present a

problem, but if the water supply is from a private well, confirm

that the levels of iron (Fe) and manganese (Mn) are less than 0.3

mg/l and 0.05 mg/l, respectively.

Notice

† OneFlow®media does not reduce silica scaling. While silica

tends to have a less significant effect on scale formation than

other minerals, it can act as a binder that makes water spots

and scale residue outside the plumbing system difficult to

remove. This 20 mg/l limitation is for aesthetic purposes.

†† All other water contaminants must meet the requirements of

the local water control agency of each specific country where

OneFlow®is sold and installed. Specific Mineral and Metal

Maximum Contaminants Level’s, identified in the above Feed

Water Chemistry Requirements list, supersedes those require-

ments. Water known to have heavy loads of dirt and debris may

require a pre-filtration prior to OneFlow®.

2.1 Feed Water Chemistry Requirements

pH 6.5-8.5

Hardness (maximum) 427 mg/l CaCO3 (28,8°dH, 51,3°fH)*

Water Pressure 1.03 - 6.2 bar

Temperature 5 - 38°C

Free Chlorine <2 mg/l

Iron (maximum) 0.3 mg/l**

Manganese (maximum) 0.05 mg/l**

Copper 1.3 mg/l

Oil & H2S Must be Removed

Total Phosphates < 3.0 mg/l

Silica (maximum) 20 mg/l

†

TDS 1500 mg/l

††

3. Installation

3.1 Installation Precautions

You are required to consult the local and state building and

plumbing codes and regulations prior to installation. If the

information in this manual is not consistent with local building

or plumbing codes, the local codes should be followed. Inquire

with governing authorities for additional local requirements.

Periodic inspection and yearly maintenance by a licensed

contractor is required. Corrosive water conditions and/or

unauthorized adjustments or repair could render OneFlow®

ineffective for service intended. Regular checking and cleaning

of the device’s internal components helps assure maximum

life and proper product function. Frequency of cleaning and

inspection depends upon local water conditions.

• Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system

• Connect system ONLY to COLD water supply. Water

temperature cannot exceed 38°C. Do NOT install system

on HOT water line. Failure to limit line temperature to

38°C may result in housing failure and damage.

• Do NOT allow system to freeze. Turn off water supply to

housing and drain housing if temperature falls below 5°C.

• Please provide a shut-off valve before and after the

OneFlow®device so it can be isolated for maintenance

at all times.

• Do NOT install system in direct sunlight or where system

is exposed to harsh chemicals or may be subjected to

being struck by moving equipment, carts, mops or any

other item that may cause damage.

• Do NOT mount the OneFlow system near any source of

heat or above any device or area that would be adversely

effected by water.

• Do NOT install system with pressure above 6.2 bar.

• Do NOT install the system backwards with the feed water

line connected to the outlet. The direction of flow through

the OneFlow unit is always Through the inlet first; keep

this in mind when determining installation location.

• The device should be installed in an upright and level

position, with both inlet and outlet connections in a hori-

zontal position.

• We do not recommend to apply any other antiscalants

before or after OneFlow.

• Do NOT use liquid pipe compounds for fitting connec-

tions 3/4”MBSP. Use two to three wraps of PTFE tape.

SOFT SCALE SPOTTING

Depending on hardness of the water, soft scale spotting

may occur on external plumbing surface. But in most

cases, these spots can be easily wiped down with a

damp cloth and will not form hard scale deposits.

5

OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding. Watts Industries reserves the right to carry out

any technical and design improvements to its products without prior notice. Warranty: All sales and contracts for sale are expressly conditioned on the buyer’s assent to Watts terms and

conditions found on its website at www.wattswater.eu. Watts hereby objects to any term, different from or additional to Watts terms, contained in any buyer communication in any form,

unless agreed to in a writing signed by an officer of Watts.

• Do NOT solder plumbing connections attached to filter

housing will be damaged by high temperature.

• Do NOT overtighten fitting connections into housing outlet.

• Always back-up valves and fittings with a wrench when

installing a fitting to avoid turning the valve.

• Position the OneFlow unit in a suitable location.

• ALLOW a minimum of 8 to 10 cm under the housing to

allow for filter replacement.

• Do NOT install the unit behind equipment where it may be

difficult to access the system for filter replacement.

• If water hammer is evident, install water hammer arrestors

before the OneFlow unit.

