LIQUIPRINT WB20141117 User manual

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

LIQUIPRINT 3D PRINTER

USER MANUAL

VERSION: WB20141117

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

Table of Contents

A. MACHINE SPECIFICATIONS ............................................................................................................................................ 2

B. SOFTWARE INSTALLATION............................................................................................................................................. 2

B.1 SOFTWARE INSTALLTION............................................................................................................................................ 2

B.2 SOFTWARE CONFIGURATION.....................................................................................................................................3

C. SOFTWARE SETTINGS ..................................................................................................................................................... 4

C.1 CONFIGURATION FILE LEAD-IN ................................................................................................................................ 4

C.2 QUICKPRINT PRINTING................................................................................................................................................ 5

C.3 FULL SETTINGS PRINTING .......................................................................................................................................... 6

D. ACCESSORIES INSTALLATION AND BASIC FUNCTIONS....................................................................................... 7

D.1 A

CCESSORIES

I

NSTALLATION

............................................................................................................................................. 7

D.2 B

ASIC

F

UNCTIONS

.............................................................................................................................................................. 8

D.2.1 MACHINE TESTS ................................................................................................................................................... 9

D.2.2 Level Build Plate (Important) ................................................................................................................................. 9

D.2.3 LOADING ............................................................................................................................................................... 1

D.2.4 Change Filament During Printing........................................................................................................................ 11

D.2.5 UNLOADING.......................................................................................................................................................... 13

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

E. MACHINE MENU EXPLANATION .................................................................................................................................. 13

F. START PRINTING............................................................................................................................................................... 14

F.1 MODEL EDITION........................................................................................................................................................... 14

F.1.1 ROTATE................................................................................................................................................................... 15

F.1.2 SCALE ..................................................................................................................................................................... 15

F.1.3 FLIPPING (MIRROR) ............................................................................................................................................ 16

F.1.4 OTHER EDITTINGS.............................................................................................................................................. 16

F.1.5 VIEM MODE ........................................................................................................................................................... 17

F.2 PRINT FROM SD CARD (RECOMMENDED) ............................................................................................................. 17

F.3 PRINT FROM COMPUTER............................................................................................................................................ 18

G. CONTINUE THE PRINT AFTER POWER CUT............................................................................................................. 20

H. MACHINE MAINTENANCE.............................................................................................................................................. 23

I. CONTACT US....................................................................................................................................................................... 24

AFTER-SALE SERVICES..................................................................................................................................................... 25

1

We are so excited to welcome you to the Liquiprint 3D printer community. 3D printers are precision

manufacturing equipment. Therefore, this User Manual is designed to start your journey with the Liquiprint

desktop 3D printers in the right direction.

Due to long distance of transportation, please kindly unpack the machine box and check all the accessories

and tool sets before using your new machine, to make sure everything is OK: bolts fastened. Also please

remove those fixtures or padding used for the transportation. If there are questions or exceptions, please feel

free to contact us any time!

Before the first print, you need to know the following:

1. This is machine have been strictly tested before delivery. If it refuses to work when you receive it, please

kindly contact us as soon as possible.

2. Please save all packing materials for the machine in case of transportation and future repair (in factory). If

the machine will go through long distance transportation or be sent back to the factory for repair work,

please make sure that the machine has been well packed as the original packing. For repair issue, it is

unnecessary to send back the related accessories, such as the glass.

3. If you encounter any malfunctions for unknown reason, please turn off the machine and contact us as

soon as possible.

4. The materials for this machine are PLA and PETG.

5. Since it is a kind of plastic modeling machine, it may give out certain unpleasant smell during printing.

Please make sure the machine is working in a place with good ventilation.

6. The machine’s working environment should be between 15 to 35

℃

.

7. Protect the machine from humidity and dust.

8. Both the build plate and the extruder are heating parts. Please keep away from these two parts during

heating or printing process. Before repair, please cool down these two parts first.

9. The glass is fragile. During maintenance or repair work, please take away the glass first.

10. A 3D printer is a machine instead of a toy. Therefore, please don’t leave the kids along with the

machine.

11. This User Manual is updated all the time. You may contact us for the latest version if we fail to notify you.

We will reserve the final interpretation on the User Manual.

12. Unpack the machine. Take out the machine as well as the accessories.

13. Install CURA, the software on the computer.

14. Power on the machine and level the build plate.

15. Load the material: PLA or PETG.

16. Transfer STL file into “.gcode”by CURA.

17. Save the “.gcode”file to the SD card and insert it to the machine. Find out the “.gcode” file that you need

to print.

