BIGREP ONE.2 User manual

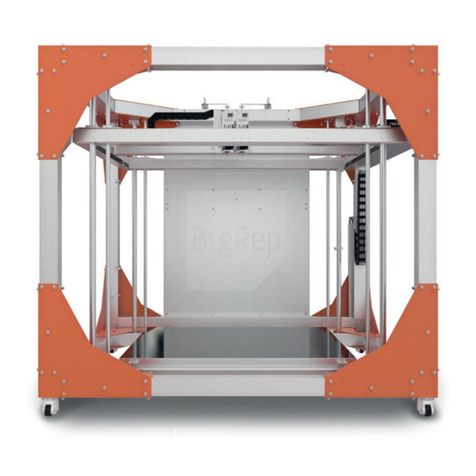

BigRep ONE.2

Full Scale 3D Printer

OPERATING INSTRUCTIONS

Translation of the original operating instructions.

2015/04/09

1.02.02

Table of contents

1. Introduction ........................................................................4

1.1. Information...................................................................... 4

1.2. Technical specifications .................................................. 5

1.3 Ships................................................................................. 5

1.4 Disposal ........................................................................... 5

2. Safety ..................................................................................6

2.1. Explanation of safety symbols........................................ 6

2.2. Safety ............................................................................... 6

3. Assembly and function ........................................................9

3.1. Short description............................................................. 9

3.2. Included in the delivery................................................... 9

3.3. Overview........................................................................ 10

3.4. The BigRep ONE.2 in detail ........................................... 11

3.5. Soware......................................................................... 12

3.6. Interface......................................................................... 12

4. Installation and commissioning .........................................13

4.1. Transport ....................................................................... 13

4.2. Set-up site / Requirements ............................................14

4.3. First use, connecting the printer....................................14

4.4. Align frames and table ...................................................14

4.5. Disassembly....................................................................16

5. Service and operations ...................................................... 17

5.1. Safety ..............................................................................17

5.2. Using the BigRep ONE.2 .................................................17

6. Changeover .......................................................................19

6.1. Changing the filament................................................... 19

6.2. Changing the hot end.....................................................17

7. Maintenance and Care .......................................................23

8. Appendix ...........................................................................24

A. Drawings ........................................................................... 26

4

1. Introduction

Please carefully read this manual before use. Save this manual in an

accessible location for future reference.

If you have any further questions please contact Customer Care at

support@bigrep.com

1.1. Information

Copyright/Masthead

© BigRep GmbH, 2015, Berlin

BigRep GmbH

Gneisenaustraße 66

10961 Berlin

Germany

Managing Directors: Lukas Oehmigen, René Gurka

Contact: support@bigrep.com

Distribution and copying of this manual is prohibited without approval.

Guarantee and Warranty

The manufacturer provides a warranty of 12 months from the date of

delivery.

Liability Limitation

The manufacturer assumes no liability for damages arising by

›Non-observance of this manual

›Use of the machine which is not according to specifications

›Use of unauthorized spare parts

›Own conversion of the machine

Status of manual / Version

2015/04/01

EN-US / Translation of the original operating instructions.

1. Introduction BigRep ONE.2

5

BigRep ONE.2 1. Introduction

1.2. Technical specifications

Manufacturer BigRep GmbH Model BigRep ONE.2

Berlin / Germany Version 1.02.02

Dimensions [mm] 1800 x 1850 x 2000

Weight control unit appx. 70 kg Weight printer appx. 410 kg

Layer thickness

resolution (Z)

≥ 300 µm (3) Tool heads Dual Nozzle

Fabrication

methods

FFF 3D Printing Print surface Heated build

surface

Build volume [mm]

(X:Y:Z)

980 x 1050 x 1100

(in CE version Z:950)

Positioning

accuracy (X:Y)

50 µm Temperature

table

Max. 100°C (2)

Max. 212°F (2)

Positioning

accuracy (X:Y)(Z)

< 20 µm Temperature

extruder head

Max. 260°C (2)

Max. 500°F (2)

Application range

(ambient temp.)

