Lipco SF 50 User manual

Instructions

Stump cutter SF 40/50

2 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

1. Introduction

Dear Customer,

We thank you for having chosen a

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

. We hope

that you will be happy with your choice.

In order that your

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

T

Ty

yp

pe

e

S

SF

F

will serve you well

for many years, we ask you to pay close attention to the Instructions

for Use and Maintenance which you will find in this manual. This will

help you to prevent breakdowns and accidents resulting from non-

observance of the operating instructions, for which our company will

not accept responsibility.

This Instruction and Maintenance Manual is to be considered an

integral part of the machine itself and therefore it must always

accompany the machine when it is sold, even in the event of its sale

to third parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will be able to have a complete

reference on hand at all times.

Note:

The illustrations, descriptions and specifications in this manual are

not binding.

L

LI

IP

PC

CO

O

reserves the right to make modifications without

notice.

Instructions

Stump cutter SF 40/50

3 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

2. Contents Page

1. Introduction 2

2. Contents 3

3. Designated use 4

4. Warning signs attached tot he machine 5

5. Safety regulations 7

6. Accident prevention 8

7. Design features 10

8. Technical Data 11

9. Preparation 12

10. Connection to the engine-driven machine 13

11. Working with the LIPCO Stump cutter 14

12. Maintenance 16

13. Replacement if the cutting blaeds 18

14. After use 19

15. Notices 20

16. Guarantee 22

17. Declaration of conformity 23

Instructions

Stump cutter SF 40/50

4 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

3. Designated use

The

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

T

Ty

yp

pe

e

S

SF

F

, when connected to single axle

tractors / power mowers, is designed to remove tree stumps.

Any other use for purposes other than those described here is

considered contrary to the designated use. The manufacturer cannot

be held liable for damage resulting from such use; the risk for such

use lies entirely with the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

and of the

engine-driven machine.

Any work, maintenance and repair on the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

S

SF

F

must be carried out by persons who are familiar with the unit and

have been informed about possible risks!

The relevant accident prevention regulations as well as the other

generally recognized maintenance, safety, industrial medicine and

road traffic rules and instructions must be observed.

The manufacturer cannot hold liable for damage resulting from

unauthorized modifications of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

S

SF

F

.