18. Wait for the printing.

19. Make sure the machine is well working and material is enough.

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

2

A. MACHINE SPECIFICATIONS

B. SOFTWARE INSTALLATION

B.1 SOFTWARE INSTALLTION

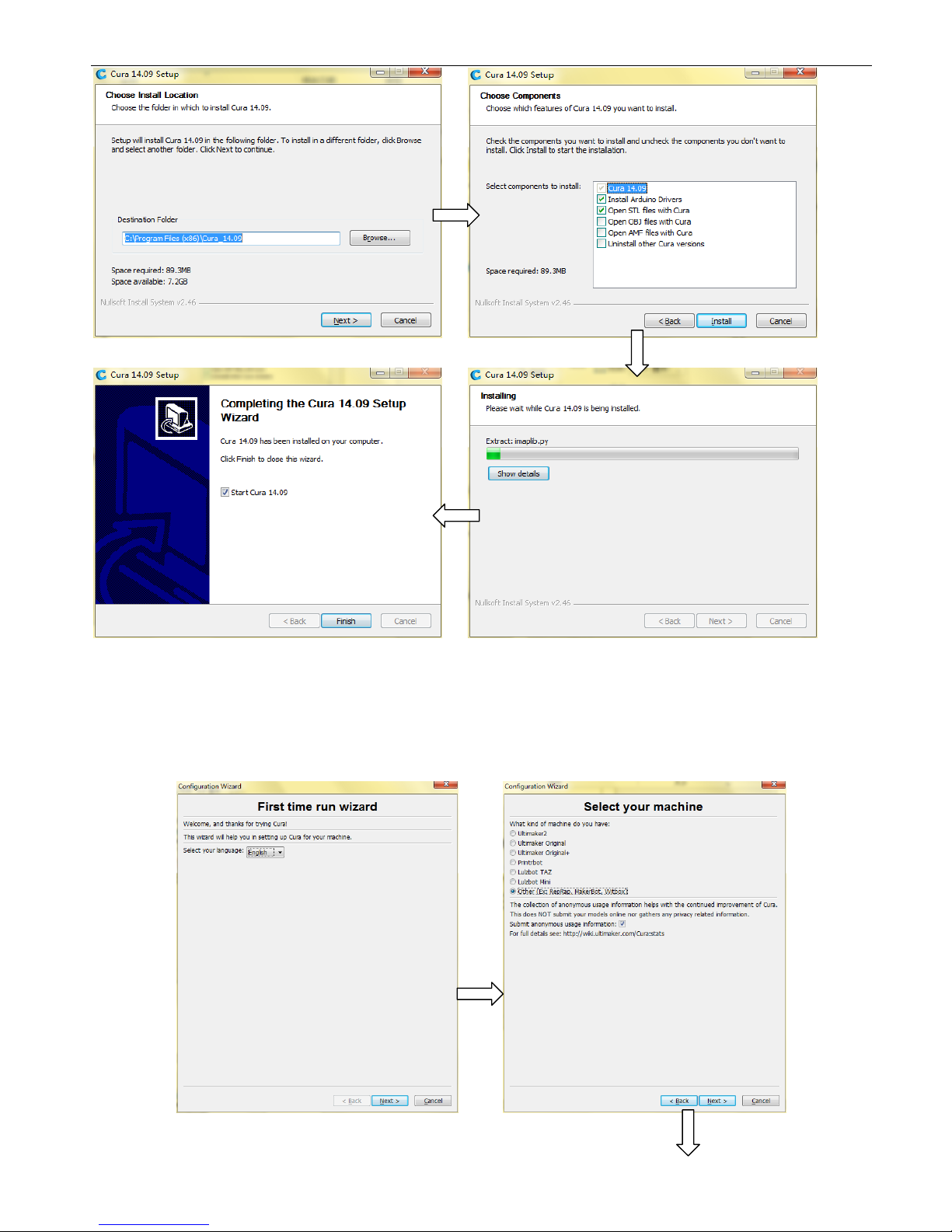

Inside the SD card, there is the operation software for our machine. Double-click on “Cura_14.09.exe” and

install it by following default options as shown below:

PHYSICAL SPECIFICATIOS

DRAGO

MACHINE SIZE: 44 x 36 x 74 mm

CBM: 56 x 485 x 96 mm

MACHINE WEIGHT: 16.2 kg

SHIPPING WEIGHT: 38.5 kg

PRACTICAL

MACHINE SIZE: 44 x 36 x 54 mm

CBM: 56 x 485 x 76 mm

MACHINE WEIGHT: 14.5 kg

SHIPPING WEIGHT: 35.4 kg

VALUE

MACHINE SIZE: 38 x 36 x 44 mm

CBM: 52 x 5 x 625 mm

MACHINE WEIGHT: 11.7 kg

SHIPPING WEIGHT: 19.7 kg

MII

MACHINE SIZE: 335 x 3 5 x 39 mm

CBM: 475 x 445 x 56 mm

MACHINE WEIGHT: 9.2 kg

SHIPPING WEIGHT: 14.4 kg

TEMPERATURE

NOZZLE TEMPERATURE:

-24

(

no

more than 26

℃

)

BUILDPATE TEMPERATURE: -11

℃

(

adjustable

)

BUILDPATE HEATING: around 5 min

NOZZLE HEATING: around 3 min

PRITIG

LAYER THICKNESS: . 6- .4 mm (adjustable)

PRITNING MATERIALS: PLA / PETG / ABS

FILAMENT DIAMETER: 3. mm

NOZZLE DIAMETER: .4 mm

NOZZLE MOVING SPEED: 2

-15 mm/s

(

ADJUSTABLE

)

POSITIONING PRECISION:

Z-AXIS: . 2 mm

XY-AXIS: . 1 mm

BUILD TYPE:

FDM (FUSED DEPOSTION MODELING)

POWER SUPPLY

Connection: USB or SD CARD

AC INPUT: 95-23 V, 5 -6 Hz

Output: 24V

Rated current: 14.6A

MACHINE POWER: 35 W (Mini Style: 15 W)

Working temperature: -2

℃

-6

℃

SOFTWARE

FILE FORMAT: .stl

Input file: Gcode

OPERATONAL SOFTWARE: Professional 3D

printer software

SUPPORTS: Windows

,

Linux

,

Mac OX

3D DESIGN SOFTWARES:

SolidWorks, PRO-E, UG, Auto CAD, 3ds-Max,

Maya etc.

