English

PIZZA DOUGH

ROLLERS 60.0

38

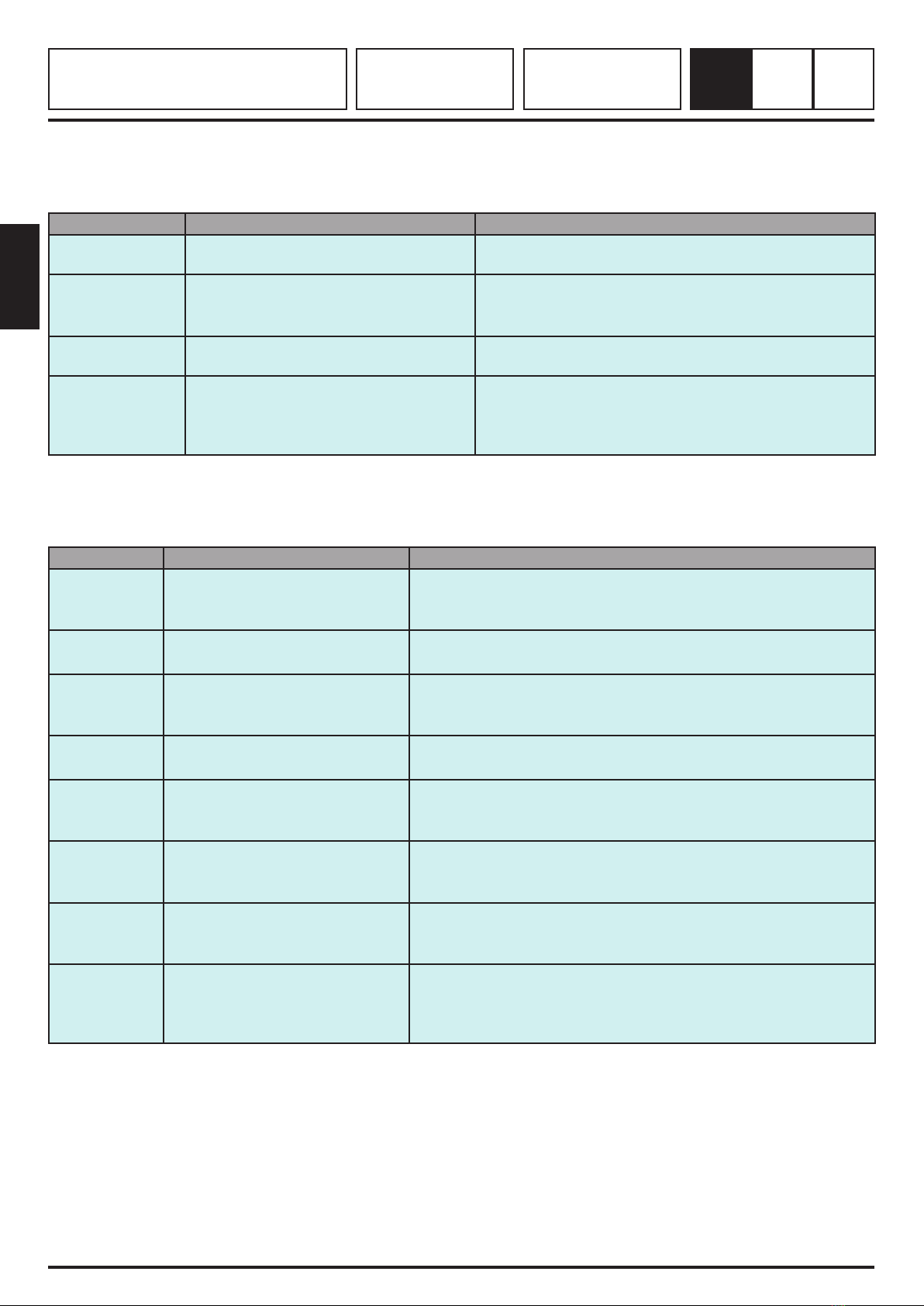

6.3. CHECKLIST:ROUTINEMAINTENANCEPERFORMEDBYTHEOPERATOR

Tableofrounemaintenance(6.3.):

Frequency Check/control Modeandndings

Beforeeachturn Checkworkarea:

•itmustbecleanandfreefromdust

Theirjobsandalltheexternalpartsofthemachinemustbe

cleaned.

Atleastonceaweek

Verifythefunconality:

•safetydevices

•stopfuncons

Performavisualinspeconandfunconalsafetydevices.

Atleastonceaweek Visualintegritycheck:

•allthelabelsareintactandnotdamaged

Ifitisunreadable,askyourservicetechniciantoreplaceiden-

calplaques.

Atleastmonthly

Visualintegritycheck:

•upperandlowerinletrollerssystem

The use of the parts indicated, determines their wear over

me.Aercleaning,visuallyinspecttheabsenceofchipping,

crackingorbreaking.Wherethereareadmissionsoffailureto

proceedwiththeirreplacement.

6.5. TROUBLESHOOTING

Beforecarryingoutanyintervenon:

•signal,withasign,thatmaintenanceisincourse;

•beforeyoustartthemachine,alwaysmakesurethattherearenopersonnelperformingcleaningormaintenanceoperaons;

•forchecksandsmallelectricalrepairsallowonlyqualiedpracsingelectricianstointervene;

•inanycasealwaysconsulttheAuthorisedServiceCentre.

