Lippert Components Level-Up User manual

Rev: 04.05.2018 Page 1 Level-Up Towable Owner's Manual

Level-Up® (Towable)

System

OWNER'S MANUAL

Rev: 04.05.2018 Page 2 Level-Up Towable Owner's Manual

System and Safety Information

• Be sure to park the unit on solid, level ground.

• Ensure all jack landing locations are cleared of debris and obstructions and also free of depressions.

• When parking the unit on extremely soft surfaces, utilize load distribution pads under each jack.

• People and pets should be clear of unit while operating leveling system.

• Be sure to keep hands and other body parts clear of fluid leaks. Oil leaks in the Lippert Leveling

System may be under high pressure and can cause serious skin-penetrating injuries.

TABLE OF CONTENTS

System and Safety Information 2

Introduction 3

Touch Pad Diagram 3

Prior to Operation 4

Operation 4

Basic Jack Operation 4

5th Wheel Operation 4

Unhitching Instructions 4

Auto Level 5

Auto Level Sequence 5

Hitch Recognition 5

Travel Trailer Operation 6

Unhitching Instructions 6

Auto Level 6

Auto Level Sequence 6

Hitch Recognition 6

Manual Operation 7

Zero Point Calibration 8

Maintenance 9

Fluid Recommendation 9

Troubleshooting 9

Error Display in LCD Screen 9

Manual Override 10

Fifth Wheel Level-Up® 4 Point Assembly 11

Travel Trailer Level-up® 4 Point Assembly 12

Fifth Wheel Level-Up® 6 Point Assembly 13

Level-Up® Electronic Components 14

Level-Up® Components 15

Level-Up® Components 16

Level-Up® Components 17

Level-Up® Components 18

Level-Up® Components 19

Notes 20-21

Rev: 04.05.2018 Page 3 Level-Up Towable Owner's Manual

Lippert Components Inc. recommends that a trained professional be employed to change the tires on the

unit. Ensure that the unit is properly supported with jack stands, or other adequate devices, under the

frame of the unit prior to commencing any service or repair procedure. Any attempts to change the tires or

perform other service while unit is supported solely by the LCI Level-Up® with Automatic Leveling System

could result in death, serious injury, unit or property damage.

