Flight Safety

1. ALWAYS WEAR APPROPRIATE EYE PROTECTION WHEN OPERATING

YOURMODEL. Fueldroplets,looseparts,andairbornedebrisejectedfromyour

model could cause serious injury or blindness. Select comfortable, well-fitting

eyewearwithhigh-impactresistancesuchasshopglasses.Prescriptionglasses

made of glass are dangerous because they could shatter if struck sharply.

2. ALWAYSWEARAPPROPRIATEHEARINGPROTECTIONWHENSTARTING

AND ADJUSTING YOUR ENGINE. Many car, airplane and helicopter modelers

ignore the sound produced by the engines on their models. High volumes and

highfrequenciesproducedbymodelenginescandamagehearing.Thisdamage

can be cumulative. Ear-phone and ear-plug style hearing protectors (sold in

sporting goods stores in the gun section) are inexpensive and effective at

reducing the most damaging and annoying qualities of engine sound. Once your

model is started and flying, hearing protection is usually not necessary.

3. NEVERSTANDOR PLACEYOUR EYES ORFACE IN-LINE WITHROTATING

MAINROTORORTAILROTORBLADES.Loosepartsordebristhrownoutward

from rotating rotors could cause injury or blindness.

4. NEVER, EVER FLY NEAR OR OVER PEOPLE. Always keep your model at a

safe distance from yourself and spectators.

5. Use only those model engines designed specifically for your Lite Machines

helicopter. Use of more powerful engines (such as racing engines) is potentially

dangerous and voids all warranties.

6. Do not use fuel containing more than 35% nitromethane. The added power and

heat of high nitro fuels can damage both the engine and your model.

7. Never allow main rotor speed to exceed 2000 RPM (as by operating with blade

pitchsettoolow,orusing ahighpowered enginewithhigh nitrofuel).Rotor parts

couldseparate fromtherotorheadandcauseserious injuryorpropertydamage.

Very high speeds can also damage the engine.

8. Flyonlyatapprovedflyingfieldsorinopenareasawayfrompeopleandproperty.

Do not fly in residential areas.

9. Before turning on your radio, ensure that your radio frequency is not already in

use. Flying clubs have organized frequency sharing procedures.

10. Range check your radio prior to the first flight of each day. If your range check is

lower than normal, do not fly.

11. Priortothefirstflightof each day, check all mechanics for smooth, unobstructed

operation. Before the main rotors reach flying speed, gently move all flight

controlsandconfirmproperfunction.Donotflyifanythingisoutoftheordinary.

12. Check for hidden damage after crashing, and replace any damaged

components.

13. Beginners should have the main rotors tracked, and model adjusted for flight by

an experienced modeler.

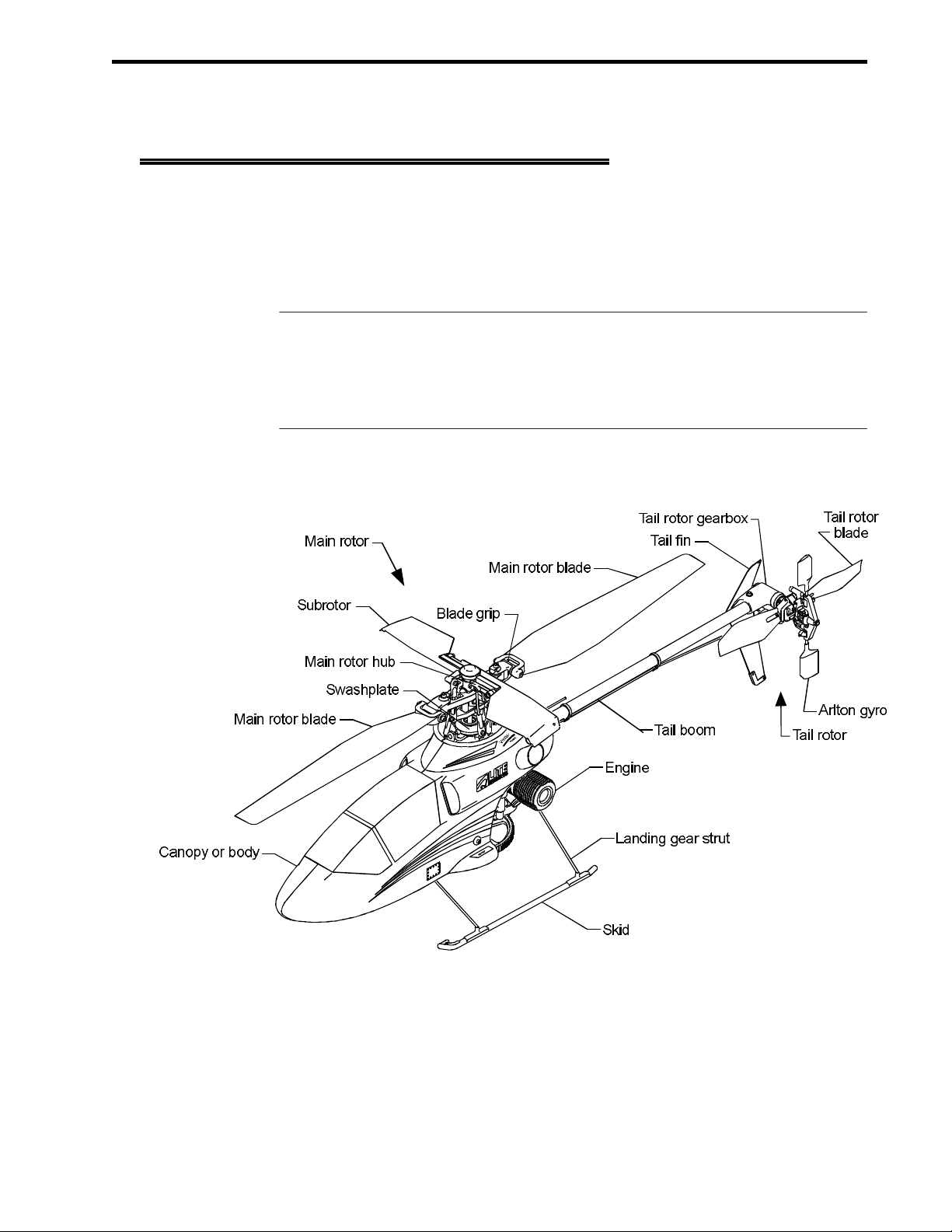

Operator's Guide Model Helicopter Safety

1-2LITE MACHINES