6

IMPORTANT NOTICE

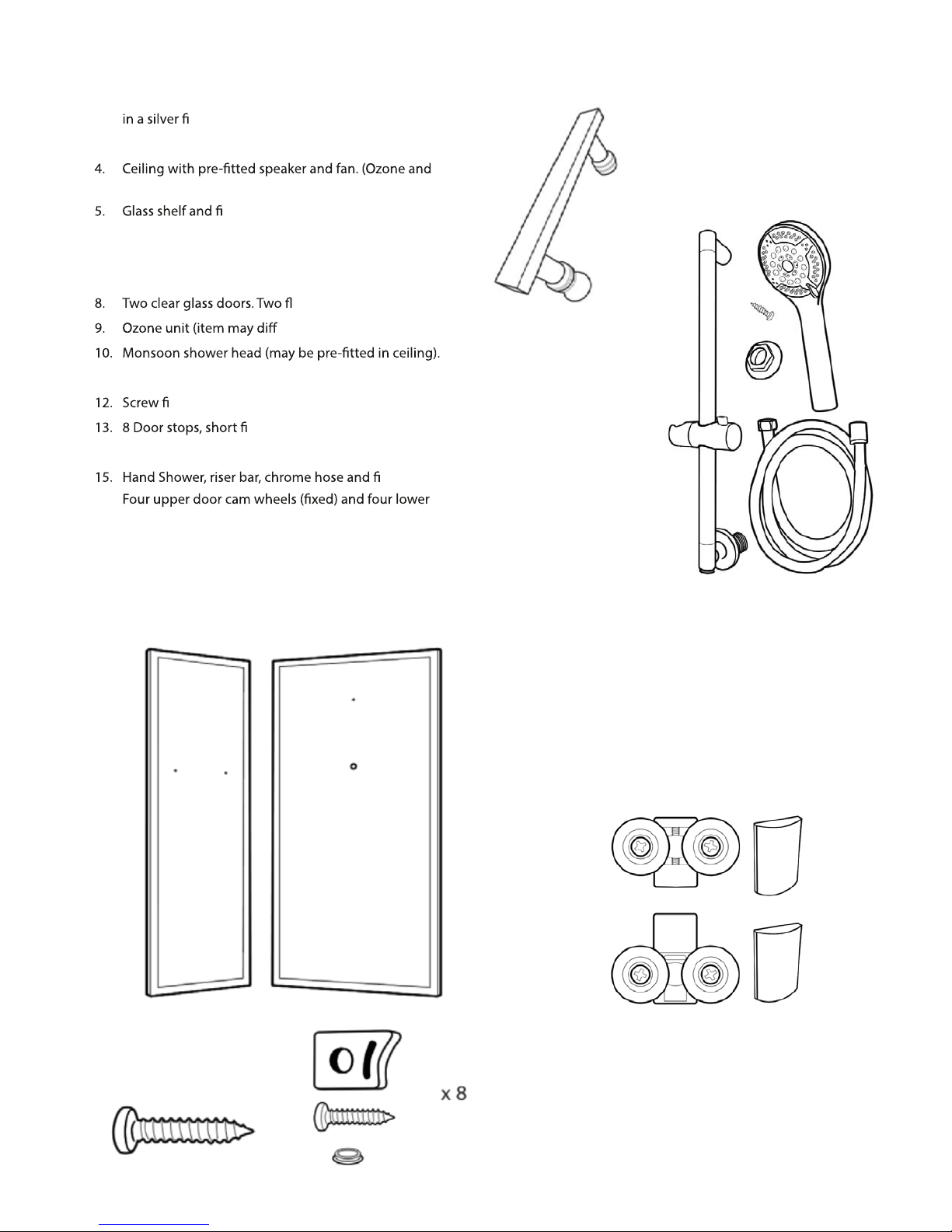

tting this product please read and understand the following:

By commencing testing and installation of the unit you are agreeing to the Terms and Conditions

set out by us and copies are available by contacting us by telephone (details on the cover of this

manual).

You are required to ensure the purchased product dimensions allows for ease of passage to the

intended installation area.

Regarding weight tolerances of installation area, it is advisable to contact a builder or refer to

oor support.

