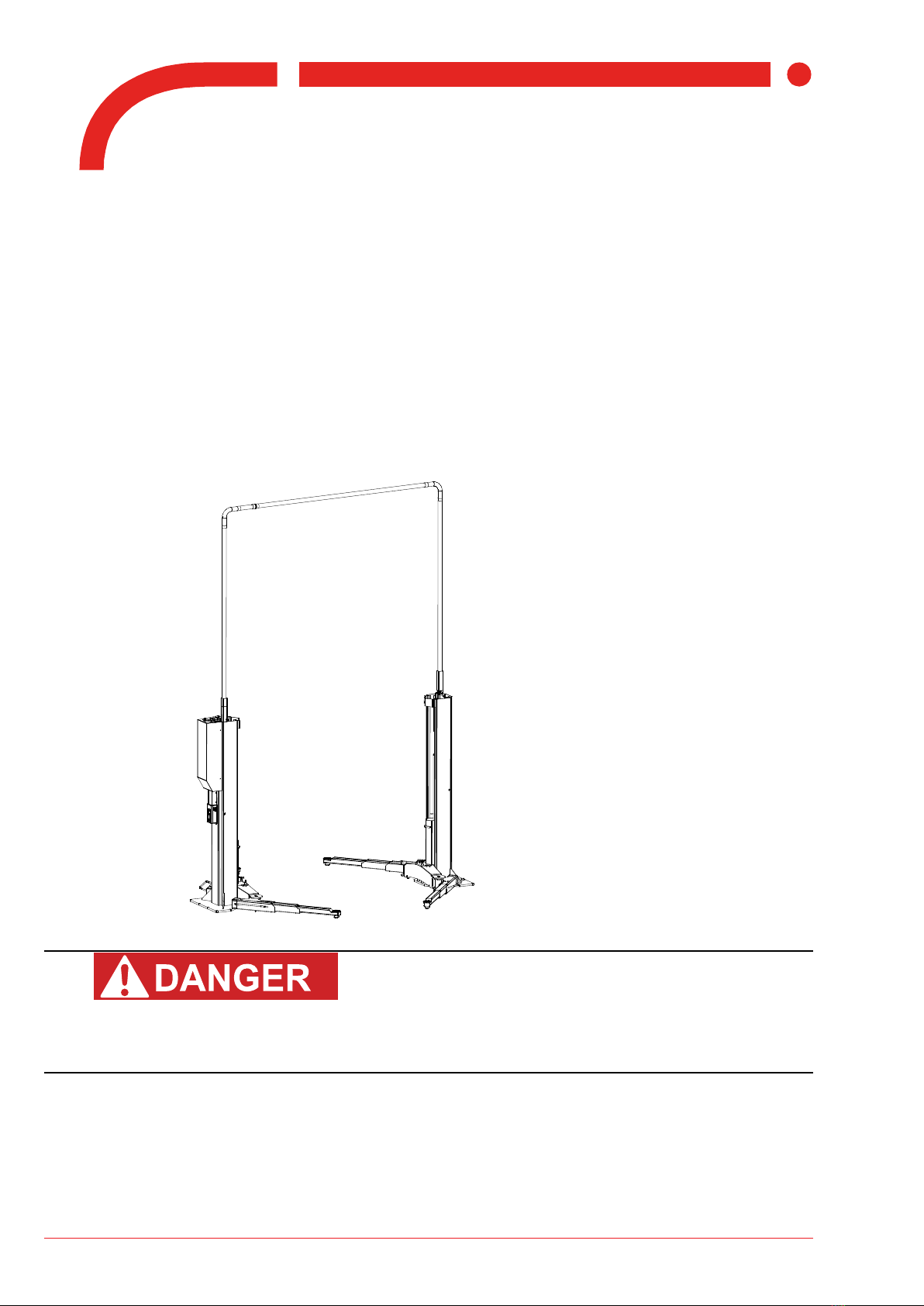

Installation and Service Manual 10 SK 2055 / 2070 / 2090

rules and guidelines can be, but are not limited to local health and safety

regulations and the guidelines provided by professional associations.

• The machine manual must be available at the machine at all times.

• Read the operating instructions before you operate or maintain the machine.

• Make sure you have obtained, read and understood all instructions.

• Make sure you have obtained, read and understood any additional

instructions for special accessories for the machine.

• Carry out all work with and on the machine as described in the manual.

• Never start or operate a damaged machine.

• Always make sure that the machine is complete before operation. Operating

the machine with missing components can cause severe damage.

• Observe all signs with safety and danger notes. Replace warning and/or

safety signs immediately if they are missing or illegible.

• Do not perform any tasks for which you are not authorized. Only explicitly

qualified and authorized personnel may operate, maintain or repair the

machine.

• Personnel in training must be supervised at all times.

• Wear and use all needed personal protection equipment and safety gear

appropriate for the job.

• Keep a safe working environment.

• If necessary, make sure the machine complies with federal and local

standards before starting work.

• Do not use the machine for purposes other than those specified.

• All personnel working on or with the machine must be aware of possible

hazards.

• Never make any changes or additions to the machine, without obtaining

explicit written approval from the manufacturer/supplier. This also applies to

the installation and adjustment of safety devices.

•Read all instructions.

•To reduce the risk of fire, do not operate equipment in the vicinity of

open contianers of flammable liquids (gasoline).

•Provide adequate ventilation when working on internal combustion

engines.

•Keep hair, loose clothing, fingers and all parts of the body away from

moving parts.

•To reduce the risk of electrical shock, do not use on wet surfaces or

expose to rain.

•Use only as described in this manual. Use only manufacturers

recommended attachments.

•Always wear safety glasses. Everyday eye glasses only have impact

resistant lenses they are not safety glasses.

•Use by untrained people could result in serious injury and/or damage.

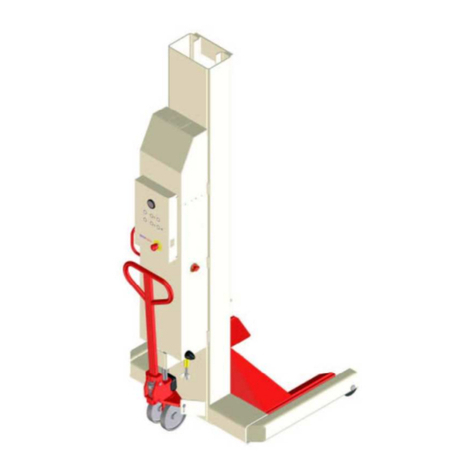

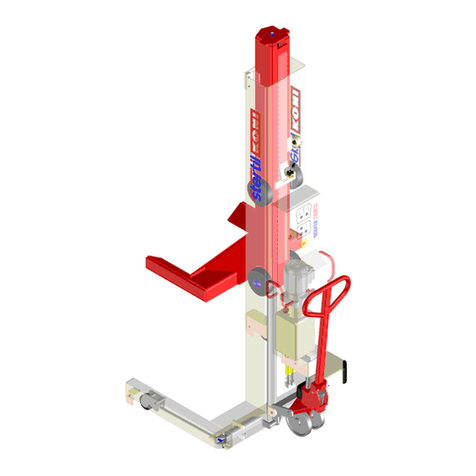

•Only authorized persons should operate the vehicle lift. These persons

are in any case familiar with the operating instructions of the lift.