LNS ITALIA s.r.l. Instruction manual series SC 500 page 2 di 21 –05-2014

Contents

Contents...............................................................................................................................................2

1. General information.........................................................................................................................3

1.1. Contents and symbols .......................................................................................................................3

1.2. Safety................................................................................................................................................3

1.2.1 Information label description and placement...............................................................................................3

1.2.2. Main safety regulations .............................................................................................................................4

1.3. Unit range of use ...............................................................................................................................4

1.3.1. Proper uses ..............................................................................................................................................4

1.3.2. Improper uses...........................................................................................................................................4

1.3.3. Operating conditions.................................................................................................................................5

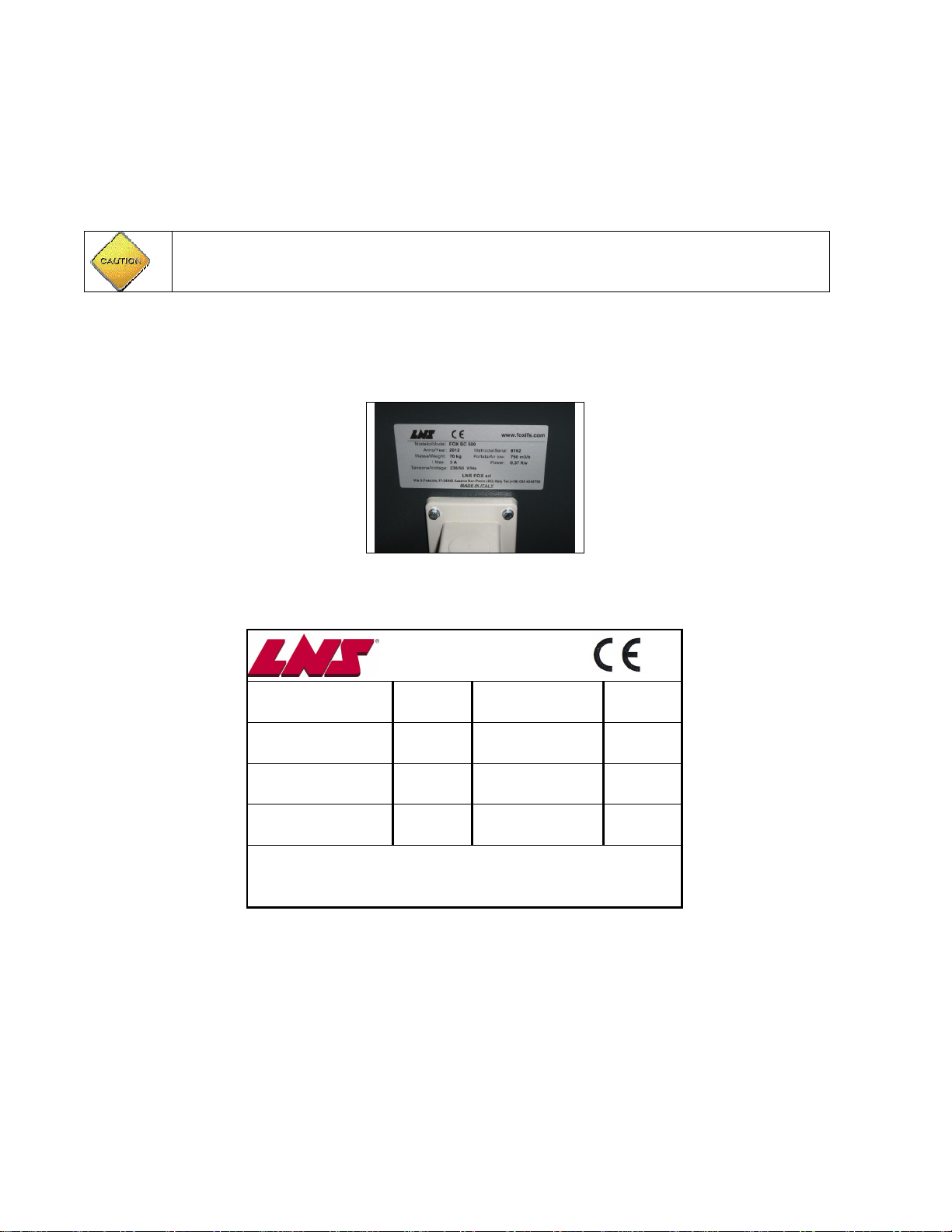

1.4. Machine identification and technical specifications.............................................................................5