+10°C – +40°C

+50°F – +104°F

Power supply 230V, 16A, 50Hz

110V, 32A, 60Hz(1)

Supported printing

materials

(*experimentel)

PLA, CoPolymer,

Laywood, Laybrick,

ABS*, PC*, PA*, TPE*

Support

material

PVA, PS

Supported filament

diameters

2,75 mm - 3 mm Supported

nozzle sizes

0,5 mm / 1 mm

(1) Only specified versions. See identification plate.

(2) Higher temperatures lead to damage.

(3) Depends on extruder head type and nozzle size.

1.3. Shipping

Completely assembled in Wooden Box (1,95 m X 1,95 m X 1,95 m).

1.4. Disposal

Disposal by a specialist disposal company is recommended. The disposal

regulations at the time of disposal of the country in which the equipment

is operated do apply. The operator is obliged to comply with these guide-

lines when disposing.

6

2. Safety

2.1. Explanation of safety symbols

2.2. Safety

Compliant Use

The BigRep ONE.2 is used to create 3D-printed objects from suitable fila-

ment. The instruction for the machine is created in a computer and then

transferred to the machine via an USB-port.

A 3D-printed object is created layer by layer from melted filament (extru-

date) from the transmitted data. (Additive manufacturing process – FFF

–Fused Filament Fabrication).

A list of tested and approved filaments can be found on our website at

www.bigrep.com

This warning indicates a potential hazard. Non-compliance can lead

to serious injury or death.

WARNING

This warning indicates a potentially hazardous situation that may re-

sult in minor or moderate injury.

CAUTION

Pay particular attention to this important information.

(damages could result if relevant precautions are not taken)

This warning indicates an imminent danger. Non-compliance leads

to serious injury or death.

DANGER

The use of non-approved filament may lead to negative printing re-

sults, contamination, damage and failure.

The printer should be used only for additive printing processes (FFF).

2. Safety BigRep ONE.2

7

Hazards

Hazard from electrical current

Never bridge fuses or take them out of service. Keep moisture away from

live parts.

Unplug the machine if there is water damage.

Completely unplug the system and separate from electrical power before

all work on electrical devices, as well as maintenance and repair work.

Work must be performed only by qualified personnel.

Hazard from chemicals

No hazardous fumes arise when authorized filament is properly used.

Hazard from turning parts

There is a risk of being caught in turning machine parts. Wear close fitting

clothing. Protect long hair with appropriate covering.

Hazard due to barriers in the head region

In case of contact with live parts, an immediate danger of death by

electrocution is possible. If the insulation of live parts is damaged,

immediately unplug the machine from electrical power and carry

out repairs by qualified personnel.

HAZARD – HIGH VOLTAGE

The use of non-approved filament may release fumes hazardous to

health.

Never clean the table surface with solvent-containing cleaner. This

can produce toxic fumes when heated.

CAUTION

Warning against shock injuries. Wear a helmet when working in the

machine.

BigRep ONE.2 2. Safety

8

Operator obligation

The operator is that person who operates the machine for commercial

or business purposes himself, or allows third parties to do so, and who,

during operation, carries legal product responsibility to protect the user,

sta or third parties.

Operator‘s obligations:

›Know and comply to valid work protection conditions

›Provide necessary protective equipment

›Make operator‘s manual available and ensure that all operators of

the unit read the manual

›Regularly check protective equipment on the machine (for examp-

le, the emergency stop button)

›Check the printer regularly for defects

›Ensure before every printing job that the machine is free of

objects and cannot be accessed by unauthorized persons

Protection

A helmet should be worn during operation on the machine.

Protective equipment

The BigRep ONE.2 is equipped with an emergency stop switch (f):

All moving parts are stopped by pressing on the emergency stop switch;

the table heat is switched o, and the printing process is interrupted!

Environmental protection

Observe the manufacturer‘s instructions for disposal of filament.