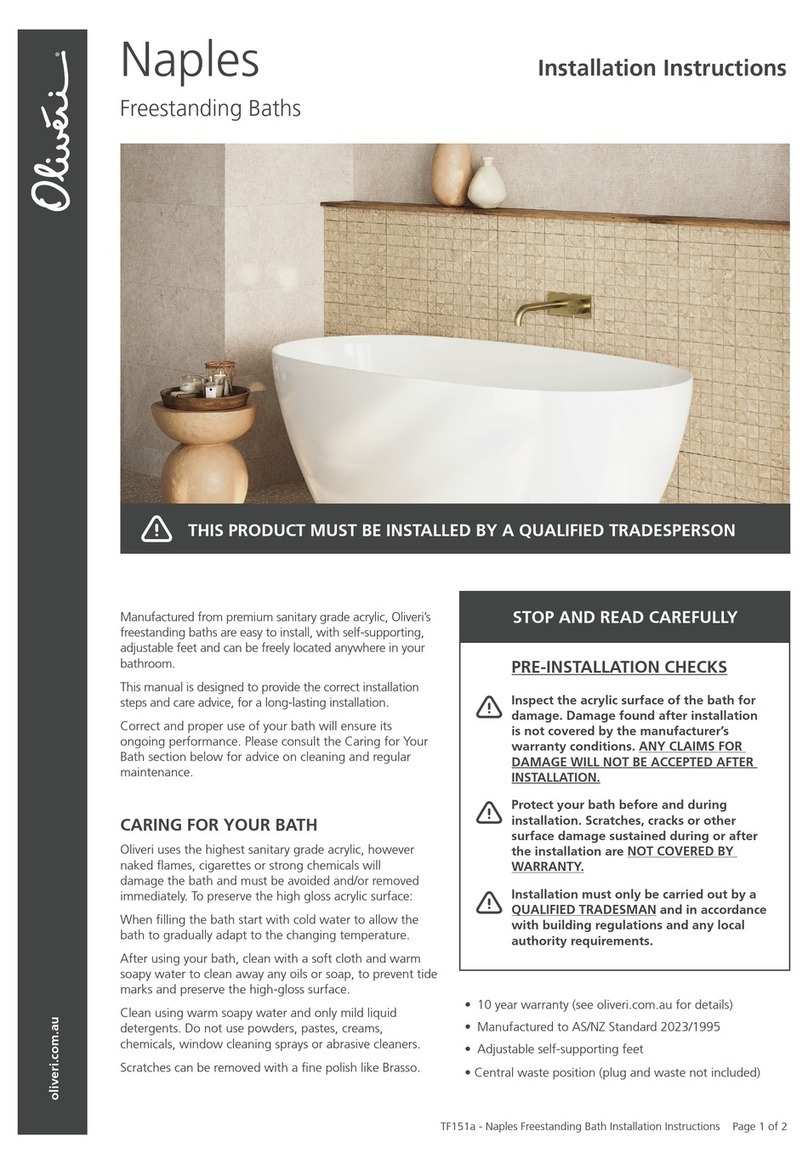

1. It is important that you ensure that your purchase has been delivered undamaged. You are required to

check the contents and report any damage that you feel needs repairing or replacing within 48hrs of

receipt of goods. Items reported damaged after this time WILL be chargeable.

ed specialist. The product requires connection to

ed electrician.

3. We are a supply only company. If you report to us any damage we will send replacements or solutions to

remedy the problem described. We endeavor to fully understand th rst by asking a series of

questions and then propose the solution. We may even ask for digital images to be sent via email to assist

the process.

tter

fully tests the unit upon completion and attends to any leaks and faults before he leaves.

tted for

transport purposes and need to be properly sealed and tightened before use. During transportation

some connections can become dislodged and therefore break any watertight seal, you are required to

x accordingly.

6. tter until you have inspected the unit. We cannot be held responsible for delays

7. We cannot be held liable for inconvenience caused due to lack of bathing facilities caused by any delay in

receiving your product or whilst awaiting parts.

8. Regarding our sales and technical support: We know our products and their requirements, but we are not

suitability of the product with a professional body. It is the customer responsibility to ensure the product

t for purpose.