WARNING!

Installation with copper (Cu)

*** We do not recommend to install OneFlow®with new cop-

per pipes or devices. Excessive copper levels can foul the

OneFlow®media. If NEW copper lines or devices had been

installed, they need to be passivated for a minimum of 4 weeks

before placing the device into service.

WARNING!

Closed systems/still water

Avoid use in closed circuits (eg hydronic systems) and low

flow installations or standing water (max. 72 to 120 hours,

depending on the quality of the incoming water).

• Do not apply any other antiscalants before or after OneFlow®.

• You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual

is not consistent with local building or plumbing codes,

the local codes should be followed. Inquire with governing

authorities for additional local requirements.

• Need for periodic inspection and yearly maintenance:

Periodic inspection and yearly maintenance by a licensed

contractor is required. Corrosive water conditions and/or

unauthorized adjustments or repair could render the device

ineffective for service intended. Regular checking and clean-

ing of the devices internal components and check stops

helps assure maximum life and proper product function.

Frequency of cleaning and inspection depends upon local

water conditions.

3.2 Installation instructions

1. Close the water system. Turn off all equipment to be fed by

the OneFlow®System.

2. Determine if the water line has an existing water treatment

system. If so, examine system for use of polyphosphate or

other scale inhibitors. OneFlow®will not be effective if used

in conjunction with other scale inhibitors. Remove the scale

inhibitors from the water line or discontinue installation.

www.watts-oneflow.com/register

4. Operation

With sufficient pressure, operation of the Watts OneFlow®

System is completely automatic. Dependable operation involves

only periodic cartridge changes and service documentation.

3. Drill the wall and insert the dowels. Screw the bracket tightly to

the wall. The system must be vertical and upright.

4. Remove the OneFlow®housing shell from the housing cap and

make sure that the O-ring is correctly in place. When attaching

the shell back to the cap, make certain the O-ring is properly

positioned.

5. Connect OneFlow®by using PTFE tape. Use two to three

wraps of PTFE tape on the fitting connection.

6. Run a suitable line from the 3/4” full-flow ball valve at the

tap water source to the inlet ball valve on the left side of the

OneFlow®system. Use 2-3 wraps of PTFE tape and brace the

inlet ball valve on the system with a wrench when connecting

7. Select the appropriate size tubing for the equipment being

fed and connect it to the outlet of the OneFlow®System.

NOTE: DO NOT connect the tubing to the equipment at this

time. Prior to making connection to the equipment, this line

will be used to facilitate flushing the system. As an option,

a drain valve in a tee on the outlet side of the OneFlow®

system could be provided in the line to facilitate flushing when

changing cartridges.

8. With OneFlow®inlet valve closed, slowly open the 3/4” full-flow

ball valve at the tap water source. Check for leaks.

9. If a drain valve was not installed on the outlet side of the

system, hold the tubing that will connect to equipment in a

clean bucket or over sink or drain. Open the system inlet feed

valve and allow water to flush through system for 2 minutes at

the specified system flow rate to allow air bubbles to escape.

NOTE: NO ACTIVATION IS REQUIRED FOR THE OneFlow®

SYSTEM TO PERFORM PROPERLY. FLUSHING IS

RECOMMENDED TO ALLOW AIR TO ESCAPE THE SYSTEM.

10. Make certain that the end of the tubing to be connected

to the equipment is clean and sanitary.

11. Connect tubing to equipment. Open all water supply valves

and check for leaks.

12. If no leaks, turn on equipment and check for normal operation.

13. Register the OneFlow®system to ensure proper operation.

6OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding. Watts Industries reserves the right to carry

out any technical and design improvements to its products without prior notice. Warranty: All sales and contracts for sale are expressly conditioned on the buyer’s assent to Watts terms

and conditions found on its website at www.wattswater.eu. Watts hereby objects to any term, different from or additional to Watts terms, contained in any buyer communication in any

form, unless agreed to in a writing signed by an officer of Watts.

5. Maintenance

Routine maintenance of your OneFlow®system involves periodic

cartridge changes and/or replacement of sump O-rings.

If the system sizing recommendations have been followed,

the OneFlow®cartridge should last two years.

5.1 Cartridge change frequency

The cartridges should be changed in response to the following

conditions.

OFTWH-R-RM • 24 months since installation or last cartridge

change.

