Linuo RR Series Manual

BALL

V

ALVE

OPERATION & MAINTENANCE MANUAL

RR&RB-Series

ZhejiangLinuo Flow Control Technology Co.,Ltd.

Weiyi Road,High-tech Park,Gexiang,Rui’an,Zhejiang,P.R.China 325200

Tel:86-577-65099777 Fax

:

86-577-65099777

E-mail: [email protected]

Website:www.linuovalve.com

8803.81/EN

RR&RB Series Ball Valve

2

CONTENTS

1

.

Description and Specification ………………………………………3

1.1 Description ……………………………………………………3

1.2 Specification ………………………………………………… 3

2

.

Construction and Dimensions ………………………………………4

2.1 Construction ……………………………………………………4

2.2 Dimensions ……………………………………………………5

3

.

Transportation and Storage ………………………………………6

3.1 Transportation……………………………………………………7

3.2 Storage …………………………………………………………7

4

.

Installation ………………………………………………………8

5

.

Dismantle and Assembly …………………………………………8

5.1 Dismantle ………………………………………………………8

5.2

Assembly ………………………………………………………9

6

.

Operation and Maintenance ………………………………………9

7

.

Trouble Shooting ……………………………………………… 9&10

8

.

Quality Assurance and Service …………………………………10

RR&RB Series Ball Valve

3

1 Description and Specification

1.1 Description

RR and RB series trunnion mounted ball valve is in two-piece body, mainly intended for shut off or isolating service.

When it is actuated, the torque is transmitted to the stem down to drive ball bore to be parallel with valve flow path at

full open position or cross with valve flow path at full closed position. It is with bidirectional tightness allowing for shut

off at both sides. Spring loaded metal and soft seated designs are available for various applications.

RR series floating ball valve

RR&RB Series Ball Valve

4

RB series trunnion mounted ball valve

1.2 Performance Specification

Size range DN15-DN500 (1/2”~20”)

Pressure rating 10-40 Bar/ANSI150-ANSI300

Testing pressure for shell 1.5 X PN

Testing pressure for seat 1.1 X PN

Air testing pressure 0.6MPa /6 Bar

Applicable temperature -29~230℃/ -20 to 445 ℉, -29-425℃/

-20 to 842 ℉

Tightness Bidirectional or unidirectional

Leakage class ISO 5208 class D for metal seated / ISO 5208 class A for soft seated

RR&RB Series Ball Valve

5

2.

Construction and Dimensions

2.1Construction

RR&RB Series Ball Valve

6

RR&RB Series Ball Valve

7

2.2 Dimensions mm

RR&RB Series Ball Valve

8

RR&RB Series Ball Valve

9

RR&RB Series Ball Valve

10

3 Transportation and Storage

3.1 Transportation

3.1.1 Check and make sure the valves and accompany accessories will not be subject to any impurities during

transportation.

3.1.2 Check and make sure the valves and accompany accessories will not be subject to any external stress

during loading.

3.1.3 Lifting device shall be used for big size valve and handling with carefulness.

3.2 Storage

3.2.1 Check and make sure the valves and accompany accessories will not be subject to any external stress

during storage.

3.2.2 Check and make sure the valves and accompany accessories will not be subject to any impurities during

storage.

3.2.3 Check and make sure the valves and accompany accessories will not be subject to exposing under

sunshine and they shall be kept in a dry room with fresh air for uncertain storage term. Do not remove the

flow port and flange sealing face protection cover. Valves are delivered and shall be remaining at full

open position for storage.

3.2.4 Valves shall be double checked and cleaned and tested after a long term storage. Particular attention shall

be paid to make sure of cleanness of the seating face.

4.

Installation

4.1 Check the marking of valve to make sure it is the one required before installation.

4.2 Remove the port protector and check if the valve is clean inside. Clean the valve if necessary.

4.3 Check the manual operation actuation device to make sure it works smoothly.

4.4 When fitting valve between flanged, center the flange gaskets carefully.

4.5 Valve shall be prohibited from installation while or immediately after the welding of pipe flanges.

4.6 Operating valve by device other than actuator original with shall be prohibited.

4.7 Fasten the nuts to until it is tight enough,

4.8 Prevent the installed valve from being squeezed.

4.9 Check and make sure space for overhaul and maintenance is reserved.

4.10 Valve should be at either full open or full closed position. RB series ball valve is not recommended for partial

stroke for throttle service.