2. Safety BigRep ONE.2

The emergency stop switch does not shut o the power.

For this purpose, always turn the main switch (e) to O.

In order to allow the unit to restart aer an emergency

stop, turn the emergency stop switch to the right to

unlock. Then press reset (g) to activate the machine

again. The printing process has to be restarted from

the beginning.

Fig. 2-1:

Emergency stop switch

9

3. Assembly and function

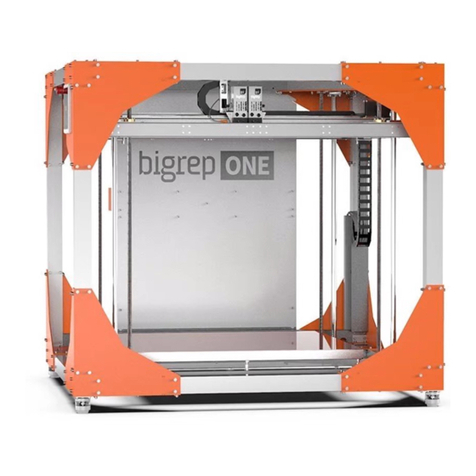

3.1. Short description

The BigRep ONE.2 is a full-scale FFF 3D-Printer for studio and professional

with an 980 mm x 1050 mm x 1100 mm (ca. 1.3m3)working volume. A printing

volume of over 1m3 makes it possible to produce prototypes and models

1:1, or to create final products, such as designer furniture, directly with the

3D printing method.

BigRep ONE.2 is constructed with an uncompromising full aluminum

frame, incorporating professional CNC components to provide strength

and robustness for thousands of successful printing hours.

3.2. Included in the delivery (depending upon model)

›BigRep ONE.2 (including extruder head)

›2 hot ends (pre-assembled), 1 mm and 0.5 mm nozzle diameters

›2 separate hot ends (1 mm + 0,5 mm nozzle diameter)

›Control panel unit

›Hex key to change the extruder head (M2, M3, M10)

