Linkoln Electric EASYTOME 1020 Mounting instructions

CUTTING MACHINE

EASYTOME

1020-1515-1530-2040

MACHINE N°

W000379055 - W000379056 - W000379057 - W000379058 -

W000379059 - W000379060 - W000379061 - W000379062

SAFETY INSTRUCTIONS FOR USE AND MAINTENANCE

EASYTOME ESSENTIAL

1530

MACHINE N°

W000400274 - W000400273

SAFETY INSTRUCTIONS FOR USE AND MAINTENANCE

EDITION : EN Instructions for use REF : 8695 4387

REVISION : H

DATE : 10-2018 Original instructions

Thank for the trust you have expressed by purchasing this equipment, which

will give you full satisfaction if you follow its instructions for use and

maintenance.

Its design, component specifications and workmanship comply with

applicable European directives.

Please refer to the enclosed CE declaration to identify the directives

applicable to it.

The manufacturer will not be held responsible where items not recommended

by themselves are associated with this product.

For your safety,there follows a non-restrictive list of recommendations or

requirements, many of which appear in the employment code.

Finally we would ask you kindly to inform your supplier of any error which

you may find in this instruction manual.

8695 4387

EASYTOME I

CONTENTS

A - IDENTIFICATION .........................................................................................................................1

B - SAFETY RULES...........................................................................................................................2

1 - AIRBORNE NOISE .............................................................................................................2

2 - SPECIAL SAFETY RULES.................................................................................................4

C - DESCRIPTION .............................................................................................................................5

1 - MECHANICAL ASSEMBLY................................................................................................5

2 - CUTTING TABLE................................................................................................................6

3 - POWER SYSTEMS ............................................................................................................6

4 - CONSOLE...........................................................................................................................6

5 - PLASMA SYSTEM..............................................................................................................7

6 - LIMIT OF SUPPLY..............................................................................................................7

7 - OPTIONAL..........................................................................................................................7

D - ASSEMBLY AND INSTALLATION..............................................................................................8

1 - CONDITIONS OF INSTALLATION.....................................................................................8

2 - ARRANGEMENT OF CABLES AND HOSES.....................................................................8

3 - PREPARING THE FLOOR .................................................................................................9

4 - PUTTING THE MACHINE IN PLACE.................................................................................10

5 - PLACING THE MACHINE...................................................................................................11

6 - ELECTRICAL AND FLUIDIC CONNECTION.....................................................................11

7 - REMOVAL AND DISASSEMBLY........................................................................................13

E - OPERATOR MANUAL.................................................................................................................14

1 - DESCRIPTION OF CONTROLS VERSION EASYTOME ...................................................14

2 - DESCRIPTION OF CONTROLS VERSION EASYTOME ESSENTIAL...............................15

3 - STARTING UP....................................................................................................................16

4 - STOPPING THE MACHINE................................................................................................16

5 - USING THE MACHINE.......................................................................................................17

F - USE OF THE PLASMA SYSTEM.................................................................................................18

1 - CUTTING TO A PROGRAM: SIMPLIFIED PROCEDURE.................................................18

2 - USE OF NERTAJET 40i ......................................................................................................22

3 - CONSUMABLES FOR TORCH OCP100 ...........................................................................23

4 - CUTTING PARAMETERS ..................................................................................................24

5 - USE OF FLEXCUT 125 CE LC125M ..................................................................................24

6 - CONSUMABLES FOR TORCH LC125M ...........................................................................24

7 -USEFUL INFORMATION FOR ADJUSTING THE PARAMETERS ..................................25

8 - RECOMMENDATIONS FOR START AND END PORTIONS............................................27

G - MAINTENANCE...........................................................................................................................29

1 - SERVICING.........................................................................................................................29

2 - SPARE PARTS EASYTOME...............................................................................................31

3 - SPARE PARTS EASYTOME ESSENTIAL...........................................................................33

4 - BLOCK DIAGRAM ..............................................................................................................34

5 - PNEUMATIC DIAGRAM .....................................................................................................35

PERSONAL NOTES ..........................................................................................................................36

8695 4387

II EASYTOME

INFORMATIONS

DISPLAYS AND PRESSURE GAUGES

The measuring devices or displays for voltage, current, speed, pressure, etc., whether analog or digital, should be

considered as indicators.

