Operator manual Konstanz STG/ASA 1/20 Version 8.0 (01/2010)

The operation of the stair lift Konstanz

Contents Page

1 General..........................................................................................................……. 3

1.1 Technical data..................................................................................................……5

1.2 Surrounding conditions.......................................................................................… 5

1.3 Test obligations.................................................................................................…. 5

2. Intended purpose.............................................................................................…. 5

2.1 Conveyance profiles...........................................................................................… 5

2.2 Improper usage..........................................................................................………. 6

2.3 User qualification...........................................................................................…… 6

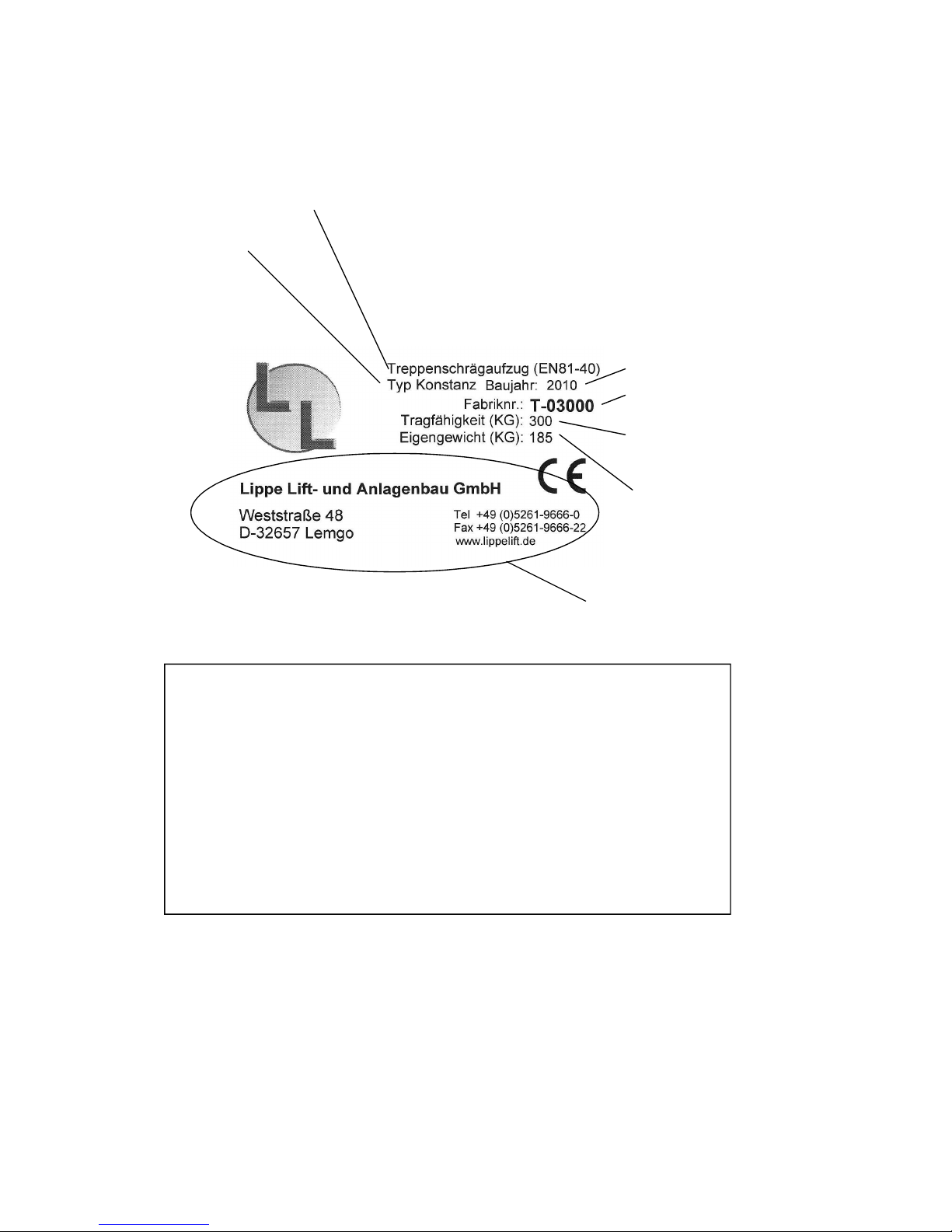

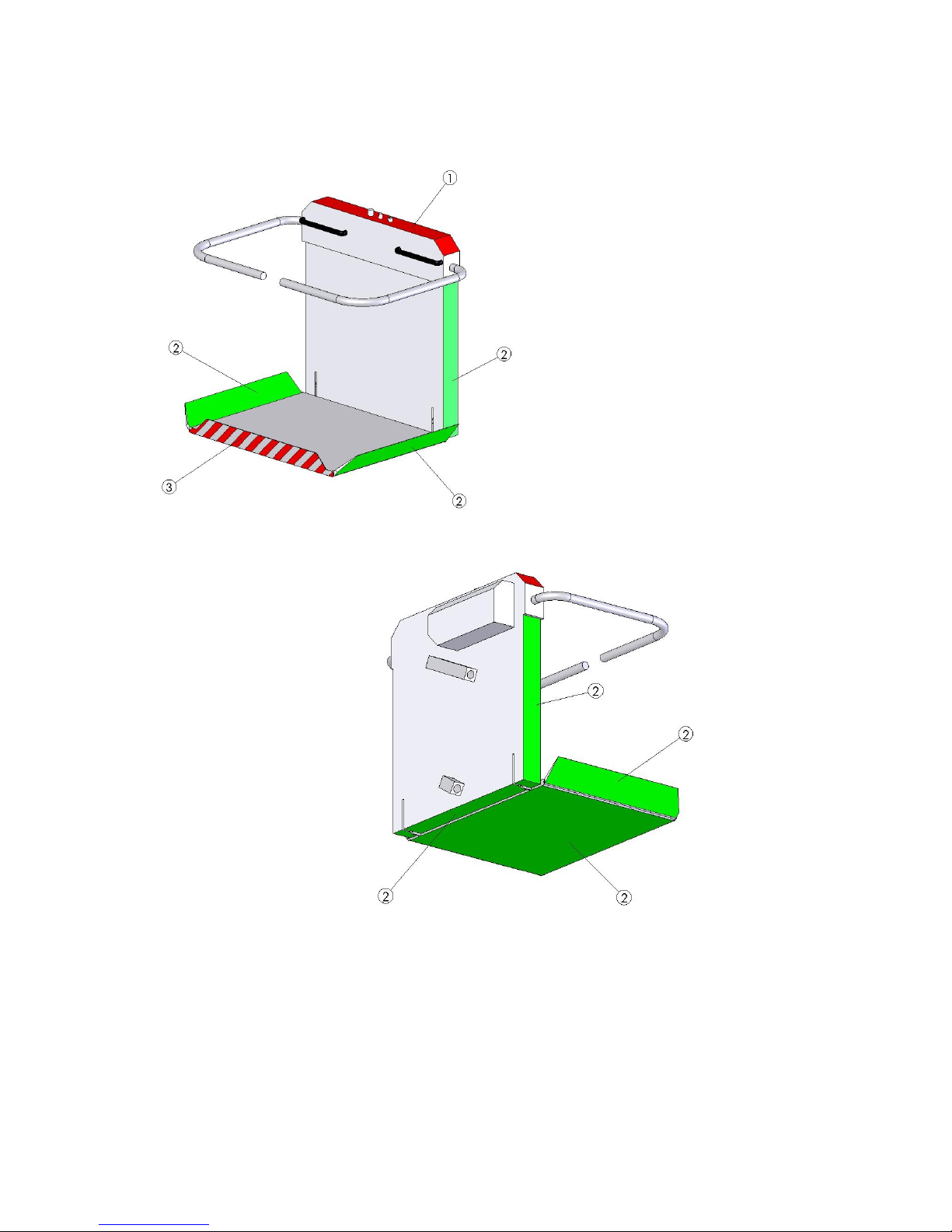

2.4 Product description.............................................................................................… 6

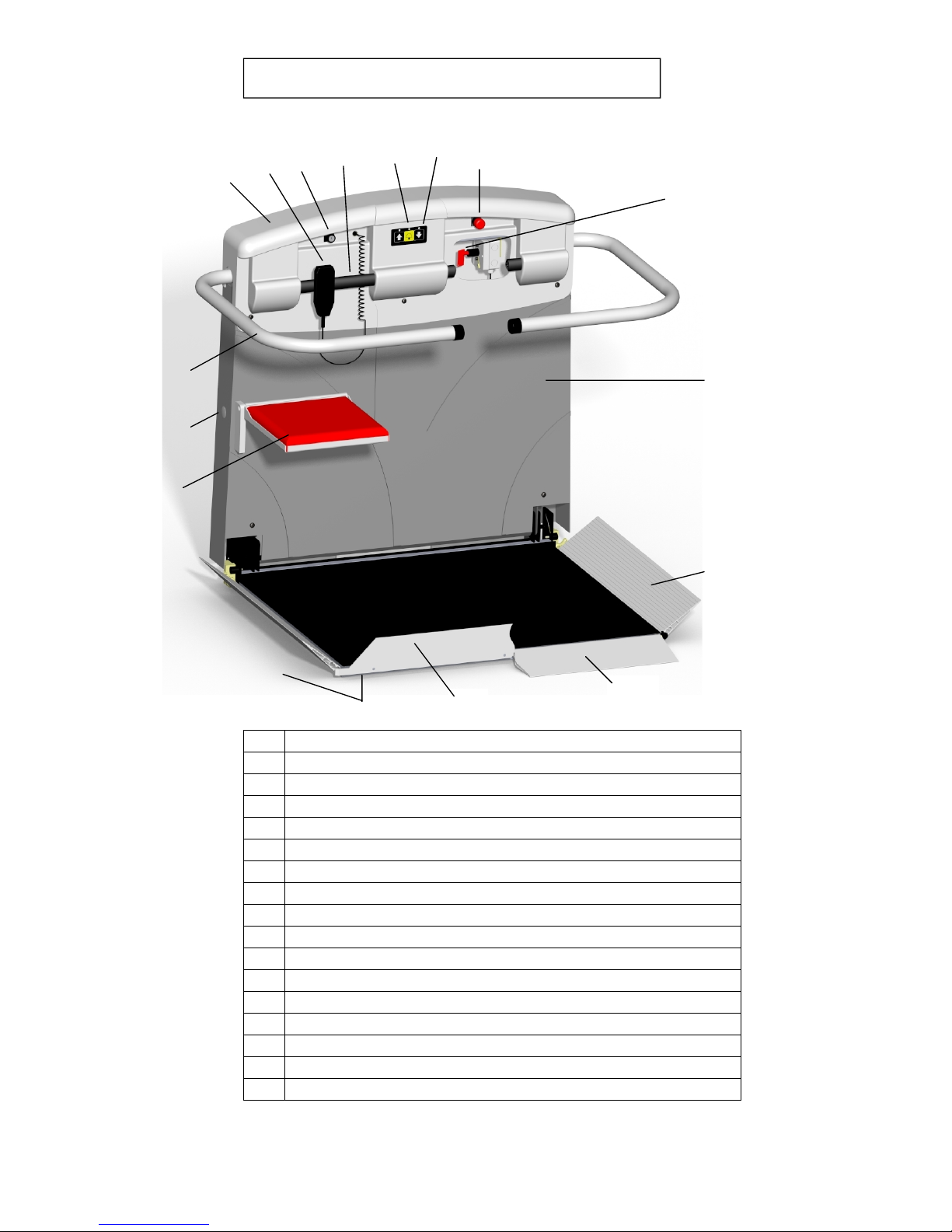

2.5 Overview sketch of the platform lift...................................................................… 7