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

3

B.2 SOFTWARE CONFIGURATION

To run the software for the first time, you will encounter a welcome interface. Click on “Next” to enter the First

time run wizard and you may follow the instructions as below:

ext C oose Ot er and ext

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

4

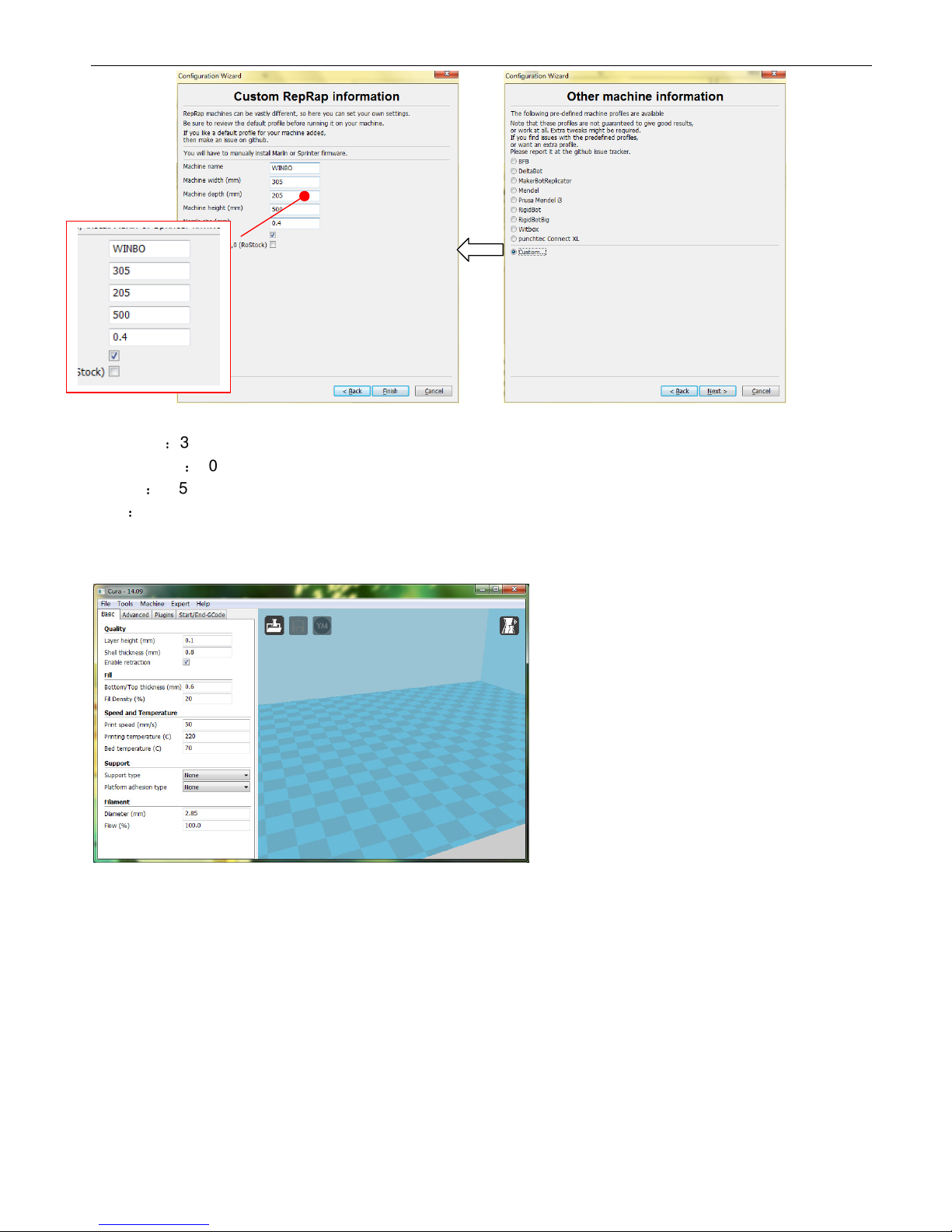

Build size:

DRAGON

:

305 x 205 x 500 mm

PRACTICAL

:

305 x 205 x 300 mm

VALUE

:

245 x 205 x 200 mm

MINI

:

210 x 150 x 150 mm

Here comes the interface for the software:

If the machine has not been connected with the computer, you may skip the First time run wizard. When

running the software, you may enter the First time run wizard by coming to the “Expert” →”ReRun first run

wizard” under the menu.

C. SOFTWARE SETTINGS

C.1 CONFIGURATION FILE LEAD-IN

You may finish the software settings by leading in the configuration file in the SD card. Click on “File” and

choose “Open Profile”. Find out the “WinBo-3D Printer.ini” and click on it.

