5

4. System Operation

4.1 Powering the System On

•Press the momentary Power/Reset switch for 1

second.

oThe switch will illuminate once power is

enabled.

oYou may notice an audible “thunk” noise of

the internal contactor switching on.

oCheck that there is voltage at the Power

Terminals with a voltmeter.

4.2 Powering the System Off

•Press and hold the momentary Power/Reset

switch for 3 seconds.

oThe switch will cease to illuminate once

power is disabled.

oYou may notice an audible “thunk” noise of

the internal contactor switching off.

oCheck that there is 0V at the output terminals

with a voltmeter.

4.2 Charging

•The charging device(s) connected to the GT

Series Lithium Battery System must be

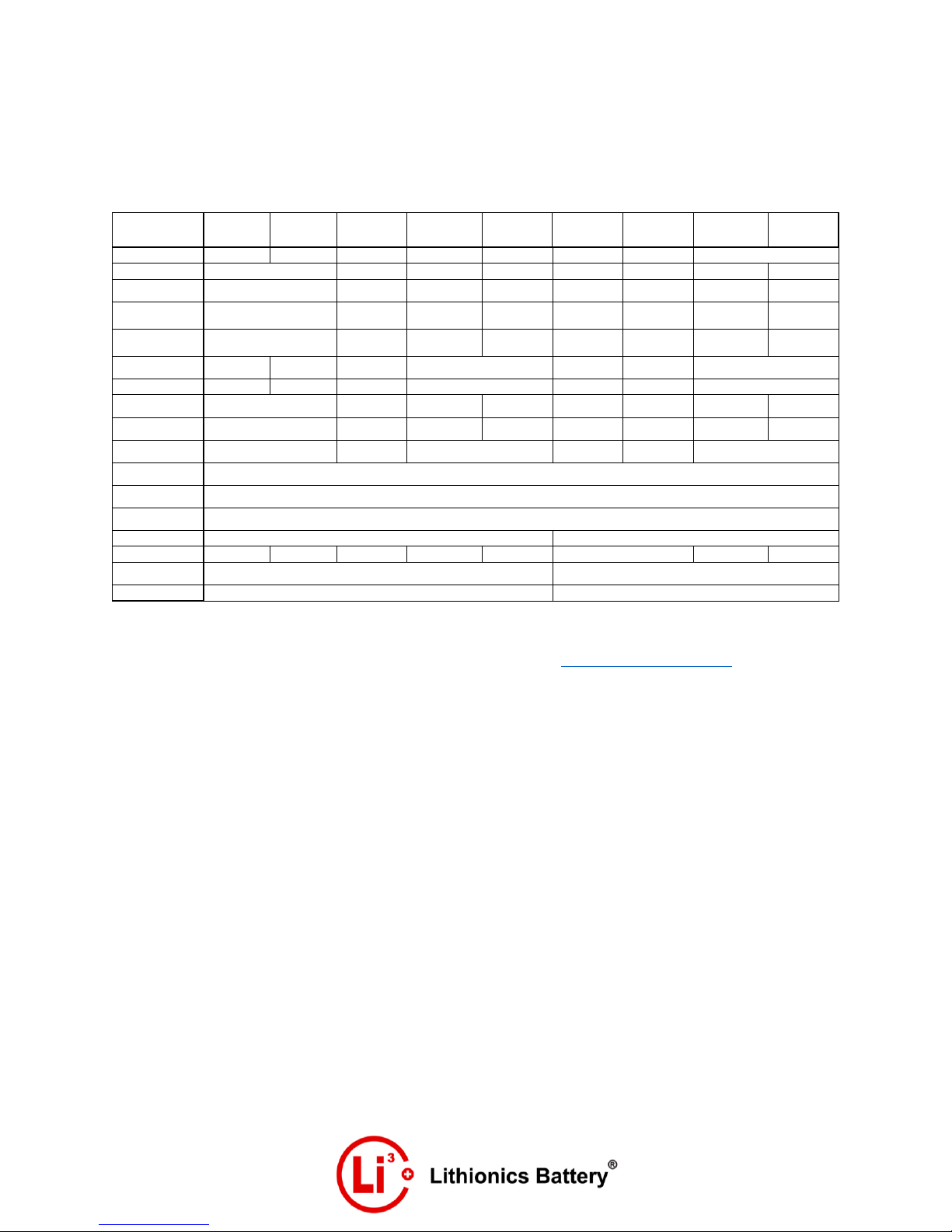

programmed as per Table 1.

•Charging may be performed at any time the

system is powered On.

oNOTE - The GT Series Lithium Battery System

will disconnect power if the voltage,

amperage, or temperature limits are

exceeded during charging.

oOnly use a Lithionics Battery approved

charging source. Please contact Lithionics

Battery for charger approval.

4.3 Initial Charging Cycle

•The initial charging cycle is required as it

calibrates the NeverDIE BMS to the Battery

Module for accurate State of Charge

percentage (SoC) monitoring.

•During the initial charging cycle the system

must reach a voltage level that is equal to the

Standard Full Charging Voltage indicated in

Table 1.

•Enable the charging device(s) so that they may

complete a charge cycle. It is recommended to

not have any discharge loads active during the

initial charging cycle, especially towards the

end of charging.

4.4 Discharging

•Discharging may be performed at any time the

system is powered On.

oNOTE - The GT Series Lithium Battery System

will disconnect power if the voltage,

amperage, or temperature limits are

exceeded during discharging.

•The NeverDIE feature allows the system to

have a “reserve” amount of energy left in the

battery. Once the system is discharged to 12.0V

or 10% State of Charge (SoC), whichever comes

first, power will be disabled to leave a “reserve”

amount of energy still left in the battery.

•To enable the remaining reserve energy of the

system, press the momentary Power/Reset

switch for 1 second.

oNOTE - Once the reserve range is enabled the

battery should be charged as soon as

possible.

oWARNING - If the reserve energy is used and

the battery module is left in a deeply

discharged state without immediate

charging, the battery module will become

permanently damaged.

4.4 System Storage Procedure

•Storing your battery at the correct

specifications is important as it keeps the

battery in the healthiest state possible for the

fastest deployment when needed.

•If the GT Series Lithium Battery System will not

be in use for greater than 2 weeks, it is

recommended to enable system storage.

•Storage mode is simply a fully charged system

in the Powered Off state.

•To enable System Storage:

oPerform a full charge cycle, ensure that the

System voltage reaches the Standard Full

Charging Voltage indicated in Table 1.

oPower off the System, press and hold the

Power/Reset switch for 3 seconds. Check that

the switch is no longer illuminated. Check