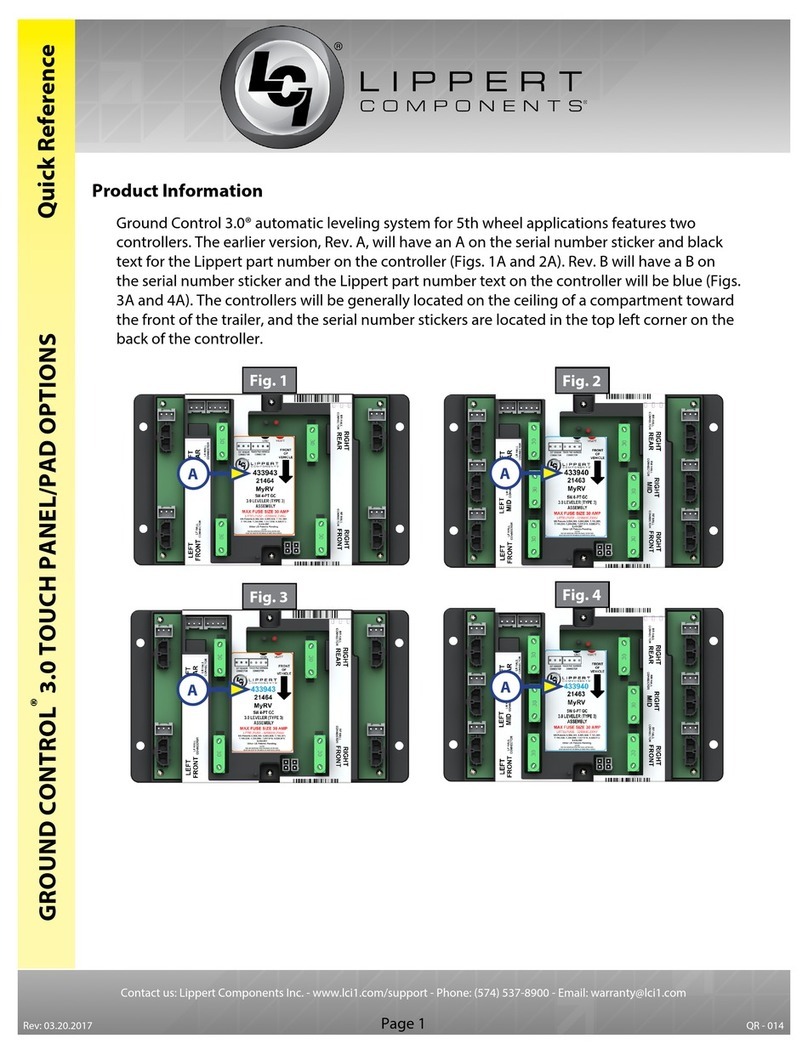

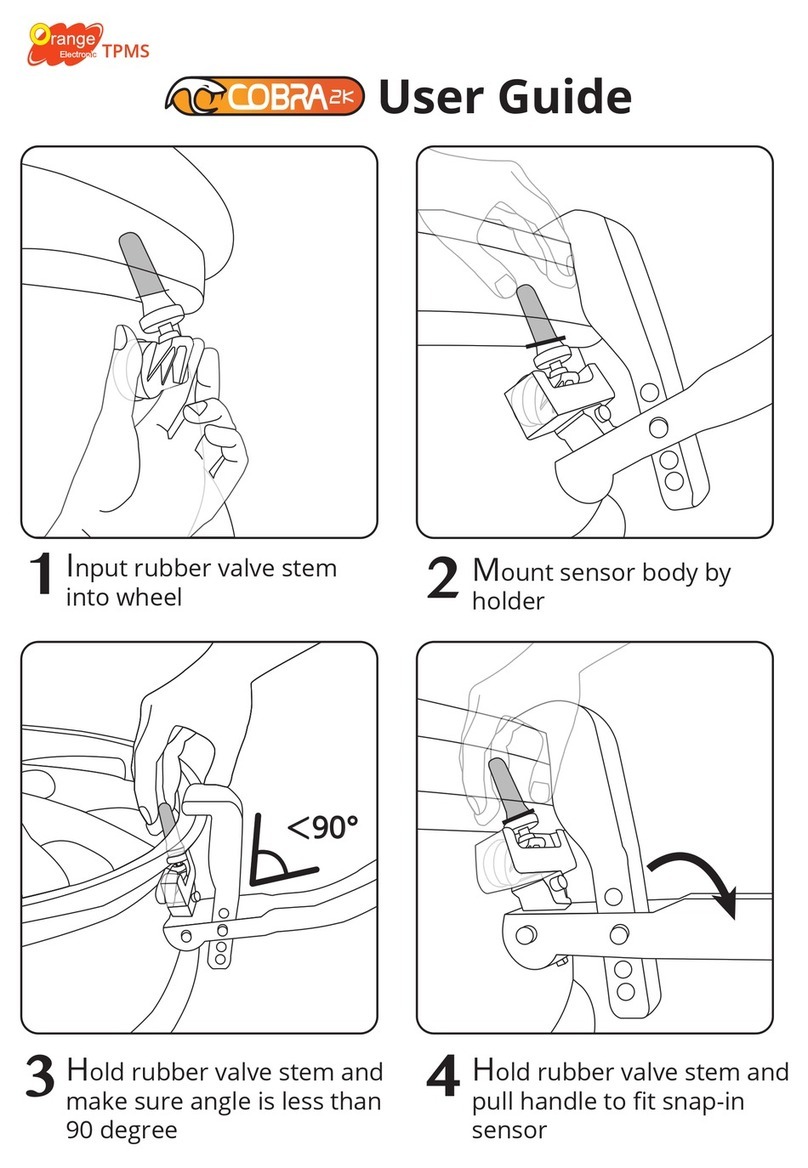

Callout Description

A Up Arrow - Scrolls up through the menu on LCD.

B Down Arrow - Scrolls down through the menu on LCD.

C Enter - Activates modes and procedures indicated on LCD.

D Retract - Places leveling system into retract mode - Manual mode ONLY.

E LCD Display - Displays procedures and results.

F Auto Level - Places leveling system into auto level mode.

G Front Button - Activates both front jacks.

H Left Button - Activates left leveling jack(s) in manual mode.

I Right Button - Activates right leveling jack(s) in manual mode.

J Rear Button - Activates leveling jacks in manual mode.

K Power Button - Turns leveling system on and off.

Fig. 1

Touch Pad Diagram

Introduction

Level-Up® is an Automatic Leveling system. This system is equipped with 14K aluminum landing gear and 8K

aluminum leveling jacks. The jacks in the Level-Up® system work in pairs.