C oose Option and ext

Put in mac ine specifications

and Finis

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

5

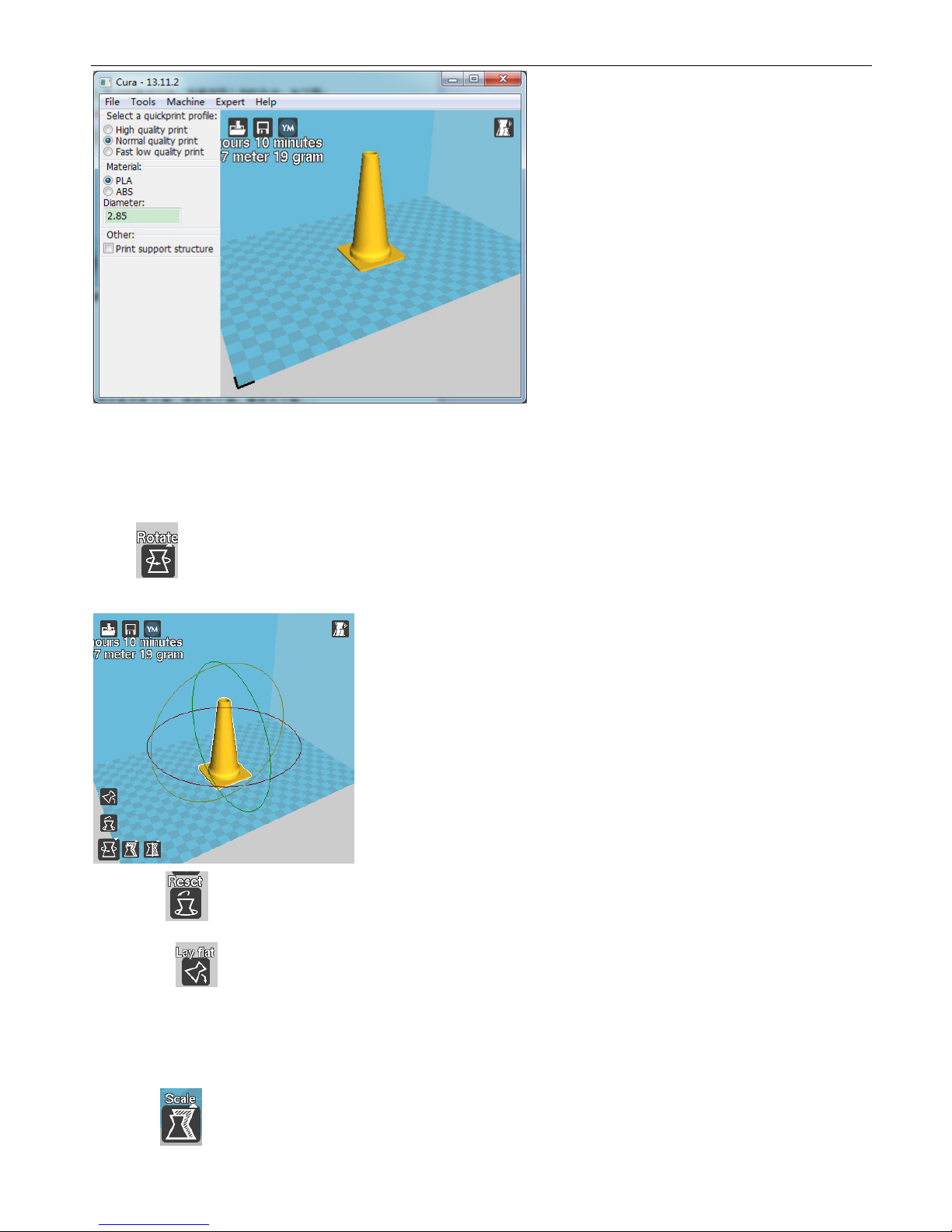

C.2 QUICKPRINT PRINTING

When running the software the default option is QUICKPRINTING mode. On the left, you will find the

Specifications and Screen as shown below:

There are 3 types of QUICK PRINT High quality print, Normal quality print, Fast low quality print. You may

print with PLA or PETG.

