E-mail support

techsupport@lmicorporation.com LMI Corporation Phone support

(810) 714-5811

Form: CA 033 September 21,

2004 R:\Quality\Calibration Instructions\CA 033.doc Rev. A Page 2 of 7

I. GAGE CONFIGURATION

Section I is a one time setup. After a successful gage configuration is finished there should be no

need to repeat section I. It is recommended to store a copy of the gage files onto a personal computer

or laptop. Consult the collector manual or if purchased the TranSend manual for further details.

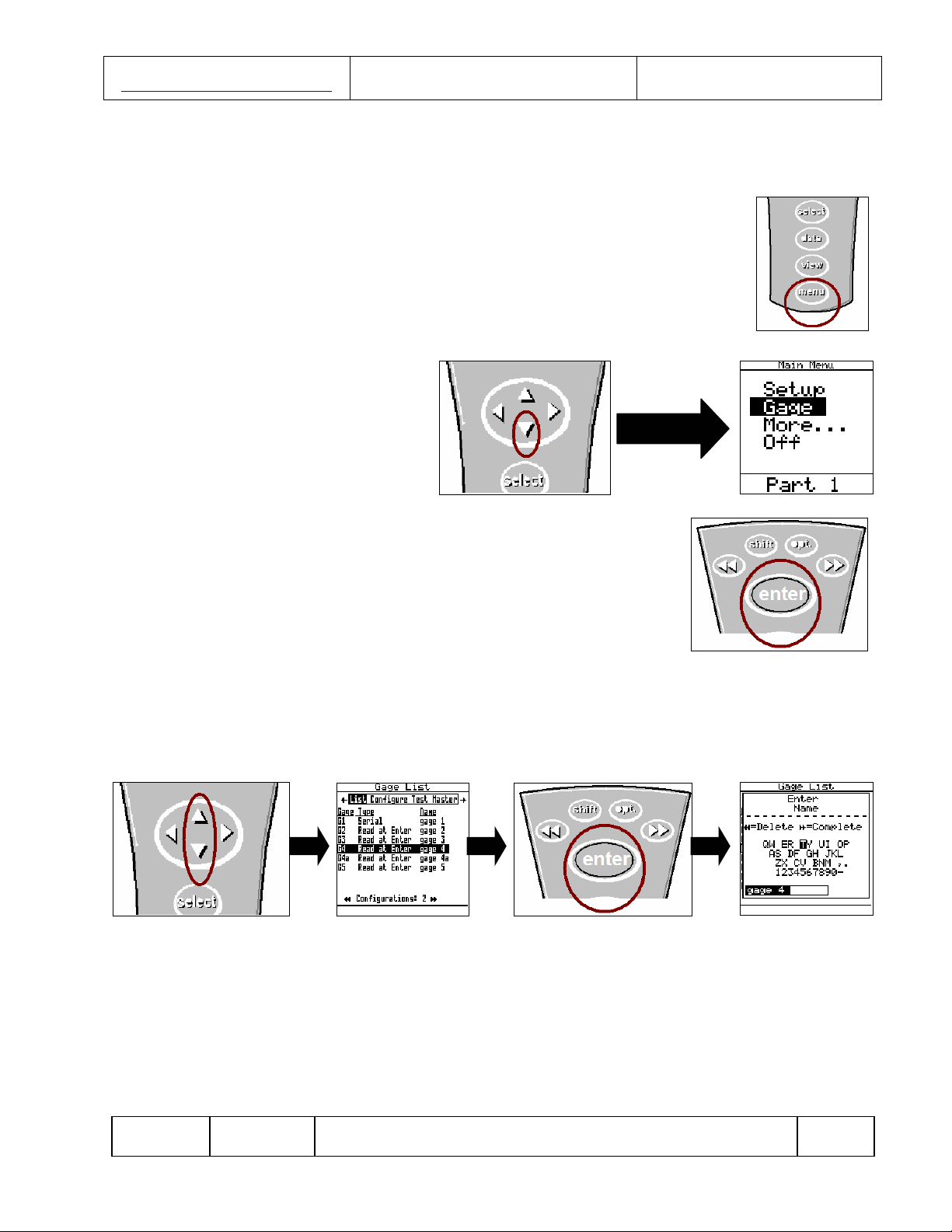

1. Press <menu> to turn on the collector.

2. Press 6to highlight “Gage”.

3. Press <enter>.