1.5. Supply contents.................................................................................................................................5

1.6. Warranty............................................................................................................................................6

2. Handling, transport and storage.....................................................................................................6

2.1. Handling and transporting packed material........................................................................................6

2.2. Unit handling and transport................................................................................................................6

2.3 Storage...............................................................................................................................................6

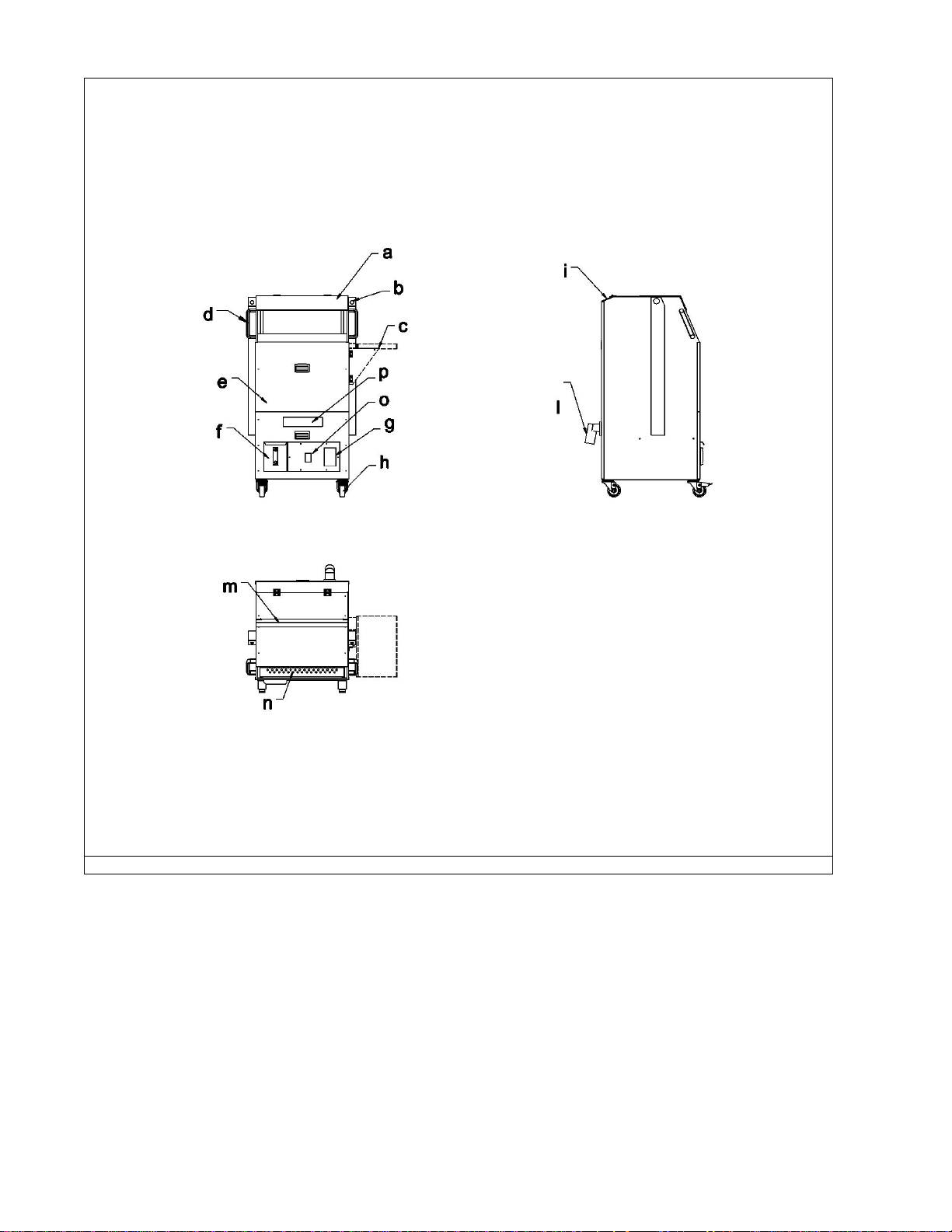

3. Unit description and technical specifications ...............................................................................7

3.1. General features................................................................................................................................8

3.2. Electrical features..............................................................................................................................8

3.2.1. 3-phase motor...........................................................................................................................................8

3.2.2. Single-phase motor..................................................................................................................................8