Instructions

Stump cutter SF 40/50

5 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

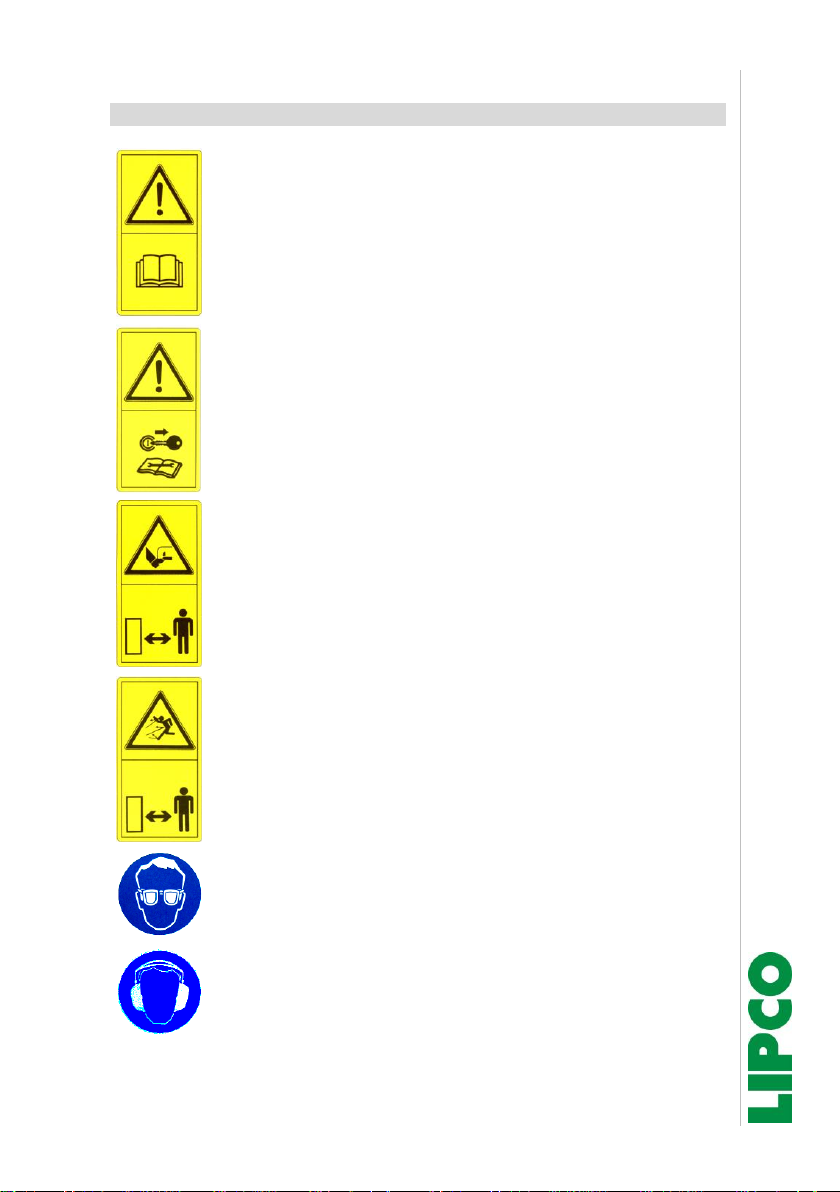

4. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

Before commencing maintenance and repair work,

switch off the engine and pull the key.

With the drive switched on and the tractor engine

running, maintain sufficient distance to rotating tools.

With the motor running, there is a risk of parts being

hurled away –maintain safety distance.

Wear eye protection.

Wear ear protectors.

