Model

J250

Mulli

~

woodcutting machine

I~STRucnoN

MANUAL

Electrical

wiring

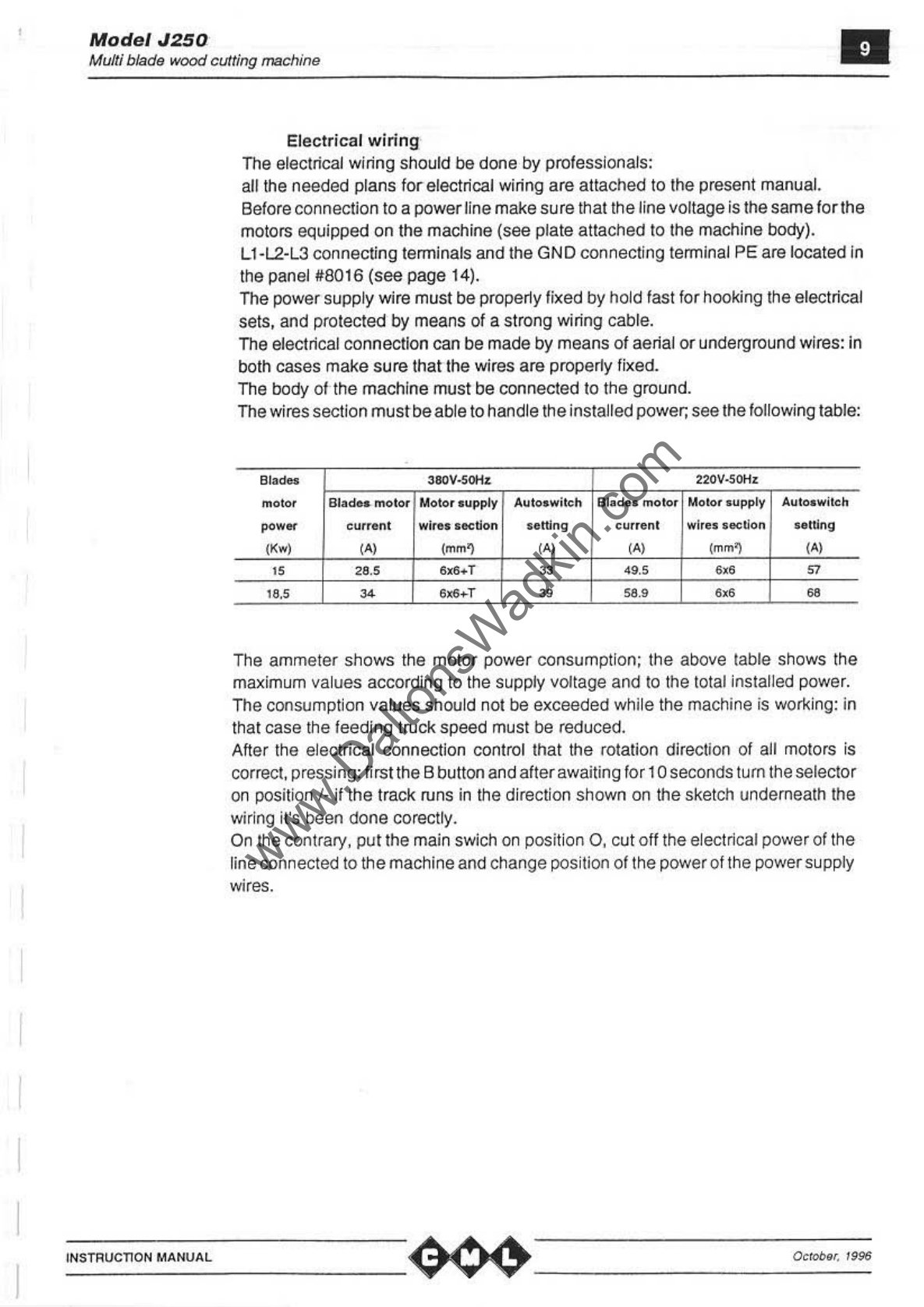

The electrical wiring should be done

by

professionals:

all the needed plans for electrical wiring are attached to the present manual.

Before connection to apowerline make sure that the line voltage is the

sameforthe

motors equipped

on

the machine (see plate attached

to

the machine body).

Ll-L2-L3

connecting terminals and the GND connecting terminal PE are located

in

tMpanel

#8016 (see page 14).

The power supply wire must be proper1y fixed

by

ho

ld

fast f

or

hooking

\I1e

electrical

sets, and protected by means of a strong wiring cable.

The electrical connection

can

be made by means of aerial

or

underground wires: in

both cases make sure that the wires are properly fixed.

The body of the machine must be connected to the ground.

The wires section mustbe

a~e

10

handle

\I1e

installed power; see thefollowing table:

.- 311OV-5otil. 220V-,Sotil.

OIOto<

el.do.

molot lIjoloroupp/J Aul""

..

ileh

81

.do

. m"lO,

1.1010,

auppl~

Au,.,..,ilCh

~

..

ou"on'

wl",.