A. 3 types of QUICK PRINT:

High quality print

Normal quality print

Fast low quality print

B. Choose the material for the printing: PLA or ABS

C. Diameter for the filaments: 2.85mm

D. Print suport for the sample

Specifications

Screen

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

6

C.3 FULL SETTINGS PRINTING

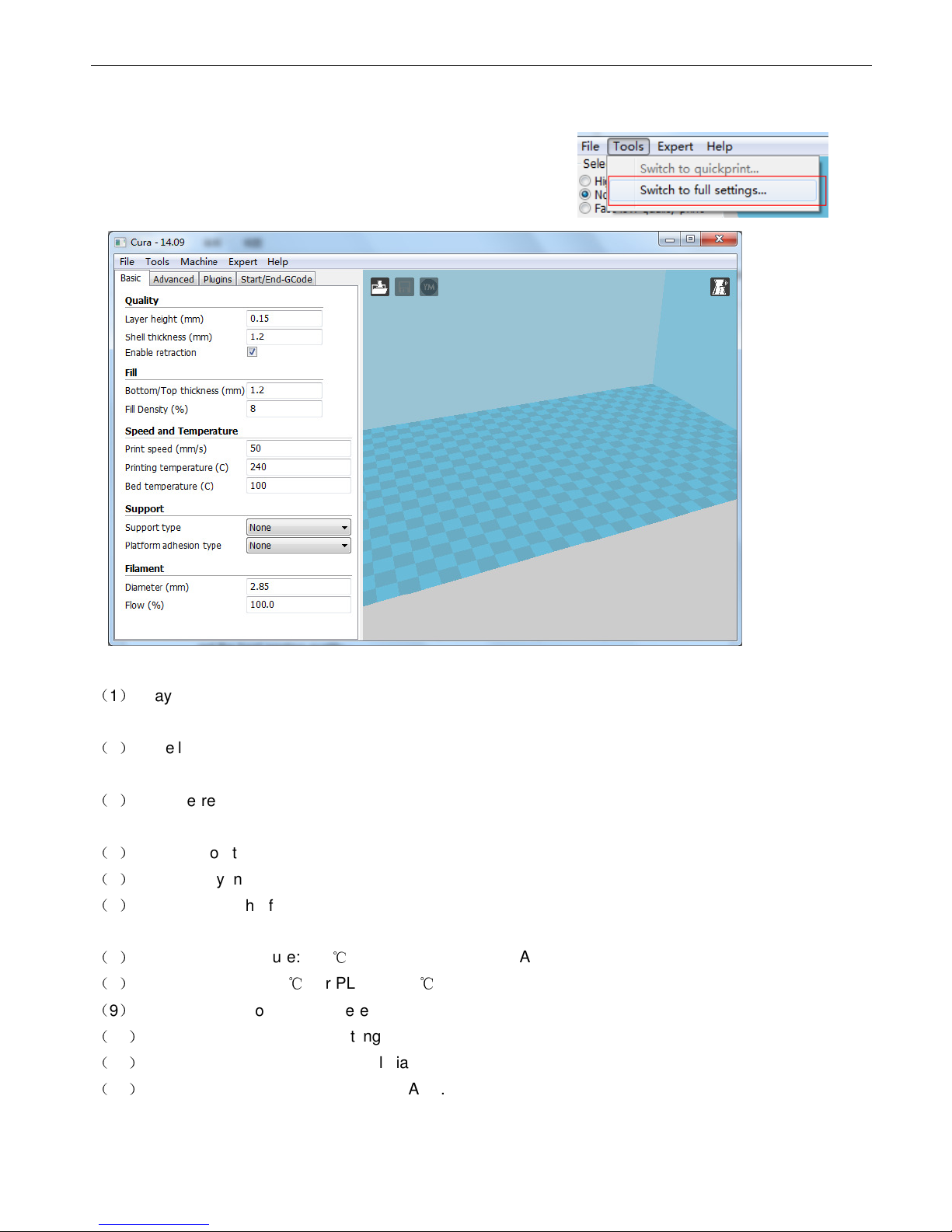

Choose “Tools” under the menu”Switch to full settings” as below:

BASIC SETTINGS ARE AS BELOW:

(

1

)

Layer height: thickness for each layer. Normally it is 0.15mm. If you need high resolution, you may

choose smaller one.

(

2

)

Shell thickness: the amount should bea multiple of 0.4. You may need to adjust this amount to get the

best printing quality.

(

3

)

Enable retraction: Retract the filament while it is not printing. Enable recommended, otherwise, it will

create fine lines during printing.

(

4

)

Bottom/Top thickness: it is related to the printing speed.

(

5

)

Fill Density: normally it is 10-30%.

(

6

)

Print Speed: the faster the print speed, the faster the feeding speed. And the result is burrs created

during printing.

(

7

)

Printing Temperature: 230

℃

for ABS, PETG and PLA.

(

8

)

Bed Temperature: 0

℃

for PLA and 70

℃

for ABS.

(

9

)

Support Type: to choose where to print the support.

(

10

)

Platform adhesion type: a setting to help the printed object stick to the printer bed.

(

11

)

Diameter: you may put the actual diameter.

(

12

)

Flow (%):100% for PLA and 85% for ABS.