A

B

E

F

CG

DH

K

I

J

Rev: 04.05.2018 Page 4 Level-Up Towable Owner's Manual

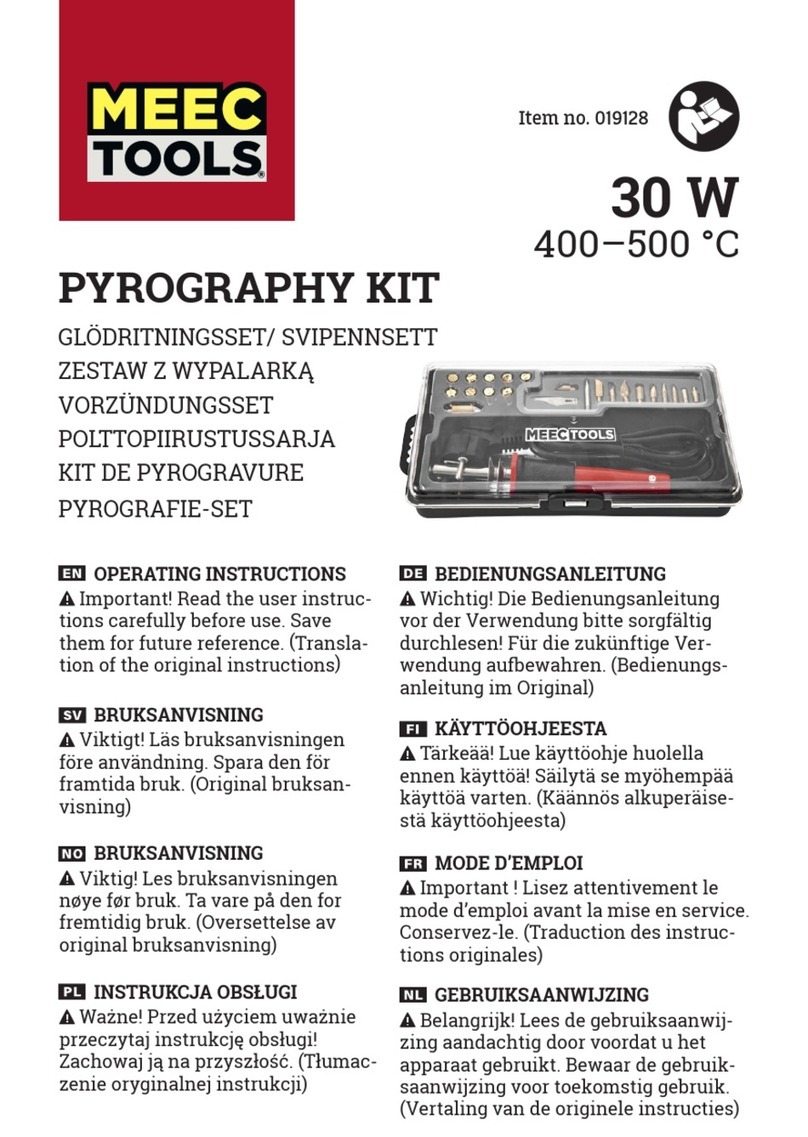

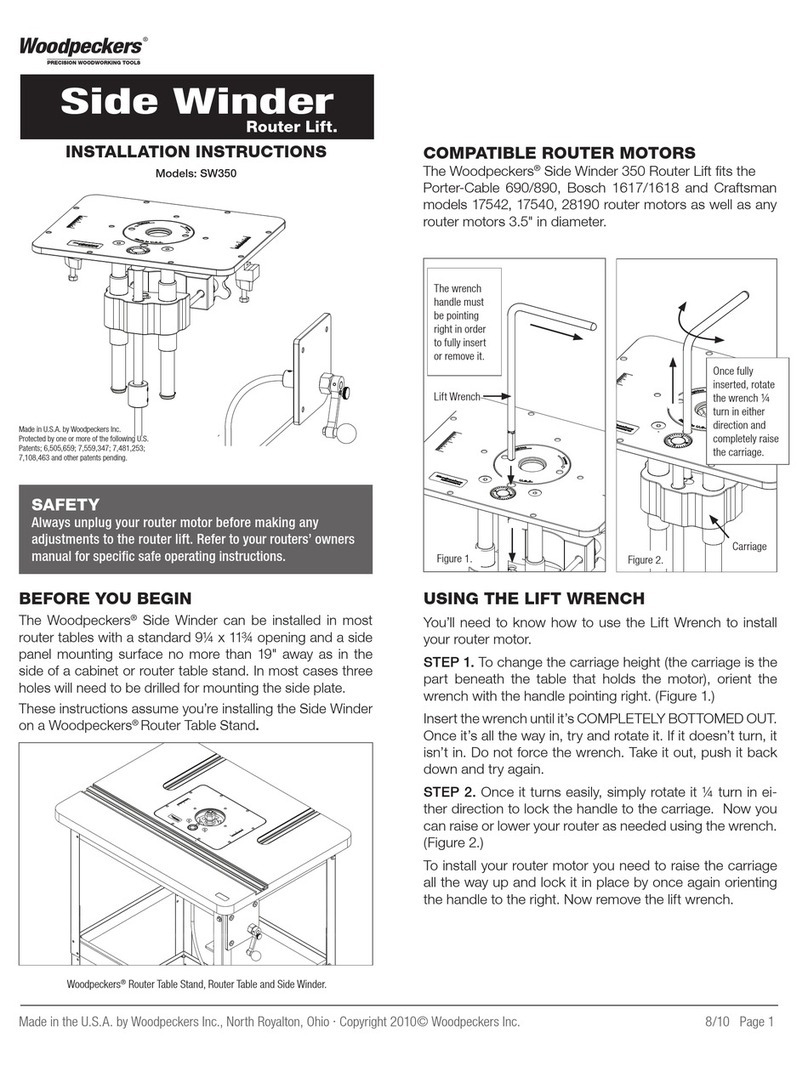

Fig. 2

Prior to Operation

The leveling system shall only be operated under the following conditions:

1. The unit is parked on a reasonably level surface.

2. Be sure all persons, pets and property are clear of the unit while LCI Level-Up Automatic System is in

operation.