REVISIONS

REVISION H 10/18

DESIGNATION

PAGE

Created in English

8695 4387 / H

EASYTOME A-1

A - IDENTIFICATION

Please report the registration number of your appliance in the table here below.

Please provide this information whenever you contact us.

1

Machine type

EASYTOME

2

year of manufacture

20xx

3

Serial number of the product

AFxxxxxxx

1

2

3

8695 4387 / H

B-2 EASYTOME

B - SAFETY RULES

General information: please refer to the document about the "SAFETY RULES" ref. 8695-7050

1 - AIRBORNE NOISE

1 - CERTIFICATION OF THE MEASURING SITE

The machine has been tested in the workshop in Pont Sainte Maxence:

5 place Chatelier

60700 PONT SAINTE MAXENCE

FRANCE

Qualification has been recorded in a report

n°17563386/1

2 - SOUND PRESSURE MEASUREMENT

The values are stated in weighted equivalent sound level (LAeq)

The measuring unit is dB (A): A-weighted decibel

The measurements were made 1.6 m away from the ground with a FUSION sound level meter, no 10925,

inspected by an approved laboratory (LNE).

3 - MEASUREMENTS (see next page)

8695 4387 / HB - SAFETY RULES

EASYTOME B-3

Refer to the special instructions supplied with the equipment.

FLEXCUT125CE

Measuring conditions

M1

M2

Intensity

85 A

125 A

Material

Carbon steel 8mm

Carbon steel 20mm

Gas

Compressed air

Compressed air

Leq. = Equivalent A-weighted acoustic pressure level

Lpc. = Peak acoustic pressure level

B - SAFETY RULES 8695 4387 / H

B-4 EASYTOME

2 - SPECIAL SAFETY RULES

MAINTENANCE CONDITIONS, CONDITIONS OF USE

No object is to be placed on the rolling tracks

For installation or maintenance operations, the operator must use the lifting eyes provided for that

purpose and shown on the drawing (see Handling section).

STABILITY

Do not climb on the cable drag chain.

Before handling plates, make sure that the safety of persons and property is protected.

The machine must be anchored to the floor (see layout paragraph).

Before using the machine, make sure that all the guards are in place.

No maintenance may be carried out on the machine when it is supplied with power.

Switch off the power source while changing the wearing parts of the torch if the plasma process is

being used.

CONDUCTING MAINTENANCE ON PIECES

The equipment for handling workpieces that have been or need to be cut is not part of the supply

and is to be provided by the customer. The customer must therefore take protective measures

appropriate for the equipment for handling the workpieces

CAUTION: While handling the metal plates to cut, take the necessary

precautions to avoid impacts on the machine and the rolling tracks.

Impacts on these elements could lead to squareness faults and

therefore unsatisfactory cutting.

8695 4387 / H

EASYTOME C-5

C - DESCRIPTION

Numerically controlled monobloc plasma cutting

machine that is particularly suited to industries that

use steel, stainless steel and aluminium.

The main intended applications are those of iron

workers, metal workers, air processing, air-

conditioning, ventilation, refractory industries,

workshops producing in small and medium runs or

support production.

The machine will be equipped with:

A plasma system with a NERTAJET 40i OCP

100 or FLEXCUT125 CE torch capable of cutting

steel, stainless steel and aluminium with air

NB: another plasma system may be used

providing it does not operate with HF.

Optional :

Possibility to add :

a pipe-cutting mandrel,

a micro-vibrations engraving marker

others on request

The NC system with the GALAAD drawing/tool

path software may also be connected to a

programming centre.

It is integrated into the control console.

Its compact dimensions make it easy to carry and

quick to install.

The extraction table incorporated into the machine

may be connected to any extraction and/or filtration

system.