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

7

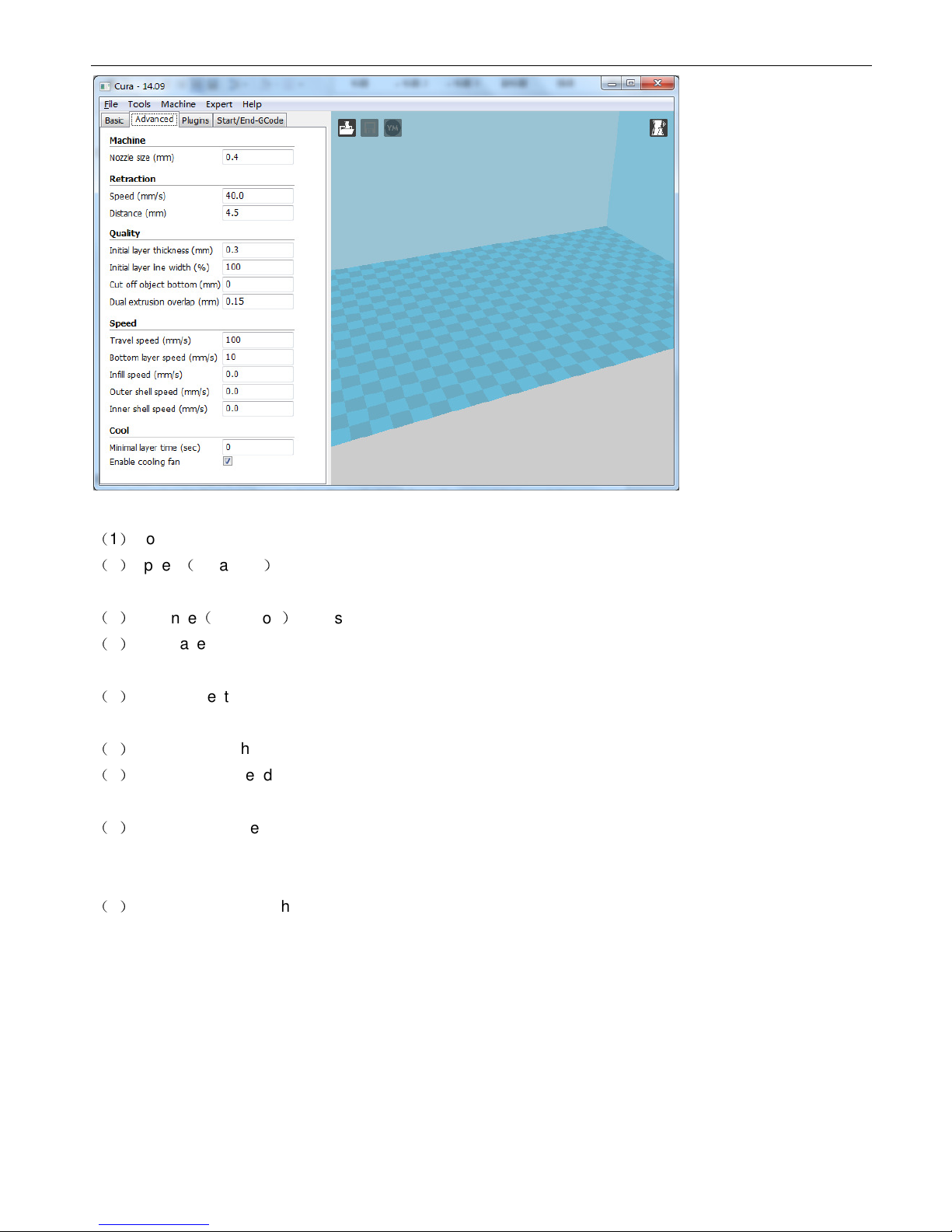

Advanced settings:

(

1

)

Nozzle size: 0.4mm (fixed).

(

2

)

Speed

(

retraction

)

: the speed for retraction. Retraction is pulling the filament back when moving over a

gap in the print.

(

3

)

Distance

(

retraction

)

: if it is 0, it mean no retraction made at all.

(

4

)

Initial layer thickness: a thicker layer gives a thicker bottom layer which is easy to stick to the platform. If

it is 0, it means the same bottom layer as the printing layer.

(

5

)

Cut off object bottom: Cut the bottom of the model, this effectively sinks the object into the printer bed. If

your object does not have a lot of contact area with the printer bed then this feature could help you.

(

6

)

Travel speed: the speed at which the printhead moves when it is not printing.

(

7

)

Bottom layer speed: the speed at which the printhead moves while it is laying down the first layer. This is

done to make the print stick easier.

(

8

)

Minimal layer time: the minimal time spent on printing a single layer. If a layer takes less time to print than

this configured time, then the layer is cooled down. This ensures that a layer is cooled down and solid

enough before the next one is put on top.

(

9

)

Enable cooling fan: the cooling fan is usually enabled and greatly improves print quality for PLA.

Note: for the Advanced setting, normally, they are default and require little adjustment.

D.

Accessories Installation and Basic Functions

D.1 Accessories Installation

Unpacking the machine, you need to install the accessories:

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

8

D.2 Basic Functions

There is a control knob on the right of the LCD panel and the functions are as below:

You may press the knob for confirmation

Rotate it counter-clockwise: you are reading the next menu

Rotate it clockwise: you are reading the last menu

With power on, the LCD panel shows as below:

Put the spool holder

Load the filaments spool

Connect the cable

Put on the glass plate

Pull out he blue buckle on the

feeder mechanism

Insert the other end of the

transparent tube

Put back the blue buckle

2

22

2

1

11

1

3

33

3

4

44

4

5

55

5

6

66

6

7

77

7

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

9

After pressing the knob, there will be “ticking” sound and then comes to the next interface on the LCD panel:

D.2.1 MACHINE TESTS

You may need to test the machine first before printing.

Check the movement on each axis.

1) Check the X-axis. If it moves, it is OK.

Go to the LCD panel and choose “Prepare” →”Move Axis” →”Move 1mm” →”Move X” and press the control

knob. If the X-axis moves, it is OK.

2) In the same way, you may check the movement on Y and Z axis accordingly.

Check the heating process.

Go to the LCD panel and choose “Prepare” →”Preheat PLA” and press the control knob. Go back to the main

menu and watch temperature fluctuations. If it is on the rise, it is OK.

Notes: by preheating the machine, you may save time waiting for the printing. You may stop the heating by go

to “Prepare” →”Cooldown”.

D.2.2 Level Build Plate (Important)

The build plate has been well leveled before delivery. However, it requires re-leveled after long time

transportation. If the build plate is far away from the extruder, the material will fail to stick to the build plate.

However, if they are too close, the extruder will fail to make printing at all. Therefore, the gap between the

build plate and the extruder should be 0.3mm.

Choose “prepare” under the main menu and then “auto home”, the X, Y and Z axis will return home. You may

use your hand to move the extruder to each point on the build plate to adjust the gap

between the build plate

and the extruder as shown below:

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

10

Tips: you may level the build plate roughly first and then make small adjustment during printing. The gap

should be 0.3mm.