3. Ensure the battery of the unit is fully charged or that the unit is plugged into shore power prior to

attempting to operate the system. Level-Up requires a minimum of 12V DC from the battery for proper

operation.

Operation

Basic Jack Operation

1. Landing gear Jacks

Landing gear jacks can be operated any time the system is “ON” but NOT in the “AUTO MODE.” By pushing

the “FRONT” button (Fig. 1G), both front or landing gear jacks can be extended. If the touch pad is put in the

“RETRACT” mode, indicated by the orange illuminated LED next to the “RETRACT” button (Fig. 1D), the front

jacks can be retracted together by pushing the “FRONT” button.

2. Level-Up jacks

The Level-Up jacks operate when the “AUTO MODE” is activated or the touch pad is in the “MANUAL MODE.”

Once system is in “MANUAL MODE,” pressing the “REAR” button (Fig. 1J) will extend all Level-Up jacks at the

same time. Press the “LEFT” or “RIGHT” buttons (Fig. 1H and 1I) to operate Level-Up jacks on the left or right

side of the unit, respectively.

5th Wheel Operation

Unhitching Instructions

1. Push touch panel “ON/OFF,” (Fig. 1K) to turn system on. LCD Screen (Fig. 1E) lights up.

2. LCD will display status … “NOT LEVEL JACKS: UP" (Fig. 2A).

NOTE: Orange arrow lights (Fig. 2B) may come on, indicating the current disposition of the unit.

3. Push "FRONT" button (Fig. 1G) to extend landing gear jacks and lift front of unit to take the weight of

the 5th wheel off of the hitch.

4. Uncouple the 5th wheel connection on the tow vehicle.

5. Pull tow vehicle away and park at a safe distance.

A

B

Rev: 04.05.2018 Page 5 Level-Up Towable Owner's Manual

Auto Level

NOTE: Prior to unhitching from the tow vehicle, ensure unit is parked on a level surface and chock the tires

of the unit.

1. After unhitching from tow vehicle press "AUTO LEVEL" (Fig. 1F).

NOTE: Pressing any button during an Auto Level sequence will abort the auto leveling cycle.

NOTE: In order for hitch recognition feature to function, the auto level sequence MUST be started with the

front of the unit above level.

Auto Level Sequence

1. Front landing gear retract, lowering the front of the unit below level, stopping, then lifting the front

end to level the unit front to back.

2. The left side leveling jack(s) extend and raise the roadside of the unit.

3. The right side leveling jack(s) extend and raise the curbside of the unit, beginning side to side leveling.

4. The front landing gear extend to complete the leveling cycle.

NOTE: Additional left to right or front to back leveling may occur if the controller deems necessary.

NOTE: If the auto level sequence does not happen as stated above, check to ensure proper manual function

in all zones.

Hitch Recognition

1. Turn on touch pad.

2. Press the "LEFT" and "RIGHT" buttons simultaneously (Fig. 1H and 1I).

3. The front of the unit will raise to the height where the auto level sequence was started.

NOTE: If the auto level sequence was started with the front of the unit in a below level condition, the Hitch

Recognition will not function and the LCD will display “Feature Disabled." In order for the hitch

recognition feature to function, the auto level sequence MUST be started with the front of the unit

above level.

4. Connect tow vehicle and make sure 5th wheel and hitch are connected and locked.

5. Push “UP” arrow (Fig. 1A) until ”AUTO RETRACT” appears in LCD screen.

6. Push “ENTER” (Fig. 1C). System will immediately retract all jacks.

Rev: 04.05.2018 Page 6 Level-Up Towable Owner's Manual

Travel Trailer Operation

Unhitching Instructions

NOTE: Prior to unhitching from the tow vehicle, ensure unit is parked on a level surface and chock the tires

of the unit.

1. Push “ON/OFF” button (Fig. 1K) to turn system “ON” (green light).

2. Push “UP” (Fig. 1A) or “DOWN” arrow (Fig. 1B) to scroll through features to “MANUAL MODE” in

display.

3. Push “ENTER” (Fig. 1C).

4. Push “FRONT” button (Fig. 1G) to extend front jacks to the ground until the trailer is unhitched from

the tow vehicle.

NOTE: The Power Tongue Jack should ONLY be used when storing the trailer.