Instructions

Stump cutter SF 40/50

6 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

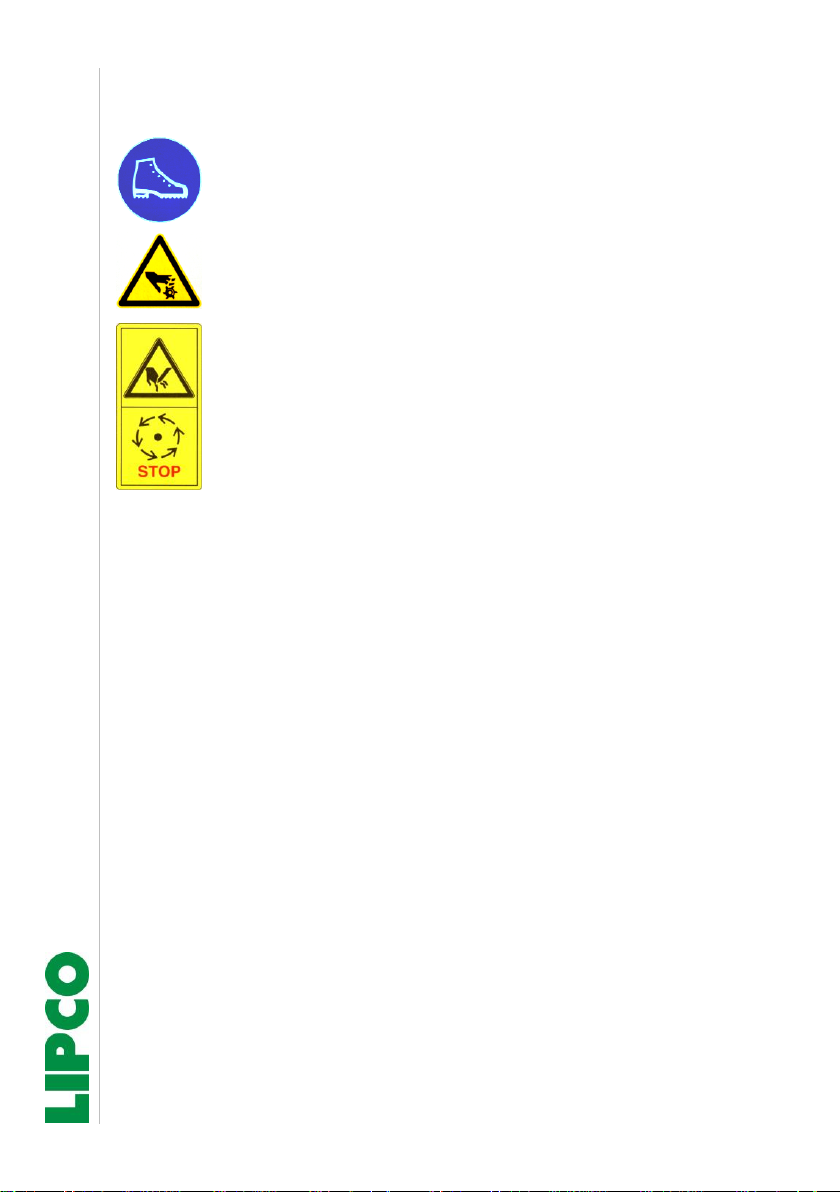

Wear foot protection.

Do not reach into rotating tools.

Machine parts should only be touched after they

have come to a complete halt.

Instructions

Stump cutter SF 40/50

7 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

5. Safety regulations

The operation of machines with rotating or moving tools always

bears risks. Please always follow the safety regulations:

•Before starting operation, the personnel must have read the

operating and safety instructions and observe them.

•Any work, maintenance and repair on the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

SF must be carried out by persons who are familiar with the unit

and have been informed about possible risks!

•The relevant accident prevention regulations as well as the other

generally recognized maintenance safety, industrial medicine

and road traffic rules and instructions must be observed.

•Never remove or alter the safety devices!

•Do not touch rotating or moving parts!

•Never lie down beneath the unit for repair or control purposes

when the unit has not been carefully secured beforehand!

•Use the machine only in perfect condition

•The warnings and signs attached to the unit give important

information on safe operation; observing these instructions

ensures your safety!

•For maintenance work, switch off the device!

•Do not wear wide or loose clothes (e.g. scarves)!

Instructions

Stump cutter SF 40/50

8 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

6. Accident prevention

Most accidents that occur during work, maintenance or transport of a

machine are due to non-observance of the most elementary rules of

accident prevention.

It is, therefore, necessary that all licensed users (relatives,

employees, colleagues) read and observe the rules given below and

written on the adhesive labels of the machine itself:

•Only work with eye and ear protection! (we recommend a

complete helmet combination)

•Turn off the engine of the engine-driven machine before carrying

out any adjustments, maintenance or cleaning on the machine!

•Prior to any work on the machine, it should be placed on level

ground! When working on the lifted unit, always ensure

mechanical protection by means of adequate supporting

elements!

•In order to achieve the highest possible performance of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

, it must always be in perfect condition.

Maintenance and repairs must be carried out by trained persons

only! Spare parts must at least comply with the technical

requirements specified by the manufacturer! This is only

guaranteed for

L

LI

IP

PC

CO

O

o

or

ri

ig

gi

in

na

al

l

s

sp

pa

ar

re

e

p

pa

ar

rt

ts

s

!

•Before each use, screws and nuts must be checked to ensure

they are firmly tightened, especially those of the tools and the

drive flange!!

•Before starting up, please make sure that no people or animals

are in the vicinity.

•Take special care when working alongside roads or pathways.

Instructions

Stump cutter SF 40/50

9 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

•During service or repair work, make sure that no one can start up

the machine accidentally!

•Do not, for any reason, climb onto the machine during operation.

•Do not act with any objects on the machine during operation!

•Never work without machine protection hood and plastic apron!

Instructions

Stump cutter SF 40/50

10 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

7. Design features

The

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

, when connected to any type of engine-

driven machine from 7 kW, is capable of removing tree stumps.

The main characteristics of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

are its universal

attachment to different engine-driven machines and its reduced

machine width, offering the possibility of achieving optimum work

results on narrow access roads and in very limited space.

As shown on the figure, the cutting disc of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

is equipped with exchangeable cutting blades (with soldered-on

hard-metal plates)

The decisive feature of the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

is the pivoting

device. (Fig. 2)

The attached engine-driven machine is lifted, leading to an oscillating

balance between the motorised device and the stump cutter. This

balance allows the machine to be lifted easily over the tree stump.