1 - MECHANICAL ASSEMBLY

This is a monobloc machine that is made up of a

very rigid mechanically welded frame that is placed on

the floor on several feet.

The cross carriage is fitted on the beam. It is guided

by two slide rails and driven by a brushless(*) geared

motor and rack assembly.

The numerical tool holder has a 100 mm travel

range and is fitted with a step motor, with plate sensing

mounted on the carriage.

Two longitudinal guide assemblies are fitted to the

frame, each with a slide rail and reverse rack. Racks

are fitted to the rails to move the beam.

The high-speed feed speed of EASYTOME is :

- Step motor version : 20 m/min,

- Step motor version : 21 m/mn

The electrical control cabinet contains all the

electrical and electronic equipment for controlling the

machine and a turning numerical control console to

allow the operator to control the machine.

C - DESCRIPTION 8695 4387 / H

C-6 EASYTOME

2 - CUTTING TABLE

This is a mechanically welded box fastened to the

floor between the machine frame, with an outlet for

connection to an extraction system.

Depending on the machine model, the table may be

divided into several sections.

For this table, we recommend the use of extraction

with filtration that is suited to machine performance.

Thanks to its 750 mm height and rails incorporated

very close to the table, loading and unloading of parts

and plates is very easy.

One or more removable supporting frames are

placed on the box.

They have easily replaceable plate support irons.

On EASYTOME 1515/1530/2040, grating with a

50x50 mm(*) mesh hold the cut parts in the event of

scrap. They are replaceable.

Several slag boxes are provided at the back of the

table and are removable for cleaning.

3 - POWER SYSTEMS

The machine has a digital power system, using either step technology as regards EASYTOME Essential or

brushless technology as regards EASYTOME 1020/1515/1530/2040.

4 - CONSOLE

Version EASYTOME

Version EASYTOME Essential

The control console includes:

A touch screen in EASYTOME and a standard screen in EASYTOME Essential

One or more emergency stops

All the controls required for starting up

The drawing and tool path software for nesting simple parts or importing programs in the form of ISO

codes from nesting software such as MAGICNEST 01 or 10 installed on an outside station.

A manual machine movement interface

A plasma cycle control interface including a parameter database.

8695 4387 / HC - DESCRIPTION

EASYTOME C-7

5 - PLASMA SYSTEM

The machine has a NERTAJET 40i plasma cutting system with an OCP100 plasma torch or a FLEXCUT125CE

with an LC125M plasma torch

That system mainly allows cutting steel, stainless steel and aluminium.

Cutting capacity:

N40i OCP100 : 12 mm production piercing, 20 mm maximum piercing, 40 mm start at the end of a

plate

FLEXCUT125CE LC125M : 25 mm production piercing, 30 mm maximum piercing, 45 mm start at

the end of a plate

Another type of plasma system may be incorporated providing it operates without high frequency.

Please refer to the safety, operating and maintenance instructions of each component, namely:

Power source: 8695 1169: NERTAJET 40i (PRESTOJET 4C)

Torch: 8695 1205: OCP100

Power source: IM10375 : FLEXCUT125CE

6 - LIMIT OF SUPPLY

The customer must supply and install a device on each source for

isolating it. The devices must be clearly identified. They must be

lockable in accordance with standard EN 60204-1.

Lincoln Electric offers the following additional items with the machine :

Table air pipe

W000010073

ARG.WLD.HOSE D10x16 40M

W000290896

BAG 10 COLLAR D10

Table/customer earth equipotential bonding cable

W000260272

WELDING CABLE H01N2D 16MM 2

W000010094

Screw lug, diam 11mm - 0-25mm2

7 - OPTIONAL

Refer to the enclosed instructions of the corresponding option :

Optional extraction fan.

Optional extraction filter : ESSENTIAL 2CD, 4CD or 6CD depending on the machine model.