OFTWH-RM • 24 months since installation or last cartridge change.

5.2 Replacement cartridges

OneFlow®systems can only be used with OneFlow®filter

cartridges. Use of replacement cartridges other than those

specified will void warranties, certifications and may compromise

equipment protection, water quality and equipment life.

Cartridge replacement procedure

1. IMPORTANT: All other equipment connected to the OneFlow®

system must be turned off prior to shutting off water supply

from filters.

2. Release pressure by turning the black screwable plastic swivel

button identified by the “VENT” sign (H).

3. Turn OFF water to OneFlow®system by closing

inlet ball valve.

4. Remove housing – use cartridge wrench if necessary.

5. Remove cartridge from housing. Clean inside of housing with

warm water. If desired, disinfect housing by adding a teaspoon

of household bleach to housing, fill with water, let stand for 5

minutes, and then discard.

6. Insert new cartridge into the housing. Match cartridge model

number to model number on bracket.

7. Check O-ring (E) for damage and replace if damaged or

distorted. Make certain the O-ring is properly positioned and

reinstall filter housing (hand tighten only).

8. Slightly open the inlet ball valve; open the pressure relief

swivel (H) to release trapped air until a small amount of water

comes out – close the pressure relief button and fully open

the ball valve.

9. VERY IMPORTANT: With water supply inlet valve OPEN and

water flow confirmed, turn on connected equipment. Failure to

supply water to equipment may cause serious damage.

Parts of OneFlow®OFTWH / OFTWH-R

Drawing ID Description

A Mounting Screws

B Mounting bracket

C Housing cap

D Replacement Cartridge

E O-Ring

F Housing shell

G Cartridge wrench

H Pressure relief screw

A

B

C

D

E

F

G

H

7

OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1

Watts Water Technologies, Inc.

UK

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding. Watts Industries reserves the right to carry out

any technical and design improvements to its products without prior notice. Warranty: All sales and contracts for sale are expressly conditioned on the buyer’s assent to Watts terms and

conditions found on its website at www.wattswater.eu. Watts hereby objects to any term, different from or additional to Watts terms, contained in any buyer communication in any form,

unless agreed to in a writing signed by an officer of Watts.

NOTICE

Please allow additional clearance above the device for making connections and replace the cartridge.

6. Dimensions

192

723

108

164

189

100

142

150

100

624

OFTWH_OFTWH-R_IT_IOM_UK_02_21_Rev1 © 2021 Watts

Guarantee

Watts products are thoroughly tested. The said guarantee covers solely replacement or – at the full

sole discretion of WATTS - repair, free of charge, of those components of the goods supplied which

in the sole view of Watts present proven manufacturing defects. The period of limitation for claims

based on defects and defects in title is two years from delivery/the passage of risk. This warranty

excludes any damage due to normal product usage or friction and does not include any modified or

unauthorized repair for which Watts will not accept any request for damage (either direct or indirect)

compensation (for full details see our website). All sales subject to the Watts terms to be found on

www.wattswater.eu

UK

CONTACTS

Austria, Germany, Switzerland

Watts Industries Deutschland GmbH

Godramsteiner Hauptstr. 167

76829 Landau

Germany

tel.: +49 (0) 6341 9656 0

fax: +49 (0) 6341 9656 560

www.wattswater.de

Belgium-The Netherlands-Luxemburg

Watts Benelux

Beernemsteenweg 77A

8750 Wingene; Belgium

tel: +32 51658708

fax: +32 51658720

www.wattswater.eu

Denmark, Sweden, Finland, Norway

Watts Industries Nordic AB

Godthaabsvej 83

8660 Skanderborg, Denmark

tel.: + 45 86 52 00 32

www.wattswater.eu

France

WATTS INDUSTRIES France

1590 avenue d’Orange CS 10101 SORGUES

84275 VEDENE cedex - (France)

tel.: +33 (0)4 90 33 28 28

fax: +33 (0)4 90 33 28 29/39

Italy

Watts Industries Italia S.r.l.

Via Brenno, 21

20853 Biassono (MB) - Italy

tel.: +39 039 4986.1

fax: +39 039 4986.222

www.wattswater.it

Poland

Watts Industries Polska sp.z o.o.

ul.Puławska 40A

05-500 Piaseczno

tel.: + 48 22 702 68 60

fax: + 48 22 702 68 61

www.wattswater.pl

Spain

Watts Ind. Ibérica, S.A.