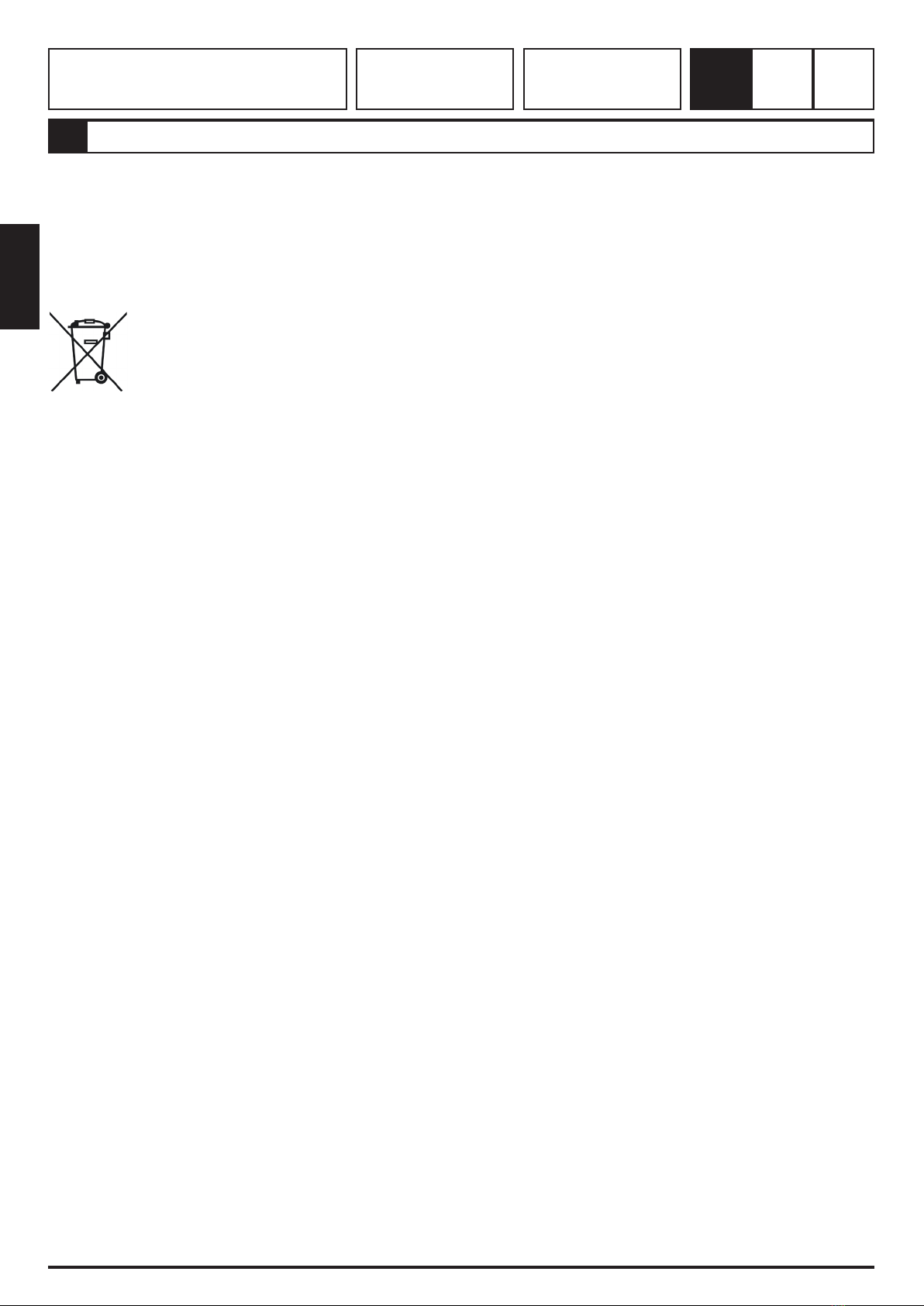

6.4. CHECKLIST:SCHEDULEDMAINTENANCEEXECUTABLEBYTHEMAINTAINANCEPERSONNEL

Tableofscheduledmaintenance(6.4.):

Frequency Check/control Modeandndings

Atleastmonthly

Check:

• inside the enclosures

•motorcompartments

Alltheinternalparts,motorcompartmentsmustbekeptcleananddry.

Providetovacuumanydustpresent.

Atleastmonthly Checktheeecveness:

•mechanicalconnecons

Perform,withtheappropriatetools,acheckoftheghteningoftermi-

nals,screws,nuts,boltsandconneconsingeneral.

At least every 3

months

Checkthefunconality:

•motorstartercontactorsofallthe

controlcircuitrelays

Performavisualinspecontoverifythestateoftherelaysandthecontrol

circuits.

At least every 3

months

Generalinspecon:

•electricalequipment

Carryouttheenreelectricalequipmentforfunconalneeds(theelec-

tricalequipmentissubjecttowear).

At least every 6

months

Verifytheeecveness

•equipotenal circuit and protec-

on

Withadequateinstrumentaonmeasurethesystemearthresistance,to

ensurethatthevaluesarewithintheacceptablelimitsoftheapplicable

standardsofthecountrywherethemachineisinstalled.

At least every 6

months

Check:

•the electrical insulaon of the

motors

Withadequateinstrumentaonmeasurethemotorinsulaonresistance,

toensurethemeasuredvaluesarewithintheacceptablelimitsdened

bytheapplicablestandardsofthecountrywherethemachineisinstalled.

At least every 6

months

Check:

•the absorpon of the individual

phasesofthemotor

Withadequateinstrumentaonmeasuretheabsorpononeachpower

conductortothemotor.Valuesthatarenotwithintherange10%indicate

faultymotors.

Atleastevery12

months

Checktheeecveness:

•conneconsoftheelectricalcom-

ponents within and outside the

enclosures

Verifytheabsenceofanylooseness.Ifanyisfoundrestoretheconnec-

onsinalasnganddurablefashion.

LLKDR30 | LLKDR40