›Scraper

›Feeler gauge for calibrating nozzle height

BigRep ONE.2 3. Assembly and function

10

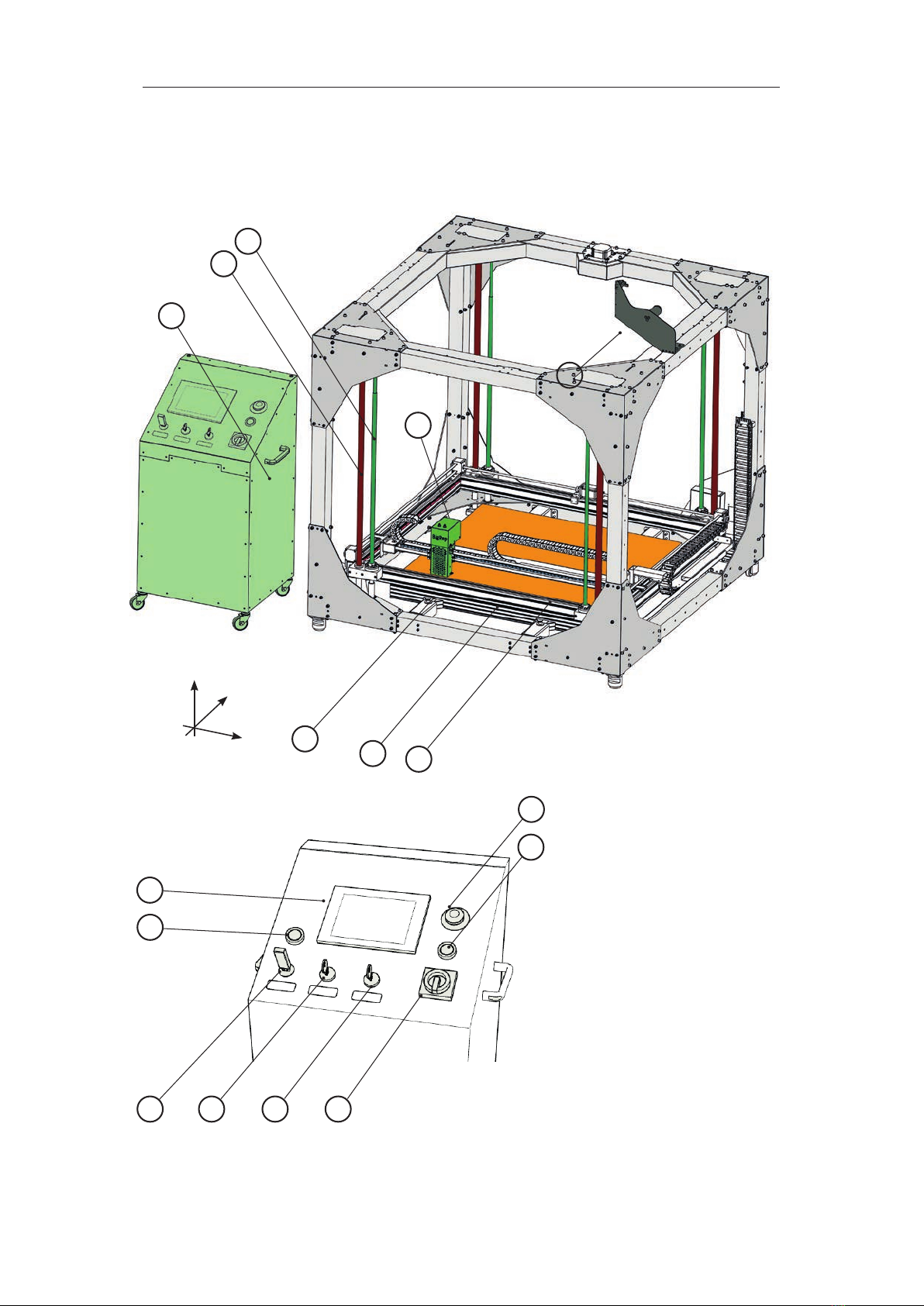

3.3. Overview BigRep ONE.2

C

B

E

F

D

b

a

c d e

g

f

G

H

A

x

y

z

AControl panel unit

BExtruder head

CPrint table

DFilament roll holder

EZ-guide shas

FZ-lead spindles

GX-guide rails

HY-guide rails

aDisplay

bUSB port

cDisplay switch

dTable heater switch

eMain switch

fEmergency stop

switch

gReset button

hZ-unblock

h

Fig. 3-1: BigRep ONE.2 with control panel

Fig. 3-2: Control panel

3. Assembly and function BigRep ONE.2

11

3.4. The BigRep ONE.2 in detail

Description of modules (&Fig. 3.1)

(A) Control panel unit

Control of the printer, display of information

(B) Extruder head with hot ends

Melting of the filament, printing

(C) Print table

Heated, covered with glued table protection layer (orange film)