Thus, no tiresome pivoting over the motorised device axis is

necessary.

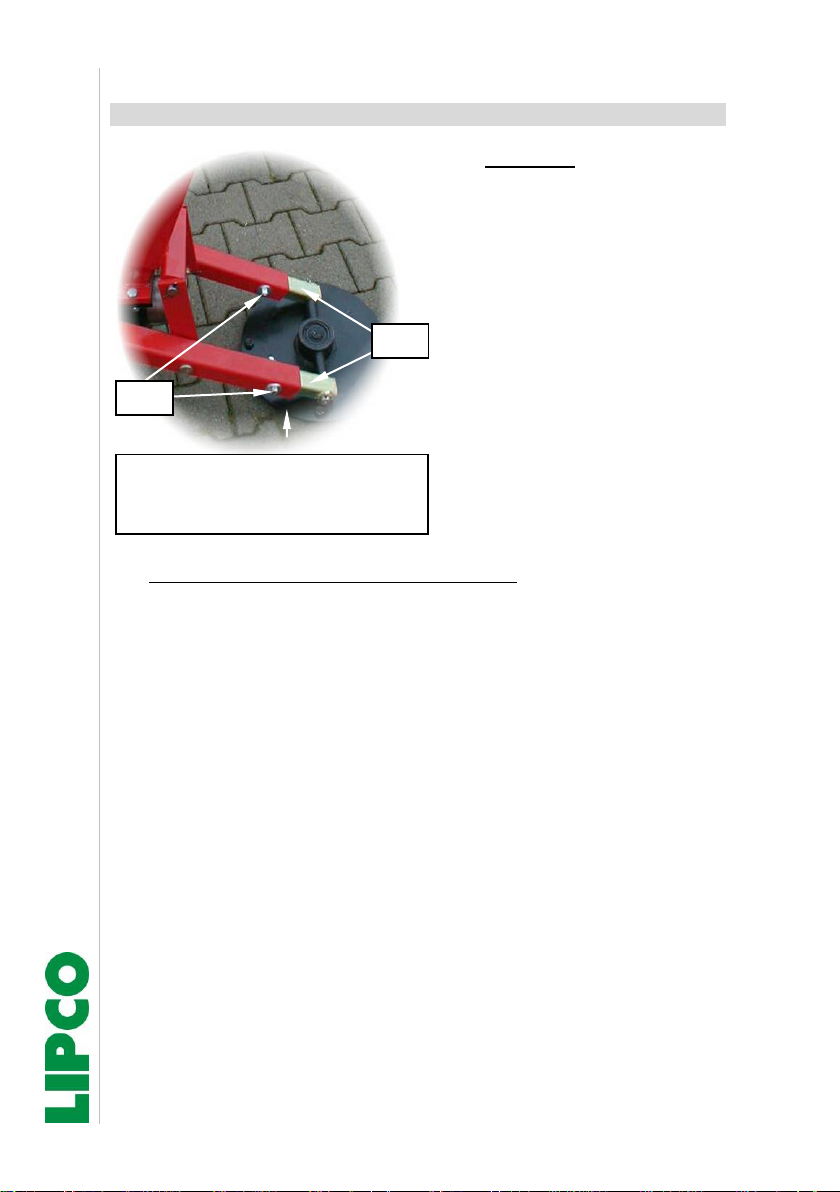

Fig. 1

Pivoting device

Cutting disk with

cutting blades

Fig. 2

Instructions

Stump cutter SF 40/50

11 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

8. Technical Data

Type

Weight

(kg)

Required drive

power

(KW)

Disc Ø

(cm)

Hard-metal

tools (pcs.)

SF 40

170

7

40

10

SF 50

175

9

50

12

Main dimensions

L1

L2

B

H

SF 40

1400

450

840

590

SF 50

1400

450

840

590

The speed of the engine-driven machine must be between

500 and 1000 rpm

Instructions

Stump cutter SF 40/50

12 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

9. Preparation

•Important! Adjust the

balance between motor

device and stump cutter

before the start-up! In this

adjustment, the bearing

arms of the support are

extended or shortened

depending on the

motorized device. To do

so, the fixing screws (A)

have to be removed and

the internal tubes (B) to be

pushed to the desired

position. Then, the bearing

arms have to be fixed with

the screws.

