Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 5

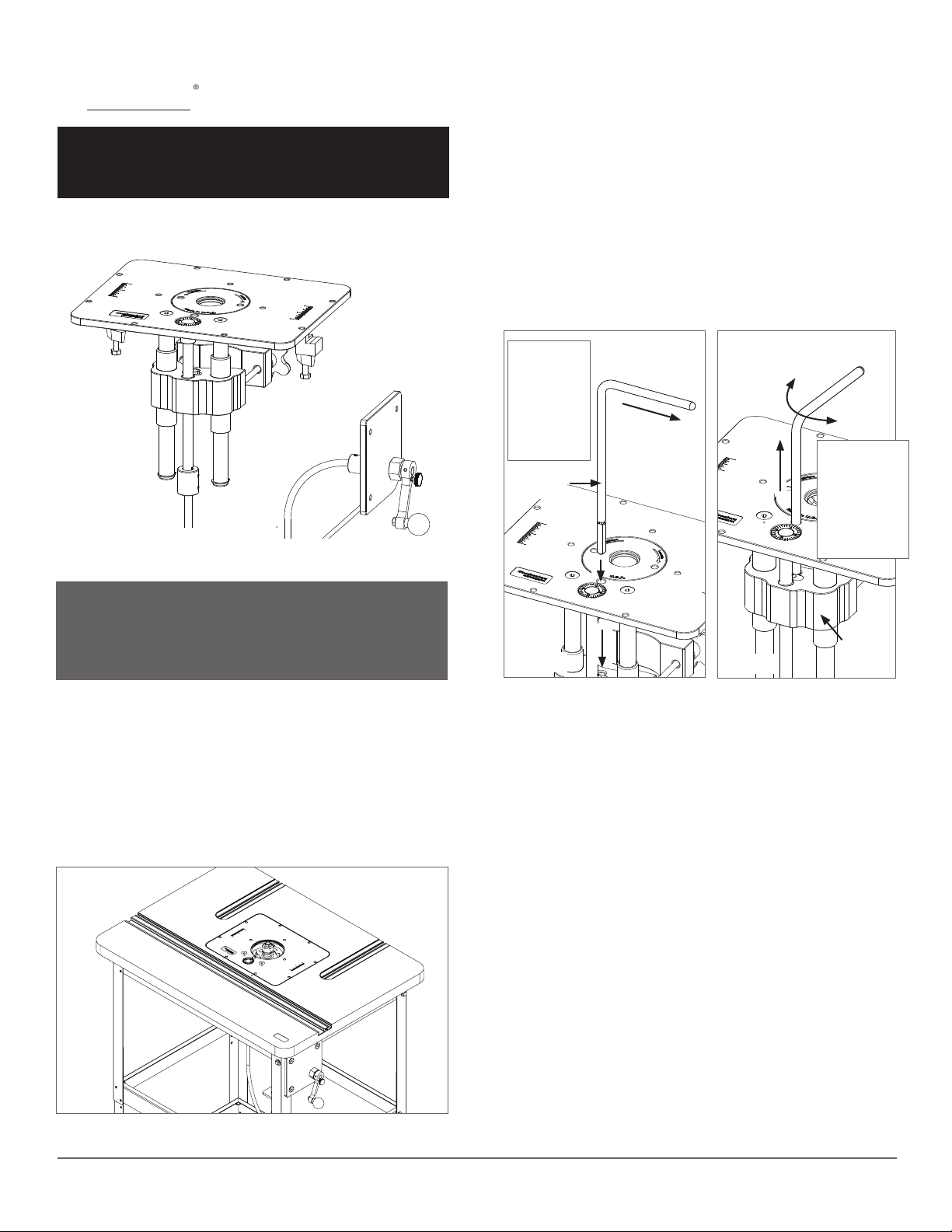

LEVELING THE PLATE

Before adjusting the leveling

screws you need to loosen

the clamp knobs underneath

the table. There are eight set

screws around the perimeter

for adjusting the height of the

plate relative to the table. Initial

leveling should be done with

just four of the screws, two each on opposite ends of the

plate. Once the plate feels flush, use a block of wood to

make sure it doesn’t catch going either direction then ad-

just the remaining screws.

