OPERATION INSTRUCTIONS

and ADJUSTMENTS

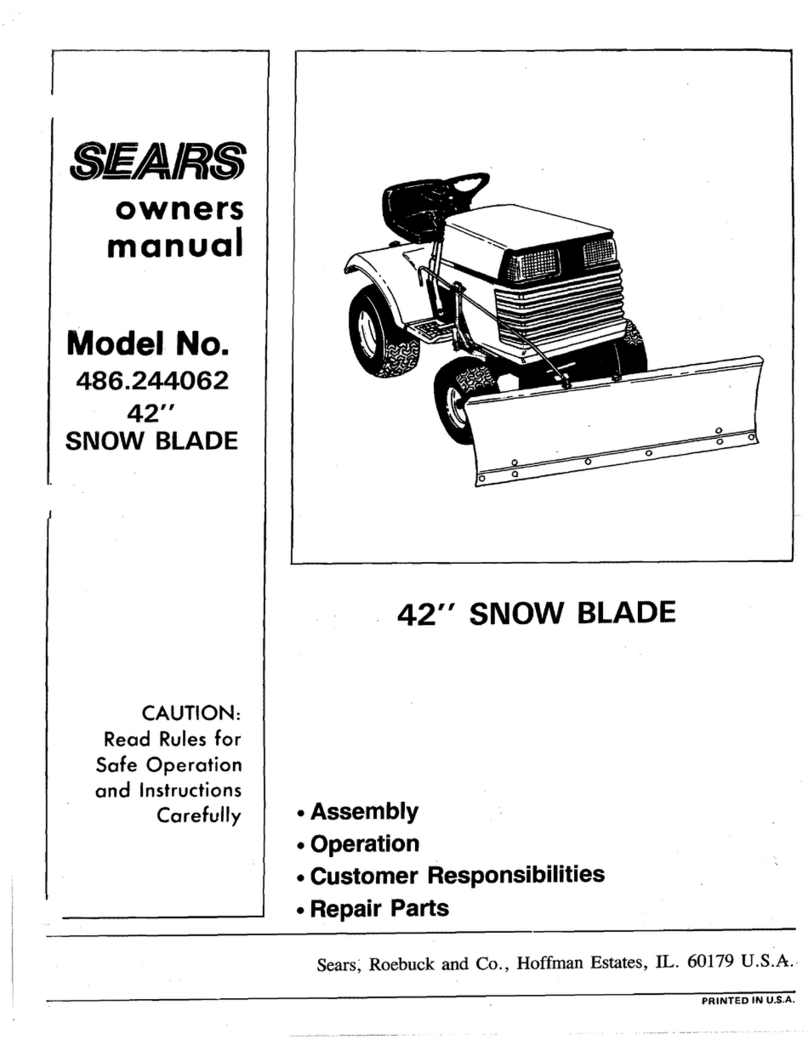

The snow blade attachment is designed to move new

loose snow in depths up to 6" -- 8"

HIDDEN OBJECTS CAN CAUSE

SUDDEN STOPS OR CHANGE IN

DIRECTION.

CONTROLS

Become familiar with all of the controls and

adjustments on the tractor and snow blade before

operating. Refer to tractor owners manual for

tractor controls. Controls for operating snow blade

are as follows:

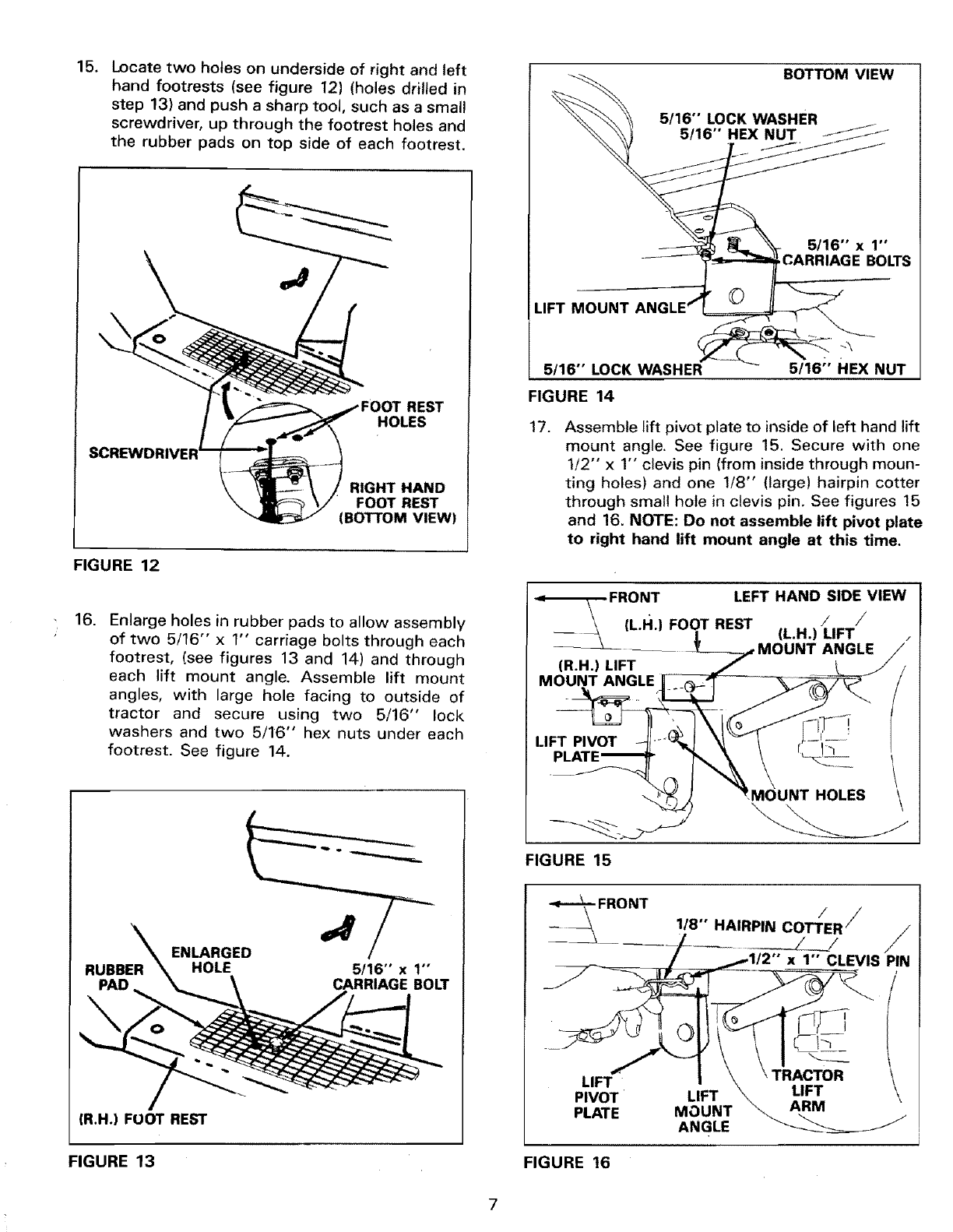

A. Lift control lever:

Located on right hand side of tractor. See figure

23, page 9. Move lever forward to lower snow

blade. Pull lever back to raise and lock snow

blade.

B. Lift lever plunger:

Located on top of lift control lever. See figure

23. Pull back on lift control lever and depress

plunger to release.