•Aim at maximum rotating disc diameter, since this leads to a

higher stability! Larger rotating discs can be ordered from the

manufacturer.

•Check the oil level in the angular gear! (see chapter:

“10. Maintenance”)

•Check whether all safety devices are in place and all screws are

tightened, especially the screws of the cutting blade and the

drive flange.

•Attach the handle! (Tighten the screw and counter it with the lock

nut.)

A

Determine maximum rotatating

disk diameter by means of

distance to motor device

B

Instructions

Stump cutter SF 40/50

13 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

10. Connection to the engine-driven machine

Before attaching the machine flange (Fig. 3, Ref. A) corresponding to

the type of engine-driven machine you have, it is recommended to

spread grease on the outer diameter of the machine hub (Fig. 3, Ref.

B). Then fix the flange with its two safety screws (Fig. 3, Ref. C) and

the lock nuts.

After having greased the connecting shaft (Fig. 3, Ref. D), insert it on

the machine shaft. When these steps are complete, move the

engine-driven machine close to the unit.

Ensure the toothed wheel work of the connecting shaft engages

correctly with the power takeoff shaft of the engine-driven machine

and the flange has a centred contact with the engine-driven machine.

Then connect the flange of the unit to the engine-driven machine.

Before beginning work: Lubricate the drive flange on the lubricating

nipple (Fig. 3, Ref. E)