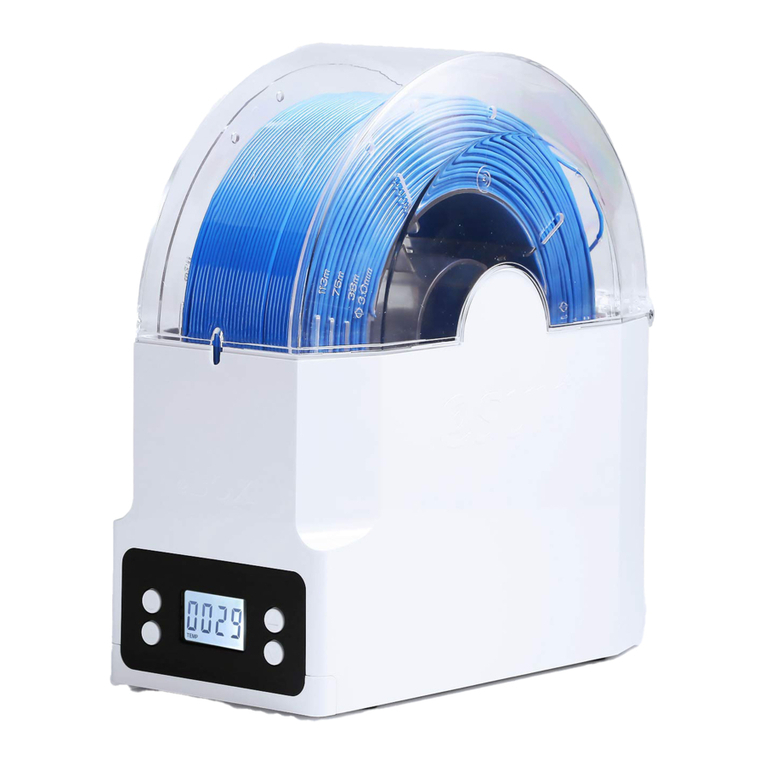

(D) Filament roll holder (2 rolls)

(E) Z-guide shas (4 pieces)

(F) Z-lead spindles (4 pieces)

(G) X-guide rails (2 pieces, one above the other)

(H) Y-guide rails (2 pieces, opposite sides)

Control panel (A) (Fig. 3.2)

(a) Display with touchscreen

Operation of BigRep ONE.2 (Graphic User Interface)

(b) USB port

For loading the print instructions (G-code) from USB media

(c) Display switch

Key switch, turns the display on/o

(d) Table heater switch

Key switch, turns the table heater on/o

(e) Main switch

Turns power on/o, starts BigRep ONE.2

(f) Emergency stop switch

Shutdown of all moving parts and the heating table

(g) Reset button

For restart aer pressing the emergency stop switch

(h) Z-unblock

Enables homing of Z-axis

BigRep ONE.2 3. Assembly and function

12

3.5. Soware

We recommend KISSlicer as slicing soware [http://www.kisslicer.com]

Use the delivered KISSlicer configuration file. This file contains all neces-

sary settings. You can request the latest version of the configuration file

from customer care.

Note: Set the correct print table size when using slicing soware dierent

to KISSlicer. The Z-Oset must be set to zero. Wrong settings can lead to

damages.

3.6. Interface

The BigRep ONE.2 is operated via the touchscreen interface (a) on the

control panel.

Note the separate manual for the interface.

3. Assembly and function BigRep ONE.2

13

BigRep ONE.2 4. Installation and commissioning

4. Installation and commissioning

4.1. Transport

The BigRep ONE.2 can be moved by utilising the four transport wheels

mounted under the frame. Immediately aer transport, the transport

wheels must be locked again to prevent accidental rolling of the machi-

nery. Turn the levelling spindles counterclockwise to loosen the transport

wheels.

The table must be aligned again aer transport. &Chap. 4.4.

4.2. Set-up site / Requirements

Make sure that the floor is level.

Ensure suicient ceiling clearance (minimum 1 m from unit to ceiling).

Ensure that the floor can bear the weight!

The machine may not be accessible to unauthorized persons especially

aer the start of the print program.

Ensure for a good printing process:

›Avoid high humidity

›The temperature in the operating environment may not exceed

40°C / 104°F

›Avoid strong dras during the printing process

›Avoid direct sunlight on the machine

›Do not install the machine on a floor that could be subject to

vibrations

›Avoid dusty operating environments (e.g. cutting dust)

The equipment must be unplugged from the power supply before

every transport operation, and the cable connection from the control

panel (A) and the equipment must be pulled out.

The device may only be operated in a safe environment (speci-

al room safety cage or the like), may be entered only be done by

trained operators and only be entered when the machine is swit-

ched o. The operator shall bear the responsibility.

The separately included transport manual must be observed before

delivery without a service setup.

14

4. Installation and commissioning BigRep ONE.2

4.3. First use, connecting the printer

If you have chosen to purchase the BigRep ONE.2 without a service setup,

you will receive a separate manual for first use.