4.11 Flush and clean the valve regularly to keep dust, oil or residual medium from accumulated, causing abrasion

and corrosion.

RR&RB Series Ball Valve

11

5. Dismantle and Assembly

Please follow the following steps for dismantle.

5.1 Dismantle

5.1.1 Gear dismantle:

a)Dismantle the fasteners of gear

b)Remove the gear

c)Dismantle the fasteners of bracket

d)Remove the bracket

e)Steps following are the same as gland dismantle

5..1.2 Lever dismantle:

a)Dismantle the fasteners of lever

b)Remove the lever

c)Dismounting retainer ring and positioning plate

d)Steps following are the same as gland dismantle

5.1.3 Gland(10) dismantle:

a)Dismantle the fasteners of gland(22,21)

b)Remove the gland

c)Remove the bearing(8)

d)Remove the packing(9)

e)Check the status of the packing

f)Steps following are the same as Upper body dismantle

5.1.4 Blind flange(4) dismantle:

a)Dismantle the fasteners of blind flange (4)

b)Remove the blind flange

d)Removetheoring(5)

f)Steps following are the same as Upper body dismantle

5.1.5 Upper body(2) dismantle:

a)Dismantle the fasteners of upper body

b)Remove the upper body

c)Remove the seat from upper body

d)Check the status of the seat

e)Steps following are the same as Ball dismantle

5.1.6 Shaft(14,17) dismantle:

a)Take the upper shaft out from the body

b)Take the lower shaft out from the body

c)Check the status of the shaft

5.1.7 Ball(14,17) dismantle:

a)Take the ball(3) out from the body

b)Check the status of the ball

NOTE: The valve parts number is corresponding to part list drawing on Page 5&6, unless otherwise stated.

RR&RB Series Ball Valve

12

5.2

Assembly

Clean all parts and arrange parts and assemble accordingly as per the sequence shown in the parts list. The

assembly sequence is reverse to that of dismantle.

6. Operation and Maintenance

6.1 Regular overhaul shall be done to make sure if the seating face is damaged or packing is worn out or body is

corroded. Do maintenance or repair if necessary.

6.2 Anticlockwise rotation by 90°for full open and clockwise rotation by 90° for full close

6.3 Valve shall be stopped for service until the problem is solved.

6.4 Be careful with the hands. The valve may be at extreme high or low temperature. Warning must be

shown.

6.5 Regularly remove dust, oil and medium staying on valve surface to prevent abrasion and corrosion, even

explosive gas caused by heat from friction.

6.6 Valve must not be dismantled when it is pressurized.

6.7 Spares needed for replacement are available for order.

6.8 Nonmetal parts shall be handled with particular carefulness during assembly and dismantle.Special tools must

be used to prevent damage.

6.9 Single part dismantled can be cleaned by immersion.Soft parts staying on valve can be done by using fibre

free silk to scrub off oil,dirt,grease and dust staying on the wall.

6.10 When soft material parts are immersed in the detergent for cleaning,it shall be done quickly.Make sure long

enough time given to the cleaned parts to dry for assembly and short enough time to avoid be dirted again.

6.11 Use lubricants compatibe with metal material,rubber parts,plastic parts and medium and give a layer of

lubricant for sealing parts groove and rubber sealing parts and shaft sealing and friction face.

6.12 Be careful to avoid any metal scraps,fibre,grease,unless permitted ones,and other impurities staying on the

surface of the parts or entering into valve vacity.