A

C

C

D

Fig. 3

E

B

Instructions

Stump cutter SF 40/50

14 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

11. Working with the LIPCO Stump cutter

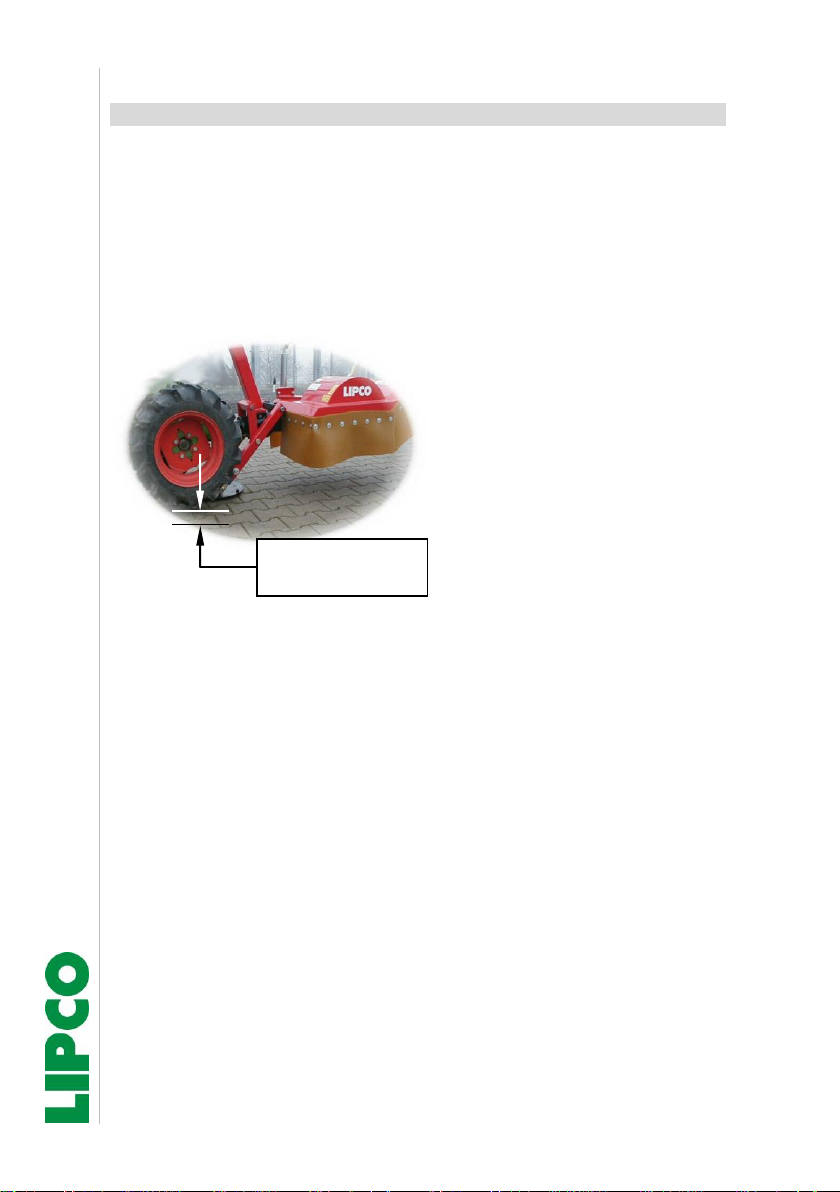

Move the Stump Cutter to the tree stump to be cut. Position the unit

such that the cutter disc is located centrally above the tree stump.

Then wind the support wheel to the top position. Lift the machine via

the pivoting device until reaching a distance above the ground of

approx. 10 cm. Do not switch on the power takeoff shaft under load;

therefore, lift the stump cutter so that the cutter disk does not contact

the tree stump when the machine is switched on.

When full speed is reached, lower the stump cutter carefully until the

disc cuts into the wood. Now, pivot the stump cutter to the right and

to the left over the tree stump and repeat the cutting process until the

desired working depth is reached.

Depending on the trunk diameter, the machine has to be shifted

forward or backward.

For safe and optimum working, it is necessary that the rotating disc

contacts the stump evenly, in some cases a support has to be

provided.