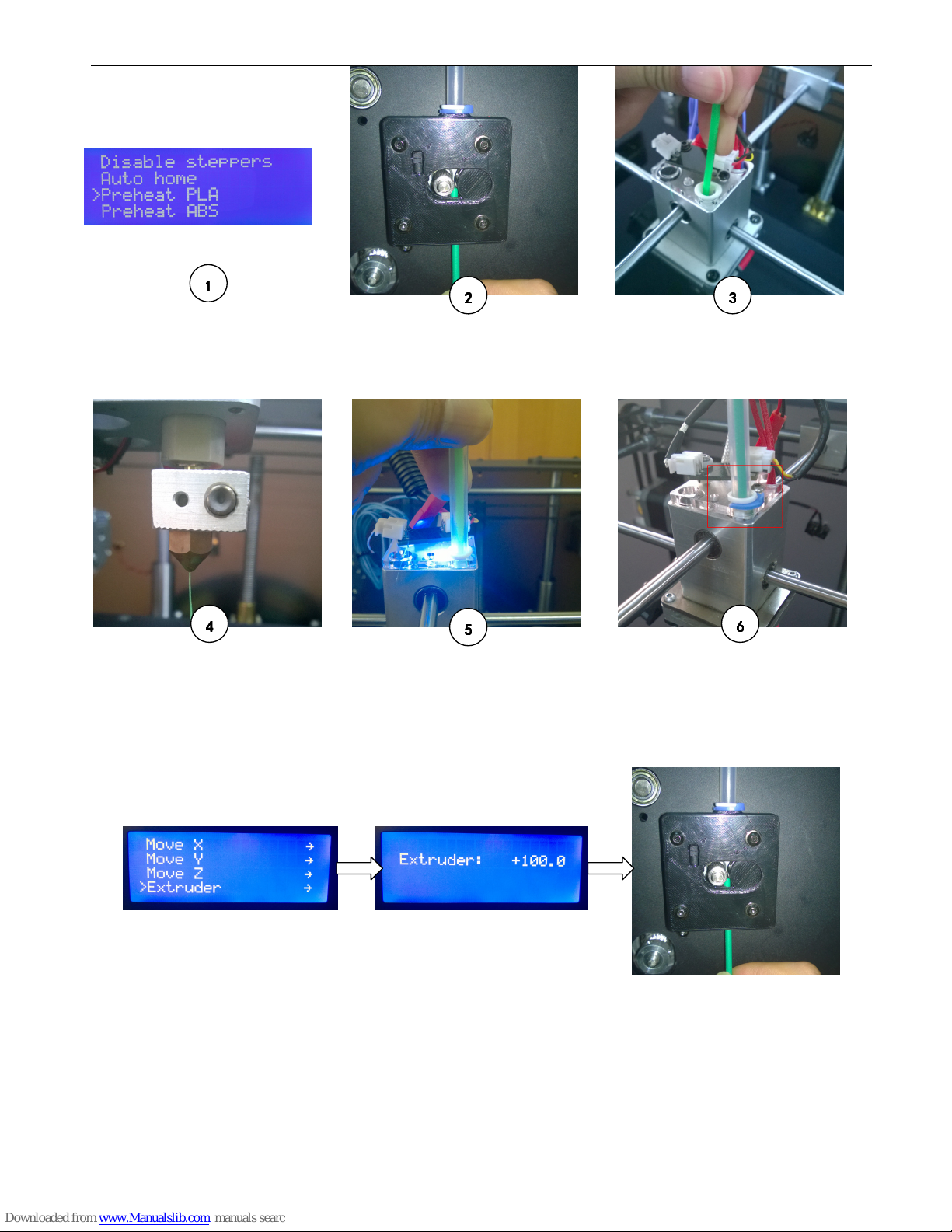

D.2.3 LOADING

For smoother feeding, the spool should be rotated clockwise as below:

The feeding should be:

Use a name card to check the gap Adjust the gap by the knobs

under the build plate

Recheck the gap

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

11

Tips: If the filament refuses to go into the feeder, you may need to preheat the extruder first and then go to the

LCD pane: “Prepare” →”Move Axis” →”Move 1mm” →”Move Extruder” to make the value as 100 or above.

After that, you may push the filament into the feeder as shown below:

D.2.4 Change Filament During Printing

If you find that the material is running out during printing or you want to change another color, you may do as

shown below. (Note: the yellow material is the current one while the green one is the new material).

On the main menu

“prepare”“preheat

PLA”or“Preheat ABS” to heat the

extruder

Push the filament through with

strength until the filament passes the

gear to the tube

After heating, inser

t the filament to

the extruder and push it down a

little

Insert the tube to the extruder

Material comes out of the nozzle

Put back the blue buckle

1

11

1

2

22

2

3

33

3

4

44

4

5

55

5

6

66

6

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

12

Use the pliers to cut one end of the

new filament and make sure the cut

is flat and smooth

In the same way, make sure the cut

on one end of the current filament

is flat and smooth

Push the new filament into the

feeder to make sure the new one

and the current one are well

jointed.

Take away the current spool

Until the green one passes

the gear at the feeder.

Replace a new one

2

22

2

3

33

3

4

44

4

5

55

5

6

66

6

1

11

1

The result

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

13

D.2.5 UNLOADING

E. MACHINE MENU EXPLANATION

By pressing the knob, you will enter the main menu as below:

MAIN MENU:

Info Screen

Prepare

Temperature

Print From SD (O CARD)

Prepare:

Sub-menu

Main

Auto Home

Move Axis

MOVE AIXS

:

::

:

Sub-menu

Prepare

Move X

Move Y

Move Z

Extruder

On the main

menu“prepare”“preheat

PLA”or“Preheat ABS”to heat the

extruder to 23

℃

Pull out the blue buckle Pin on the lock catch and pull

out the transparent tube

Put back the blue buckle

Unloading

1

11

1

2

22

2

3

33

3

4

44

4

5

55

5

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

14

Pre eat PLA

Pre eat PLA:

Sub-menu

Pre eat PLA All

Pre eat PLA

Pre eat PLA Bed

Pre eat ABS

Pre eat ABS:

Sub-menu

Pre eat ABS All

Pre eat ABS

Pre eat ABS Bed

Cool Down

Switc Power off

Disable Steppers

Temperature

:

::

:

Sub-menu

This menu is involved with mahcine’s working condition. It is not adviced that changes shoould be madeonit.Here

we will make introduction to certain functions.

Main

ozzle

Bed

Fan Speed

With the start of printing, there will be more functions appear on the main menu and they are

Temperature

、

Pause

print

、

Resume Print

、

Stop print.

Temperature

:

::

:

Sub-menu

Main

ozzle

Bed

Fan Speed

Pause print

:

::

:

suspend the printing.

Resume Print:

Continue the printing.

Stop print

:

::

:

cancel the printing.