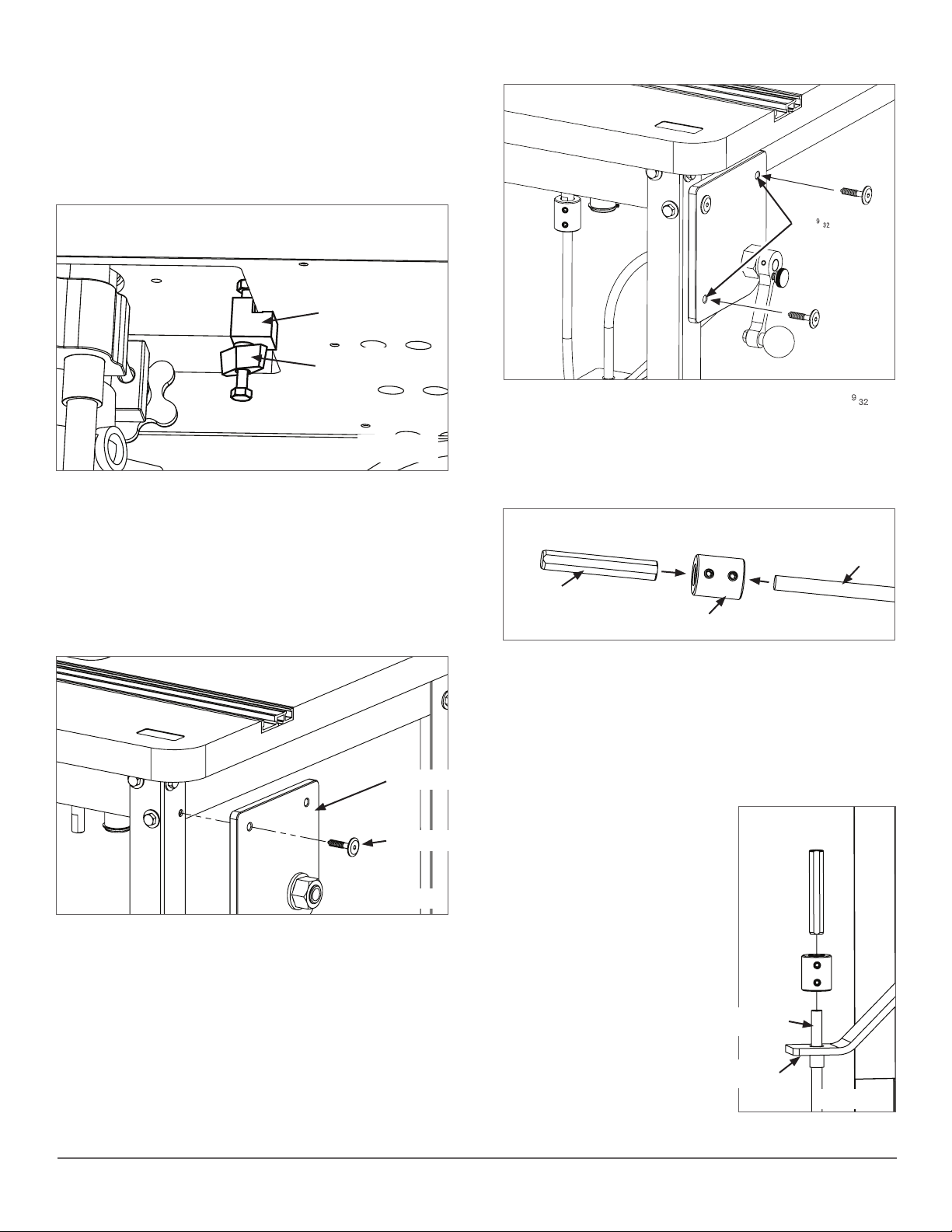

CHANGING BITS

First use the spanner

wrench to remove the Twist

Lock Ring. Now use the lift

wrench to raise the router

chuck completely above

the plate. Use the wrench-

es supplied with your rout-

er to change the bit. (Image

may not match your Side

Winder but the process is

the same.

GENERAL OPERATING INFORMATION

ROUTINE MAINTENANCE

The Side Winder is made primarily from aluminum and steel

parts. The steel parts will have a light coating of petroleum

jelly when it leaves the factory. After unpacking, if necessary,

clean aluminum parts, including the main plate, with mineral

spirits or lacquer thinner. Do not use any water based cleaner.

The two steel posts should be wiped with a clean rag and

lubricated with petroleum jelly or a very light machine oil. The

flex shaft can be periodically sprayed with a lubricant such as

WD40 then wiped dry.