Engine-driven

machine lifted up

Instructions

Stump cutter SF 40/50

15 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

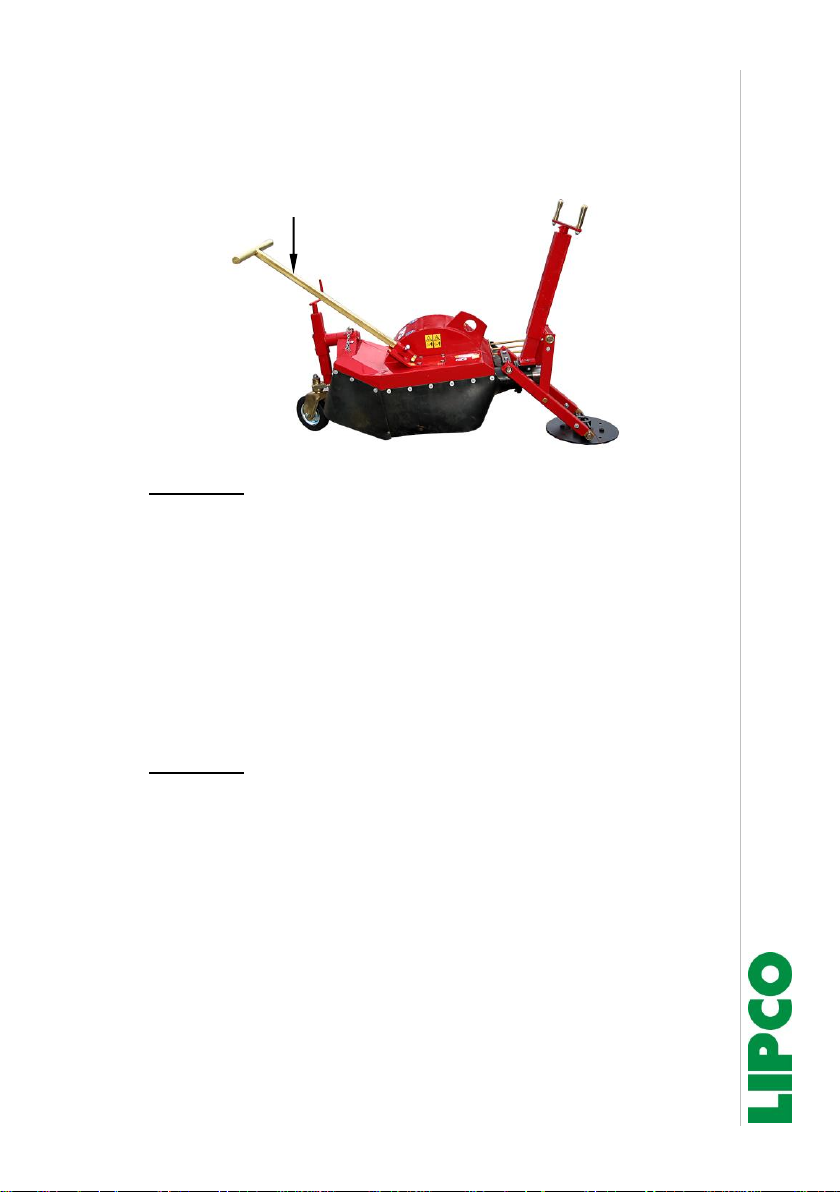

When working with a second person, the additional handle is

clamped firmly on the machine. Now, the second person can assist

the machine operator "from the front".

•Attention!

Turn off the engine of the engine-driven machine before

making any adjustments (e.g. winding the pivoting device

upward). In case of vibrations, immediately stop working

and inspect the cutting blade. Due to the high speed, an

imbalance might be caused by missing or seriously

damaged cutting blades.

•Only work with the personal protection equipment! (Eye and ear

protection)

•Attention!

When working in hillside position, the tree may only be cut

uphill or downhill for safety reasons. Never sideways!

Additional handle

Instructions

Stump cutter SF 40/50

16 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

12. Maintenance

Steps to be carried out in order to maintain the machine in good

working condition:

•Check the oil level in the

angular gear. (Fig. 4) In

horizontal position the

gear drive should be

filled with gear oil to the

lower edge of the filler

neck. The first oil

change should be

carried out after 50 to

60 operating hours.

•Use SAE 90 gear oil in

an amount of 0.85 L.

•Drive flange: It should

be lubricated at least

once a month via the

lubricating nipples

provided for this

purpose. (Fig. 5)

•Then turn the drive

flange to allow the

grease to become

evenly distributed –

while doing so, check

for smooth running.

•Remove drive flange once a year, clean and regrease it.

•Check the plastic apron and replace it, if necessary!

Fig. 4

Oil level

Oil filler neck

Lubricating nipple

Fig. 5

Instructions

Stump cutter SF 40/50

17 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

•Check whether all screws, especially those of the cutting blades,

are firmly tightened. Replace damaged screws immediately.

(See chapter "11. Replacement of the cutting blades").

Note: Only use original screws.

•Lubricate movable parts, e.g. pivoting device at the bearing

points.

•The lubricating nipple on the supporting wheel must be

lubricated once a month.

(Fig. 6)

Fig. 6

Lubricating

nipple

Instructions

Stump cutter SF 40/50

18 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

13. Replacement if the cutting blaeds

When replacing the cutting blades, make sure that the machine is

secured against unintentional tilting! When working with the unit

lifted, always ensure mechanical protection by means of adequate

supporting elements!

When a cutting blade becomes broken, immediately stop work and

replace the damaged parts.

Cutting Disc

Cutting blade

Instructions

Stump cutter SF 40/50

19 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

14. After use

If the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

is to remain unused for a longer period, it

is necessary to carry out the following steps:

•Thoroughly wash and dry the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

!

•Check the function of all movable parts and lubricate them!

Replace damaged or worn parts!

•Check the screws and retighten, if necessary!

•Check the oil level in the angular gear!

•Grease all unpainted metal parts to protect them against

corrosion, cover the

L

LI

IP

PC

CO

O

S

St

tu

um

mp

p

C

Cu

ut

tt

te

er

r

and store it in a dry

place so that it will be ready for use any time.

•Attention!

Before using the unit again, follow the instructions in

chapter "10. Maintenance".

Instructions

Stump cutter SF 40/50

20 - 24

150040-02-EN BA SF 40_50 / 22.03.2019

15. Notices

This manual suits for next models

1

Table of contents