Connect the unit only to the mains aer you have aligned frames and

table. &Chap. 4.4. Align frames and table

4.4. Align frames and table

Alignment of the frame

Aer each transport, the machine must be aligned horizontally using the

adjustable feet with the aid of a spirit level.

In order to set the height and the horizontal alignment of the machine,

the height adjustment (levelling spindles) should be turned accordingly

to Fig. 4-3, and the horizontal alignment must be checked with a water

level (Fig. 4-4).

Also the table must be checked monthly, aer each transport and regular

use.

Fig. 4-3: Height adjustment Fig. 4-4: Alignment of the frame with spirit level

15

BigRep ONE.2 4. Installation and commissioning

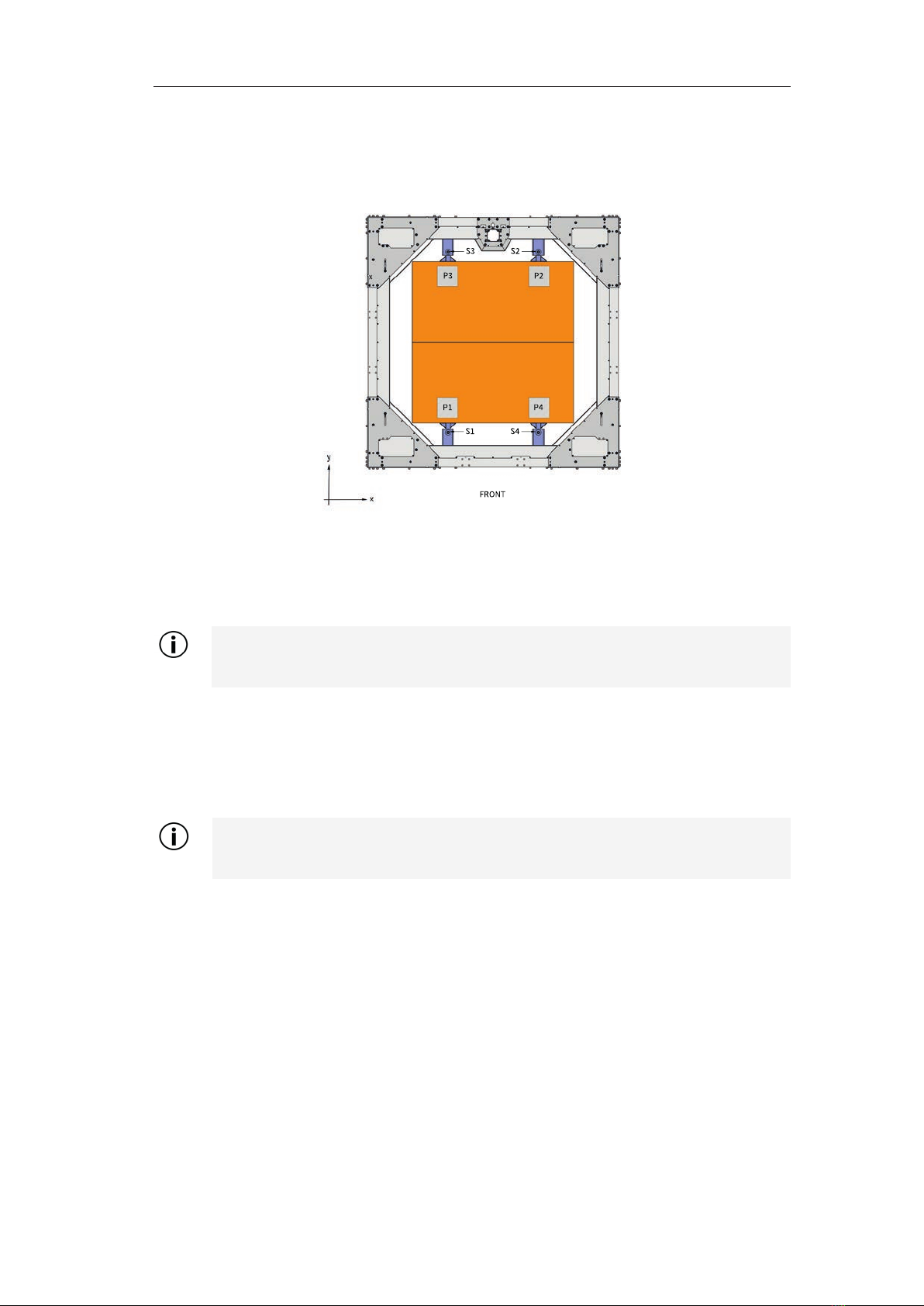

Alignment of the print table (leveling)

›Move the table up/down by turning screws S1-S4 (Fig. 4-5)

Clockwise moves table up, counterclockwise moves the table

down.

›Move the extruder head to the home position using the interface.

&Interface-Manual | Homing

›Switch o the BigRep ONE.2 using the main switch (e)!

›Move the extruder head (B) manually by hand to P1 area (Fig. 4-5).

›Put the fitting blade of the feeler gauge (delivered with the ma-

chine) between the table and the nozzles. (The reference value is

0,35 mm. This is about the thickness of a sheet of paper).

›Turn screw S1 in a clockwise direction until the nozzle and the

gauge blade nearly touch without clamping.

›Remove the gauge blade. (Never leave the blade on the table

when manually moving the extruder!)

›Set the extruder head manually by hand to P2, and set the

distance between the table and nozzle in the same way

›Proceed in the same way for P3 and P4.

FRONT

P1

P2

P3

S1 S4

S3 S2

P4

Never completely unscrew the screws, otherwise the table will sepa-

rate from the suspension.

Never move the extruder head manually by hand while machine is

connected to power source! Induced voltage leads to damage.

Fig. 4-5: Alignment of the table

16

4. Installation and commissioning BigRep ONE.2