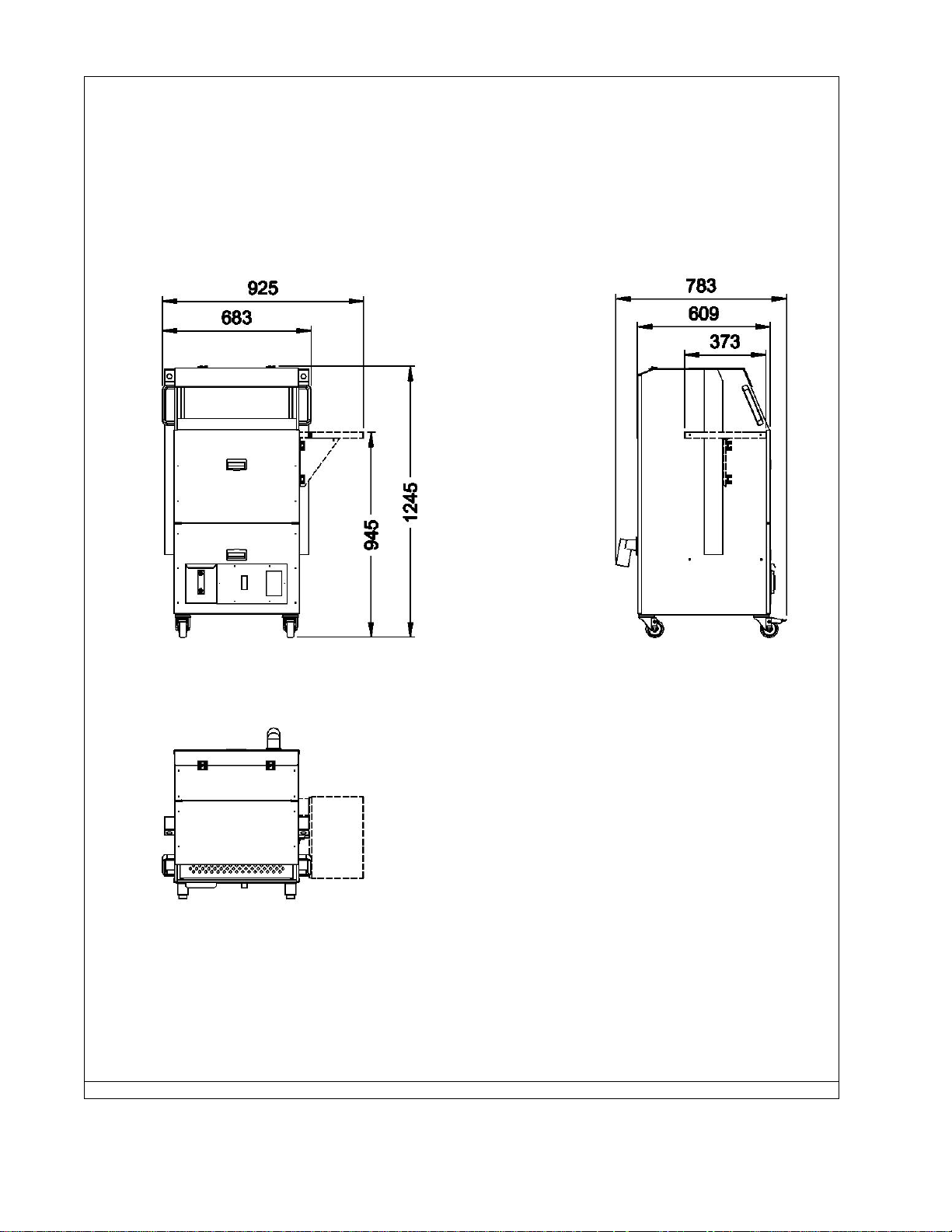

3.3 Dimensions.........................................................................................................................................9

4. Installation .....................................................................................................................................10