Optional disconnecting elements: electrical cabinet

8695 4387 / H

D-8 EASYTOME

D - ASSEMBLY AND INSTALLATION

1 - CONDITIONS OF INSTALLATION

THE LAYOUT OF THE INSTALLATION MUST COMPLY WITH SAFETY STANDARD NF EN 547 -

1 -3 TO ENSURE PERSONAL PROTECTION

THE FOLLOWING CONDITIONS MUST BE COMPLIED

WITH BEFORE INSTALLING THE EQUIPMENT

ELECTRICITY SUPPLY

VERY IMPORTANT

For compliance with European safety standards, the connection to the electricity supply is to be

made via a wall-mounted cabinet with an individual protective sectioning switch with rating

appropriate for the mains voltage and the consumption by the devices.

The protective disconnector must offer breaking capacity of 100KA

We market cabinets that meet these criteria.

POWER CONSUMPTION

EASYTOME and EASYTOME Essential

230V 5A

NERTAJET 40i- OCP 100

400V 25.2A

FLEXCUT 125 CE - LC125M

400V 40A

PNEUMATIC SUPPLY

Provide a source of compressed air with a regulator that can supply the required flow

and pressure. The air must be clean, de-oiled and degreased.

Supply pressure values

of the system

Max. flow rate used

in m3/h

Extraction table

5 bar +/- 0,5

5

NERTAJET 40i OCP 100

7 Bar +/-0,5

13 (220 l/min)

FLEXCUT 125 CE - LC125M

6,21 to 8,27 bar

15,6 (260 l/min)

2 - ARRANGEMENT OF CABLES AND HOSES

The customer must provide the means to support and protect cables and hoses from

mechanical, chemical or thermal damage from their source up to the entrance to the cable drag

chain.

8695 4387 / HD - ASSEMBLY AND INSTALLATION

EASYTOME D-9

3 - PREPARING THE FLOOR

The installation of EASYTOME does not require any particular preparation of the floor.

However, we recommend clean concrete, so as to ensure that the machine is stable.

The machine location must follow the standard layout recommendations of the machine,

as given in drawing W000379245. Here is an excerpt:

D - ASSEMBLY AND INSTALLATION 8695 4387 / H

D-10 EASYTOME

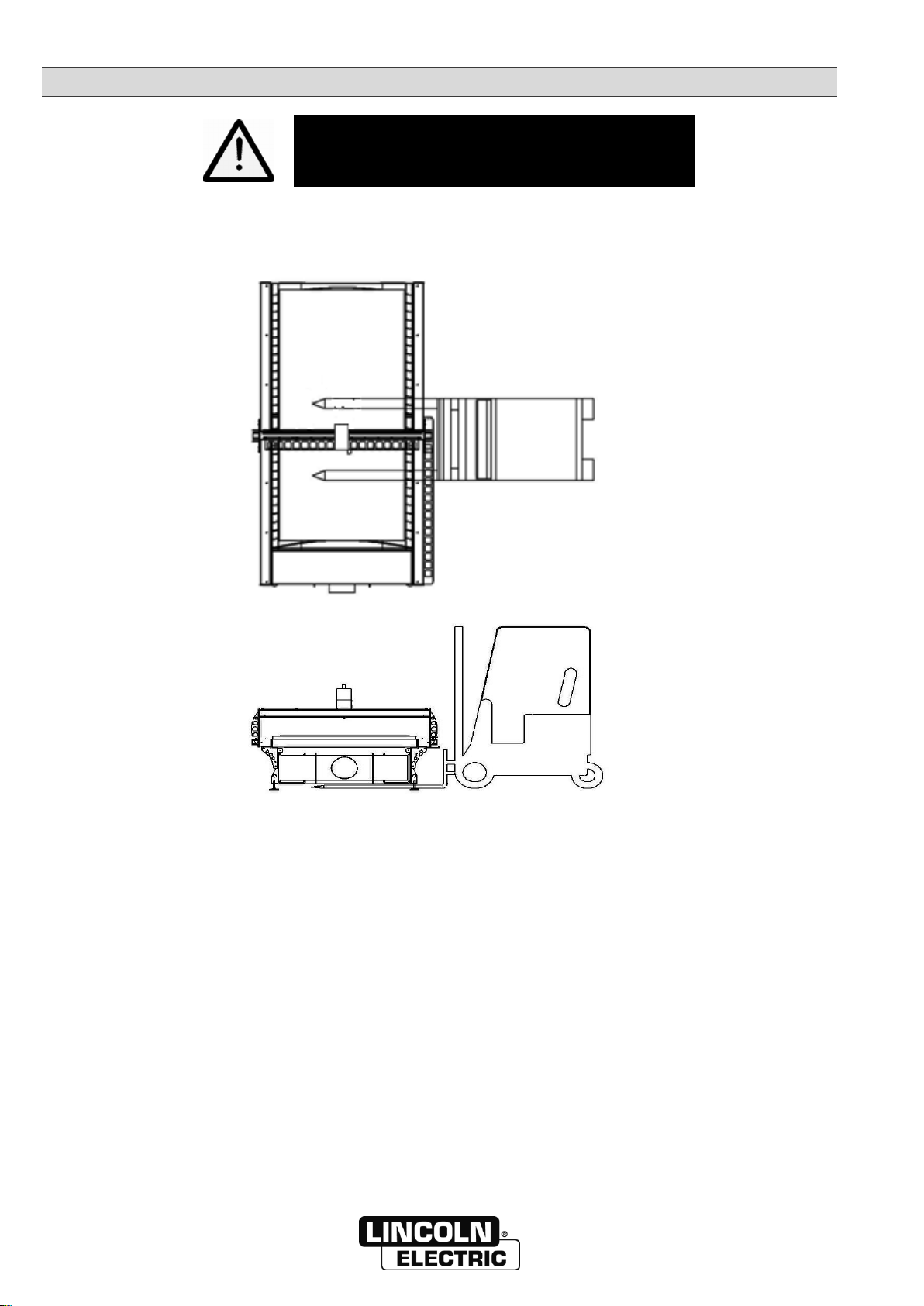

4 - PUTTING THE MACHINE IN PLACE

Operator protection:

Helmet - Gloves - Safety shoes

The machine and the cutting table are

transported simultaneously

The components of the system may only be transported

using the lifting points provided, with appropriate equipment

Machine

Weight

W000379055

EASYTOME 1020 CNC LEFT

1000 Kg

W000379056

EASYTOME 1020 CNC RIGHT

1000 Kg

W000379057

EASYTOME 1515 CNC LEFT

1000 Kg

W000379058

EASYTOME 1515 CNC RIGHT

1000 Kg

W000379059

EASYTOME 1530 CNC LEFT

1700 Kg

W000379060

EASYTOME 1530 CNC RIGHT

1700 Kg

W000379061

EASYTOME 2040 CNC LEFT

2100 Kg

W000379062

EASYTOME 2040 CNC RIGHT

2100 Kg

W000400273

EASYTOME Essential 1020

1000 Kg

W000400274

EASYTOME Essential 1530

1200 Kg

8695 4387 / HD - ASSEMBLY AND INSTALLATION

EASYTOME D-11

5 - PLACING THE MACHINE

The machine must be placed in the workshop in accordance with the recommendations of the layout

drawing W000379245.

Adjust the horizontality of the machine in both planes with a level offering precision to 1/10th of a metre

using the feet.

The low inertia of the machine means that it does not have to be fastened.

However, if you do want to fasten it, the feet have holes for that purpose

6 - ELECTRICAL AND FLUIDIC CONNECTION

Electrical:

Lincoln Electric recommends using electrical connectors according to the recommendations in the layout drawing

W000379245. Excerpt:

Supply by the customer of the three power supplies + earth 5 Ohms max

Machine:

2.5 KVA 220/230V

Single-phase wall socket

Power source:

-25.2A/400V (N40i)

- 40A/400V (FLEXCUT125CE)

Three-phase wall socket

Building earth

5 Ohms max

Examples of wall sockets to use:

Three phase 400V

Single phase

230V

D - ASSEMBLY AND INSTALLATION 8695 4387 / H

D-12 EASYTOME

Equipotential bonding:

Caution! The machine requires equipotential bonding between the table and the earth of the customer’s building.