›Then run through all four points P1-P4 again. Double check all 4

points until the correct distance between the table and the nozzle

at all four points is the thickness of the gauge blade.

Move the extruder head slowly across the table. The table may not touch

any point, as the table protection layer or the nozzle could be damaged.

Turn on the main switch (e) again when the distance is set correctly. The

machine is ready for use again.

4.5. Disassembly

The machine must be disconnected from the mains before disassembly.

Please contact Customer Care if you have questions:

support@bigrep.com

17

BigRep ONE.2 5. Service and operations

5. Service and operations

5.1. Safety

Wear a helmet when working with the machine as well as taking things

out of the machine!

The machine may only be operated when completely assembled. Other-

wise, the safety of man and machine is not guaranteed and the operating

license expires.

5.2. Using the BigRep ONE.2

Print a component

Preparation

›Check and verify that the machine operates normaly

›Clean the print surface &Chap. 7. Maintenance and Care

›Turn on the main switch (e)

›Turn on the display (c), switch on the table heating (d)

›Home the extruder head &Interface Manual | Homing

›Check the filament. If necessary, change the filament.

&Chap. 6.1. Changing the filament

The machine has both hot and rotating components. Aer ending

the printing process, components and the printed object may be

hot. Danger of burns!

Seek a doctor immediately in case of burns!

CAUTION

Do not reach into the machine during the printing process. There is

an injury hazard from moving parts!

CAUTION

Note in the following steps the separate Interface Manual as well as

the on-screen assistance of the interface.

The current corresponding interface manual for your specific firmware

can be found on our website [www.bigrep.com].

Before any print operation ensure that the machine is free of objects

and cannot be accessed by unauthorized persons

18

5. Service and operations BigRep ONE.2

›Control the hot end. If necessary, clean the nozzle (Fig. 6-1, (iv)).