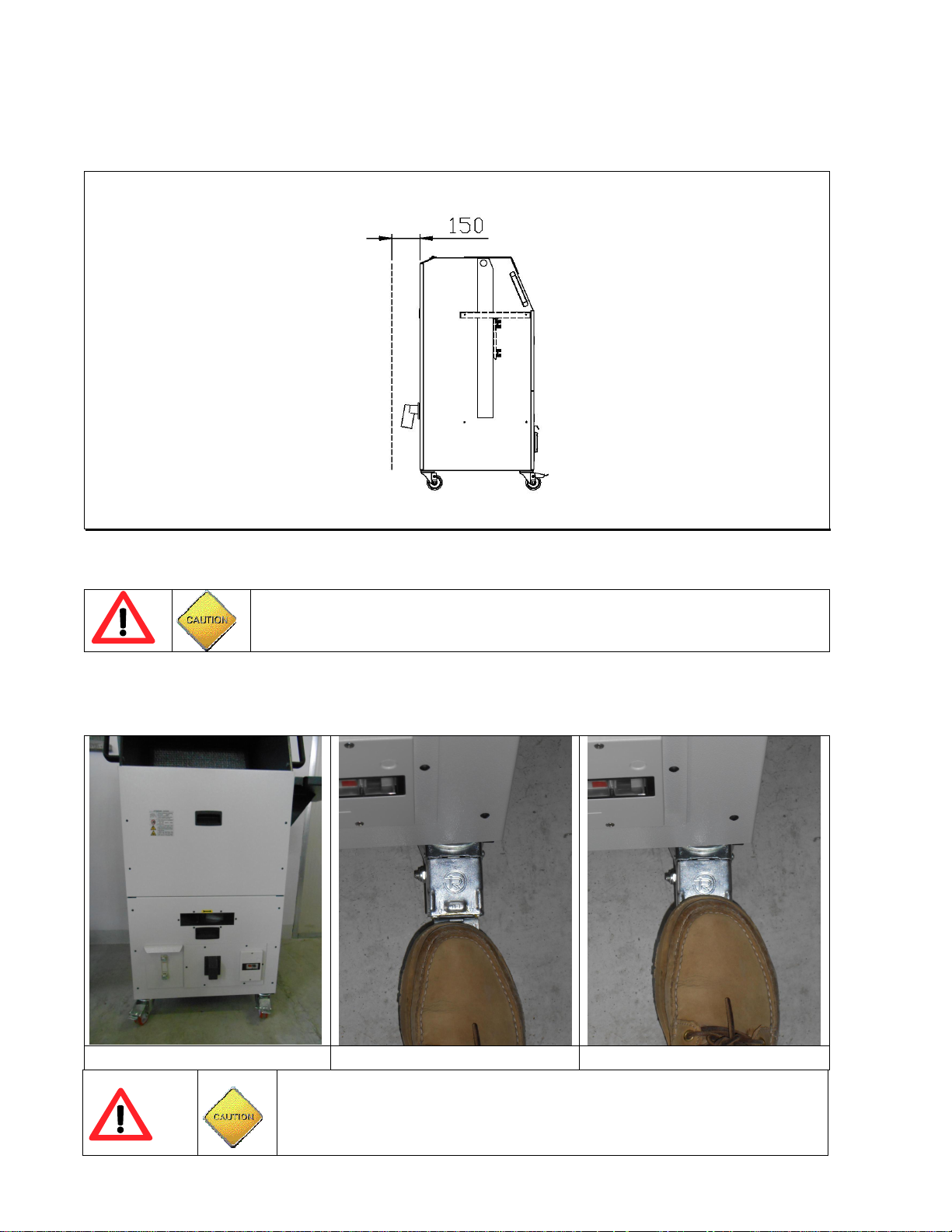

4.1. Minimum installation space..............................................................................................................10

4.2. Support floor, and wheel lock...........................................................................................................10

4.3 Preload siphon..................................................................................................................................11

4.4 Using side tray..................................................................................................................................11

4.5. Electrical connections......................................................................................................................12

4.5.1 Rotation control for the version with three-phase motor............................................................................12

4.5.2. Checking the setting of the motor protector .............................................................................................13

4.5.3. Available voltages/frequencies................................................................................................................13

4.5.4. Motor protector settings chart..................................................................................................................14

5. Unit use ..........................................................................................................................................14

5.1. Starting and stopping.......................................................................................................................14

6. Maintenance...................................................................................................................................15

6.1 Maintenance chart............................................................................................................................15

6.2. Routine maintenance.......................................................................................................................15

6.2.1. Pre-filter and filter tray maintenance........................................................................................................15

6.2.2. Main filtration cartridge maintenance.......................................................................................................16

6.2.3. Condensed liquid container.....................................................................................................................18

6.3. Periodic checks................................................................................................................................18

6.4. Troubleshooting...............................................................................................................................19

6.5. Disposal and scrapping....................................................................................................................19

6.5.1 Disposal of consumables .........................................................................................................................19

6.5.2 Scrapping ................................................................................................................................................19

7. Spare parts.....................................................................................................................................20

7.1 Spare filters ......................................................................................................................................20

8. Wiring diagrams ............................................................................................................................21