ADJUSTMENTS

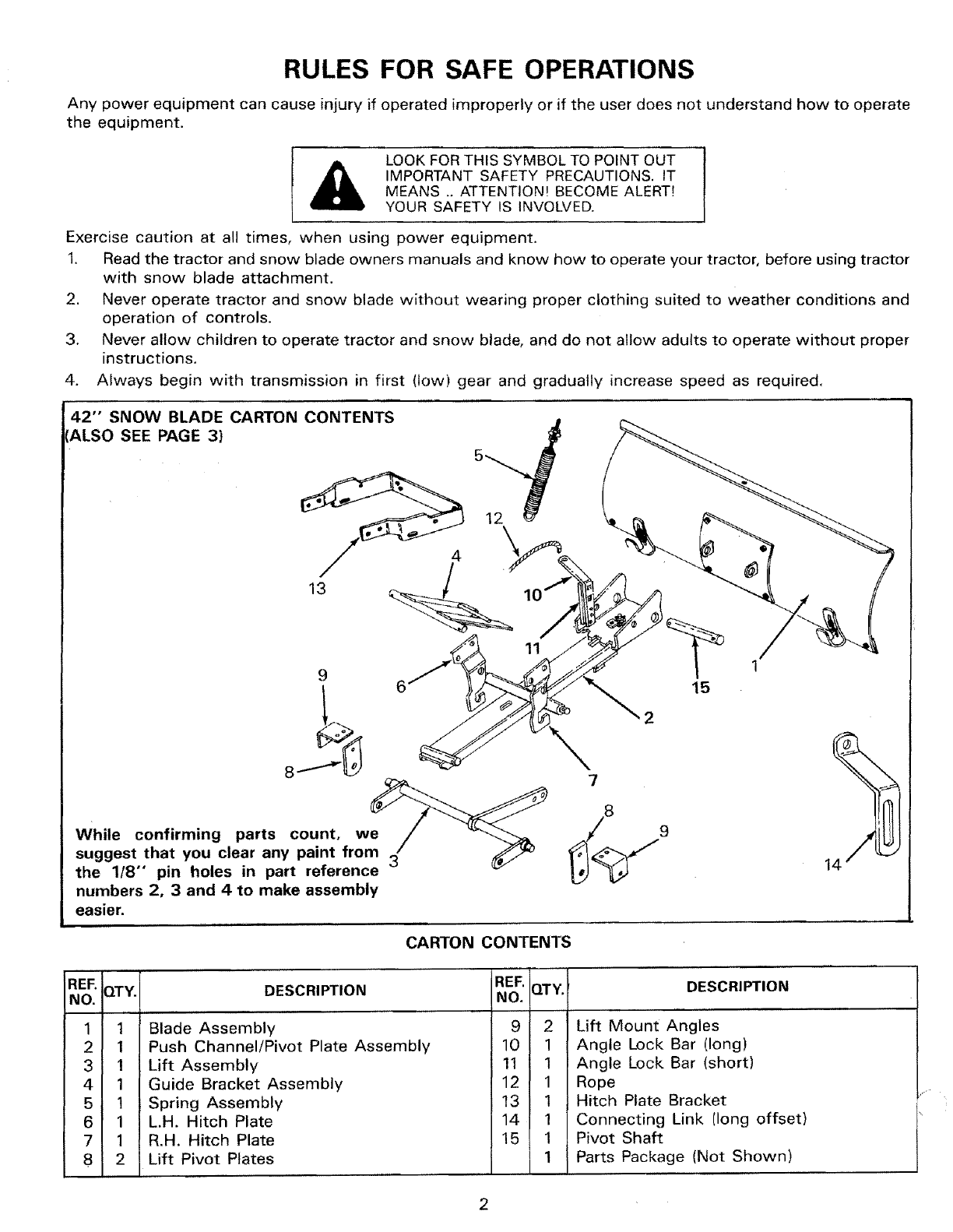

A. Blade angle lock bars:

Blade angle can be adjusted at the blade pivot

in front of tractor by first raising the blade to

transport position, pull back on angle lock bars

to release the blade and pivot to the right,

center, or left positions. Release lock bars to

lock.

To adjust blade angle from the tractor seat:

Raise blade to transport position, shift tractor

to low speed range, pull back on rope to release

angle lock bars. Move.tractor forward slowly,

dragging the right, or left end of blade against

snow bank (or other object) to angle blade to

right or left. Release rope to lock.

B. Adjust blade spring:

Blade adjust spring tension is adjustable to

permit blade to tilt forward to by pass solid

obstructions.

KNOW THE TERRAIN. AVOID EXCEP-

TIONALLY SHARP SLOPES OR DROP-

OFFS WHICH MAY BE HIDDEN BY

THE SNOW.

NEVER RUN THE SNOW BLADE

INTO HEAVY MATERIAL AT HIGH

SPEED.

C. Blade shoe adjustment:

Blade shoes on ends of blade, (see figure 23),

may be raised for close work on smooth

surfaces or lowered to raise the blade to work

on rough or uneven areas. Make sure both shoes

are set evenly and nuts are tightened securely,

_1_ NOTE

Wheel weights and tire chains should

be used with your snow blade to im-

prove traction. These accessories are

available at your nearest Sears retail

or catalog store.

OPERATION

&WITH THE SNOW BLADE IN THE "UP"

POSITION DO NOT DEPRESS THE

PLUNGER WITHOUT HOLDING BACK

ON THE LIFT CONTROL LEVER OR

SNOW BLADE MAY SUDDENLY DROP.

.

.

10

&INSPECT THE AREA TO BE WORKED

CAREFULLY BEFORE OPERATING

THE SNOW BLADE. AVOID PIPES,

ROOTS, CURBS OR OTHER HEAVY

OBSTRUCTIONS.

Prepare the lawn tractor engine for cold weather

use following instructions furnished with lawn

tractor.

Always begin with transmission infirst (low)

gear and gradually increase speed as required.

another free manual from www.searstractormanuals.com