LINCOLN ELECTRIC supplies the required connection:

W000260272

WELDING CABLE H01N2D 16MM 2

W000010094

Screw lug, diam 11mm - 0-25mm2

The machine table may be made up of several modules. Make sure that an equipotential cable is connected

between the different modules.

Schematic diagram of the equipotential connection:

Pneumatic:

Lincoln Electric recommends the supply of pneumatic supplies as recommended in the layout drawing

W000379245. Excerpt:

System air

Dry and oil free air

Hose connector Ø 10

Hose connector Ø 6

Table

5m3/h

7bar ±0,5

Nertajet 40i: 13 m3/h or 220 l/min, 7bar ±1

FLEXCUT125CE, 15,6 m3/h (260 l/min), 6,21 to 8,27 bar

The valves must be lockable with venting on all feeders.

Filter and extraction connections: please refer to the corresponding instructions

Equipotential link

Equipotential cable

table modules

Plasma

_

+

Building

earth 5 ohms

max

8695 4387 / HD - ASSEMBLY AND INSTALLATION

EASYTOME D-13

Caution! For any work on the machine, you must disconnect the elements separately: machine, power source and

filter.

A warning label on the supply points of the different components and the different components that are supplied

warns of the hazard:

7 -REMOVAL AND DISASSEMBLY

Please enquire with LINCOLN ELECTRIC

Caution! The machine, the extraction system and the power

source are powered separately.

Before any work, make sure that their power supplies have

been switched off.

8695 4387 / H

E-14 EASYTOME

E - OPERATOR MANUAL

1 - DESCRIPTION OF CONTROLS VERSION EASYTOME

The disconnector on the electrical cabinet of

EASYTOME controls the power supply to the machine.

The console has:

A touchscreen

An electrical safety circuit reset switch (green)

Two emergency stop buttons

PC starting up button

Remote buttons for starting up extraction

Keyboard and tactile mouse for programming

and using the machine

USB port

USB port

Electrical safety reset

Emergency stop

PC start

Remote controls for fume

extraction:

Manual or auto mode

Manual operation

Manual stop

Emergency stop

Touch mouse keyboard for

machine programming and

use

8695 4387 / HE - OPERATOR MANUAL

EASYTOME E-15

2 - DESCRIPTION OF CONTROLS VERSION EASYTOME ESSENTIAL

The disconnector on the side of the console of

’EASYTOME Essential controls the power supply to the

machine.

The console has:

A standard screen

An electrical safety circuit reset switch (green)

One emergency stop button

PC starting up button

Remote buttons for starting up extraction

Keyboard and mouse for programming and

using the machine

USB port

On the side of the

machine console (right or

left depending on machine

layout):

Main electric

disconnector

Electrical safety

circuit reset button

USB port

Remote controls for fume

extraction:

Manual or auto mode

Manual operation

Manual stop

Emergency stop

Keyboard and mouse for

machine programming and

use

E - OPERATOR MANUAL 8695 4387 / H

E-16 EASYTOME

3 - STARTING UP

Procedure for the machine

Turn the disconnector of the electrical cabinet

Press the Start PC button

Press and hold down the green reset button

Procedure for the extraction system

NB: the remote controls must be connected to the extraction control unit (optional service from the fitter)

Select the manual or automatic mode

Manual mode: extraction starts when the manual On button is pressed

Automatic mode: extraction starts automatically at the start of the automatic cutting cycle of the program

4 - STOPPING THE MACHINE

Procedure for the machine

Use the emergency stop button

Use the On/Off button or the Windows shutdown button on the PC

When the PC has shut down, turn the disconnector of the electrical cabinet

Procedure for the extraction system

Manual mode: extraction stops when the manual Off button is pressed

Automatic mode: extraction stops automatically at the end of the automatic cutting cycle of the program

If the operator is away for an extended period of time or if any work is done on the cutting tools, the energy

supplies must absolutely by shut off

Caution! The rotary switch on electrical cabinet only isolates the gantry machine,

but not the plasma cutting process or the extraction system

This manual suits for next models

11

Table of contents