Auto Level

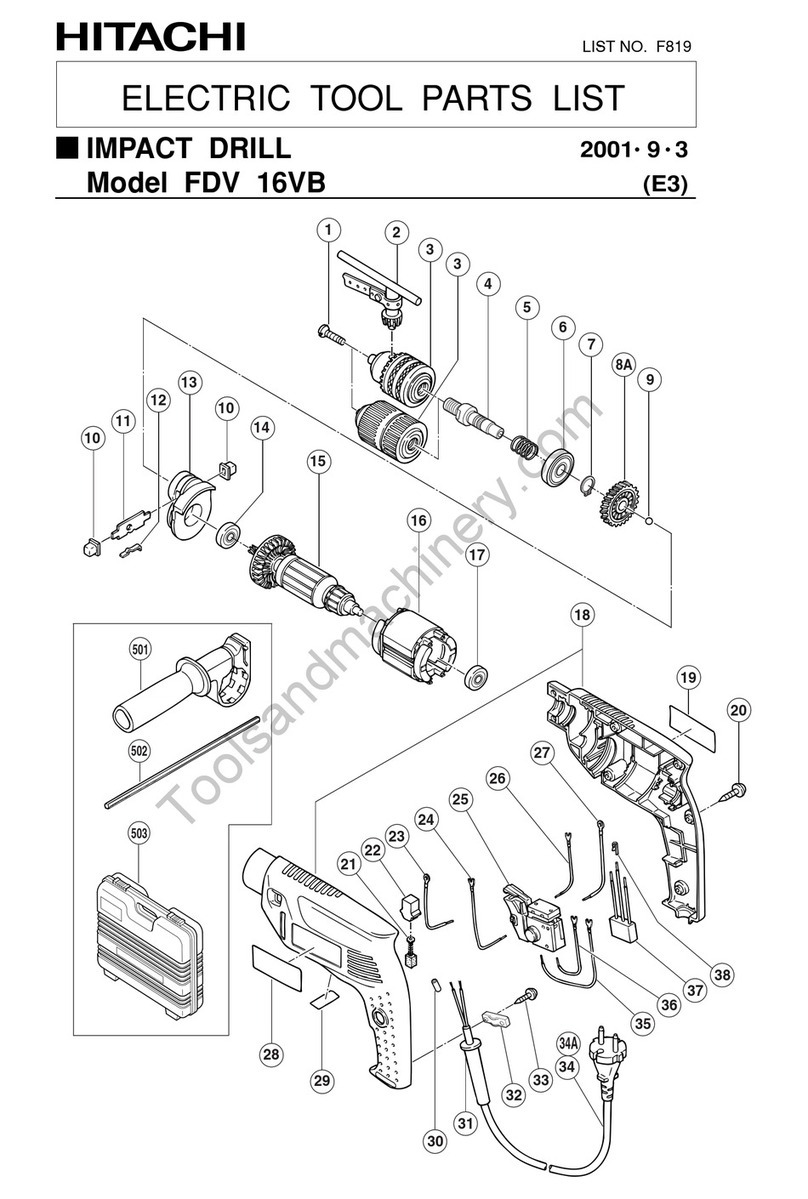

NOTE: The Power Tongue Jack MUST be retracted prior to starting auto level sequence (Fig. 3 shows the

LCD alert).

1. After unhitching from tow vehicle press "AUTO LEVEL" (Fig. 1F).

NOTE: Pressing any button during an Auto Level sequence will abort the auto leveling cycle.

NOTE: In order for hitch recognition feature to function, the auto level sequence MUST be started with the

front of the unit above level.

Auto Level Sequence

1. Front jacks retract, lowering the front of the unit below level, stopping, then lifting the front end to

level the unit front to back.

2. The rear left side leveling jack extends and raises the roadside of the unit.

3. The rear right side leveling jack extends and raises the curbside of the unit, beginning side to side

leveling.

4. The front jacks extend to complete the leveling cycle.

NOTE: Additional left to right or front to back leveling may occur if the controller deems necessary.

NOTE: If the auto level sequence does not happen as stated above, check to ensure proper manual function

in all zones.

Hitch Recognition

1. Turn on touch pad.

2. Press the left and right buttons simultaneously (Fig. 1H and 1I).

3. The front of the unit will raise to the height where the auto level sequence was started.

Fig. 3

Rev: 04.05.2018 Page 7 Level-Up Towable Owner's Manual

NOTE: If the auto level sequence was started with the front of the unit in a below level condition, the

Hitch Recognition will not function and the LCD will display “Feature Disabled.” In order for hitch

recognition feature to function, the auto level sequence MUST be started with the front of the unit

above level.

4. Connect tow vehicle and make sure travel trailer and hitch are connected and locked.

5. Push “UP” arrow until ”AUTO RETRACT” appears in LCD screen.

6. Push “ENTER.” System will immediately retract all jacks.

Manual Operation

1. Front landing gear (5th Wheels) or Front jacks (Travel Trailers)

NOTE: The landing gear or front jacks will operate manually any time system is “ON” except in “AUTO

MODE.”

A. Push “ON/OFF” (Fig. 1K) to turn system on.

B. Push “UP” arrow (Fig. 1A) once or until screen reads “MANUAL MODE” (Fig. 4).

C. Push “ENTER” (Fig. 1C) once while screen reads “MANUAL MODE" Fig. 4).

D. Push “FRONT” (Fig. 1G) to extend front landing gear or front jacks.

E. Push “RETRACT" (Fig. 1D) and orange LED (Fig. 5) comes on.

F. Push “FRONT” (Fig. 1G) to retract front landing gear or front jacks.

NOTE: If orange LED (Fig. 5) is on, landing gear or jacks will retract. If orange LED (Fig. 5) is off, landing gear

or jacks will extend.