3 Safety.............................................................................................................…… 9

4 Operation........................................................................................................….. 11

4.1 The main switch.................................................................................................… 11

4.2 The deep unloading protection and loading............................................................ 11

4.3 Check of the loading………............................................................................….. 11

4.4 The loading device............................................................................................…. 11

4.5 Getting and sending of the platform...................................................................… 12

5/4/01 Automatic platform.......................................................................................……. 13

5/4/02 Manual platform.......................................................................................………. 13

4.6 Driving with the platform..................................................................................…. 14

4.7 What do you do in the case of an unexpected stoppage......................................... 14

7/4/01 Hand wheel operation………………..................................................................… 15

7/4/02 Evacuation (metal cover)….................................................................................... 16

7/4/03 Evacuation (plastic cover)............................................................................……... 17

5 Options / Extras................................................................................................…. 18

5.1 The folding seat....................................................................................................... 18

5.2 The emergency call.................................................................................................. 18

5.3 The lateral drive-up flap..................................................................................…… 18

5.4 Acoustic/optical signal...................................................................................……. 18

6 When malfunctions occur................................................................................…. 19

7 Acoustic warning signals.................................................................................…. 19

8 Services for your platform lift at a glance.............................................………. 20

! Important !

Please read the operator manual before using the lift.

Make certain that every user of the lift has read and understood the operator manual.

The manufacturer assumes no liability for errors in the operator manual.

This is a translation of the original German operating instructions