..

c~on

....

ng

cumm'

..

i,.

..

..

~

..n

....

ng

(

~w

l

'"

(mm~

'"

'"

tmm~

,

.,

" Z&

.S

6.6.T

"

~g.5

,

..

"

13.5

~

5)($...T

~

~.

••

~

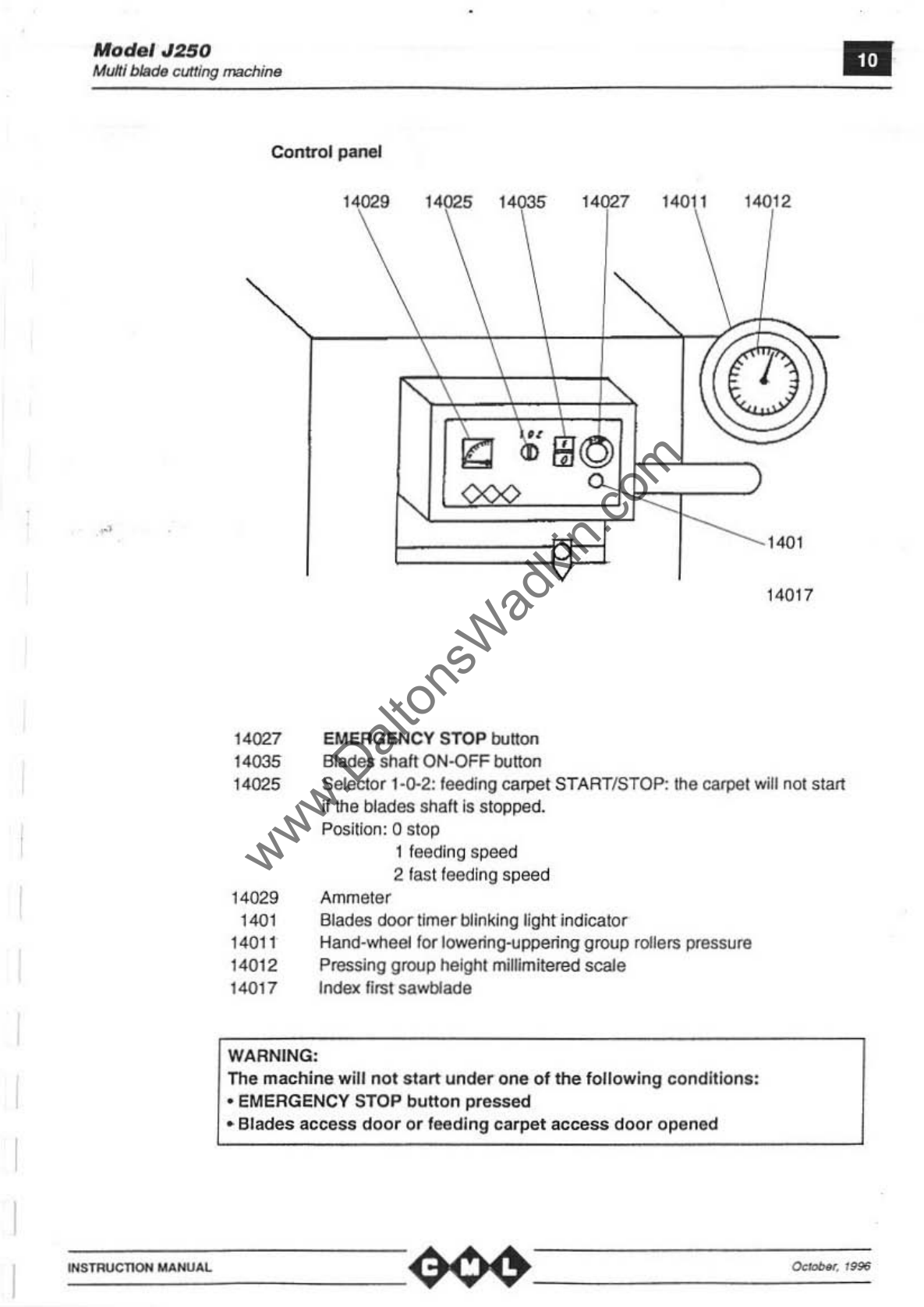

The ammeter shows the motor power consumption; the above table shows the

maximum values according to the suppty vottage and

to

the total installed power.

The consumption values should not

be

exceeded while the machine

is

working: in

that

caselhe

feeding truck speed must be reduced.

After the electrical connection control that the rotation direction

of

all motors is

correct, pressing: firstthe Bbutton and alterawaiting for 10 seconds

tu

rn

the setector

on

position /. if the track runs

in

th

e direction shown on the sketch underneath the

wiri

ng

it's been done corectty.

On

the contrary. put the main swich

on

position

0,

cut off the electrical power of the

line connected to the machine and change position of

th

e powerofthe powersupply

wires.