G. Push “ON/OFF” to turn system off.

H. After 3 minutes system will turn off by itself.

Fig. 4 Fig. 5

2. Level-Up jacks - EXTEND

A. Turn “ON/OFF” button “ON."

B. Push scroll arrow to display “MANUAL MODE” (Fig. 4).

C. Push “ENTER" button, “MANUAL MODE” displayed (Fig. 4).

NOTE: By pushing “RIGHT,” passenger side Level-Up jacks operate. By pushing “LEFT,” driver side Level-Up

jacks operate, and so on.

3. Level-Up jacks - RETRACT

A. Push “RETRACT" and orange LED (Fig. 5) will come on.

B. Push “REAR” to retract all Level-Up jacks.

C. To extend, the “RETRACT“ light (Fig. 5) should be off.

NOTE: The side to side movement in manual mode is limited to 5oof tilt.

Rev: 04.05.2018 Page 8 Level-Up Towable Owner's Manual

Zero Point Calibration

The “Zero Point” is the programmed point that the unit will return to each time the Auto Level feature is used.

The “Zero Point” must be programmed prior to using the Auto Level feature to ensure the proper operation of the

system.

NOTE: Prior to starting this procedure, double check all connections on the controller, jacks, and touch pad.

1. Manually run the jacks to level the unit. This is best achieved by placing a level in the center of the unit

and leveling it both front to back and then side to side. (See “Basic Jack Operation” for instructions on

how to manually operate the system).

2. Once the unit is level, turn off the touch pad.

3. With the touch pad off, press and release the “FRONT” button (Fig. 1G) ten (10) times and then press

and release the “REAR” button (Fig. 1J) ten (10) times.

4. The touch pad will flash and beep and the display will read “ZERO POINT CALIBRATION ENTER to set,

Power to Exit” (Fig. 5).

5. To set the current position as the zero point, press the “ENTER” button (Fig. 1C).

6. LCD display will read “Zero Point stability check” (Fig. 6).

7. LCD display will read “Zero point set successfully” once process is complete (Fig. 7).

8. The system will set this point as its level state and the touch pad will turn off.

Fig. 5

Fig. 6

Fig. 7

Rev: 04.05.2018 Page 9 Level-Up Towable Owner's Manual

Troubleshooting

Error Display in LCD Screen

NOTE: To clear Error Code, push "ENTER" - If error remains, the code will appear again.

Maintenance

1. Each month, check that the fluid level is within ¼" of the fill spout lip while jacks and slide-outs are fully

retracted.

NOTE: Always fill the reservoir with the jacks and slide-outs in the fully retracted position. Filling reservoir

when jacks and slide-outs are extended will cause reservoir to overflow into its compartment when

jacks and slide-outs are retracted.

2. Inspect and clean all power unit electrical connections prior to the first use of the unit of the season

and prior to storing the unit. If corrosion is evident, clean all corrosion with a wire brush and apply

dielectric grease to the connections.

3. Remove dirt and road debris from jacks as needed.

4. If jacks are down for extended periods, it is recommended to spray exposed leveling jack rods with a

silicone lubricant every three months for protection. If the unit is located in a salty air environment, it is

recommended to spray the rods every 4 to 6 weeks.

Fluid Recommendation

The Lippert Electronic Leveling System is pre-filled, primed and ready to operate direct from the

manufacturer. Type “A” Automatic Transmission Fluid (ATF) is utilized and will work. ATF with Dexron III® or

Mercon 5® or a blend of both is recommended by Lippert Components, Inc.

In colder temperatures (less than 10° F) the jacks may extend and retract slowly due to the fluid’s molecular

nature. For cold weather operation, fluid specially formulated for low temperatures may be desirable. For a

list of approved fluid specifications, see TI-188.

LCD Message What's Happening? What Should I Do?

"EXCESS ANGLE" Unsecured controller.

Uneven or sloped site.

Check and secure controller placement.

Relocate the unit.

"BAD CALIBRATION" Unit zero point was not set correctly. Reset zero point. See "Calibration."

"FEATURE DISABLED" Front of unit below level when

starting Auto Level process.

Raise front of unit above level and restart

Auto Level process.

"LOW VOLTAGE" Bad connection or wiring.

Discharged or bad battery.

Check wiring - repair or replace.

Test battery voltage under load - charge or

replace.

"OUT OF STROKE" Unsecured controller.

Uneven or sloped site.

Check and secure controller placement.

Relocate the unit.

"EXTERNAL SENSOR" Bad connection or wiring. Replace or repair connection to rear remote

sensor.

"JACK TIME OUT" System could not level in expected

time.

Check for obstructions, leaks, fluid level and

voltage to power unit motor under load.

"AUTO LEVEL FAILURE" Unsecured controller.

Voltage drop.

Check and secure controller placement.

Test battery voltage under load - charge or

replace.