Mount the correct nozzle if there is a new hot end filament diame-

ter

&Chap. 6.2. Change the hot end

Preheat device

›Set the extruder temperature in accordance with the filament in

use

›Set the temperature of the table in accordance with selected

filament

›Press Pre-Heat in the interface

Load the print file (G-code)

›The G-code which has been generated with your slicing soware

is transfered via USB medium (b)

›Select the G-code from the USB media using file explorer

›Check that the printing speed is set to that given in the G-code

Start printing

›Only start the print aer the extruder and the table are heated

correctly.

›Check that the printing process has begun properly

Stop / pause printing

›You can see on the display when the print is finished

›The printing is paused or stopped by pressing on Pause or

Resume

Remove component

›Move the extruder head manually with the interface so that the

printed part is freely accessible

›Let the table cool to under 40°C / 104 °F

›Carefully remove the print object from the table by providing the

plastic scraper

If the printed part taken before the table is cooled there is a risk of

irreversible change in shape!

The machine must be homed position before each print job!

&Interface Manual | Homing

19

BigRep ONE.2 6. Changeover / Retooling

6. Changover / Retooling

Read the following instructions completely before you begin replacing

any components.

6.1. Changing the filament

The filament change can be done before or during printing process.

Please note the dierent procedure.

Filament change before printing

Move the extruder to home position via the interface.

Remove the filament strand next to the filament guide (3).

With the interface function Retract remove the remaining filament from

the extruder head.

Extrude remaining filament in the nozzle manually via interface. Clean

the nozzle if necessary.

If the filament is changed before the filament roll currently being used is

used up, roll up the remaining filament and remove the roll.

Load the filament roll holder (D) with the new filament roll. Load the fila-

ment end into the extruders heads filament guide (Fig A-2 (5)). Adjust the

temperature on the interface if using a new filament material.

Filament change during printing process

Press Pause in the interface to pause the printing process.

Aer pausing, the extruder can be moved in X- and Y-direction via the in-

terface in order to change the filament. Take care that the extruder head

never touches the print object while moving.

Remove the filament strand next to the filament guide (3).

Store filament rolls in a dry and cool place. Avoid knotting of the roll

by securing the loose filament end into the roll.

Hot nozzle can cause burns. Do not touch hot nozzle.

CAUTION

Never use the homing function during an ongoing print process.

Never move extruder head manually in Z-direction. Do not quit the

printing process. Otherwise the print object will be unusable.

20

6. Changeover / Retooling BigRep ONE.2

With the interface function Retract remove the filament from the extru-

der head.

Extrude remaining filament in the nozzle manually via interface. Clean

the nozzle if necessary.

Load the filament roll holder (D) with the new filament roll. Load the fila-

ment end into the extruders heads filament guide (Fig A-2 (5)). Adjust the

temperature on the interface if using a new filament material.

Manually extrude a small amount of the new filament to check whether

print process works proper.

Press Resume in the interface to continue the print process. The extru-

der head will automatically move to the position were the machine was

paused.

Advanced Tipp

You can change the filament during an ongoing print process without

pausing the process. Therefore cut the filament strand next to filament

guide (3), load the new filament roll and insert the new filament strand

to the filament guide directly aer the old one.

6.2. Changing the hot end (Fig. A-1a / A-1b / 6-1)

The filament is heated in the hot end (8) and gui-

ded through the nozzle (iv) with pressure. The

extruder head of BigRep ONE.2 is equipped with

two separate hot ends that can be replaced indi-

vidually, for example, to use other nozzle diame-

ters. There is a dierence between replacing the

hot end mechanicals (i) and a complete hot end

exchange including the electrical parts (iii).

The hot end mechanics are exchanged in order

to use another nozzle diameter. When chan-

ging the hot end mechanics, the electrics (car-

tridge heaters and sensors) are taken from the

removed hot end and mounted in the hot end which will be installed.

&Changing the hot end mechanics

Hot nozzle can cause burns. Do not touch hot nozzle.

CAUTION

iii

i

ii

iv

Fig. 6-1: Hot end

Table of contents

Other BIGREP 3D Printer manuals