6.13 No in line maintenance for welding is allowed

7. Trouble Shooting

Symptom Possible fault Action

Leakage through

packing gland

1.Loose packing

2.Worn out or damaged packing

3.Too high operation torque

1.Tighten the nuts

2.Replace the packing

3.Operation without exerting excessive torque

Leakage through

seat

1.Wrong stop screw adjustment of

actuator

2.Damaged ball surface

3.Damagedseat

4.Worn out or damaged o ring

5.Ball can not move freely

1.Adjust the stop screw for the closed position

2.Turn the ball 180 degree

3. Replace the seat

4.Replace the o ring

5.Clean the seating face and seat

RR&RB Series Ball Valve

13

Leakage through

connection flange

1.Loose nuts

2. Worn out or aged gasket

3.Inproper selection of gasket

1. Tighten the nuts

2. Replace the gasket

3. Reselection and replace the gasket as per application

conditions.

No valve movement

1. Valve or actuator is freezed

2. Damaged actuator

3. Lacking of lubricants

4. Damaged shaft

1.Heat valve or actuator or inject freeze proof solution.

2.Check and repair the actuator.

3. Inject lubricants onto the surface of seat and drivers

4. Replace the shaft

8.

Quality Assurance and Service

8.1 Quality Assurance

8.1.1 The valves supplied by us is quality guaranteed for 12 months, covering the deficiencies in material and

workmanship. Malfunction caused by improper operation, installation and maintenance will be out of

guarantee.

8.1.2 Immediately inform us once valve with deficiencies or with such potential are found. We would manage to

give the quickest response while the right to check the truth of deficiencies is reserved.

8.1.3 The quality guarantee duration and scope can be extended as per agreement reached.

8.2 Service

8.2.1 On site installation and commissioning can be provided as stipulated in the order.

8.2.2 Regularly quality tracing will be done for valve delivered and service can be offered upon request.

Zhejiang Linuo Flow Control Technology Co.,Ltd.

Lupu, Pandai, Ruian, Zhejiang, P.R.China 325200

Tel:86-577-65099777 Fax

:

86-577-65386988

E-mail: linuo@linuovalve.com

WWW:http://www.linuovalve.cn

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

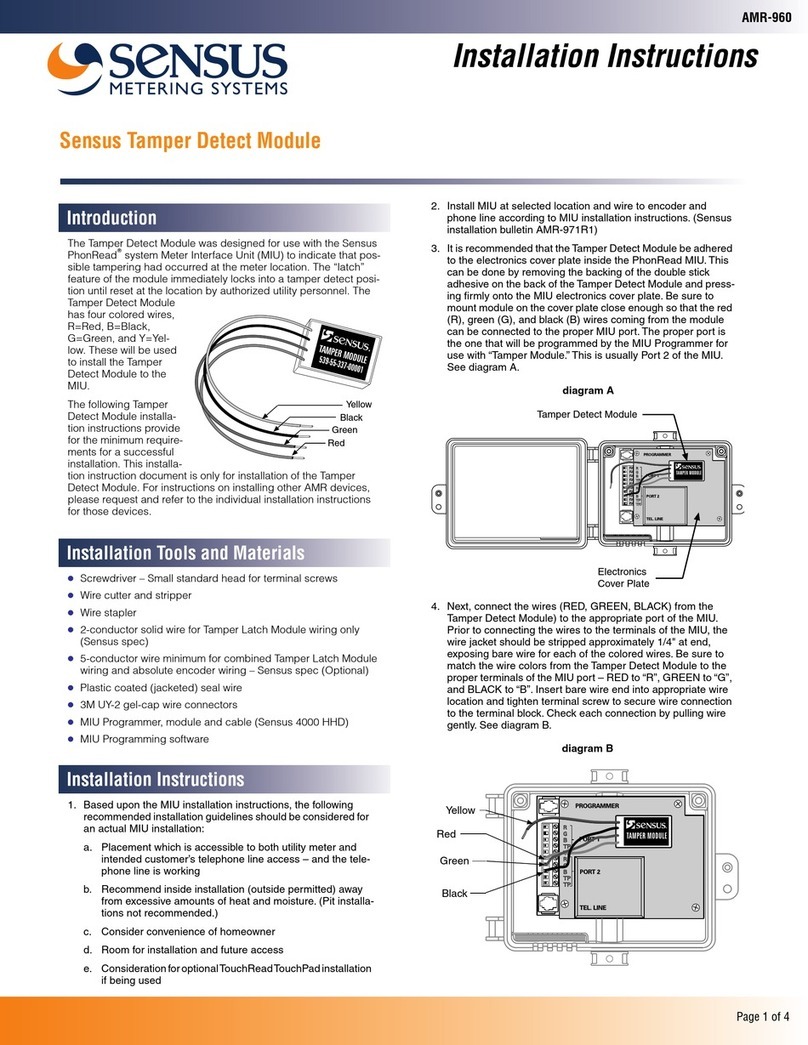

Sensus

Sensus AMR-960 installation instructions

Sangoma

Sangoma EXP100 quick start guide

Realtek

Realtek RTL8188SU user manual

Carrier

Carrier INFINITY SYSTXCCITC01 owner's manual

Zeta Alarm Limited

Zeta Alarm Limited SmartConnect Multiloop instruction manual

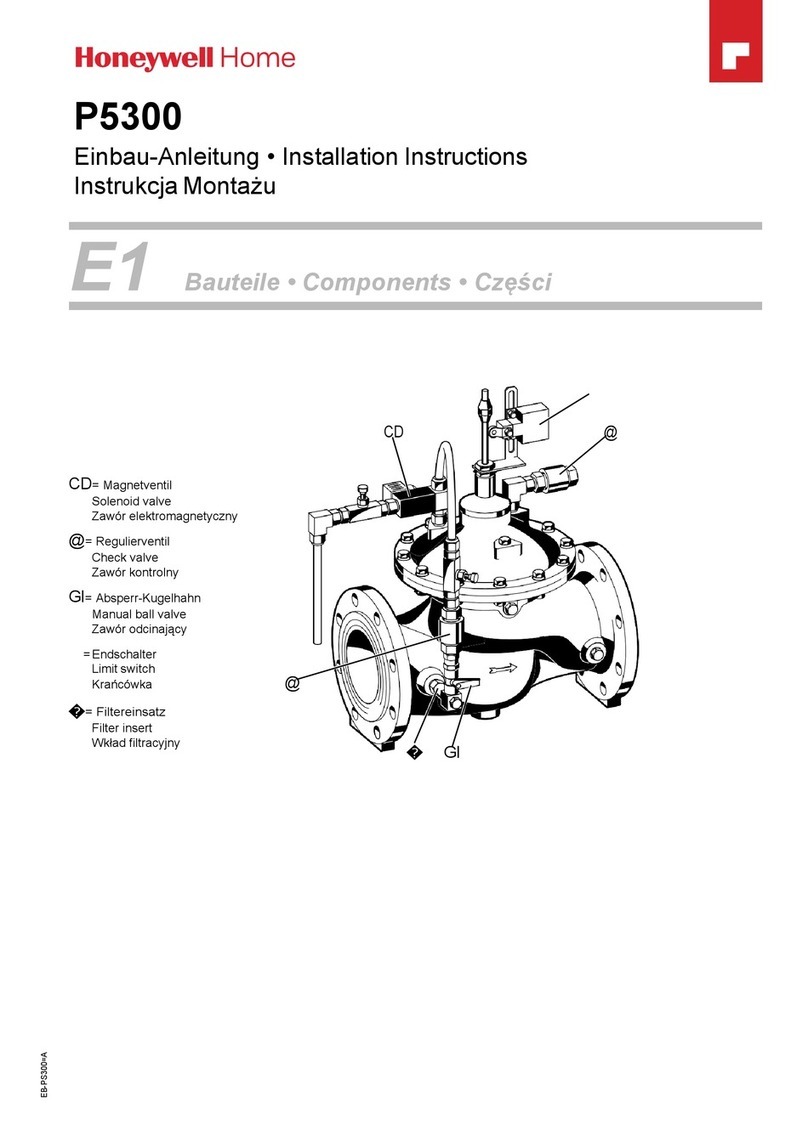

Honeywell Home

Honeywell Home P5300 Series installation instructions