Pol. Ind. La Llana - Av. La Llana, 85

08191 Rubí (Barcelona)

Spain

tel.: +34 902 431 074

fax: +34 902 431 075

www.wattswater.es

UK

Watts Industries UK Ltd

Colmworth Business Park

Eaton Socon

St. Neots

PE19 8YX

United Kingdom

tel.: +44 (0) 1480 407074

fax: +44 (0) 1480 407076

www.wattswater.eu

Russia

Customer service

Alexey Muratov

Mob.phone: +7 495 920 14 75

www.wattsindustries.ru

Other manuals for OneFlow OFTWH-R

1

This manual suits for next models

1

Table of contents

Other Watts Control System manuals

Popular Control System manuals by other brands

Motorisation+

Motorisation+ X-TRA4 Instructions and warnings for installation and use

Measurement Computing

Measurement Computing CIO-DAS1401/12 user manual

Gilderfluke

Gilderfluke Br-miniBrick4 manual

resideo

resideo VR8205 installation instructions

Invertek Drives

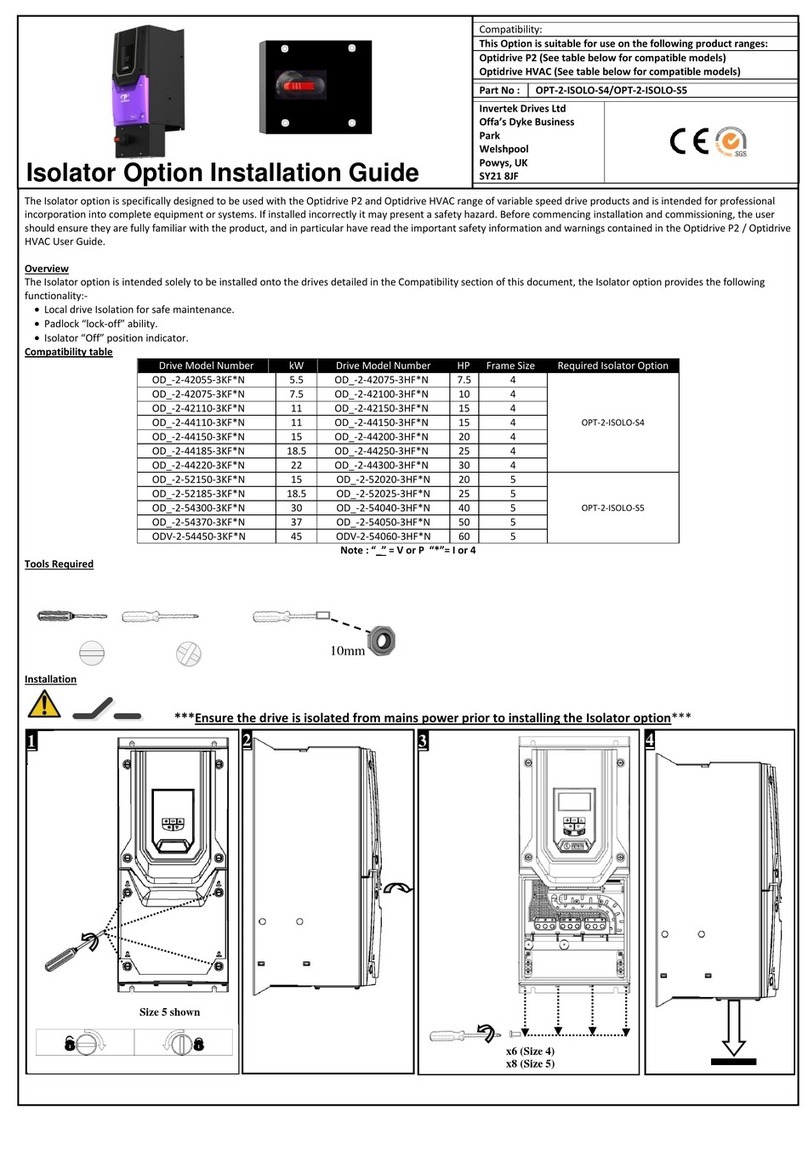

Invertek Drives OPT-2-ISOLO-S4 installation guide

Magnetic

Magnetic MHTM MicroDrive Access XL2 operating instructions