Minor surface rust on any steel parts can be removed with

abrasive nylon pads like a scotch bright pad. All steel parts

should be kept lubricated with petroleum jelly or thin machine

oil, particularly the posts and lift screw.

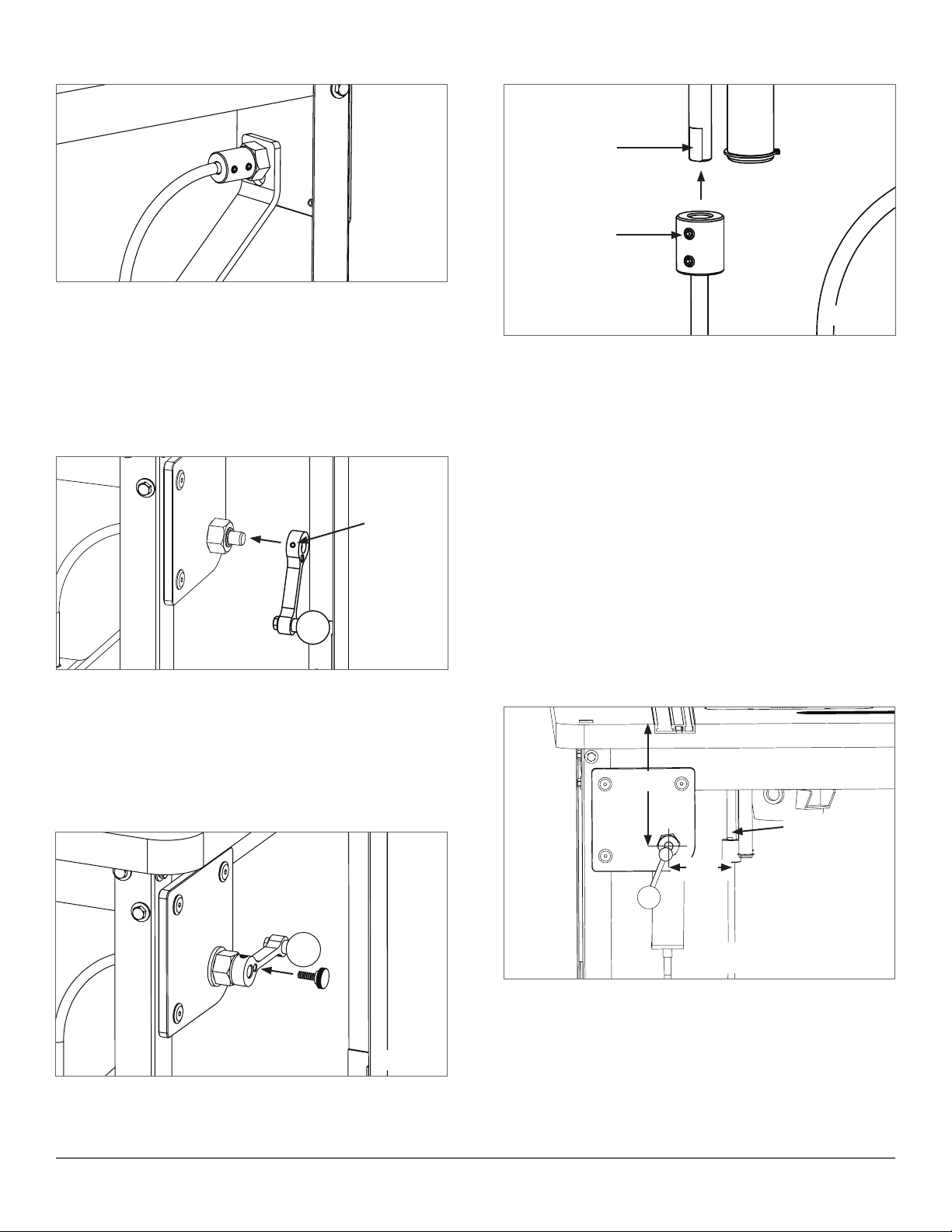

ADJUSTING THE SCALE

The adjustable scale is used

to reference the amount of

height change relative to a

starting position. One rota-

tion equals 1⁄32". Each line

equals .001".

The scale

can be adjusted by apply-

ing downward finger pres-

sure then rotating it in either

direction. Built in friction

keeps it from free spinning.

Adjustable scale.