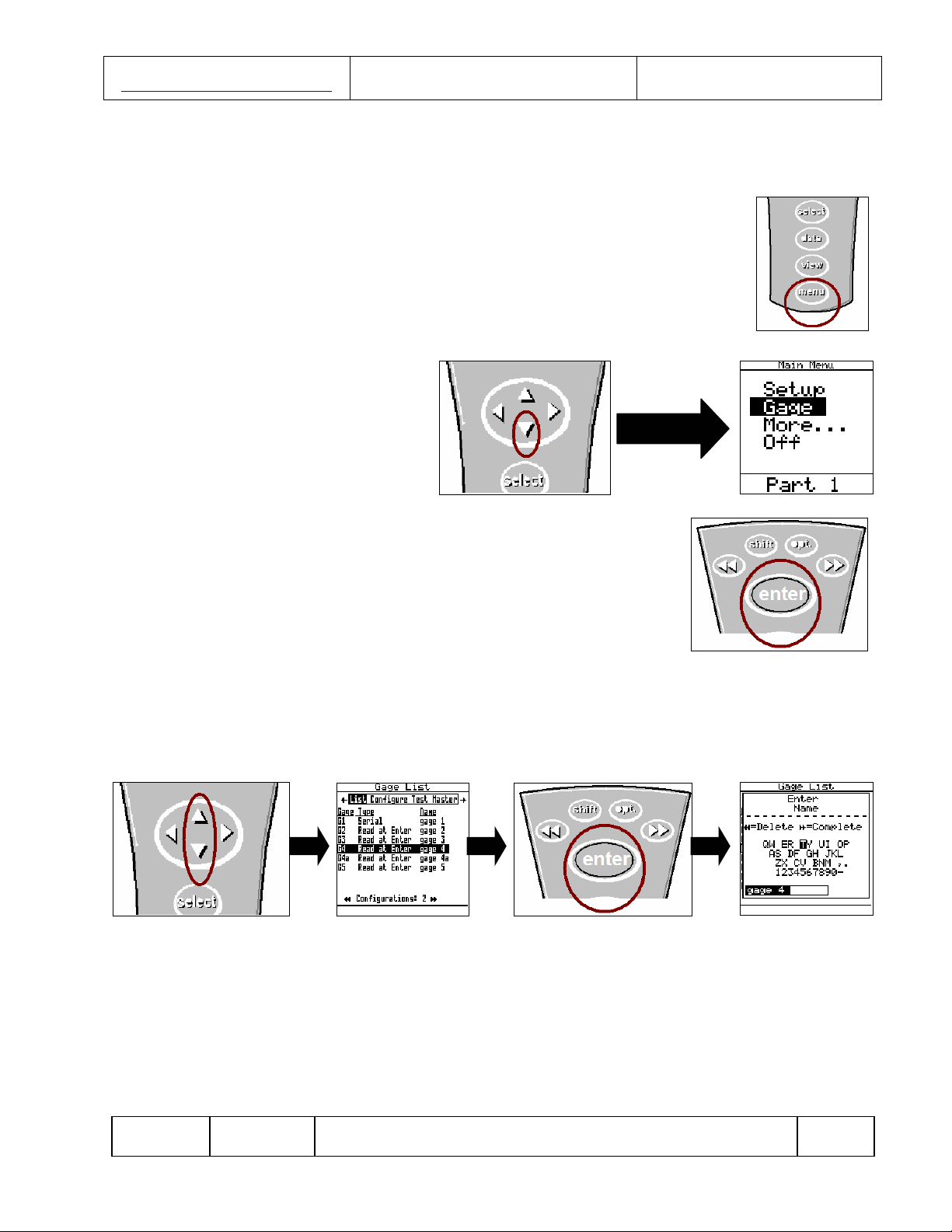

It is recommended to assign simple user name to the gage files such as; 200, probe, lmi probe, etc.

This will help to identify different setups.

4. To assign a gage file name press the ▲or ▼to highlight gage “G4”* in the “Gage List”, and

press <enter> on the collector. The alphanumeric screen will then appear.

*G4 and G5 can both read the 200 series probes. The only rule to follow is the gage file must match

the source code in part file, see collector manual for details. The balance of this instruction will be

based on G4. To use G5, perform the following steps using the G5 gage file.