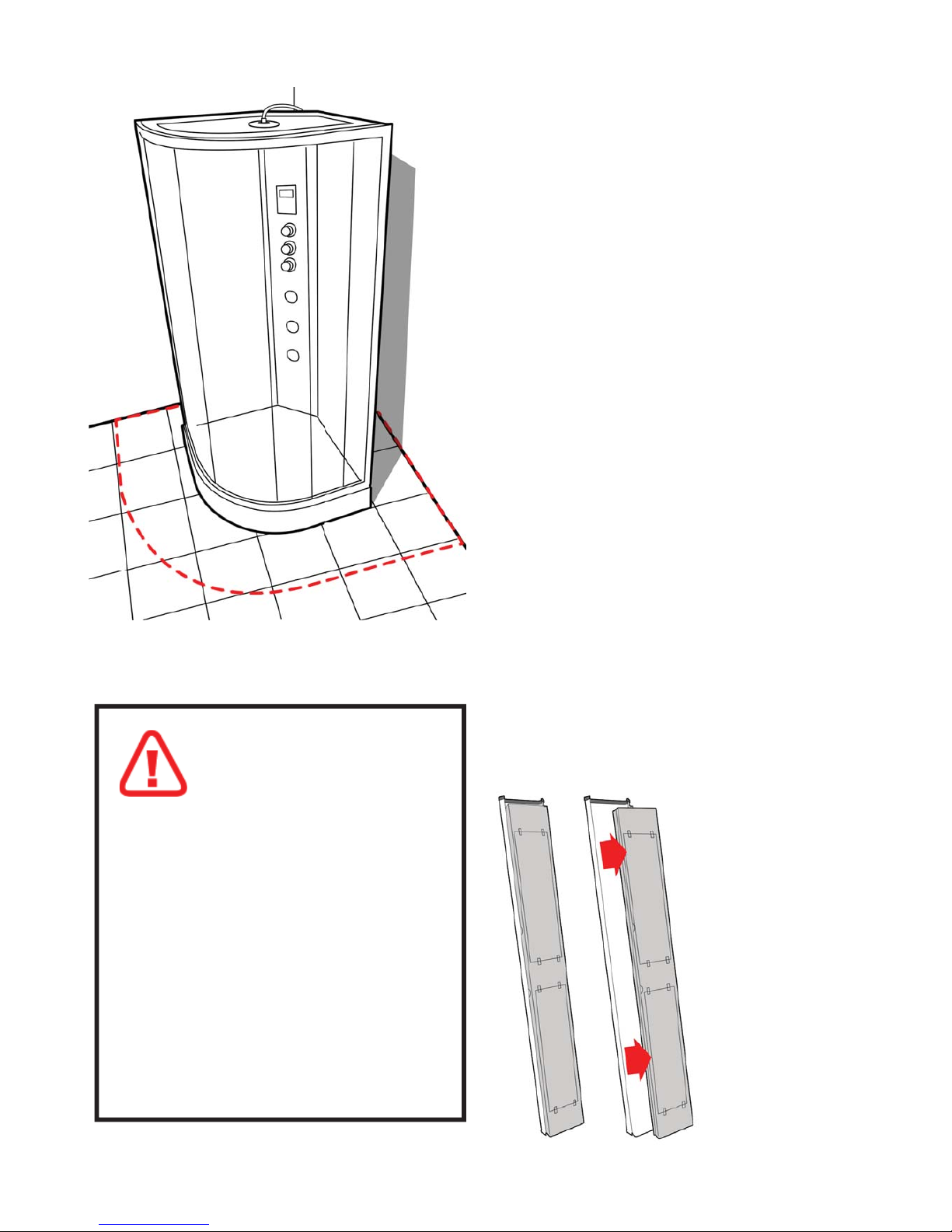

The best advice we can oer our customers when they ask “what is the best way to build this” is to follow the

instructions and perform a dry run to ensure you are condent with the build and you understand fully how

the unit is assembled. When we use the term “DRY RUN”this means you do not silicone anything, just simply

construct the shower, align, drill and screw everything together. Once you are happy with the build take the

unit apart and carry out the full installation, using your silicone sealer at all points outlined in the manual.