Rev: 04.05.2018 Page 10 Level-Up Towable Owner's Manual

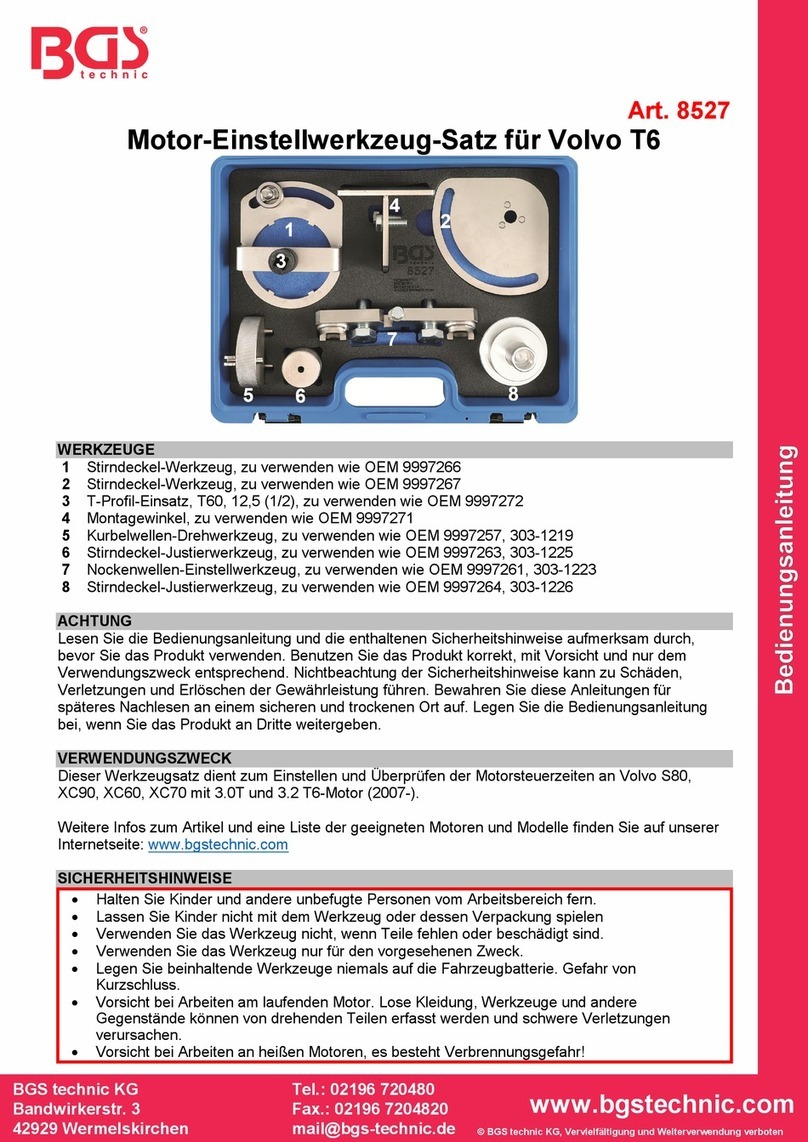

Manual Override

The LCI Level-Up Automatic Leveling System can be manually operated with an electric drill. In the event of

electrical or system failure, this manual method of extending and retracting the jacks can be used. See the

instructions below.

NOTE: Unhook the power unit motor from the power source prior to attempting the manual override

procedure.

1. Locate the valves that are paired with the landing gear or leveling jack to be manually overridden.

A. Landing Gear - Valve located on the landing gear (Fig. 8).

B. Leveling Jacks - Valve located on manifold (Fig. 9).

2. Using a ⁄” hex wrench, open the valve by turning the manual override set screw clockwise (Fig. 10A).

3. Remove protective label (Fig. 11A) from power unit to reveal the manual override coupler.

4. Using an electric drill with a ¼" hex bit, insert the hex bit into the manual override coupler to manually

operate the Level-Up system (Fig. 12).

A. Run the drill forward (clockwise) to retract the landing gear or leveling jack (Fig. 12A).

B. Run the drill in reverse (counterclockwise) to extend the landing gear or leveling jack (Fig. 12B).

5. Be sure to turn the manual override set screw on the valve (Fig. 13A) back to the counterclockwise

position after extending or retracting the landing gear or leveling jack.