F. START PRINTING

F.1 MODEL EDITION

Run the software and click on to choose the model that need to print:

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

15

There are many functions to make adjustment to the model, such as flipping, rotating, scaling and so on.

F.1.1 ROTATE

Click and you can rotate the model from X, Y or Z axis. The red one is X-axis, green Y-axis and yellow

Z-axis.

Reset : reset the model that has been rotated.

Lay flat : lay down the model that has been rotated.

F.1.2 SCALE

Click on to adjust the size of the model. You may make adjustment by dragging the mouse on the

three points or inputting exact value as below:

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

16

TO max : to make the model to the maximum size within the build size.

Reset : reset the model that has been adjusted.

F.1.3 FLIPPING (MIRROR)

Click on to flip the model as below:

Mirror X : flip the model toward X-axis.

Mirror Y : flip the model toward Y-axis.

Mirror Z : flip the model toward Z-axis.

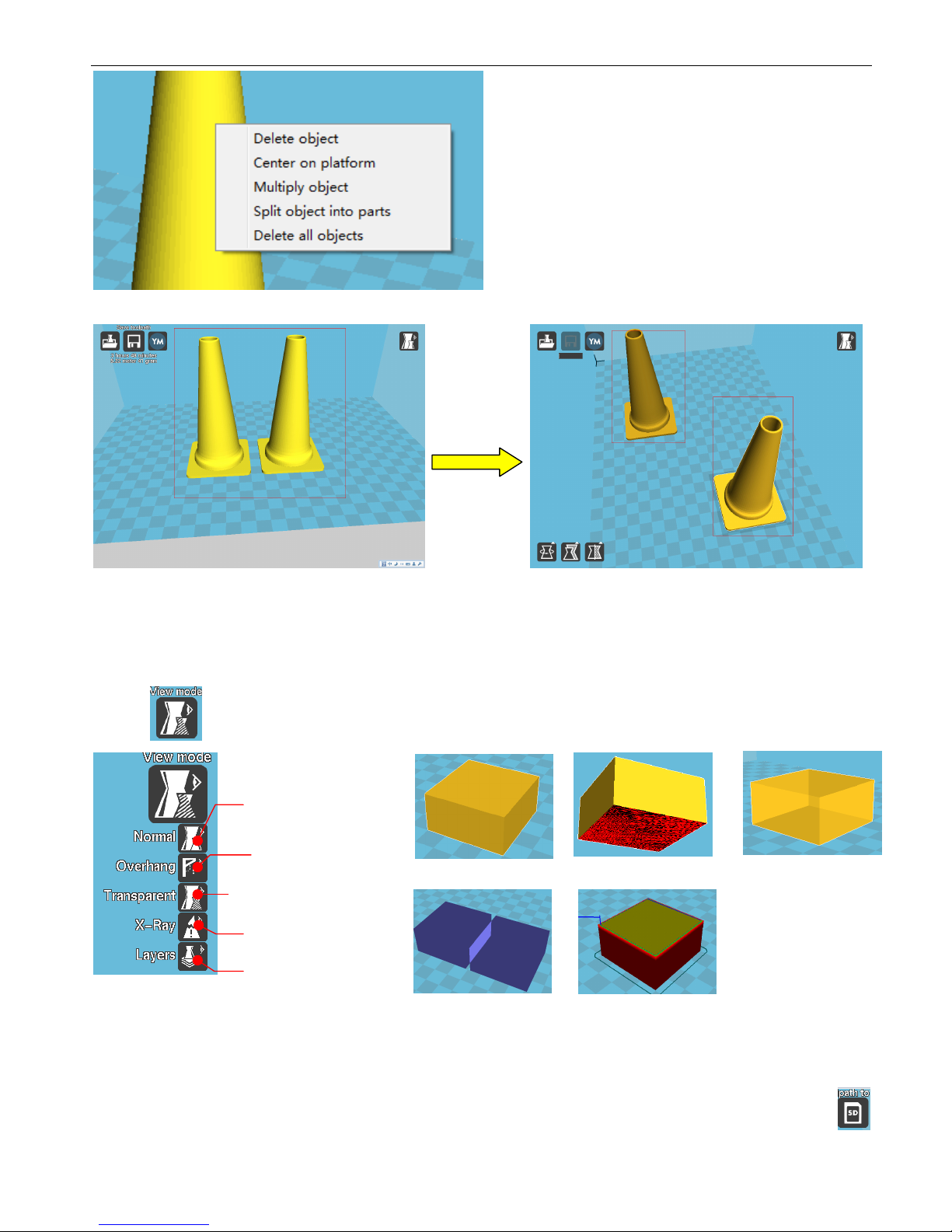

F.1.4 OTHER EDITTINGS

Right click on the model and you will find other editing functions: delete object, center on platform, multiply

object, split object into parts and delete all objects as shown below:

User Manual for LIQUIPRINT 3D Printers

Version:

WB20141117

17

Note: Slit object into parts is to separate two models instead of slitting a model into two parts.

F.1.5 VIEM MODE

You may adjust the view mode for better checking and editing on the model.

Click on and you may change view mode for the model as below:

F.2 PRINT FROM SD CARD (RECOMMENDED)

After editting, you may save it into SD card as G-Code. Insert the SD card and click on ”Toolpath to SD”

to save the model. The model is saved into SD card automatically. If there is no SD card, click on “Save

Standard view mode

Pending view mode

X-Ray view mode

Scenograph view mode

Layering view mode

Standard view mode

Pending view mode

Scenograph view mode

X-Ray view mode

Layering view mode

A whole Two wholes

Split into two models

Table of contents