A

A

A

A

B

Fig. 8 Fig. 9 Fig. 10

Fig. 11 Fig. 12 Fig. 13

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 11 of 22

LEVELING AND STABILIZATION

FIFTH WHEEL LEVEL-UP® 4 POINT ASSEMBLY

Spade Coil x3

Nut ½" x20

Bolt ½" x20

Swivel Straight Fitting x2

Quick Disconnect x2

Cartridge Valve x3

90° Elbow Fitting x15

T-Fitting x2

Hollow Hex Plug x2 Hex Plug

Landing Gear Bracket x2 Leveling Jack Bracket x2

Landing Gear x2 Leveling Jacks x2 Manifold

Power Unit

Assembly

Hollow Hex Plug x2

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 12 of 22

LEVELING AND STABILIZATION

TRAVEL TRAILER LEVEL-UP® 4 POINT ASSEMBLY

Spade Coil x3

Nut ½" x20

Bolt ½" x20

Swivel Straight Fitting x8

Cartridge Valve x3

90° Elbow Fitting x21

Leveling Jacks x4

Power Unit

Assembly

Hollow Hex Plug x2

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 13 of 22

LEVELING AND STABILIZATION

FIFTH WHEEL LEVEL-UP® 6 POINT ASSEMBLY

Spade Coil x3

Nut ½" x20

Bolt ½" x20

Swivel Straight Fitting x13

Quick Disconnect x2

Cartridge Valve x3

90° Elbow Fitting x17

T-Fitting x2

Hollow Hex Plug x2 Hex Plug

Leveling Jack Bracket x4

Landing Gear x2 Leveling Jacks x4 Manifold

Power Unit

Assembly

12v Deutsch Coil

Landing Gear Bracket x2

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 14 of 22

LEVELING AND STABILIZATION

LEVEL-UP® ELECTRONIC COMPONENTS

Pressure

Switch Controller

Rear Sensor

Harness

Touch Pad

Harness

Controller

Harness

Touch Pad

80 AMP 12V

Breaker

Rear Sensor

Mounting

Plate Remote

Rear Sensor

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 15 of 22

LEVELING AND STABILIZATION

LEVEL-UP® COMPONENTS

Callout Part # Description

A251910 Vertical Power Unit

B251909 Horizontal Power Unit

C118246 Dual Polarity Solenoid

D174184 Deutsch Coil

E176954 Spade Coil

F177094 Cartridge Valve

G142927 Pressure Switch

H167576 Power Unit Motor

I157505 Fill Cap

I

H

G

F

E

D

C

B

A

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 16 of 22

LEVELING AND STABILIZATION

LEVEL-UP® COMPONENTS

J

M

O

P

Q

R

Callout Part # Description

J234802 LCD Touch Pad

K241316 Touch Pad Harness

L237855 Deutsch 2 Wire Pigtail Harness

M241129 Controller

N *135461 80 AMP 12V Breaker

O241318 Controller Harness

P232201 Rear Sensor

Q231775 Rear Sensor Mounting Plate

R241314 Rear Sensor Harness

NOTE: * Circuit Protection requirement is 50 amps to 100 amps

as needed by RVIA Standards and OEM requirements.

K

L

N

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 17 of 22

LEVELING AND STABILIZATION

LEVEL-UP® COMPONENTS

Callout Part # Description

S257125 Right 14k lb. Rated Landing Gear, Aluminum

T257126 Left 14k lb. Rated Landing Gear, Aluminum

U195860 8k lb. Rated Leveling Jack, Aluminum

V 113309 Footpad

W123932 Footpad O-Ring

X178208 Footpad Washer

Y118076 Bolt; ½" - 20

Z178210 Nut; ½" - 20

AA 134989 Mount Bracket

AB 218210 Mount Bracket

AB

AA

Y

X

W

V

U

T

S

Z

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 18 of 22

LEVELING AND STABILIZATION

LEVEL-UP® COMPONENTS

Callout Part # Description

AC 113042 Hose Union Fitting

AD 113131 Straight Fitting

AE 113128 JIC to O-Ring 90 Degree Elbow Fitting

AF 113130 T-Fitting with O-Ring on Run

AG 113134 Swivel Elbow Fitting

AH 113135 Swivel T-Fitting

AI 113129 45 Degree Elbow Fitting

AJ 113133 Swivel Straight Fitting

AK 141020 Swivel Elbow Fitting

AL 216288 Steel Cap Fitting

AM 139417 Long Straight Fitting

AN 138423 Union T-Fitting

AO 136225 Cross Fitting

AP 138416 Hose Coupling

AQ 140457 Quick Disconnect

AR 141323 Hex Plug

AS 140998 Hollow Hex Plug

AG

AF

AE

AD

AC

AS

AR

AQ

AP

AO

AN

AM

AL

AK

AJ

AI

AH

Rev: 04.05.2018 Contact us: Lippert Components Inc. - www.lci1.com/support - Phone: (574) 537-8900 - Email: [email protected] Page 19 of 22

LEVELING AND STABILIZATION

LEVEL-UP® COMPONENTS

Callout Part # Description

AT 138420 Manifold

AU 138421 Restricted Manifold

AV 166078 8 Port Header Block

AW 248654 Orange Hose

AX 248653 Black Hose

AY 194712 4 Position Eirc Block w/ Mounting

Holes and Pass Through

AT

AY

AX

AW

AT

AV

AT

AU

ATAT

Rev: 04.05.2018 Page 20 Level-Up Towable Owner's Manual

Notes

Other manuals for Level-Up

5

Table of contents

Other Lippert Components Tools manuals

Popular Tools manuals by other brands

ITW Gema

ITW Gema PG 1-R1 Operating instructions and spare parts list

Cornwell Tools

Cornwell Tools CAT850XLR operating instructions

American Lubrication Equipment

American Lubrication Equipment DEF-52H33S manual

Challenger Mobility

Challenger Mobility J2840 Assembly instructions

Mountz

Mountz TorcoTronic operating instructions

XPOtool

XPOtool 61479 Operation manual